-

32bit Brain with a measureKing?

04/20/2020 at 20:45 • 1 commentNew thoughts:

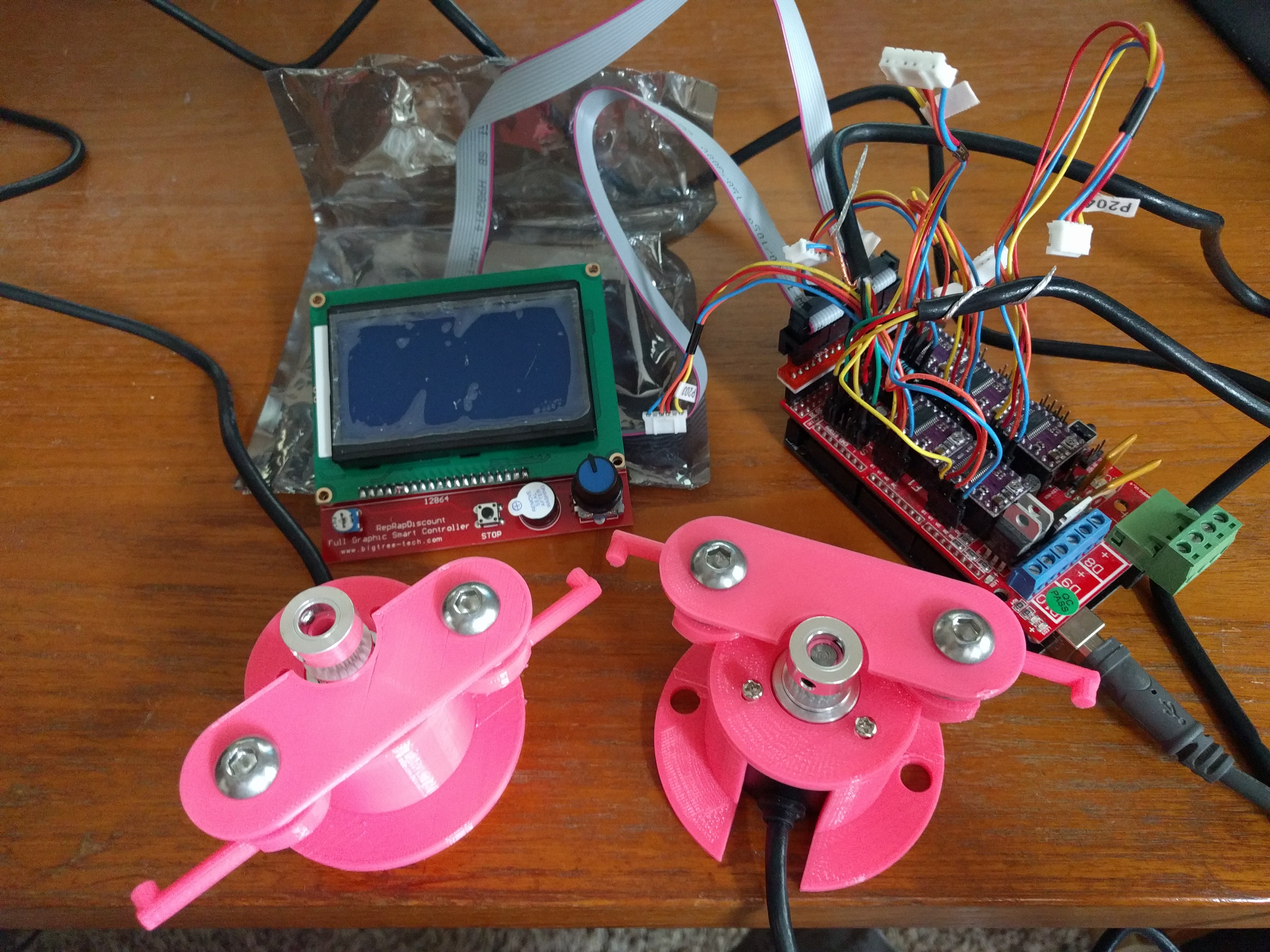

So the trouble has been getting the triangulation to work. What if we upgraded the brain to a 32 bit controller like the bigTechTree SKR V1.3 with the bigTechTreeTFT35 to use as user input.

Next I wanted a cheap way to measure the distance from two points. My new thought was to use the Measure King. So I bought one and ... not amazing. It isn't a laser range finder at all but instead a sonic range finder so that won't work. But the string measure might work as a range of 11ft (ok with me). I would need to pull it apart and find a way to read out the measurement. Take two of them and put the two cords as close to the bit and as close together as possible (to decrease wrong measurements if the device is rotated). Next Make sure the string are a straight line to some arbitrary points in the upper right and left hand corners of the work piece.

I'll have to work on getting in the guts of a measureking. I also have an SKR on its way to my house :-).

-

Cheap Triangulation

07/12/2018 at 17:38 • 0 commentsSo some further thoughts. this project is mostly stuck on an efficient/cheap triangulation methods. My rotary encoders are not working :-(. I thought I fried the transistors by hooking it up wrong. But after replacing them it still doesn't work.

