-

Hexachord Origin Story

10/01/2018 at 21:03 • 0 comments -

The Completed Hexachord (and Future Plans)

08/22/2016 at 20:05 • 0 commentsI first showed my Hexachord at the Bay Area Maker Faire in 2014, and again in 2015, and won editor's choice ribbons at both events. I was fortunate enough to give a couple talks about making the instrument at Two-Bit Circus' STEAM Carnival in the fall of 2014.

A year after making this first Hexachord, I made a new version that was quite a bit smaller, and featured only a single chamber with the same number of strings. This second Hexachord was controlled by an Arduino Uno and six servos.

Designing and building new musical instruments is very rewarding for me, and I hope to make a series of different instruments that are able to interact with each other and effect each others' performances. Stay tuned for more about that upcoming project.

-

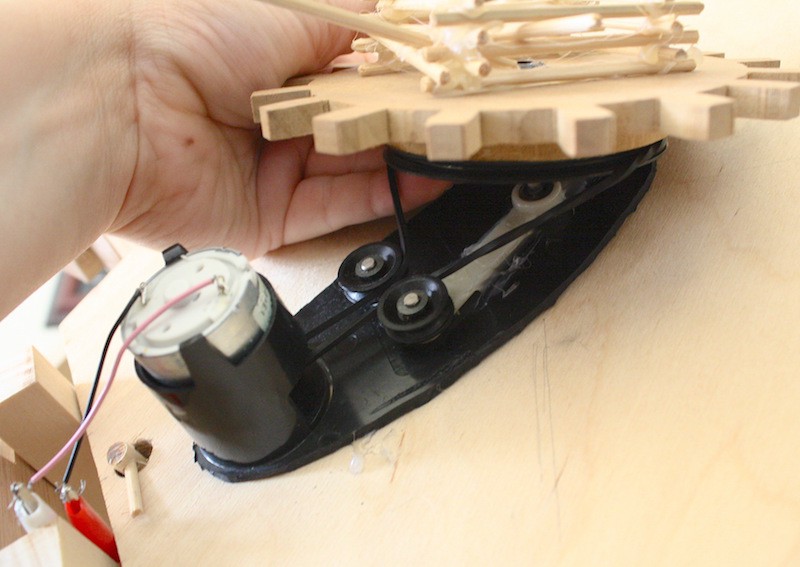

Face and Plucking Arm

08/22/2016 at 19:56 • 0 commentsTo play the instrument, I pulled a DC motor, pulley, belt, and tension wheels from an old videocassette rewinder and mounted them to the face. The center wheel has a hand-cut wooden gear attached, which is a reference to an early design, which had the Hexachord powered by hand crank and a series of wooden gears. (I've done several geared projects since then, including a geared noisemaker, and a beveled gear fidget bracelet.) The gear is base for the plectrum arm, which has a guitar pick attached to a zip tie. I initially had the pick attached directly the wood, but the pick was too rigid without the flexibility of a musician's fingers, and the arm was frequently stopped by the tense strings.

The motor is powered by a variable AC-DC converter, so the speed can be changed.

![]()

![]()

![]()

![]()

