I started out by investigating ultrasonic cat repellents. It turns out they are of dubious efficacy, so I determined to use a water spray.

There are many similar projects to be found through a quick search, all of them along the same lines. PIR modules can be had from eBay for a few dollars, and interfacing to them is straightforward and uninteresting. However, I wanted to mount mine high on the wall, angled down, to avoid getting splashed. A quick session in DesignSpark Mechanical and I had an angled mount. Two holes, sized to self tap with a #1 screw, are provided. It is designed to have the screws enter from the back, as there are components on that side which would be difficult to avoid when designing the mounting surface. I didn't have any #1 screws, so a pair of mismatched screws from an eyeglass repair kit were substituted. Something to keep in mind for designing mounts is that it is very difficult to turn screws if the path for the screwdriver is not kept clear, which I discovered.

The only real area of divergence between all the cat squirters seems to be how to actually squirt water under electronic control.

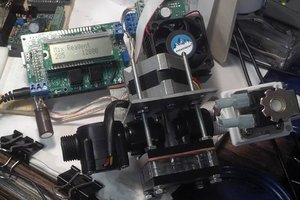

One project (listed at http://www.jaycar.co.nz/makers.asp) used a servo on a spray bottle. I designed a servo mount for a spray bottle I had lying around, which you can see in the gallery. It worked, but the Hitec HS-311 servo, rated for 51 oz. in. of torque, could only manage an anemic dribble fed directly from VCC. I thought about adding a large capacitor for energy storage, but only after I had disassembled the mount and moved on.

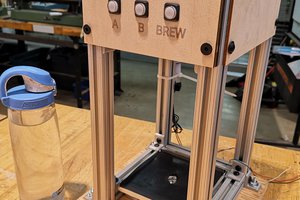

Another project I saw (http://www.nerdkits.com/videos/servosquirter/) uses a piston pump. Their recommended one is $5, but with $20 shipping. For that much money, I had an easier option in mind. I went to Toys R Us and, it being the start of the summer season, got a Super Soaker Hydrostorm motorized water gun on sale for $16. I took it apart briefly to have a look inside (so many screws!), and determined it would be fairly easy to disassemble and control, but I would rather leave it whole and in working order, to be able to retain its use as a water pistol when necessary.

I briefly considered servoing the trigger, but the trigger pull is as heavy or heavier as the spray bottle, and the handle/trigger guard geometry is complex and would be annoying to design around. Instead, what I have determined to do is to physically tie back the trigger and control the power instead. I printed a replacement battery pack, with holes for two wires to make loops on the contact end. This gets stuffed with some wadded paper towels to provide some friction and water protection, and I will switch the power (9V from VIN) through a relay (or a MOSFET, but a relay is what I have on hand).

I have tested the replacement pack, and it works in all orientations. More to come....

zaphod

zaphod

James Newton

James Newton

Sean Morton

Sean Morton

Peter Buckley

Peter Buckley