I originally intended the endstops to be micro switches. I read about how important homing was for delta printers and decided to scrap the micro switches pretty early on. Hall effect sensors were highly regarded with great accuracy and repeatability. This is mainly due to no actual touching of the sensor by the axis slider. There were premade hall effect endstops available but I knew I could make my own much cheaper. A little bit of googling later and I found some hall effect sensors with a handy little application circuit in the datasheet - perfect. The sensors I chose were Infineon TLE4906L from RS Components. I also bought some 5mm disc neodymium magnets to trigger them. The magnets were glued to the top of each vertical slider.

Micro switch endstops with dodgy brackets

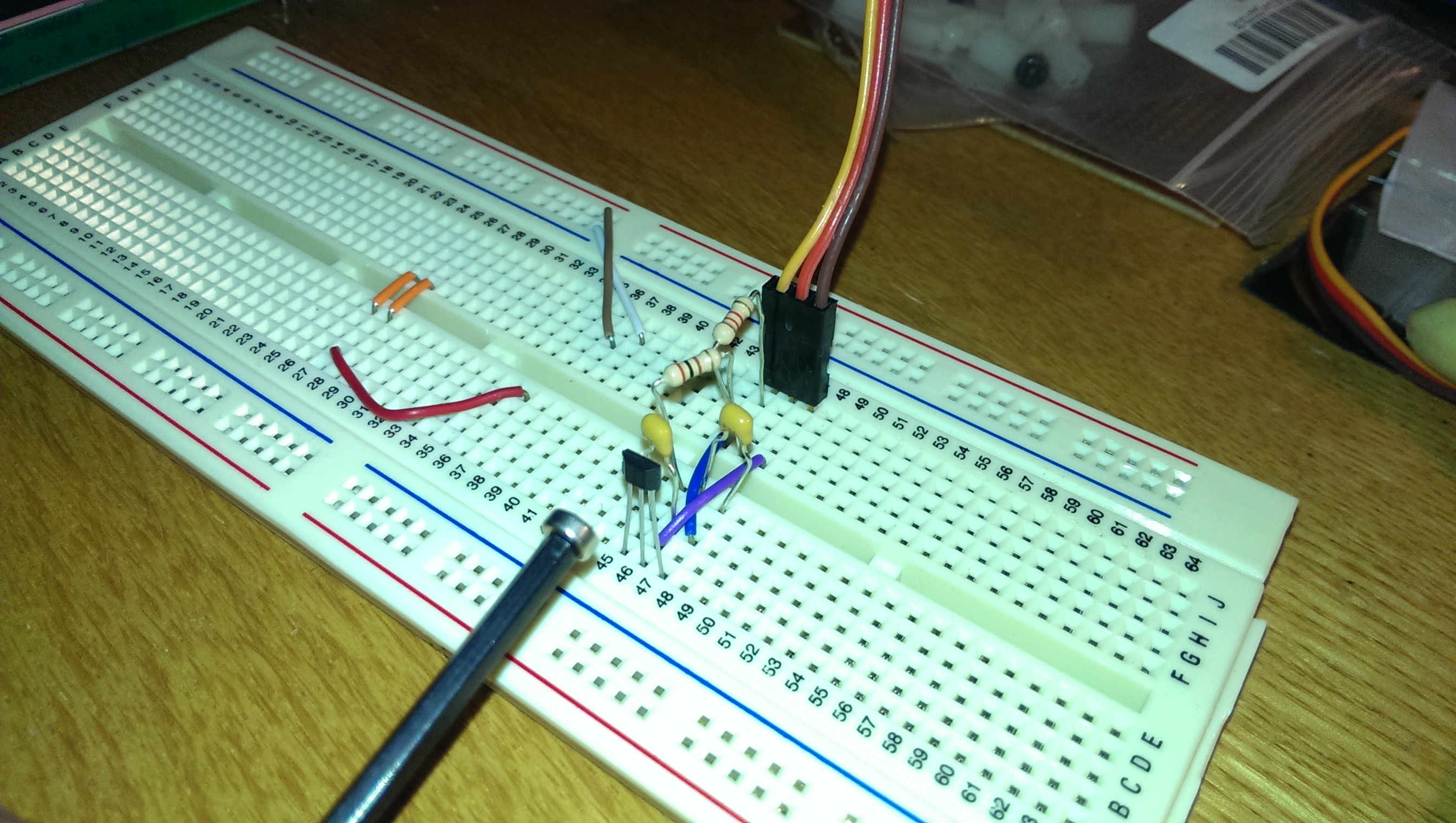

Prototyping the hall effect endstops

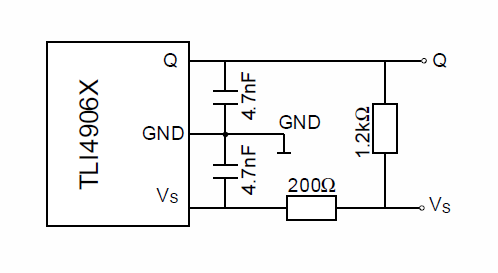

Application circuit from datasheet

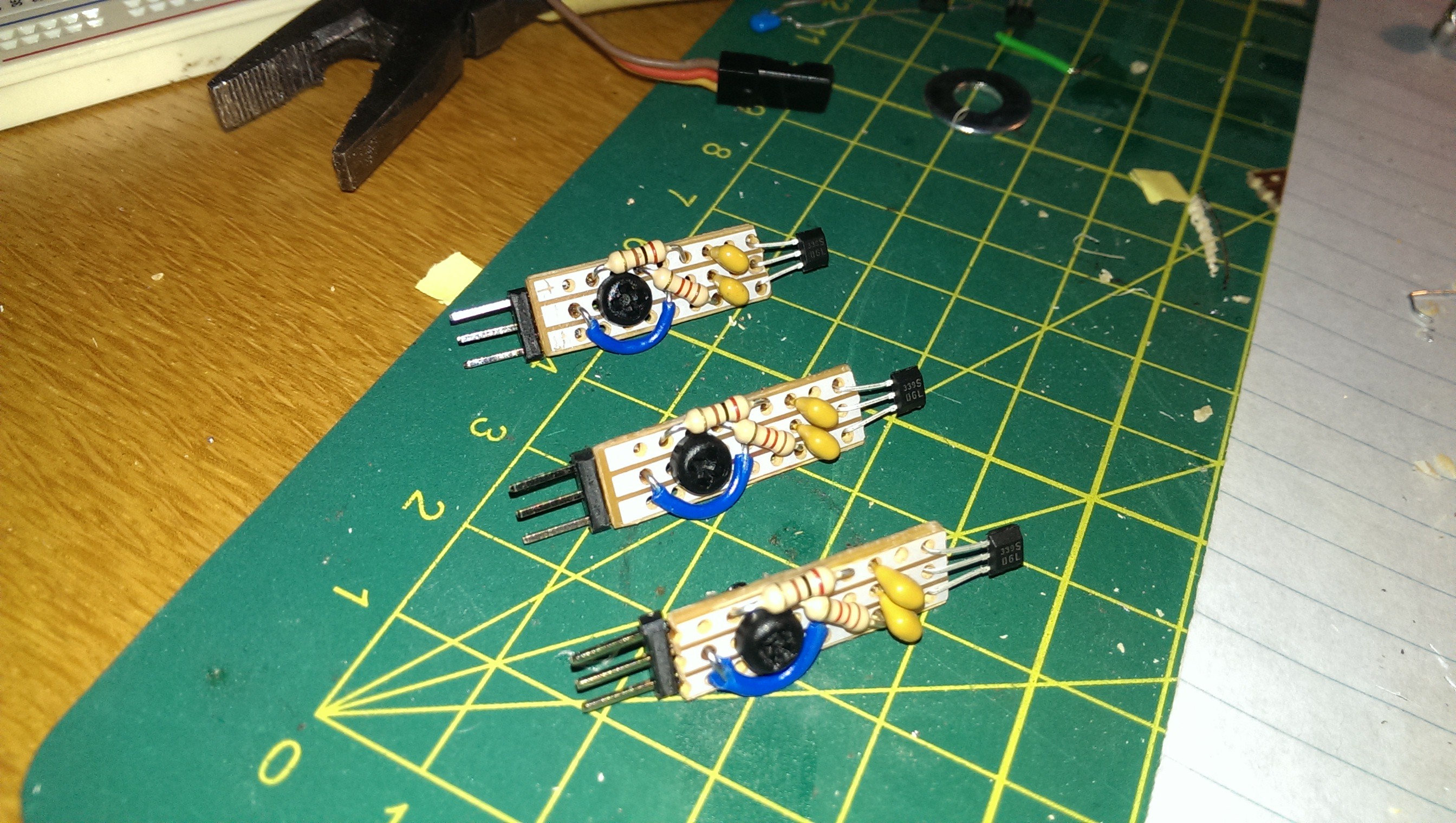

I had had some strip board and made up the endstops. They are mounted on a nylon standoff and can be adjusted by bending the legs of the sensor slightly. This would effectively change the trigger distance and adjust the axis when homing. I knew that this was possibly not the best idea but you only need to adjust them after moving the printer so it wouldn’t be very often. I also ensured that they had a “standard” endstop interface (+5V, GND, SIG).

