-

Self Imposed Deadlines

07/11/2014 at 09:28 • 0 commentsSo my self-imposed deadline of ordering Shapeways parts for the Z and X axis by 7/11 looks like it will be met! There is still clearly a ton of design work to be done, but I'll be purchasing the spectra line pulleys and Z-axis carriage to get a full side operational and run some preliminary testing.

There have been a few comments about injection molding in relation to this project. To be clear the parts WILL be injection molded if we choose to do a kickstarter, they are being 3D printed currently to expedite the build process. I have personally designed 34 injection molds to date, some of which were complex multi-part molds with collapsing internal mandrels (Worked in electronics packaging for a well known corp). Low run production is quite accessible for hobbyists in relation to injection molding, a Morgan press [ http://www.morganindustriesinc.com/ ] can provide more than enough pressure and injection volume to produce any of the parts for the TOME, I believe Techshop is equipped with a similar injection molding machine. We will be utilizing professional injection molding equipment with molds produced on our CNC machinery.

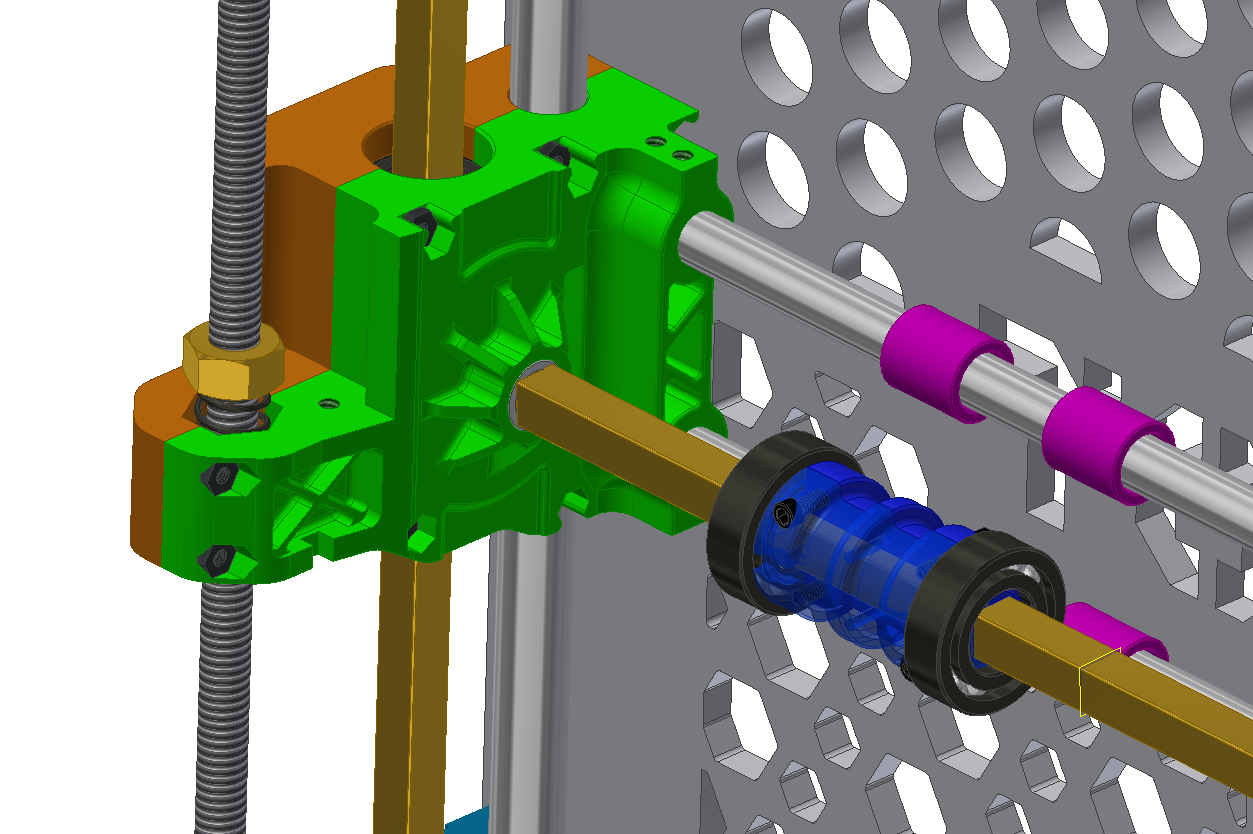

