Introduction

E-textiles (a.k.a. soft circuits or wearables) is a rapidly growing field of electronics. Projects generally consist of interactive circuits embedded in textiles using conductive thread and Arduino-based microcontrollers. The components commonly used are designed to be hand-sewn and worn (for instance, the Lilypad and Flora).

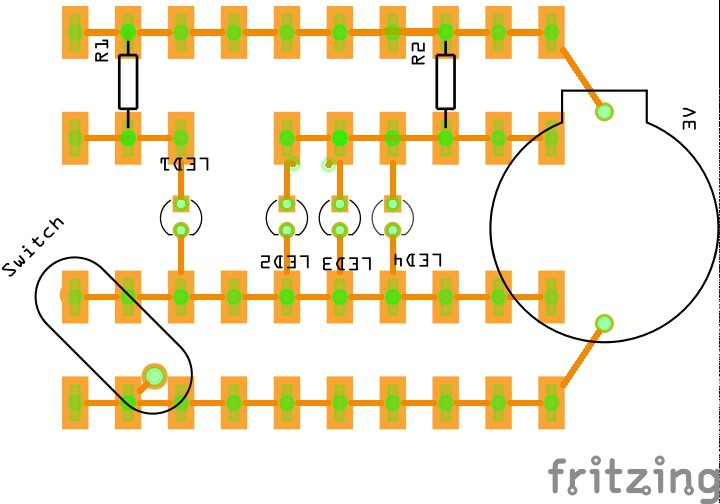

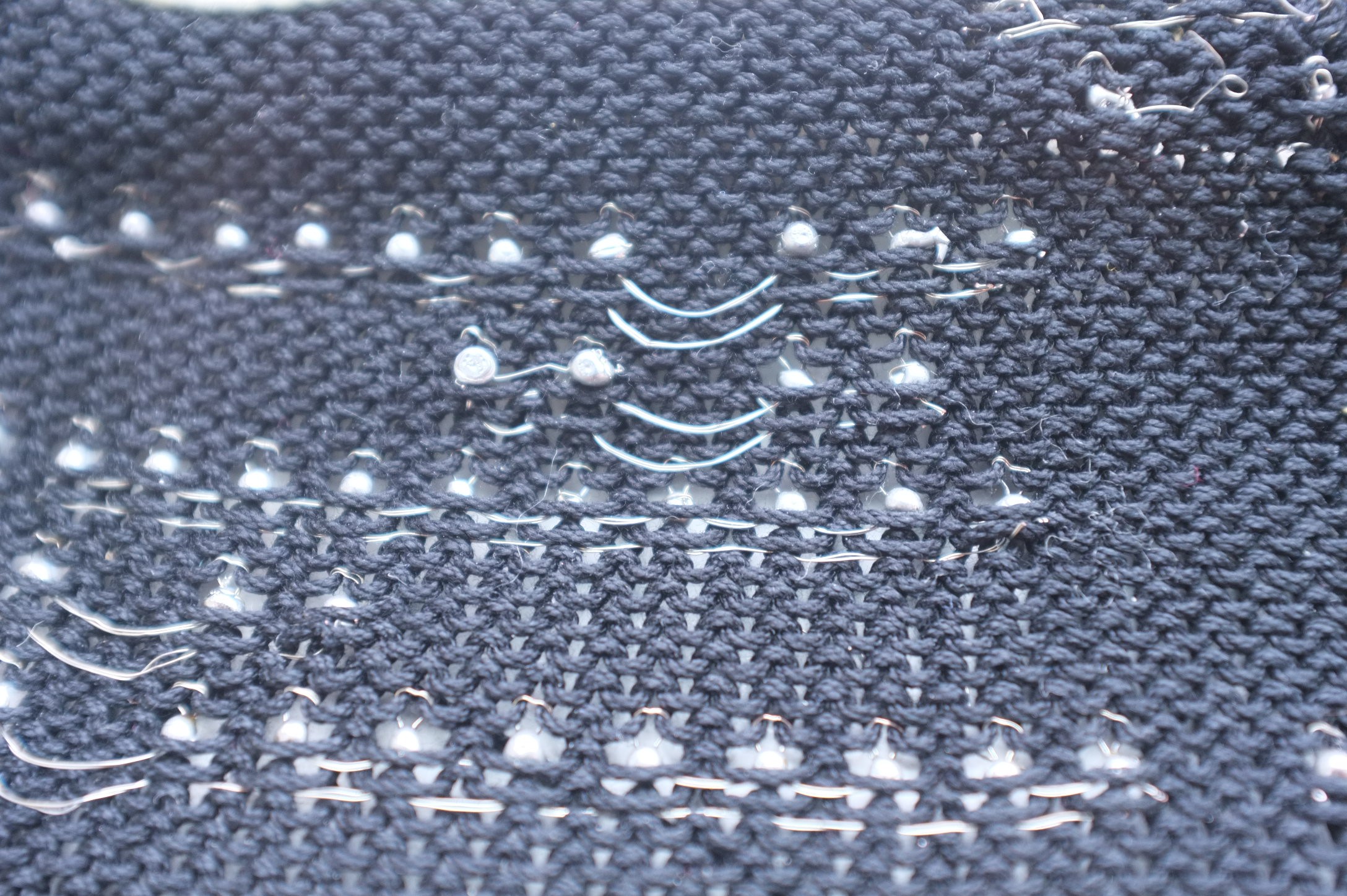

I've developed a new method for creating wearables, machine knitting with bus wire.

Bus wire is pre-tinned copper wire used in electronic circuits. It is inexpensive, solders easily, has stable conductivity, and negligible resistance.

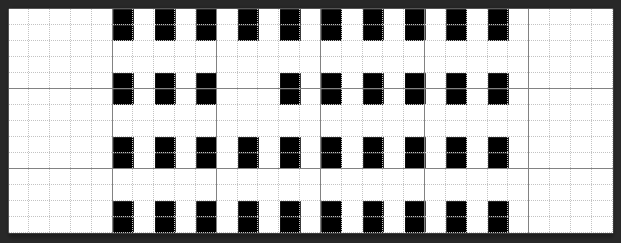

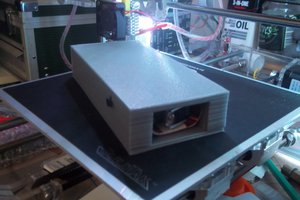

Home knitting machines are designed for rapid production. Patterns can be uploaded as electronic files, and shared in jpeg or bmp formats-- a form of CNC production.

Advantages

- Unlike conductive silver thread, bus wire does not tarnish and lose conductivity. It also has negligible resistance, unlike stainless steel thread (e.g. resistance of stainless steel thread might be in the range of 18ohm/ft). It's also much cheaper than these fibers. (Spools of several thousand feet of bus wire cost less than $15.)

- Bus wire is easily solderable, unlike conductive threads which generally require careful hand knotting/stitching to components.

- The wire is machine knittable, which allows for rapid production and digital sharing of patterns.

- The method works with conventional electronic components as well as components designed for e-textiles. This opens the door to a much wider range of possible circuits.

Limitations

Lead solder should not be worn against the skin. Circuits need a lining for the wearer's protection.

- I am exploring other options for when safety and comfort are a priority: sealing joints with liquid electrical tape, lead free solder, and solder free crimp connections.

Wires should not be handled roughly or bent. The wire should not be worn where it will be repeatedly bent with a tight radius. However, if treated with the same care usually reserved for hand knitted textiles, it holds up fine.

- I've successfully been able to machine knit stainless steel thread, and have developed a method for soldering with it. I plan to eventually explore this approach further, specifically for creating circuits that can handle more wear.