-

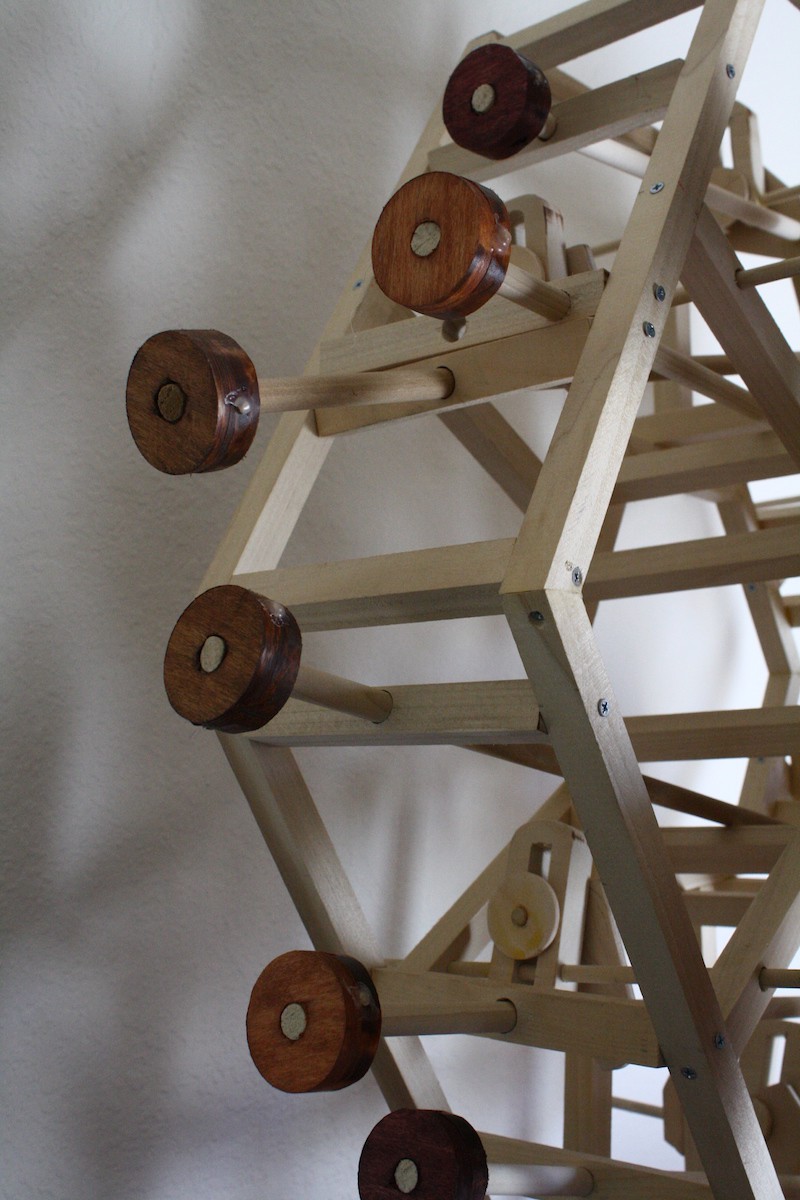

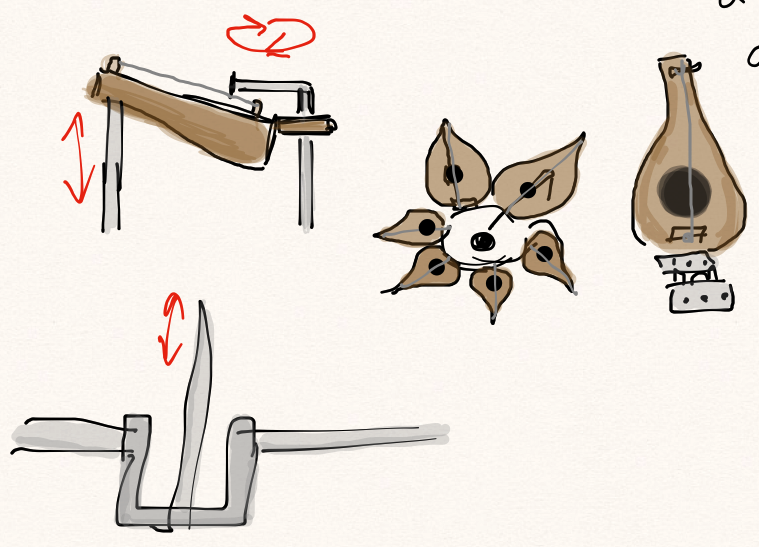

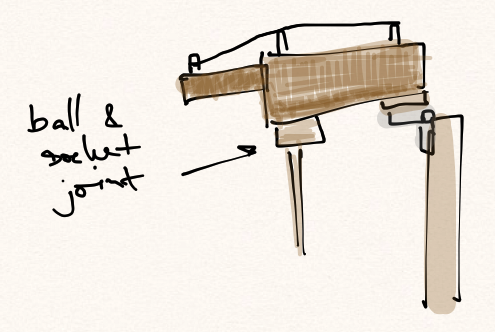

Mechanisms

08/22/2016 at 19:33 • 0 commentsTo make the Hexachord playable by a single person, I put knobs all along one side to control the individual sound chambers. Each knob was attached to a dowel that ran through the frame of the instrument to a scotch yoke mechanism, converting rotary to reciprocating motion. The scotch yoke mechanisms attached to ball and socket joints on the back of each sound chamber, allowing them to pivot on their wooden hinges, and move the strings in or out of the way of the spinning plectrum arm.

![]()

![]()

![]()

![]()