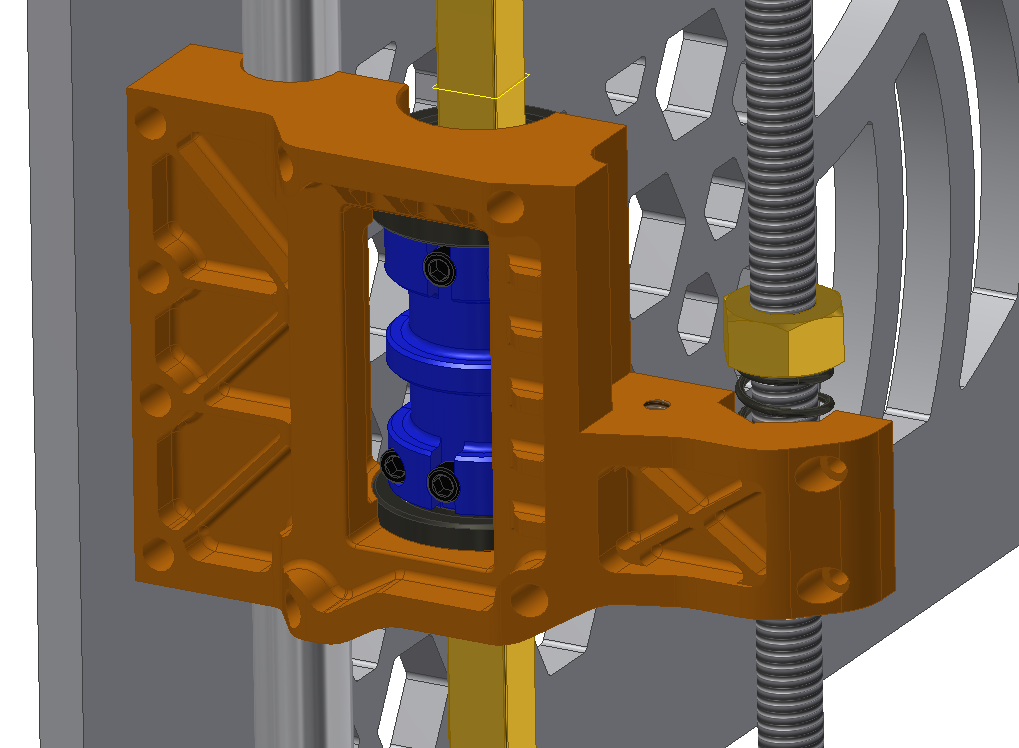

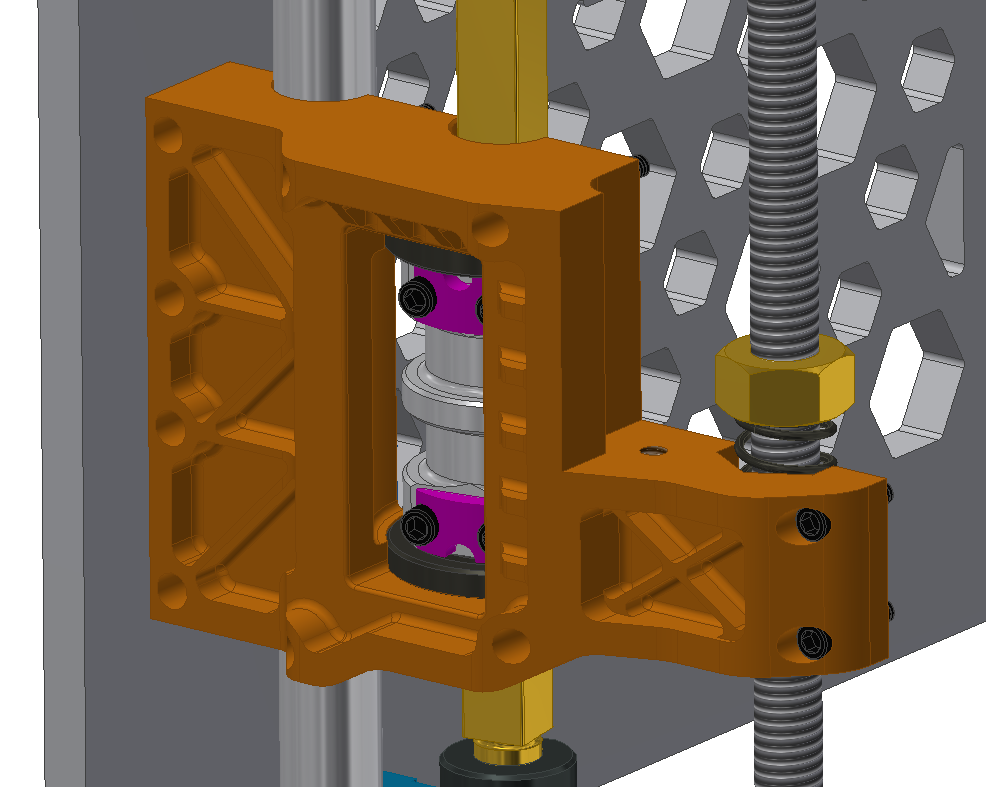

Here you can see the Z-axis clamshell complete, I'm happy with the current design and I'll be reproducing this on the opposing side with a few tweaks to fit the Y-axis control hardware. I hope to begin work on the Y-axis gantry in order to clarify the design intent and validity. I have received several comments about the potential problems with a cantilever design but I am confident the FEA will support my current design. I will post the results for the FEA study when it is complete.

I still need to draw up the anti-backlash nut holder, but this is a simply part that can be FDM printed without degrading performance of the piece.

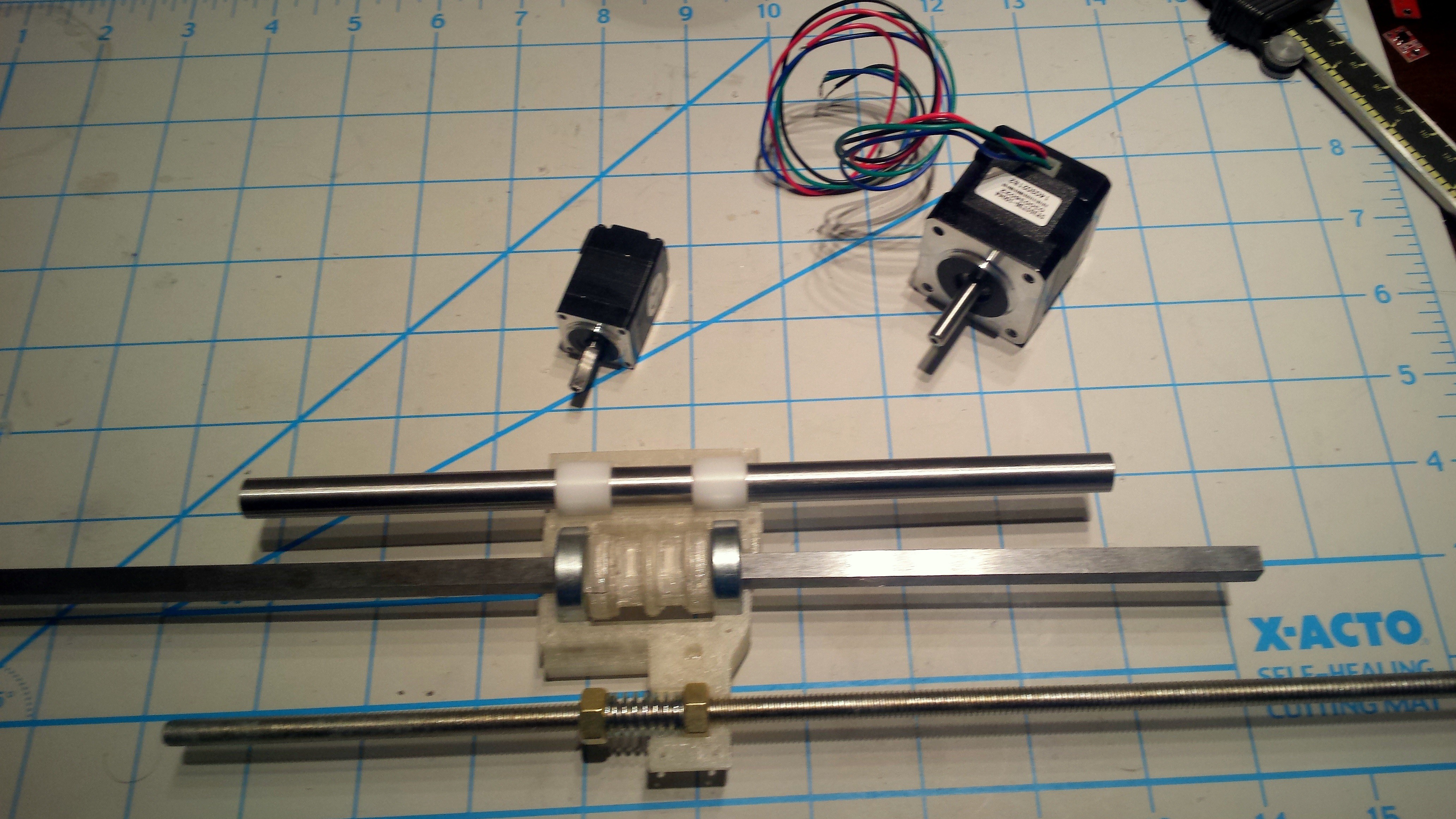

Corey was able to get most of the Z-axis hardware machined, just waiting on two metric drills to properly size the coupler holes for our stepper motors. Should have a prototype Z-axis running soon!

![]()

-

Let the Machining Begin!

07/09/2014 at 07:27 • 0 commentsFirst off I would like to thank everyone who voted for us in the first round of the Hackaday prize! We are honored to be in the top 15 and will wear our HaD shirts with pride.

