-

Hackaday Prize 2016 Finalist ADITI

10/10/2016 at 13:58 • 0 commentsThanks for the overwhelming support, We have got great support and feedback.

Regardless of the outcome my team has received enough support to keep us motivated.

A prize wouldn't hurt though :).

Please support us by sharing this video and following our project.

Quoting the great Nelson Mandela,

![Image result for Nelson mandela quotes civilization]()

-

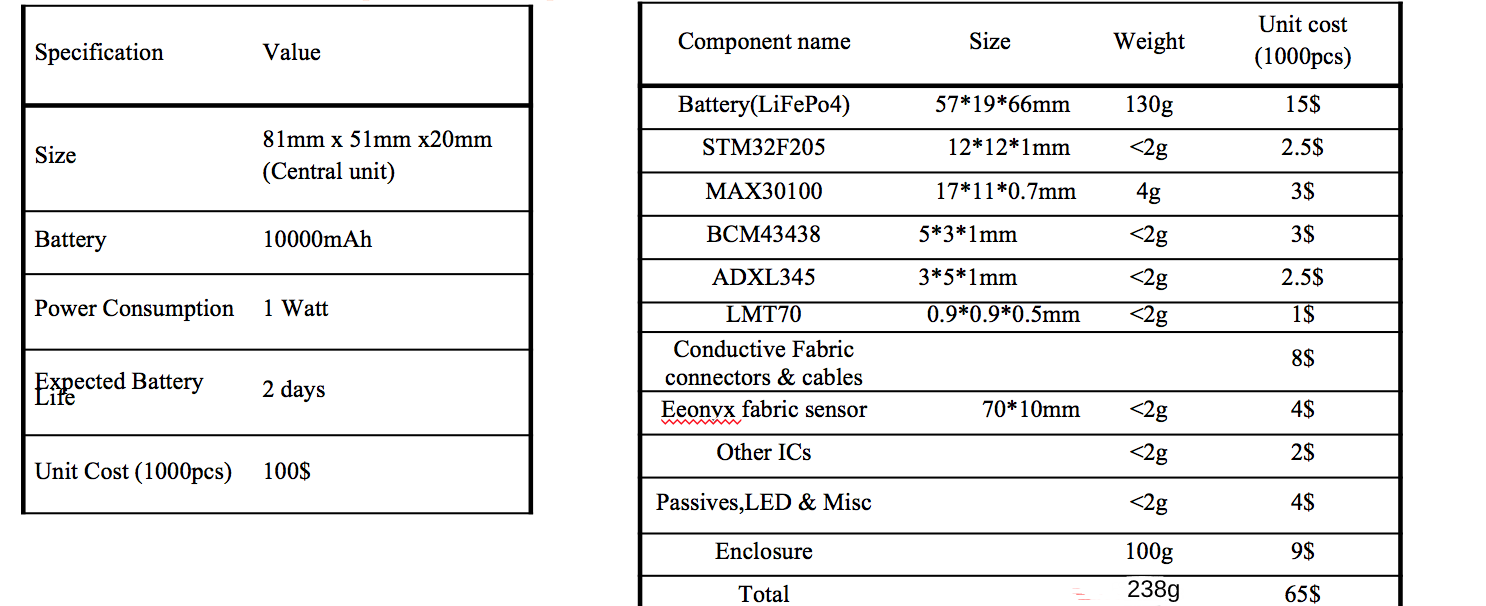

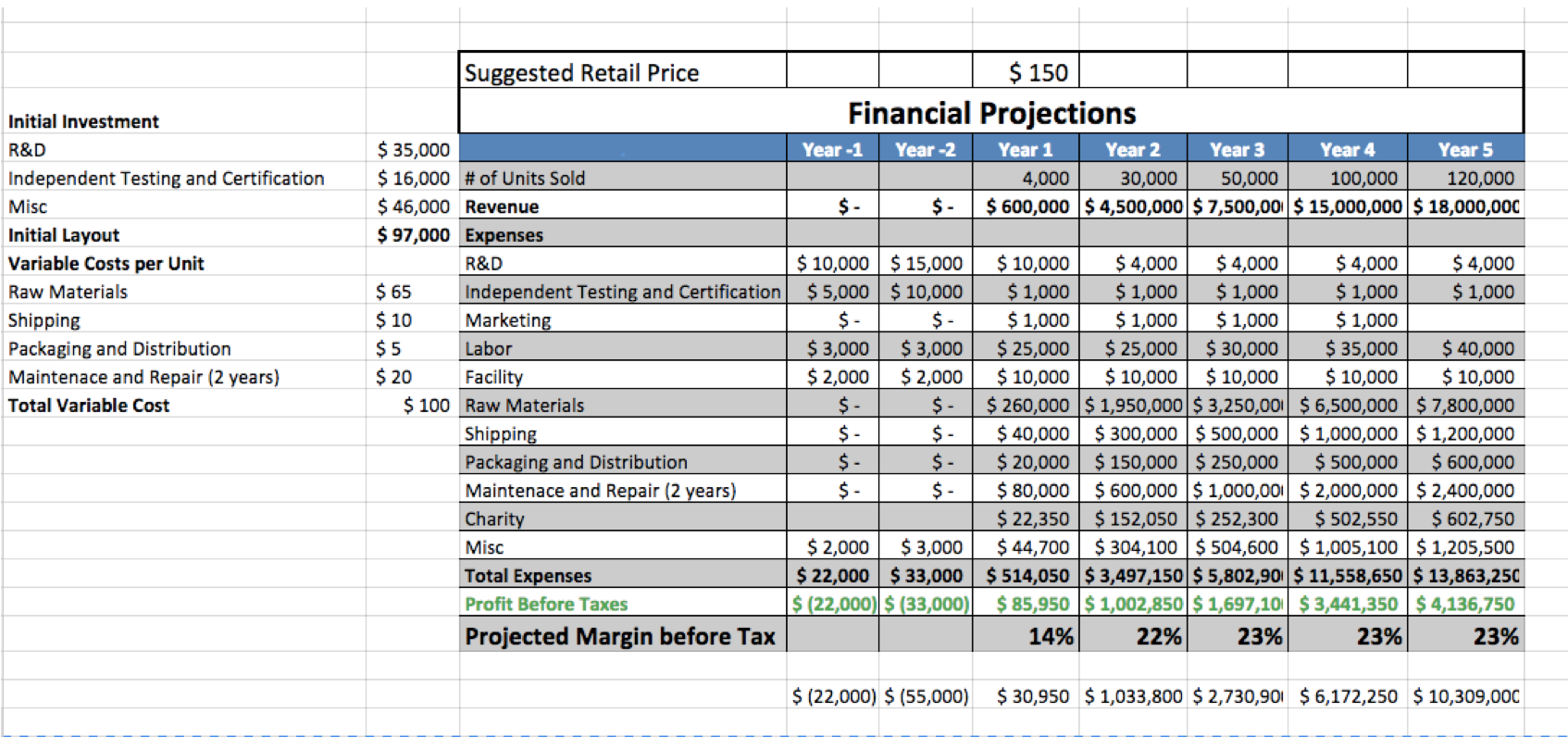

BOM cost split-up

10/10/2016 at 13:43 • 0 commentsWe have primarily chosen off the shelf components in the development of ADITI to make it easy to replicate by anyone.

Weight was a major concern for us with the battery pack itself weighting at 130gBOM & Weight cost split-up:

![]()

Financials

![]()

Our go to market strategy is to work with NGO's like the Gates Foundation and work with Community Healthcare workers through UNICEF. -

Power Management

10/10/2016 at 13:19 • 0 commentsFor the prototype we have used an inexpensive(15$) Oneplus 10000mAh 2A USB powerbank to power the power hogging warmer system.

![Image result for Oneplus power bank]()

The recent Samsung Galaxy Note 7 explosions brought to light the fundamental flaws in Lion/LiPo chemistries and thus we decide to move away from it in the future.