Who this method is for:

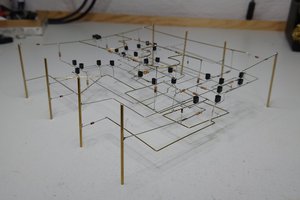

- Artists. As an artist, I'm creating large circuit knit sculptures for gallery display (not wearing). Rapid production and inexpensive materials is important in this application.

- Costumers. People often create e-textiles for "special occasion" wear (i.e. costumes, party wear). For these kinds of projects, rapid production is more important than ruggedness. This is especially true with accessory pieces (i.e. a bracelet or hat). I had these makers in mind when developing this method.

- Electronics novices. Bus wire makes knitted circuitry easy to solder. This makes it approachable by novices. I've already conducted a "learn to solder" workshop with it, and plan to develop more workshops, which will hopefully appeal to a wider, more craft-oriented audience.

- Knitters (machine and hand). Sometimes the means is just as important as the ends. :-)

Project Plans:

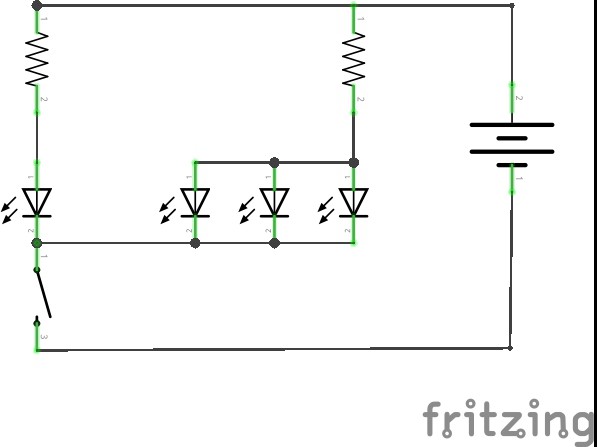

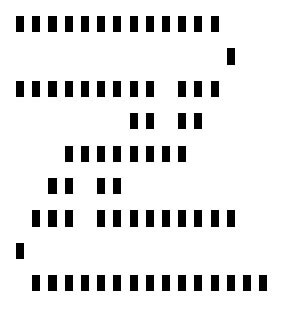

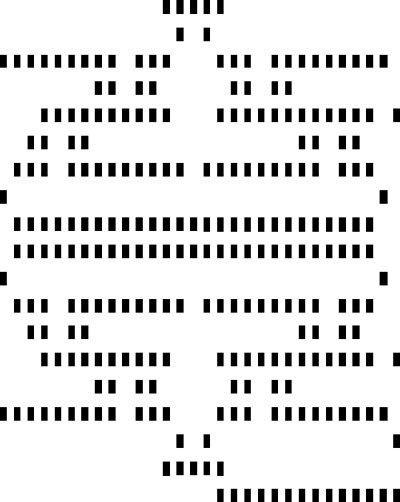

A library of stitch pattern circuit diagrams.

Diagrams for easy reading by hand knitters + bmp versions of the files that can be uploaded directly to electronic knitting machines for printing the circuit board.

Patterns to include:

- Educational patterns that demonstrate principles of electronics. These are inspired by the electronic circuits I use to teach my students (on breadboards) in my class.

- E-textile patterns that embed circuits particularly useful for wearables/textiles.

- Written tutorials/explanations for each pattern.

- Circuitry designs for knitting sensors.

Hardware:

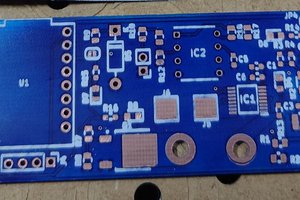

- A catalog of methods for employing electronics hardware into machine knitted circuitry.

- Components designed for knitting machine circuitry.

Resources

My work continues from the work of many others before me.

Hi-Low Tech Research Group of the MIT Media Lab. In particular, the work of Leah...

Read more » Jesse Seay

Jesse Seay

Xylitol

Xylitol

MaBe42

MaBe42

Kelly Heaton

Kelly Heaton

Vedran

Vedran