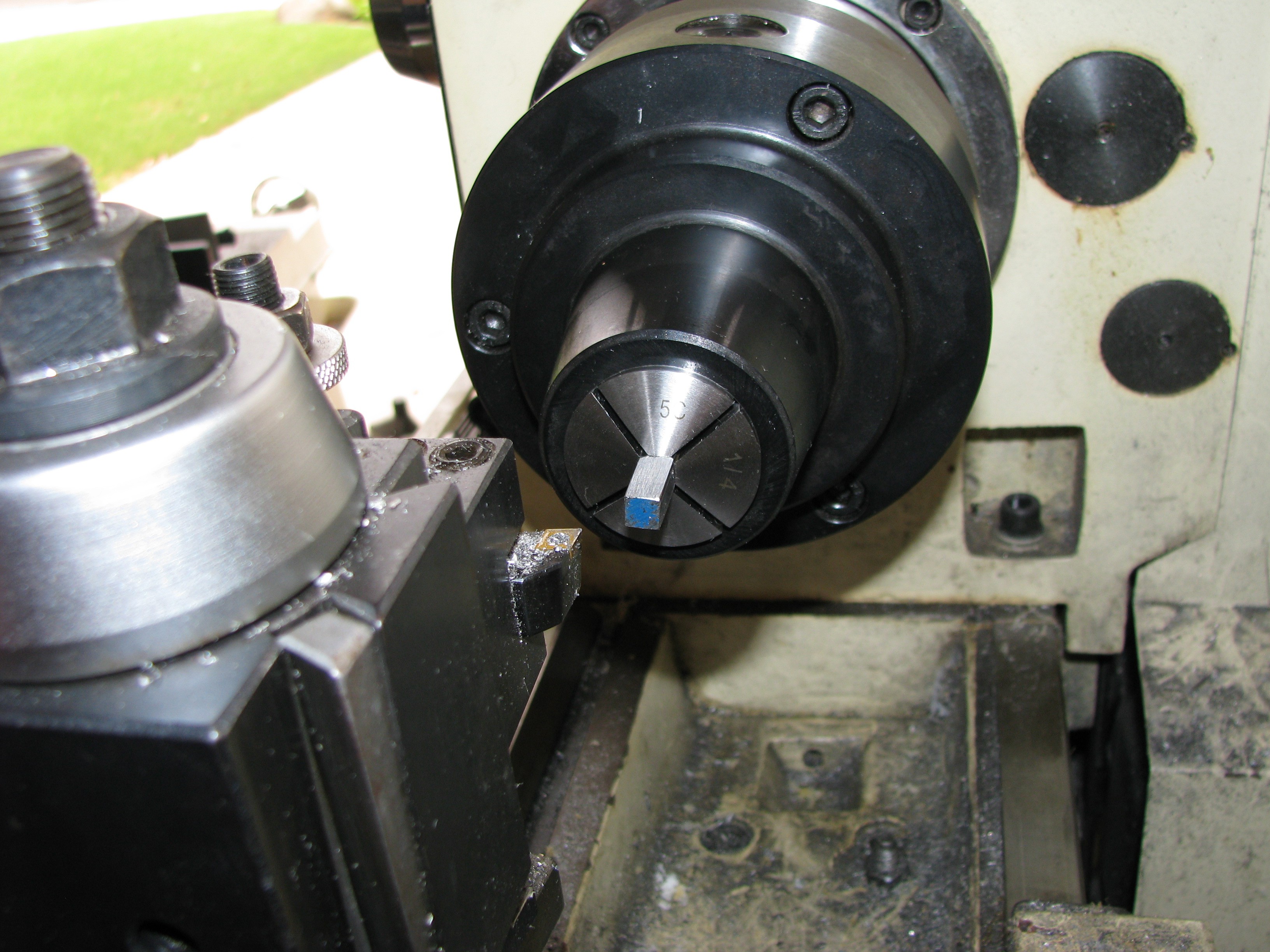

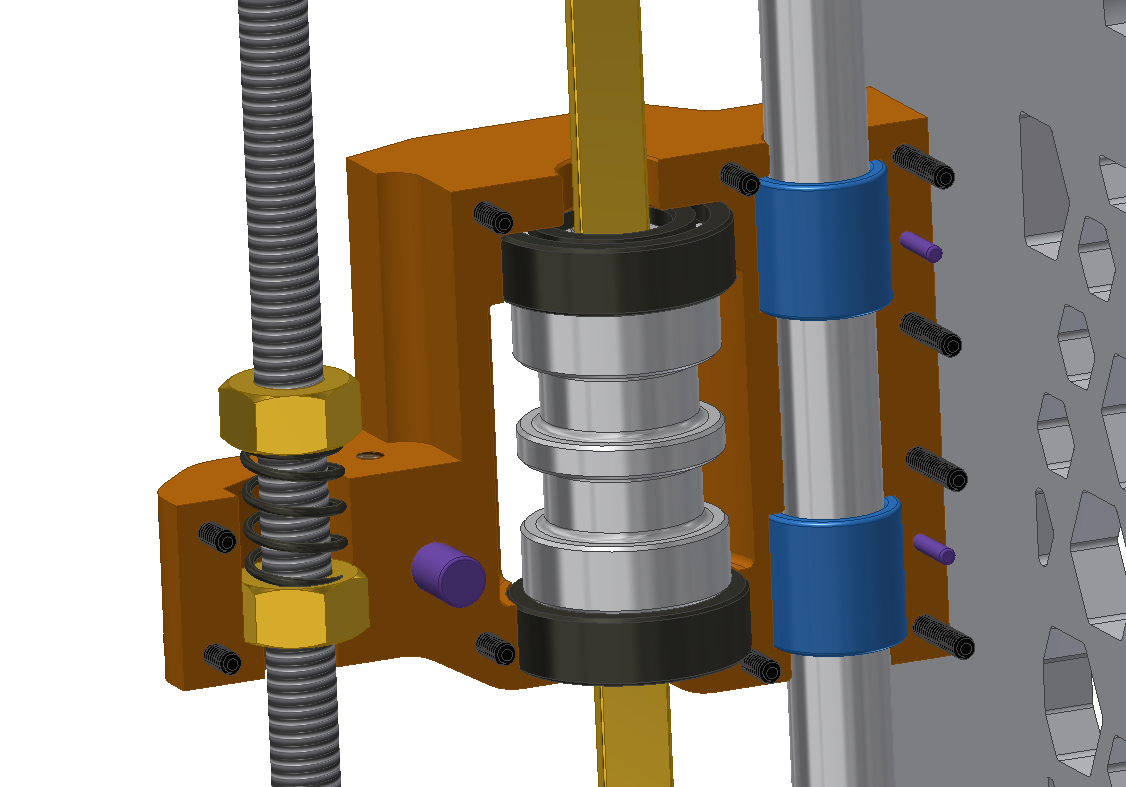

Exciting news in this update! We have officially begun manufacturing the components for the Z-axis. Corey is working on completing the spectra line pulley, square drive shafts, Z-axis lead screws, and motor couplers; With any luck we will have the parts for one side of the Z-axis assembled for testing within the next 2 days.