-

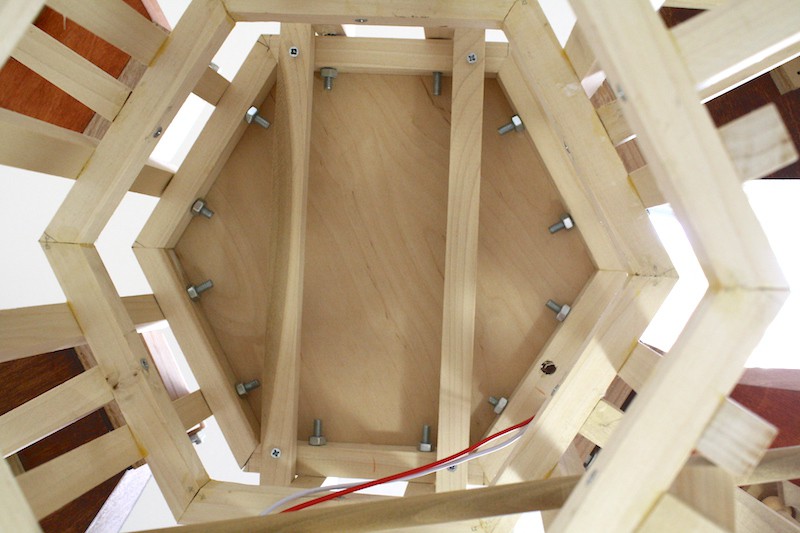

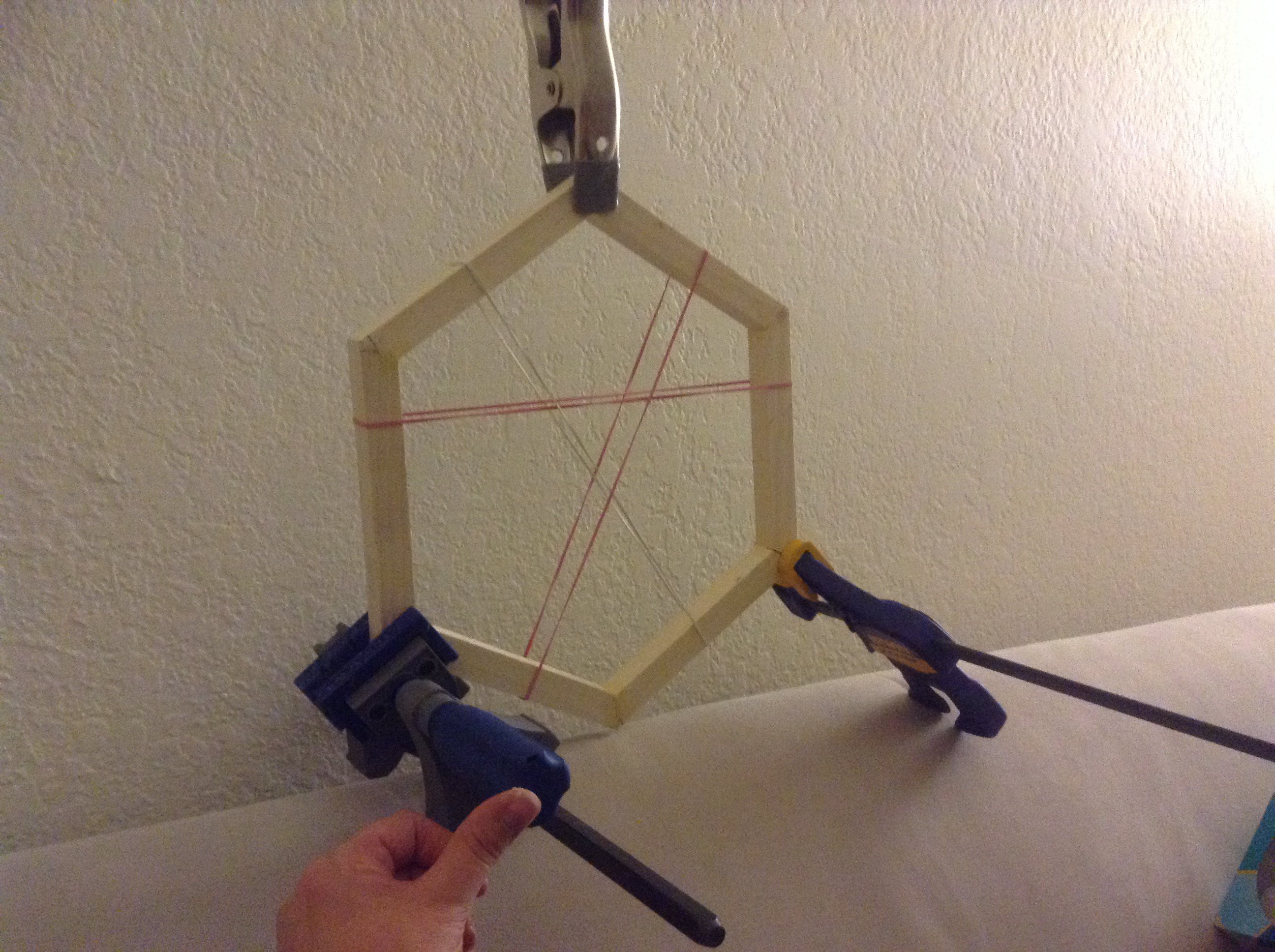

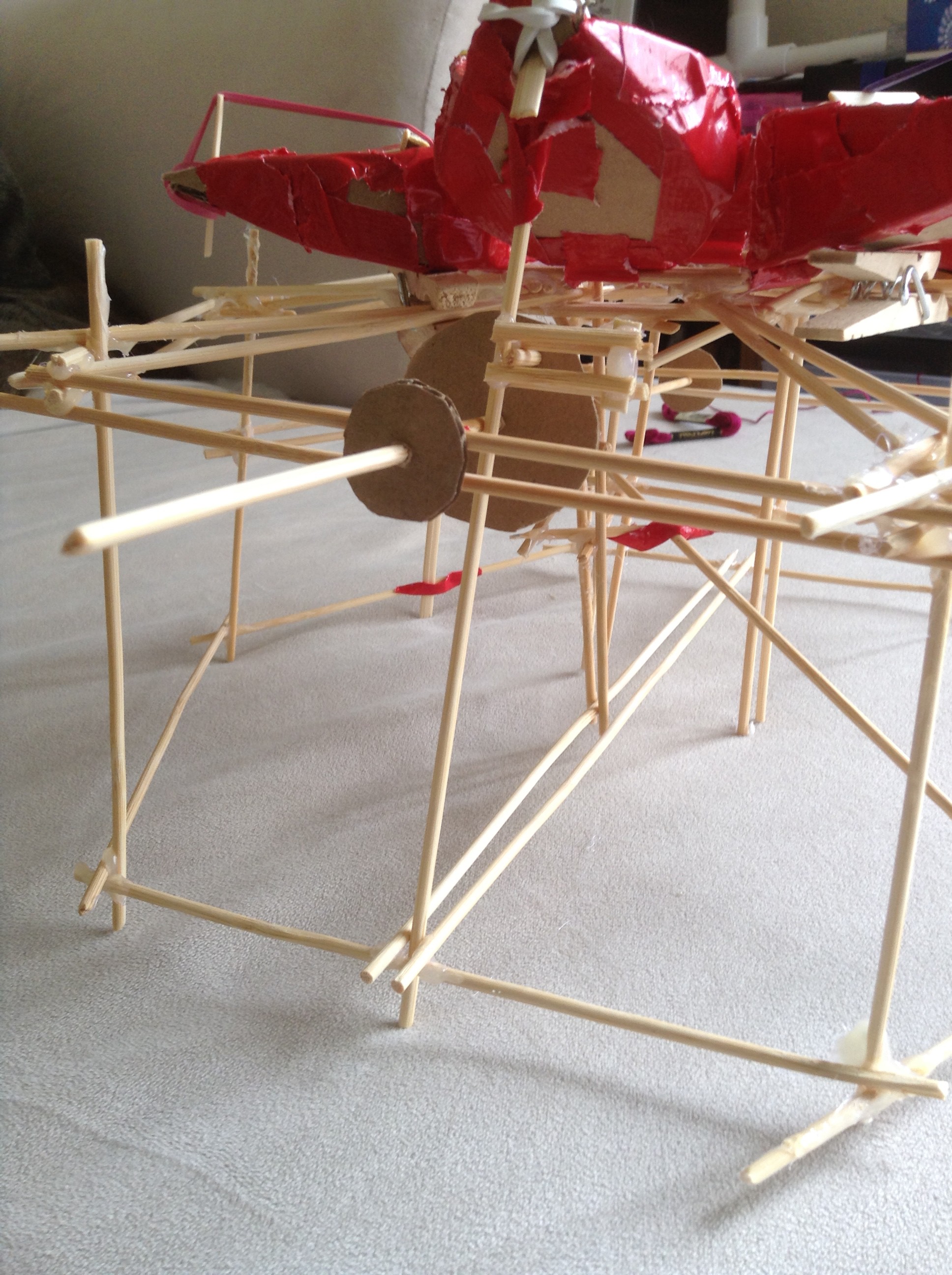

Frame

08/20/2016 at 23:55 • 0 commentsThis is where a large number of $1 hand clamps are most useful. To ensure this was strong enough (because obviously it needed to not only hold 6 sound chambers, but also house all of the mechanisms to move them), I first glued, then screwed. I had a drill already, but needed to get a new, smaller drill set to attach things from inside, as the old one wouldn't fit. The set I got are 12V Makitas (which is also what we use at Tinkering School LA), and I still love them.

-

Sound Chambers

08/20/2016 at 23:47 • 0 commentsI cut most of the pieces for this on a scroll saw (and got very good at being precise with it) due to the size of the material I was working with. The first version was inexpensive 3/4" plywood, and I went with progressively better material until I was happy with the design and construction.

Each sound chamber was stained one of three colors to help associate them with the knobs that would control each.

![]()

