I started out with a cheap clone J-Head hotend running 3mm filament. Once I started tuning I was having difficulty with consistent flow rates and temperature. I also had occasional jams. I’d read amazing reviews of the E3D V6 hotend so ended up purchasing one. Supposedly it would drop straight into the grove mount in my end effector. It turns out that the J-Head required a 5mm thick groove whereas the E3D V6 needed a 6mm thick groove. This was quickly solved with a printed washer-clip.

Washer clip thing

The rest of the upgrade was fairly straightforward. I had to reprint the fan duct. Luckily I had designed it with a somewhat parametric fan size so it was easy to scale.

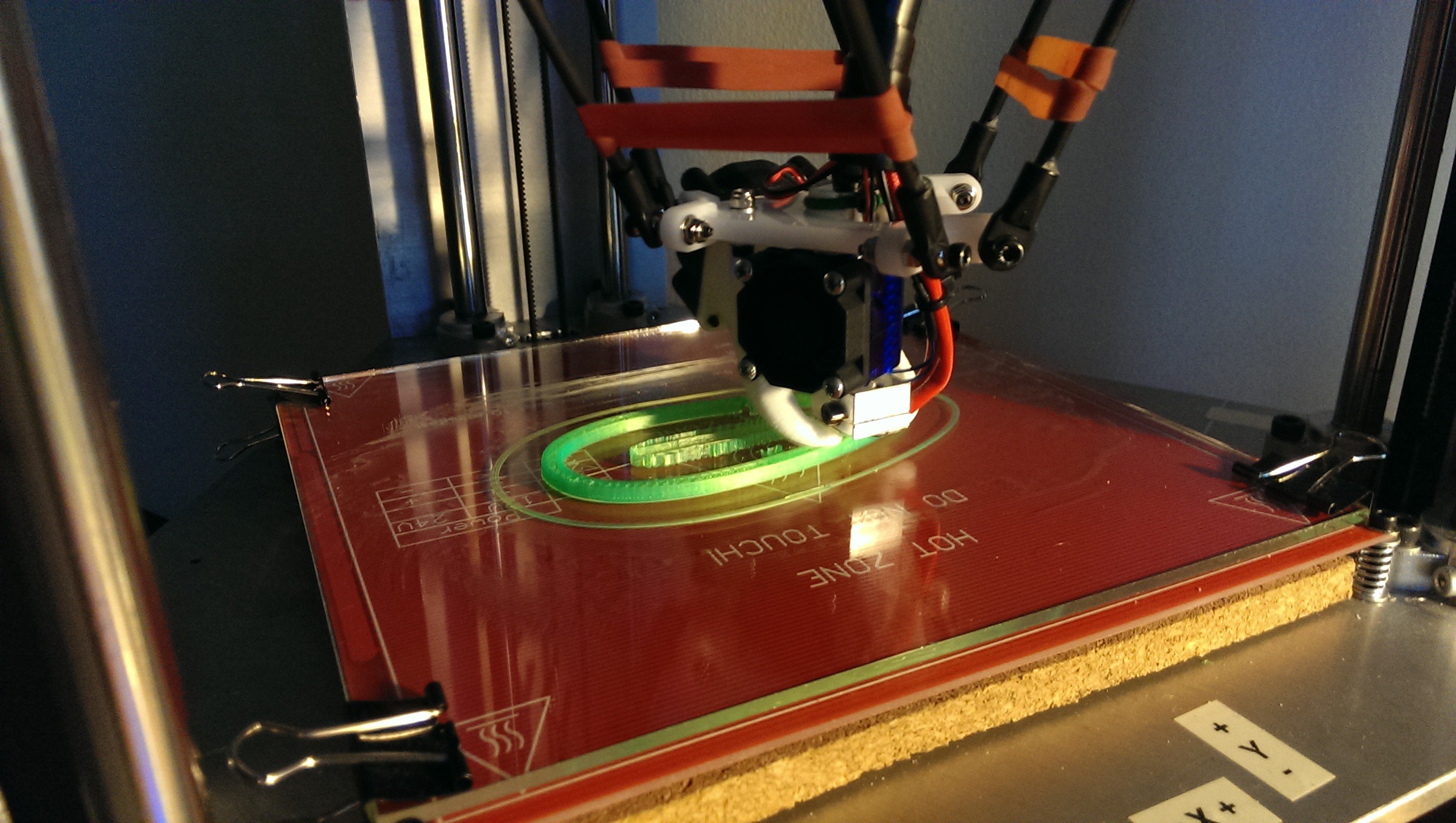

Printing an ocarina half with the new E3D V6

The Greg’s Hinged Extruder was designed for both 1.75mm and 3mm filament so the only thing required at the cold end was to swap the Bowden push fitting for a smaller one.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.