Endstops ready for installation

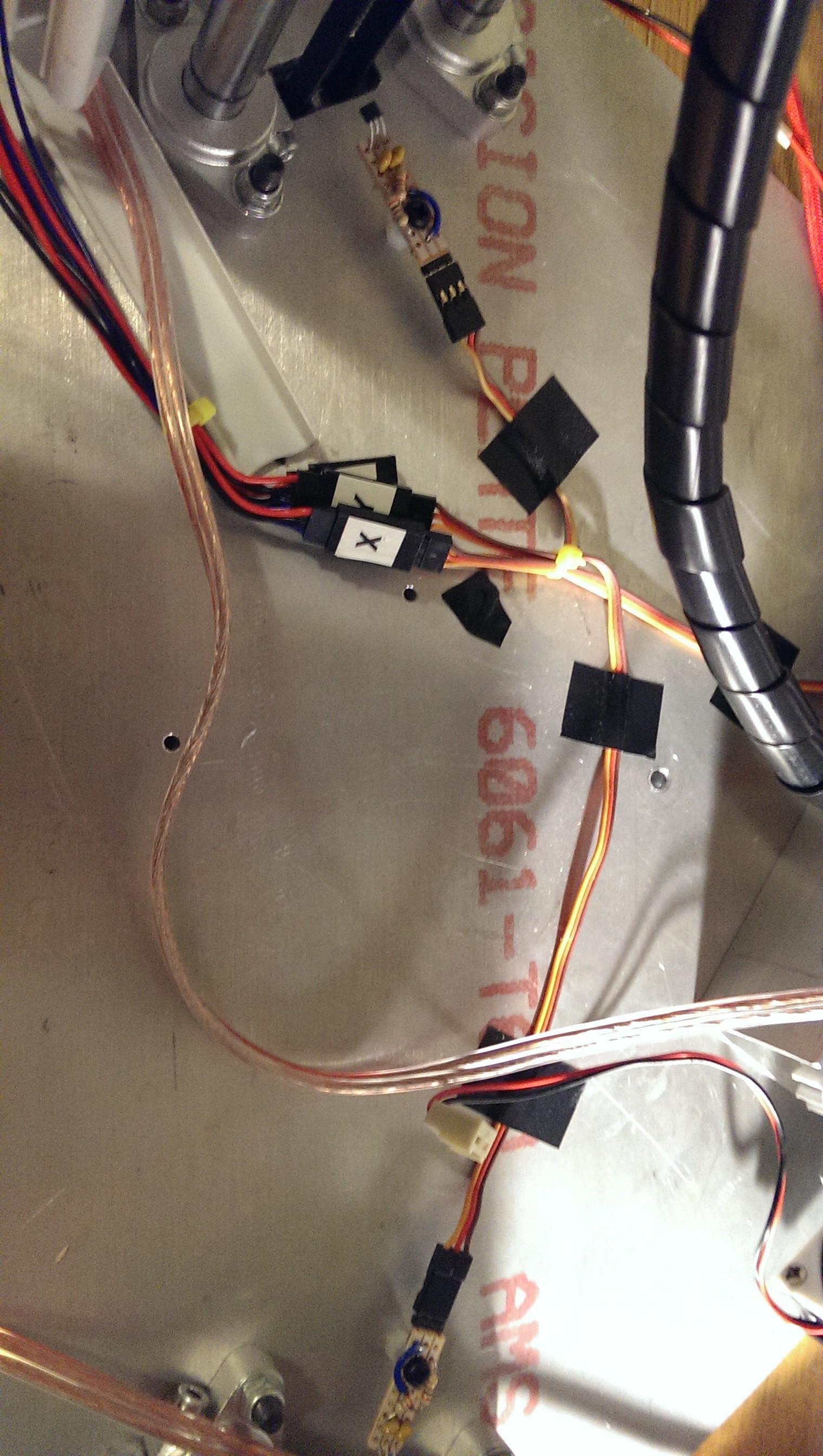

Mounted under the top plate

I was really happy how they turned out and they worked great with high repeatability.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.