-

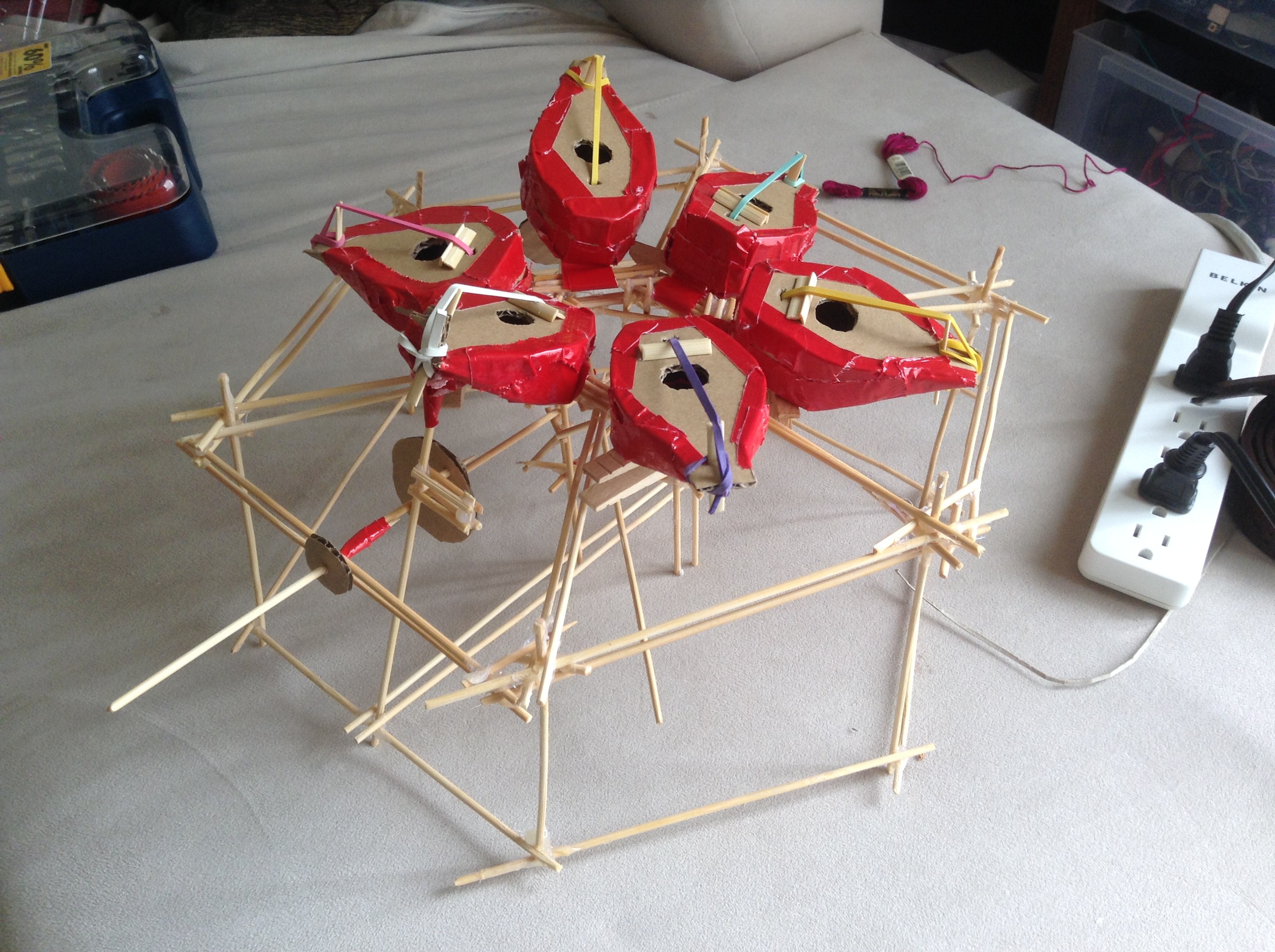

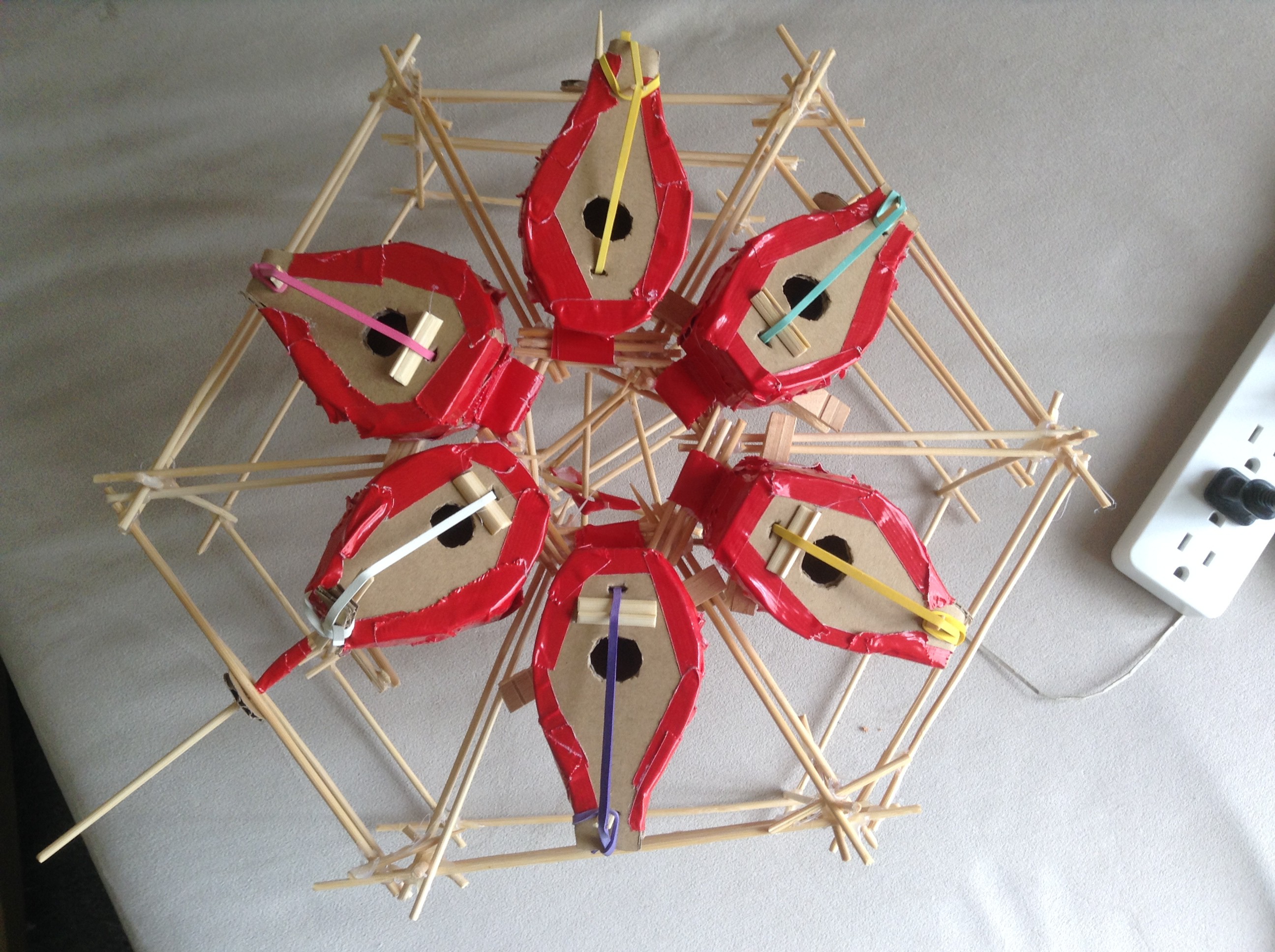

Rapid Prototyping

08/20/2016 at 23:36 • 0 commentsI have a regular set of quick prototyping materials that include skewers, cardboard, duct tape, and hot glue. This is what my prototypes were made from. They didn't last long, but they didn't have to. I was able to wrap my brain around the project.

(Throughout the process, I shared my progress with the fine folks at CRASH Space. Somehow, the fact that this little first version was only about a third the size of the final thing escaped them, and by the time the 3-foot tall version started coming together, there was a lot of surprise.)