A 6.4 V, 10000 mAh Lithium Iron Phosphate battery pack is to be in the upcoming revisions of our system. LiFePo4 chemistries are very safe and are unlikely to explode thus making us choose it over LiPo.

![Image result for Lifepo4 6.4v battery]()

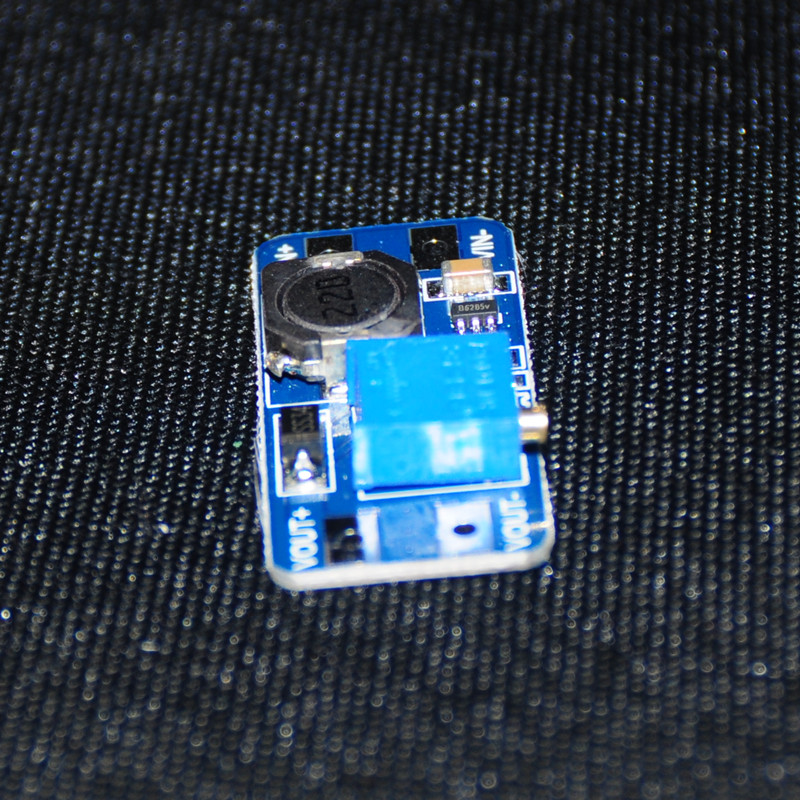

For powering the heating element at 7V we use a MT3608 boost convertor to get a stable 7V from the 5V input.

![Image result for mt3608 buck boost]() The net current consumption (Including sensor&MCU power) was about 550mAh with the heater on and total power consumption was a 2.75W.

The net current consumption (Including sensor&MCU power) was about 550mAh with the heater on and total power consumption was a 2.75W. Due to the lack of electricity in rural areas, We aim to make the battery packs hot swappable with solar charging system for charging the batteries individually.

-

MCU and wireless

10/10/2016 at 13:09 • 0 commentsWe have used the particle photon for building our prototype.

![Image result for particle photon]()

For processing the data it has powerful STM32F205 microcontroller is used for interfacing various sensors. Sleep modes are used frequently to increase the battery life of the wearable. It has a Broadcom BCM43438 module to provide wireless connectivity to the system and a version of it also supports both Bluetooth Low Energy and WiFi. Even though WiFi is power consuming (Redbear duo), we have used it to directly post the data to the cloud over WiFi in the prototype. The WiFi transmission is done in bursts to conserve battery.It has an inbuilt chip antenna though since we used an aluminium enclosure for the electronics, A external PCB WIFI antenna was used in the system.

The future iterations would use a Nordic Semiconductors nRF52832 BLE Micro controller for its extremely low power consumption and low cost. Further due to the presence of NFC in the MCU, Pairing would be extremely simple even for parents without prior education.The data can either be transferred through the parent’s smartphone if available or through a dedicated gateway device bundled along with the sensor which would send the data to the cloud over Mobile Networks. Even though the availability of mobile network is limited in very remote areas, Initiatives like the Google Project Loon is likely to expand connectivity to even remote locations around the world.