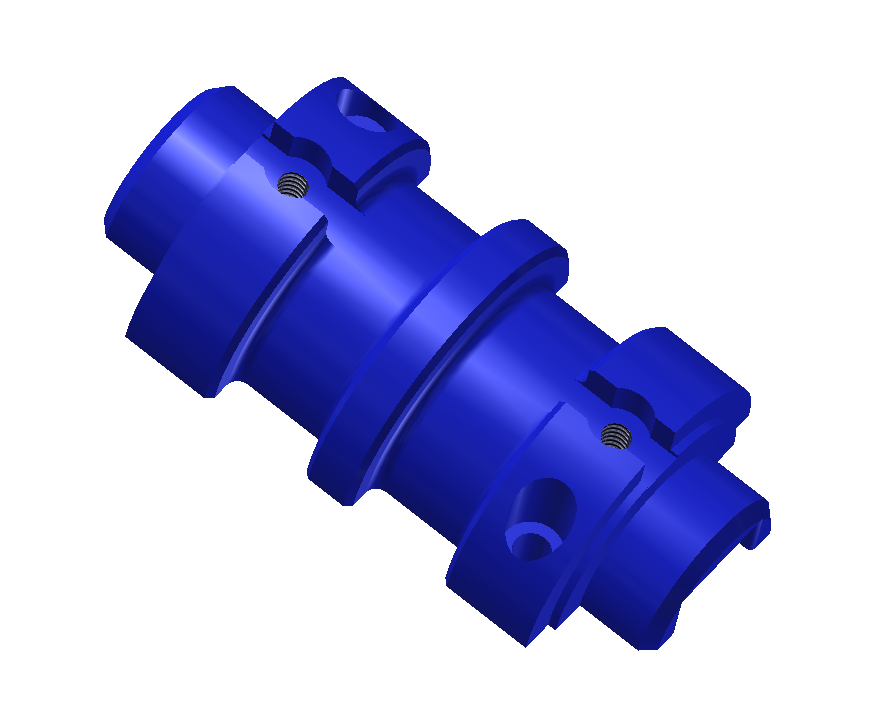

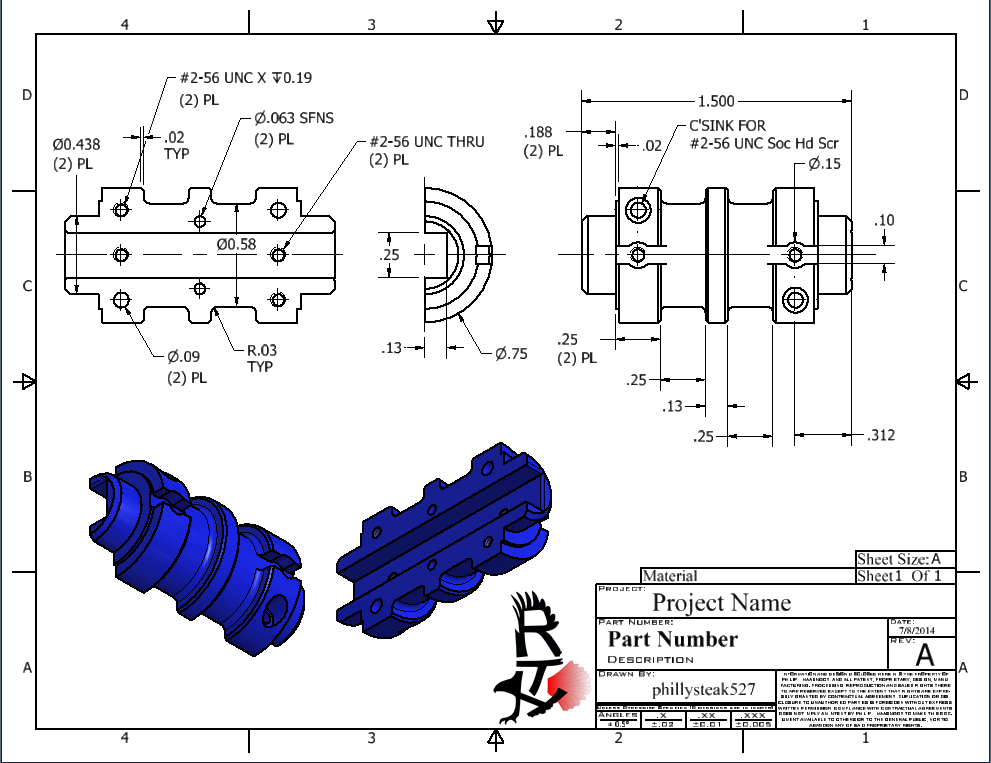

The Spectraline pulley has been redesigned to make manufacturing easier and more cost effective. It is now a clamshell design with two locating dowel pins. It will be machined as two halves, assembled, and turned down as one assembly to ensure complete concentric with the square drive shaft. The specraline retainer has also been changed to a single #2-56 socket head screw, eliminating 4 parts.

I'm starting to build up a set of engineering drawings for release, currently they are in a very crude form just to get the ball rolling on manufacturing. Once the parts have been prototyped (Not FDM printed, actual prototypes) I will clean up the drawings and release them. We are still playing around with a few different part numbering schemes, but will choose one shortly to simplify the drawing structure for the TOME.

Here is another render showing that the new spectraline pulley still conforms to the original envelope.

More coming very soon! Please follow us to keep up-to-date on our progress.

-

Aw Nuts!

07/03/2014 at 04:44 • 0 commentsBefore prototyping the second half of the Z-axis clamshell I was waiting for a McMaster order to arrive. Today it came and I was able to get everything to fit, primarily for a form/fit/function verification. Now that I know everything fits appropriately I'm going to finish the other half of the Z-axis clamshell. The deadline for us to order Shapeways parts for the Z/X axis drives is the 17th, but I hope to have them ordered by the 11th.

If anyone has any feedback this far, or has any experience with Kickstarter that they are willing to share please feel free to drop us a line at Contact@Tome3D.com , we would love to hear from you!

![]()