-

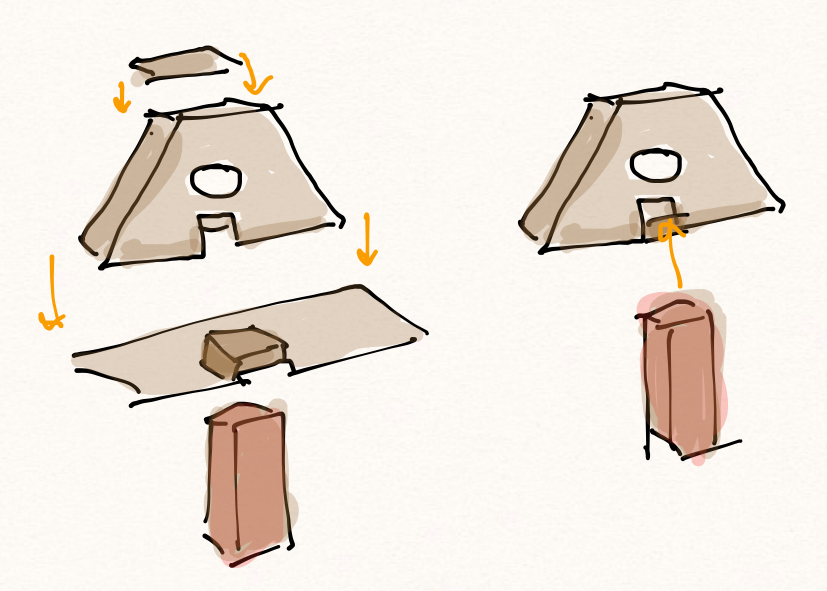

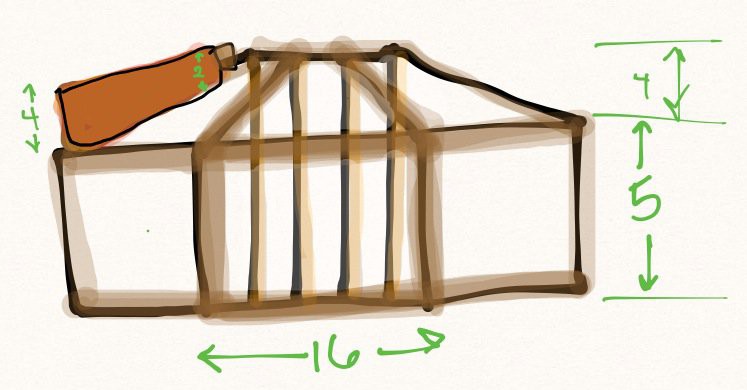

Design

08/20/2016 at 23:27 • 0 commentsI sketched out several possible designs and options for the mechanisms that would move the sound chambers. The measurements changed over the course of the project, especially right after the rapid prototyping stage that came next.

-

Tools and Materials

08/20/2016 at 23:15 • 0 commentsWood (and lots of it):

- Various types of plywood - a future version will use hardwood for the sound chambers.

- 3/4" Solid (Poplar, Oak, etc) Boards

- Various Size Round Dowels

- 1x1" Poplar Square Dowels

- Bamboo Skewers

- Large Wooden Beads

Adhering:

- Wood Glue

- Screws (and a LOT of them, I went through over a hundred)

- Bolts for attaching sound chambers

Tools:

- Drill and Driver

- Clamps - I bought a ton of dollar clamps from Home Depot, plus a few larger clamps

- Good Ruler/Protractor/Square

- Scroll saw

- Drill Press - with various bits and hole saws

- Belt sander

- Dremel

- Orbital sander

- Various hand tools for tweaking

Other:

- Soprano Ukulele Strings

- Tuning pegs

- Guitar Pick

- Motor and Hookup Wire - I used a motor from a video cassette rewinder, along with other bits from the machine, such as the belt and pulleys

- Zip Tie

- Wood Stain, Multiple Colors

I went through various types of plywood in the learning/tinkering process of building the sound chambers. By the time I got to the nice 1/8" baltic birch ply, I had refined the design, process, and my skills to have a satisfying result.

The Hexachord

A six-chambered, motorized, mechanized, rotary musical string instrument.

barb

barb