-

Temperature Sensing

10/10/2016 at 12:59 • 0 commentsTemperature plays a crucial role in preterm infant's life thus it is very important to monitor it accurately.

Temperature is also also used for feedback in the PID system to know when to power the heating element.

The site for measurement of temperature we have chosen is the armpit since it is standard testing site.We have used the LM35 temperature sensor for it's accuracy and simplicity also because I coincidentally had a 3 channel fabric cable.

![Image result for lm35]()

The sensor gives a proportional output voltage to temperature. The accuracy is only limited by the resolution of the ADC.

The particle photon however has a 12 bit ADC, By using the 5V Vin supply we were able to get accurate temperature data.

Here is the final appearance of the sensor![]()

Due to the use of a textile cable for wiring we can comfortably monitor temperature. -

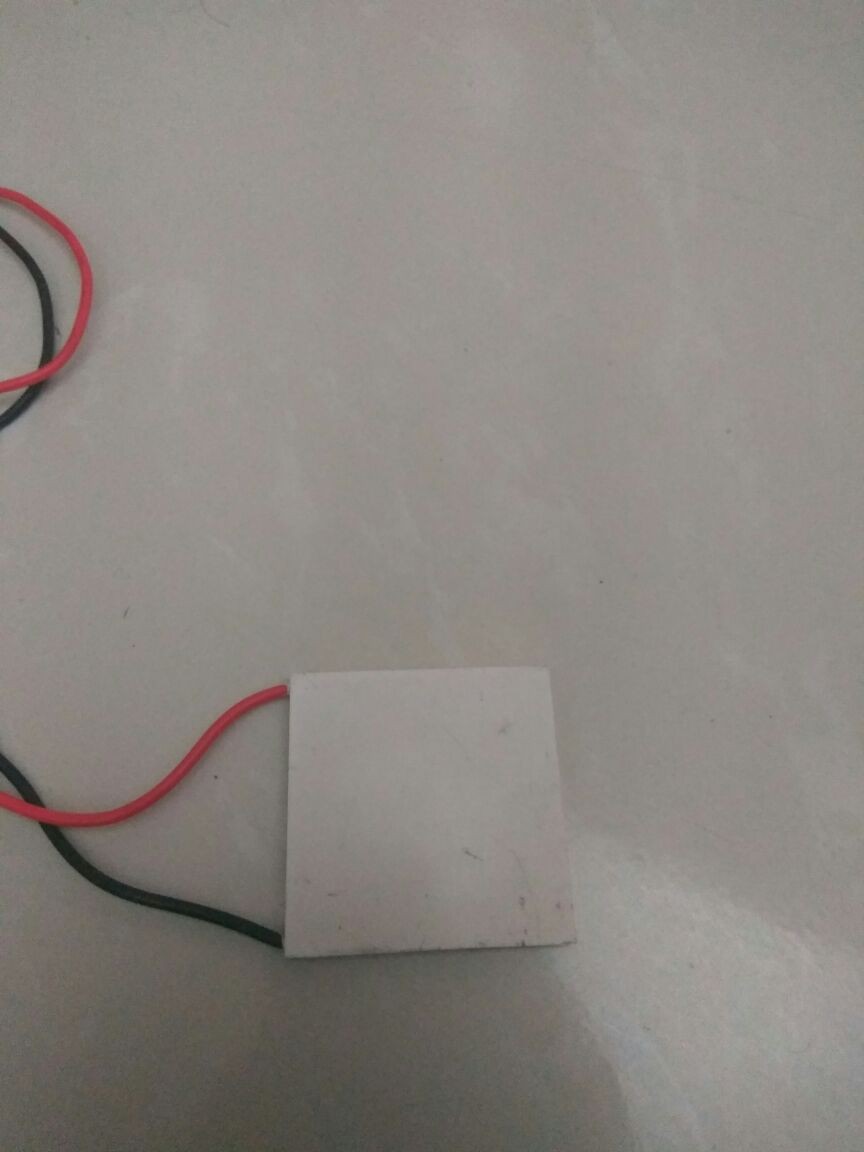

Exploring use of Peltier elements

10/10/2016 at 06:15 • 0 commentsOne other alternative I had to textile based warmers was the use of a thermoelectric module(Or Peltier element). A typical thermoelectric (TE) module is composed of two ceramic substrates sandwiching many pairs, or "couples" of Bismuth Telluride dice. The (pairs of) dice are connected electrically in series, and thermally in parallel, between the ceramics. One of these ceramics will be the "hot-side" and the other, the "cold-side."

