-

Gear Box

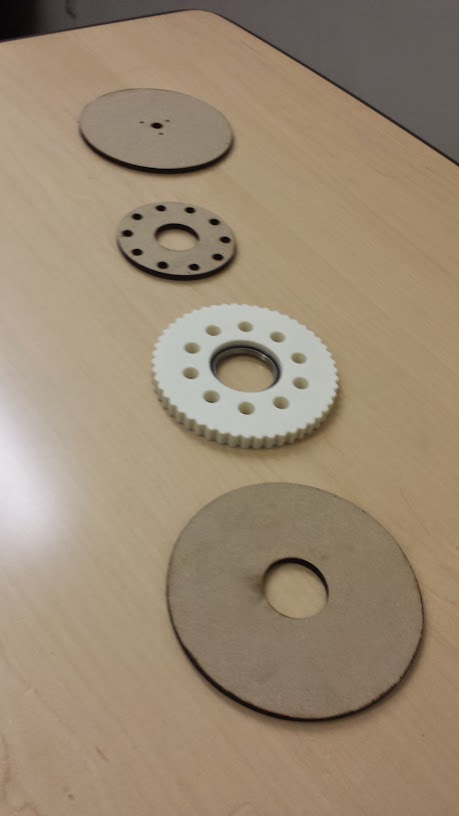

06/05/2014 at 04:07 • 0 commentsOur goal was to use a high RPM brushless DC motor and gear it down to useful speeds. The motor we had was about 8,000 RPM at top speed with no load. We figured that in order for the motor to be useful we would need about a 100:1 gear reduction. Our finished prototype was able to get a 50:1 gear reduction, using a cycloidal gear drive.

![]()

The reason we used a cycloidal gear was because it is not backdriveable, efficient, and offers high gear reduction in a small flat package. The downside to a cycloidal gear is that it vibrates due to the eccentric cam.

![]()

I've never had good experience using a 3D printer for gears, as the teeth themselves will pretty much shear under any substantial load. The added bonus of using a cycloidal gear with a 3D printer is that the gear teeth are all rounded and a high number of teeth are in contact at the same time. To save print time top and bottom plates were made from laser cut cheap mdf.

![]()

The final assembly involved a small layer of gorilla super glue between the outer gear teeth and the top and bottom plates. We attached the motor to the eccentric cam using a motor collet designed for propellers.

Spare carbon fiber tubes were attached to the gear housing and output shaft of the gear box. The last touch was to laser cut some arm brackets and strap on the battery.

![]()

-

Start!

06/05/2014 at 03:32 • 0 commentsLast weekend, we spent 30 hours at OSU's HWeekend event hacking together a single joint as a prototype for what will eventually be a full-body exoskeleton.

![]()

We don't have a fully fleshed-out plan for this yet, but hopefully this will be something relatively cheap to build with tools and materials commonly available to hobbyists while still being a capable machine: fast enough to feel immaterial and strong enough to fully support a 150-pound human body.

Of course, we need to think about this more seriously to verify those are realistic numbers to attain without adding another 100 pounds of machinery on our backs, but after just 30 hours, we've already glimpsed some of the potential fun we could have with this:

Note the arm is under open-loop, bang-bang control and is capped at 15% of maximum power. The motor is undersized, the gearbox is oversized and is loosely toleranced, etc, etc. We'll be iterating soon.

Soo-Hyun Yoo

Soo-Hyun Yoo