-

GrabCAD and Z-axis proto

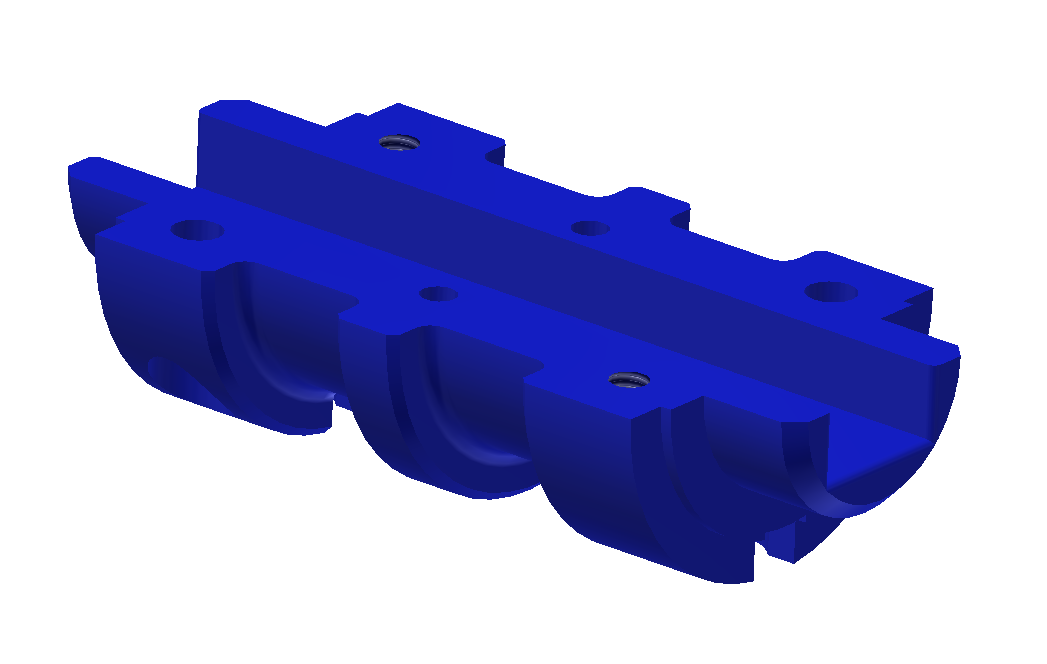

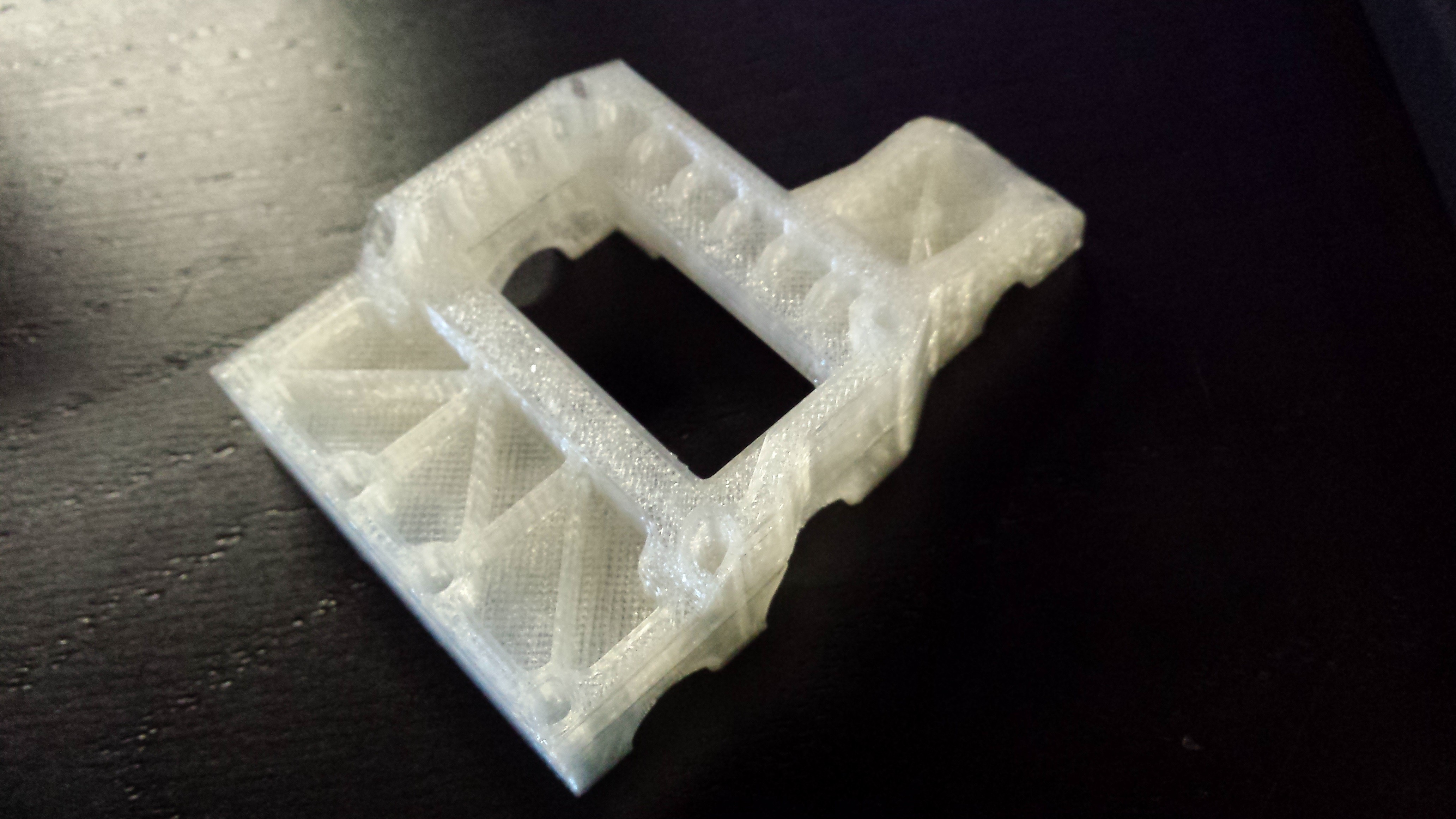

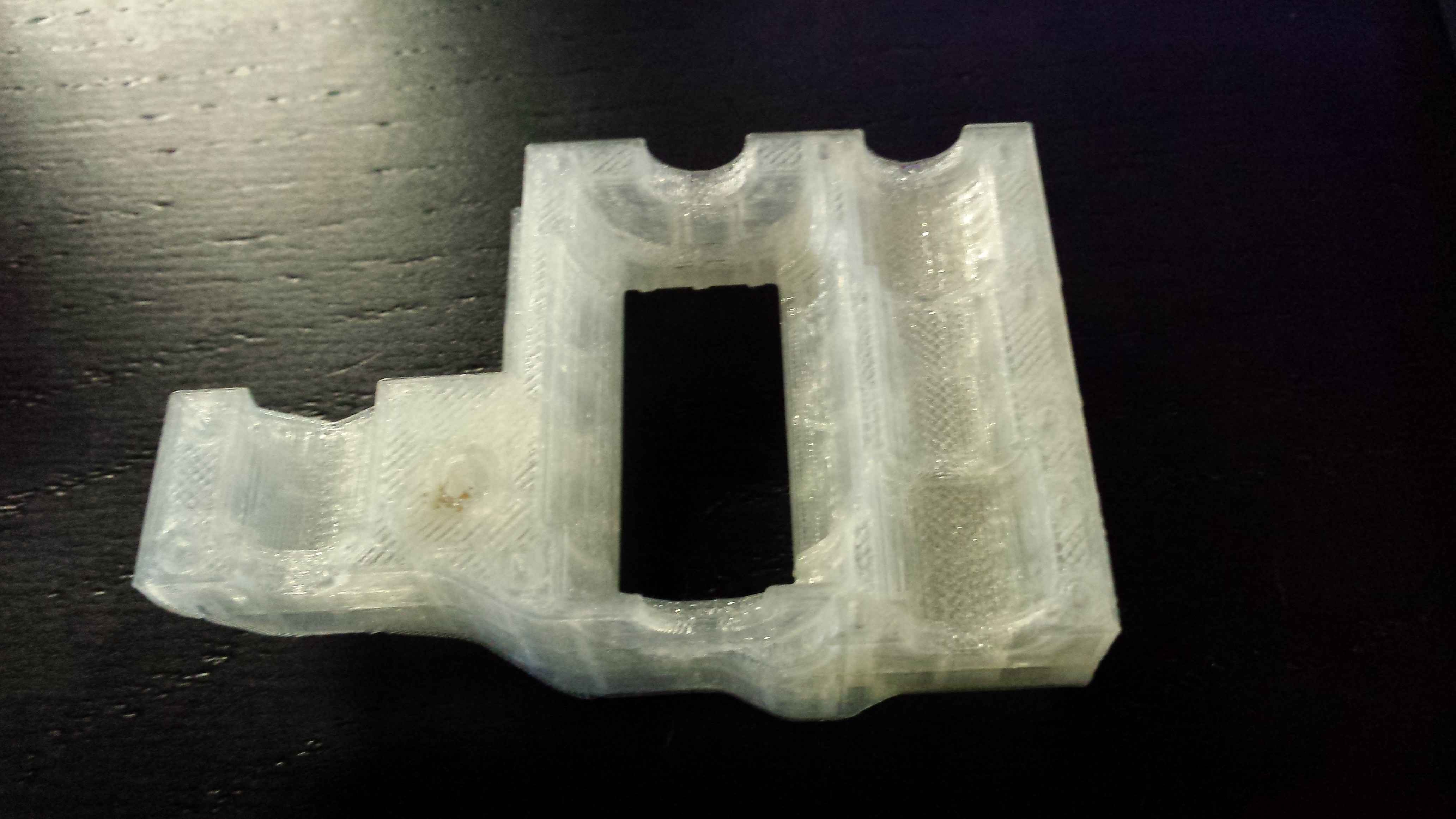

06/30/2014 at 17:12 • 0 commentsThe Z-axis clamshell half was printed today and will be test fit tonight.

I went ahead and created a GrabCAD project page to start sharing CAD files with the community. Please just be aware that the TOME is still under heavy development and the CAD models will change significantly by the time the first prototype is finished. If you want to check the files out they will be uploaded to this project:

https://grabcad.com/library/tome-3d-printer-1

Just please be patient, they will be uploaded after they are prototyped for accuracy.

Clamshell 3D print for reference:

![]()

![]()

-

Z-axis Carriage

06/29/2014 at 08:52 • 0 commentsI was finally able to scrounge together an hour and a half to start designing the Z-axis carriages, I finished the Z-axis side 1 clamshell, tomorrow I will be finishing the mating half which will allow me to begin mounting the X-axis guide rods. I would like to have the X-axis guide rods mounted on both sides of the Z-axis by the middle of next week so that the design for the flip out Y-axis truss can begin.

Here you can see the opening to access the X-axis spool for spectraline installation and adjustments. The spectraline pulley bearings are sealed and no lubrication will be required. This image is also missing the lead screw anti-backlack nut housing which will be modeled after the mating half of this clamshell is designed.

On the back side we can see all of the mounting hardware protruding, as well as 3 alignment pins to keep both halves of the clamshell in place. The Z-axis carriage is a subassembly, exploded views will be available, I'm also planning to emboss part numbers on anything that will be injection molded (For a kickstarter) so that it is easy to assemble / reassemble.

For anyone looking at this project that does not feel they have the technical expertise to repair their TOME. Fear not! The TOME is being designed with the end-user in mind and a user manual will be released!

Tomorrow I plan to 3D print this clamshell with the mating component, the goal is to have one side of the Z-axis operational this week!