More on infrastructure thoughts would be to use the same ramps board but use kilipper with a rasberry pi to control the steppers. Next put all the logic on the PI.For triangulation I could use two usb mice mounted to the shaper. Then two tape measures mounted with the ends connected to the corners. Next run the tape in front of the mouse to get accurate x/y triangulation.

https://www.raspberrypi.org/forums/viewtopic.php?t=80987

Another thought would be to use two echo locators to triangulate the shapers position:

-

Can Anyone Help?

10/16/2016 at 17:12 • 0 commentsSo I have put together most of the electronics. I was working on the encoders first. I can wire + - A (Signal) into the +X endstop and the B into the -X signal. I have started the code but can't seem to get a good signal from the encoder.

I was using J.Carter(of Earth) from Arduino Rotary Encoders but it was never showing a change in direction. When I changed the code to just print A or B I get a bunch of A and every once in a great while a B. It does the same for both encoders. I don't know if I have a bad encoder or not wired correctly. Anyone have any ideas?

#include "U8glib.h" #include <SPI.h> #include <SD.h> #define LCD_PINS_RS 27 #define LCD_PINS_ENABLE 29 #define LCD_PINS_D4 37 #define LCD_PINS_D5 35 #define LCD_PINS_D6 33 #define LCD_PINS_D7 31 //************************************************** // Change this constructor to match your display!!! //U8GLIB_SH1106_128X64 u8g(LCD_PINS_D4, LCD_PINS_D5, LCD_PINS_D6, LCD_PINS_D7); void int0() { Serial.print("A"); } void int1() { Serial.print("B"); } void setup() { Serial.begin(9600); //setting up encoder A digitalWrite(2, HIGH); digitalWrite(3, HIGH); attachInterrupt(0, int0, CHANGE); attachInterrupt(1, int1, CHANGE); } void loop() { Serial.println(); delay(1000); }![]()

![]()

-

Started construction on ZXY axis

09/27/2016 at 14:31 • 0 commentsI have build the Z, X and Y axis for the shaper. The z is build using the mostly printed CNC Z. It is probably too tall but I wasn't certain what the max height would be so I will wait till then to trim it. As for the X and Y it was made out of wood and primitive tools (jig saw, router and sander) so it is not a very tight fit but it will work for a proof of concept. Next I need to 3D print the encoder mounts as well and the X and Y motor mounts.

![]()

![]()

![]()

-

Parts Ordered

09/20/2016 at 18:05 • 0 commentsI ordered all of the parts I needed from the standard bay (cause I'm cheap). I should have all the parts I need here in 5 days to 6 weeks. I have finished 3D printing most of the parts I need for the Z setup borrowed from the Mostly Printed CNC. When I get the chance I was going to start building the shaper like x-y auto correction system.

-

Using mice for X Y offset

09/14/2016 at 18:38 • 0 commentsIn further investigation (thanks to PointyOintment's suggestion) it may be simpler to use multiple PS2 mice instead of the belts. You can do deadest reckoning with two mice read http://www.instructables.com/id/Optical-Mouse-Odometer-for-Arduino-Robot/step4/Further-Modifications-and-Finishing-Up/ and https://www.researchgate.net/publication/221645389_Dead_Reckoning_for_Mobile_Robots_Using_Two_Optical_Mice. But this always assumes you haven't cut large lines out of your working surface. This means many mice would have to be used and ignore the extreame values.

-

X Y calculations

09/13/2016 at 12:09 • 0 commentsIt looks like the XY calculations are quite easy. Its called forward kinematics and can be seen calculated here https://www.marginallyclever.com/2012/02/drawbot-overview/. Next I have to do interrupts on the encoder rotation to make sure I get every tick. For version 0 I think I'm going to put the encoders on the work surface and weights on the belt like a draw bot for simplicity. Then all I need is power to the drill and z stepper. For v0 the electronics will be kept off the shaper and won't have auto correct .

-

Further Problems

09/12/2016 at 18:31 • 0 commentsIt was brought to my attention that a large problem with the encoder input for positioning is that when a person rotates the router it looks like a move left or right instead of a rotate. To keep the simplicity there I would like to keep the encoder for positioning, so here are my thoughts. Move the GT2 belts to the bottom. Make sure there is nothing to get in the way of them for 180 degrees. Find some way to move the first point that the belt touches on the shaper as close to the bit as possible. Then they need to do their best to keep it straight.

-

Removed Raspberry PI

09/12/2016 at 18:26 • 0 commentsI know we all love our Raspberry PI but it was simply adding complexity to feed data to the mega. Further searching I was able to find an LCD smart display with SD card. I can simply read the data I need from the SD card and the complexity is all gone. I also add the feature of a screen for user feedback as well as user input.

Simple & Cheaper CNC Shaper

I love the Shaper Origin, it could solve many needs for the home maker and care taker. But at the price many can't afford it.