-

Stepper Drivers Chosen

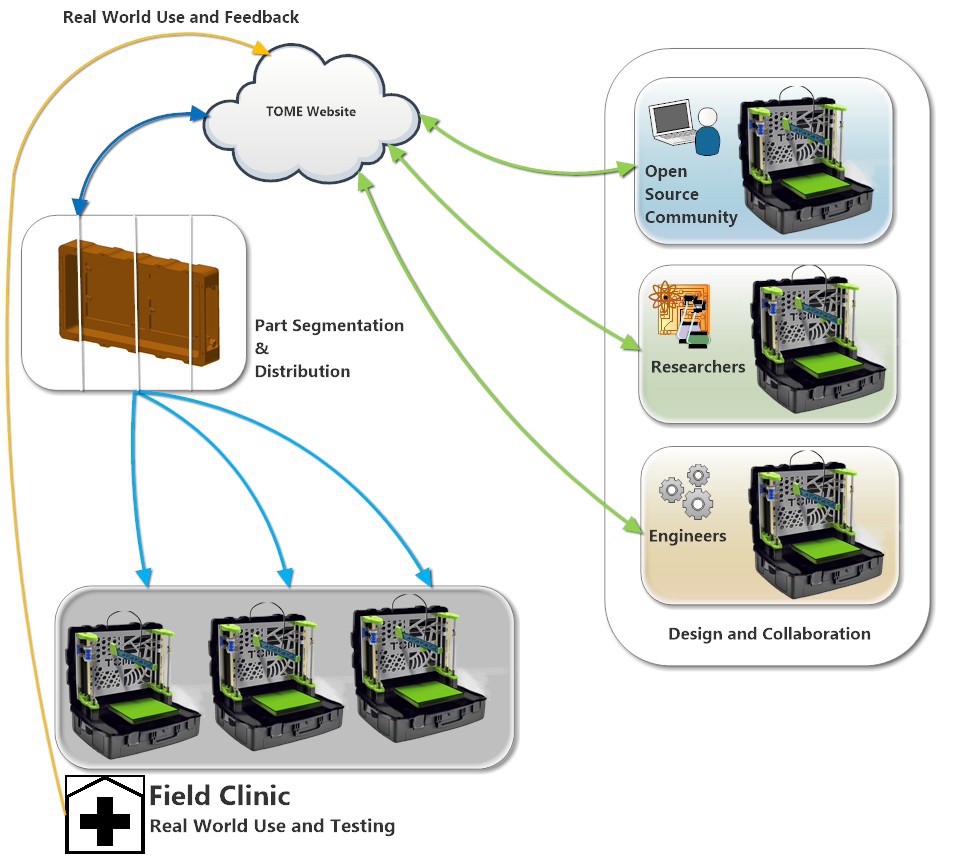

06/27/2014 at 07:26 • 0 commentsOne of the major enhancements to 3D printing that the TOME brings is portability, and when this is combined with several TOME printers interacting with one another we can print some fantastic things. Picture a field hospital with several TOMEs and a problem, they need to 3D print an arm brace but it's far too large for a single TOME. This model can be printed and split between all of the TOMEs at their disposal to quickly print the arm brace. Remote printing will also take a large leap by allowing teams to print collaborate on projects by printing parts to each others TOMEs for more rapid project development. Being able to collaborate over large distances seamlessly, deliver engineered products to those who need it remotely, and then receive real feedback with one system will enable us to develop technology faster and be able to help a wider audience.

![]()

The overall block diagram for the TOME electrical schematic is underway, and I hope to be able to post the first version tomorrow for everyone to see. Dean Gouramanis is a good friend of ours and has been working on some powerful stepper motor drivers, Corey and I decided to incorporate them into the TOME. Dean has also been working on a RepRap style Arduino MEGA shield that utilizes his stepper stack, unfortunately the TOME requires a different form factor in order to achieve the compact size; Therefore I'll be spinning a custom PCB set for the TOME.

[Data Sheet here: http://www.jameco.com/Jameco/Products/ProdDS/2210221.pdf ]

![]()

Video In action:

-

Artistic Renders

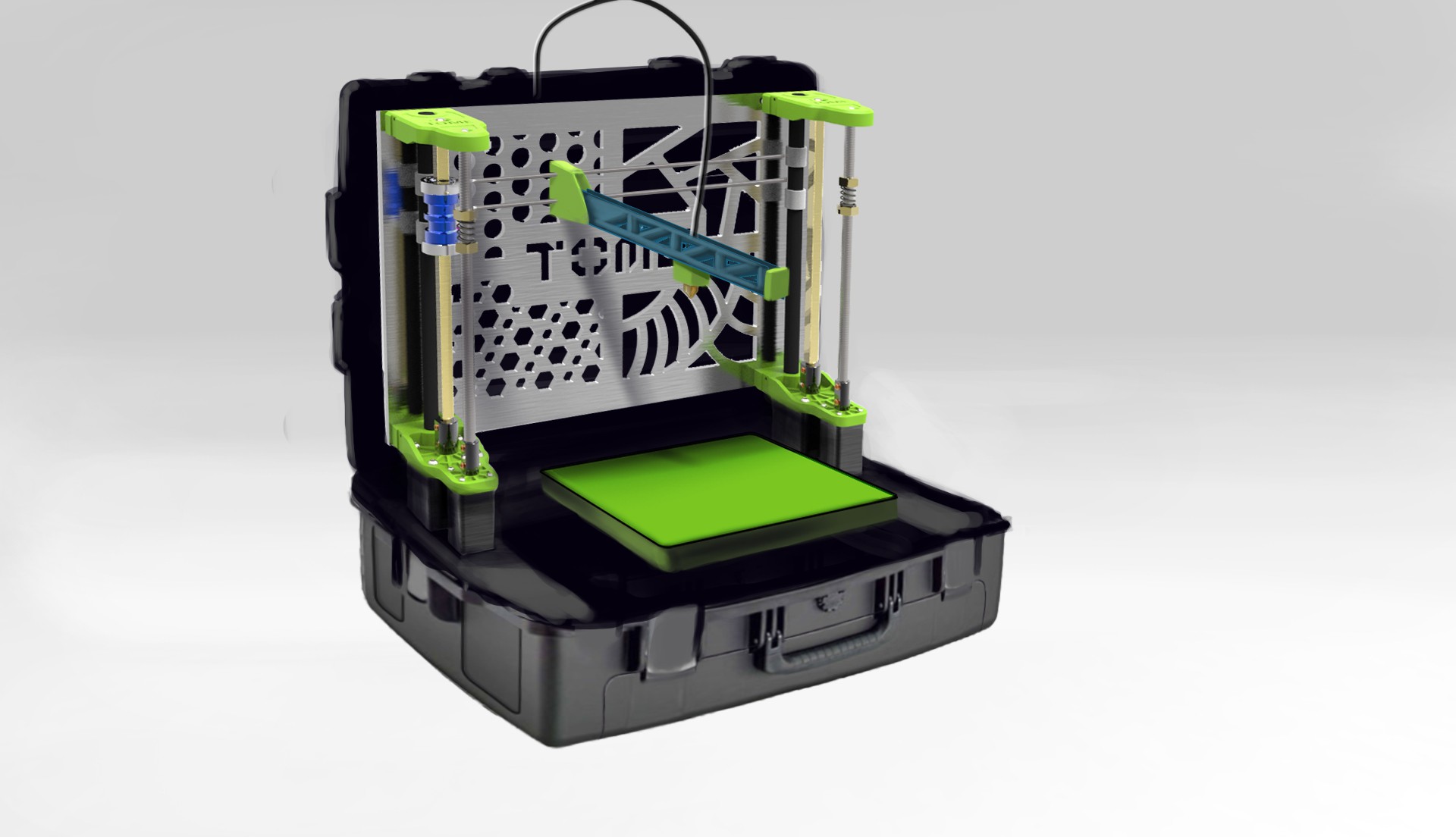

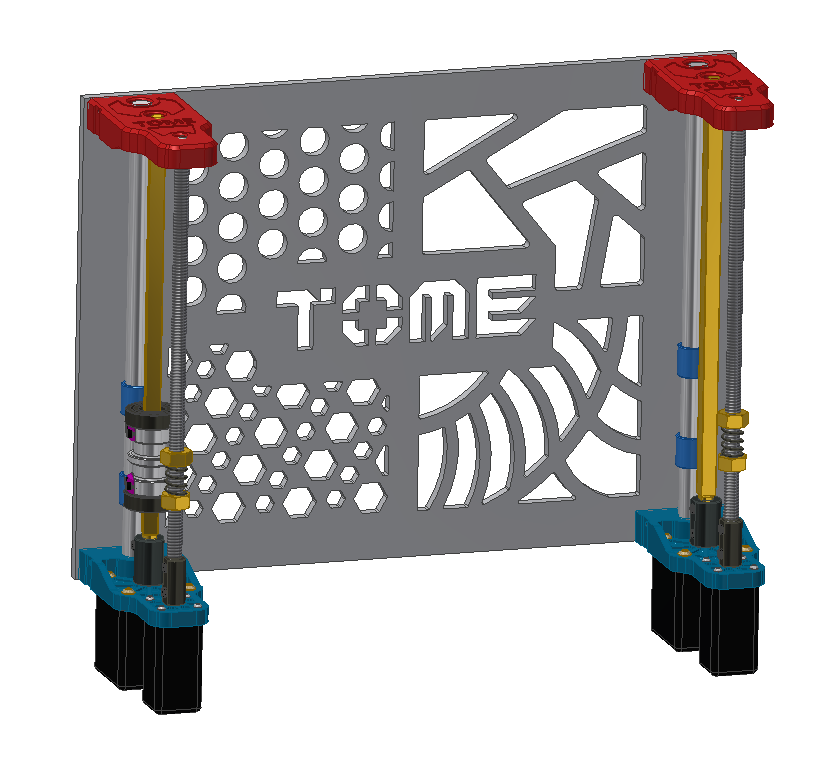

06/25/2014 at 23:21 • 0 commentsOne of the major questions we have received for this project has been "What will it look like when complete?" A completely valid answer as most of the design is still stuck up in our heads until we have time to document it properly.

To combat this an extremely talented designer and friend David Neal took up the challenge of rendering a more complete version of the TOME. Keep in mind that this style of TOME is aimed primarily at medical, scientific research, and military applications (Think Rapid Equipment force). The commercial version of the tome will have an injection molded / leather wrapped case for more of an every day use. Stay tuned for more updates!

Enjoy =D

![]()

![]()

-

Small, but meaningful progress

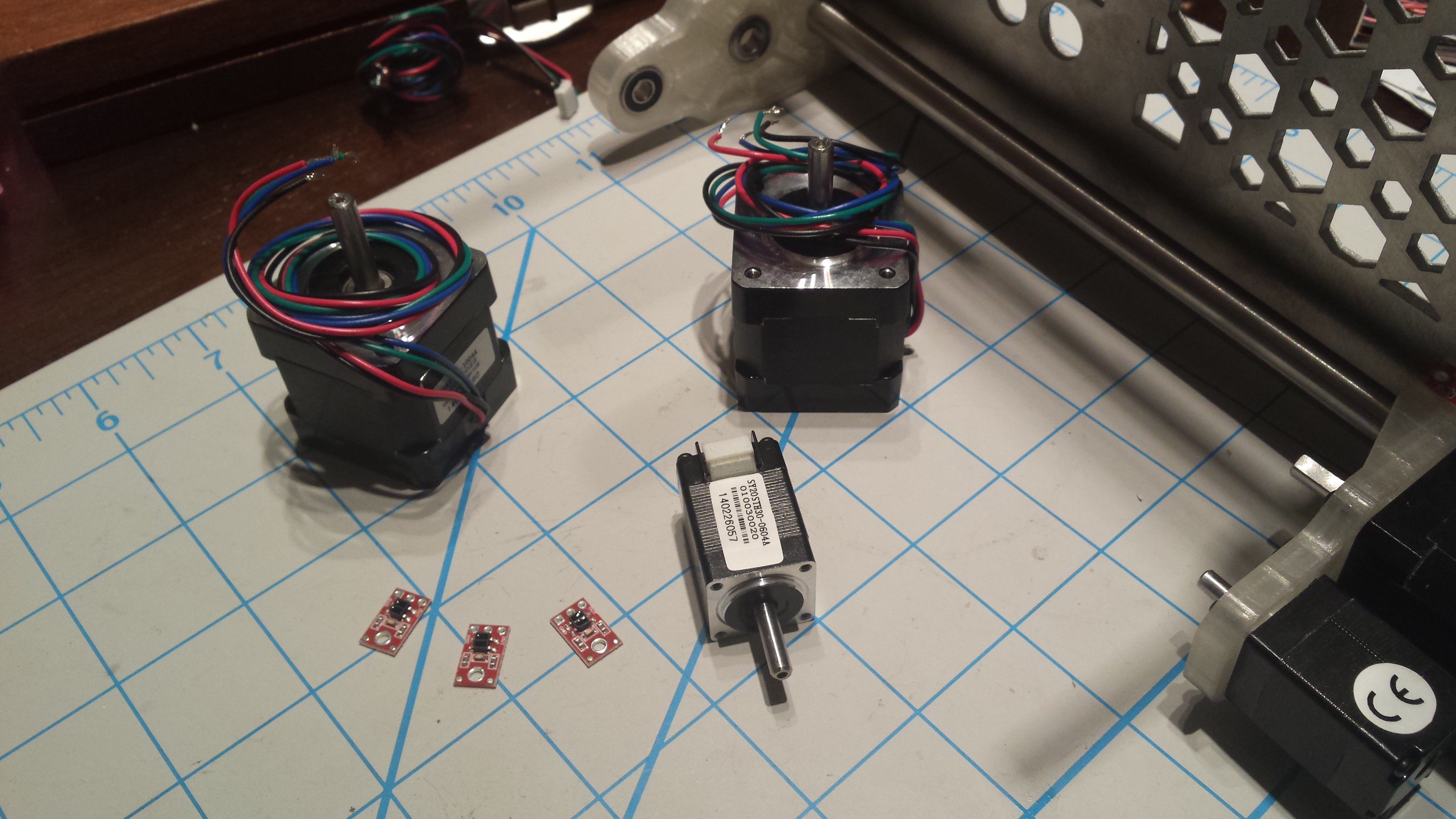

06/24/2014 at 05:17 • 0 commentsI unfortunately had to drive 12 hours away this weekend for a family emergency and couldn't get much done on the TOME this weekend. However upon my arrival back home I found that my Pololu order had arrived containing the remaining NEMA 14 stepper motors, the second NEMA 8 Stepper, and the optical end stop sensors.

![]()

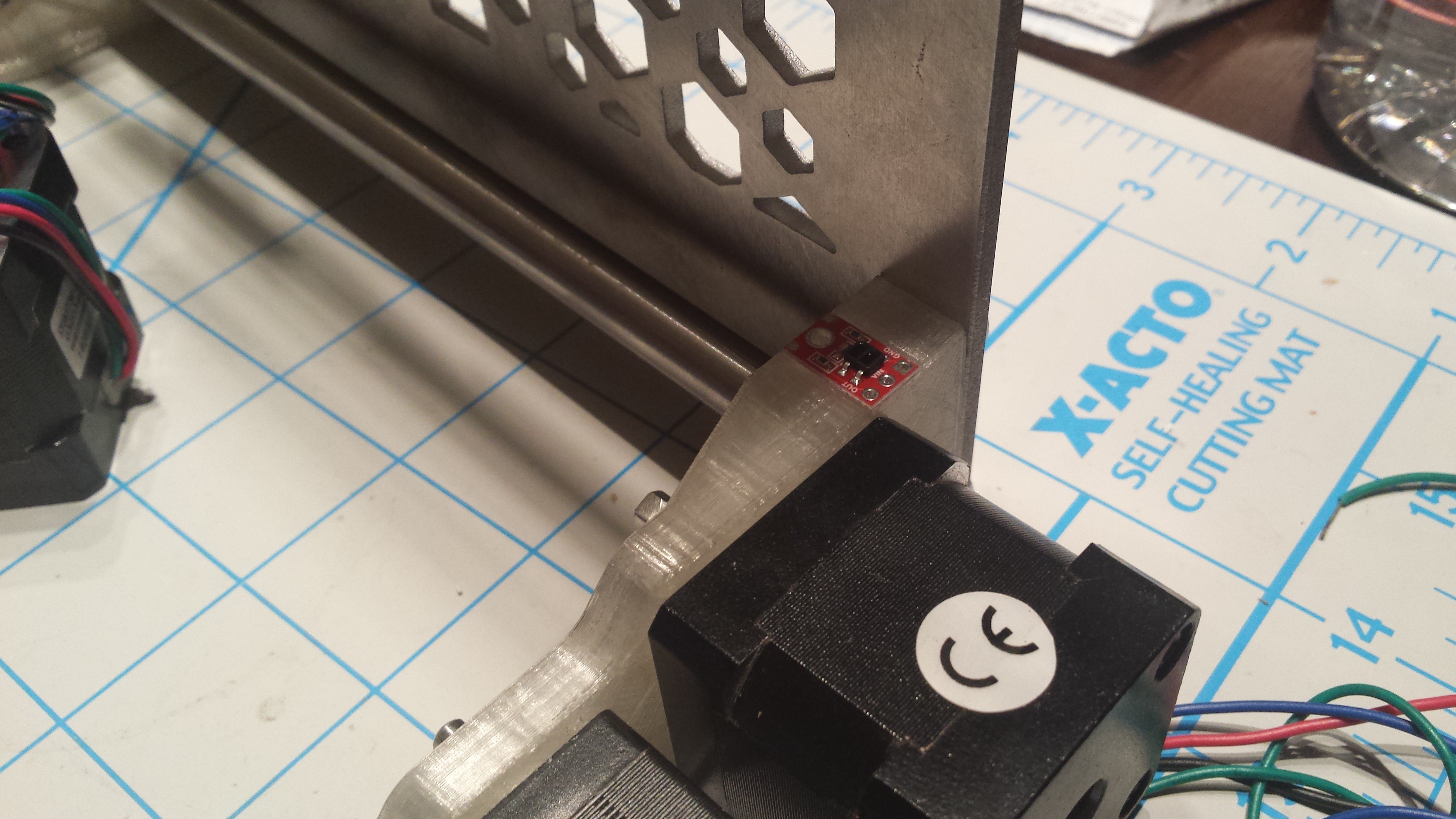

Here you can see an optical sensor installed, there will be one sensor for each axis (The other stop will be software, the TOME will home on each print) with one sensor to detect that the filament is present in the extruder.

![]()

-

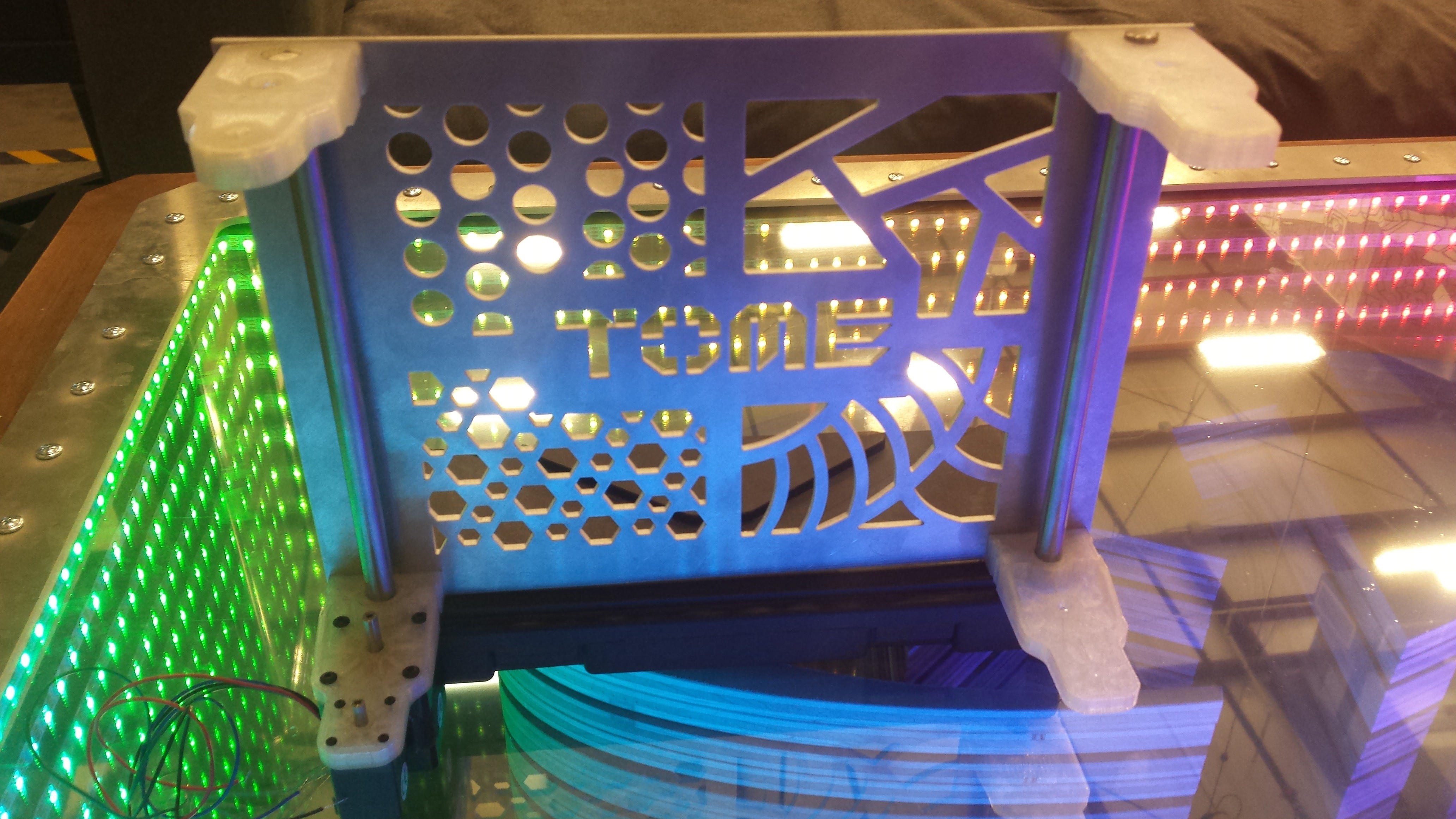

Waterjet Backplate

06/20/2014 at 17:34 • 1 commentThe first backplate has been waterjet to test the fit and get the overall feel. I'll be traveling this weekend and won't have too much time to work on the TOME until I return. Next week will be a busy week of 3D printing to get the Z and X axis prototyped.

![]()

Here it is next to a new Makerbot for size comparison:

![]()

Z-axis Carriages are currently being designed and will hopefully start printing on Monday.

Thank you everyone for the support thus far, cheers!

-

Back Pane Cutout

06/20/2014 at 08:42 • 0 commentsI couldn't decide on a pattern for the rear panel cutout, if anyone has any ideas feel free to post. Each quarter of the rear panel is a different style cutout to get a feel for how it looks (Circular, curves, angles, and hexagons). I'm going to cut this out tomorrow to mount the motor/bearing mounts and get a feel for the overall size.

If anyone has an cutout pattern ideas please feel free to chime in! Personally I like the top right quadrant.

TOME - Portable 3D Printer

Portable and self contained FDM 3D printer designed to be the ideal tool for field hospitals short on supplies and nomadic engineers alike.

Philip Ian Haasnoot

Philip Ian Haasnoot