![]()

(Credits: Advanced Thermoelectrics)

While both P-type and N-type materials are alloys of Bismuth and Tellurium, both have different free electron densities at the same temperature. P-type dice are composed of material having a deficiency of electrons while N-type has an excess of electrons. As current (Amperage) flows up and down through the module it attempts to establish a new equilibrium within the materials. The current treats the P-type material as a hot junction needing to be cooled and the N-type as a cold junction needing to be heated. Since the material is actually at the same temperature, the result is that the hot-side becomes hotter while the cold-side becomes colder. The direction of the current will determine if a particular die will cool down or heat up. In short, reversing the polarity will switch the hot and cold sides.

These modules are extremely efficient in heating/cooling application of about 70% and have extremely long cycles of operation.

Let's now look at a peltier element![]()

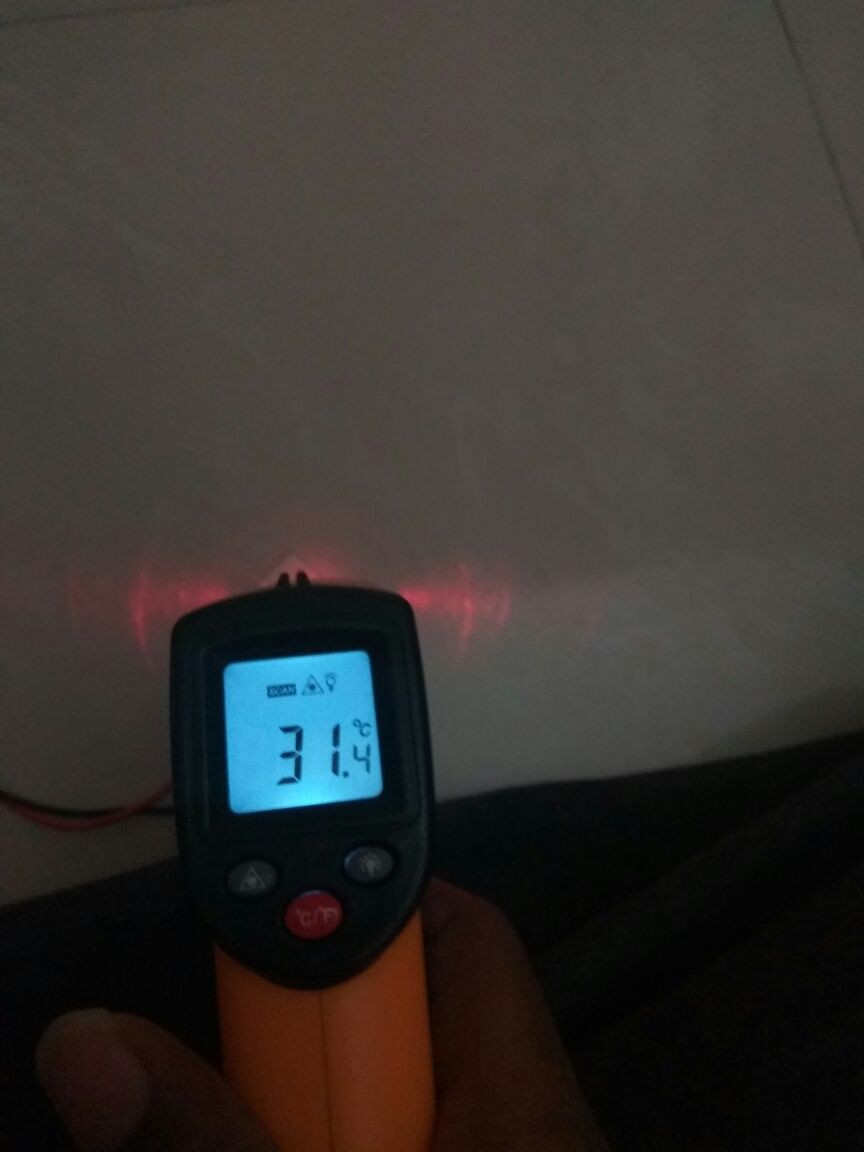

Here is the base temperature of the peltier element![]()

Temperature is in Celcius for those of you in the USA,

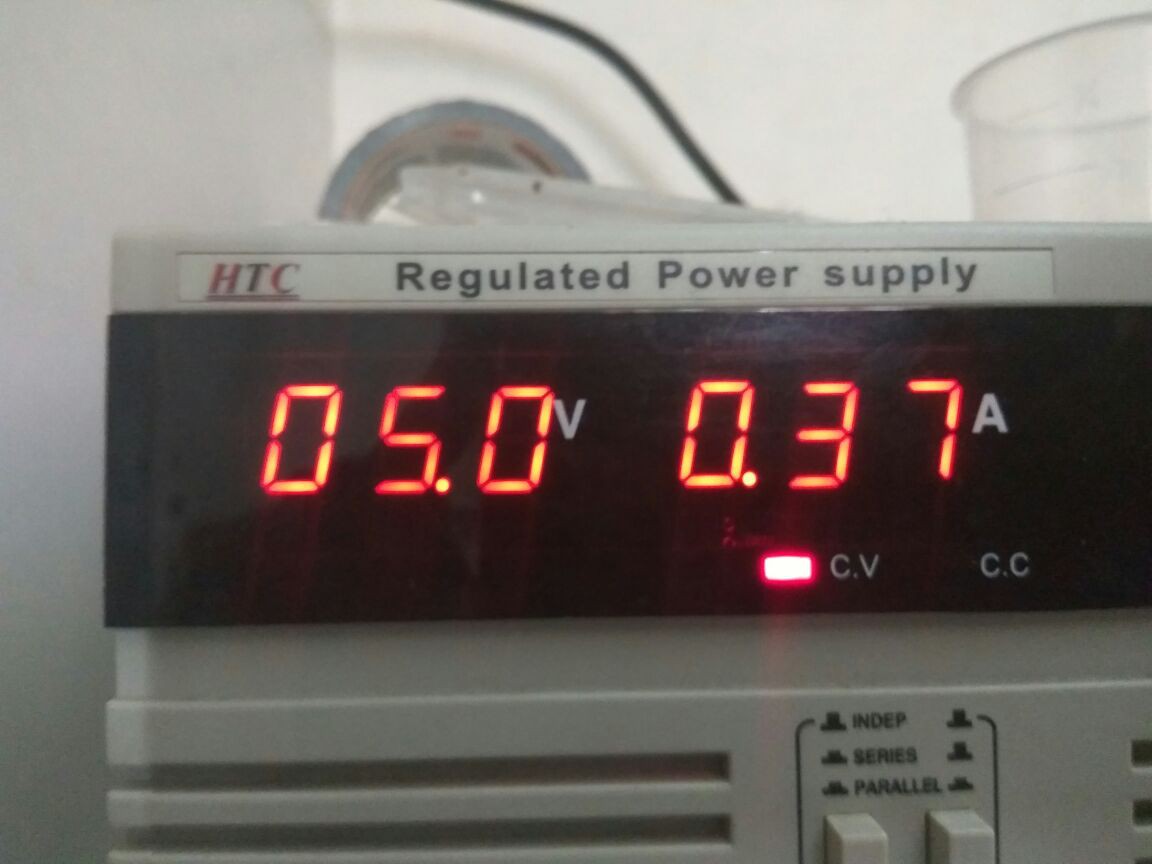

Now I'll set my power supply at 5V![]()

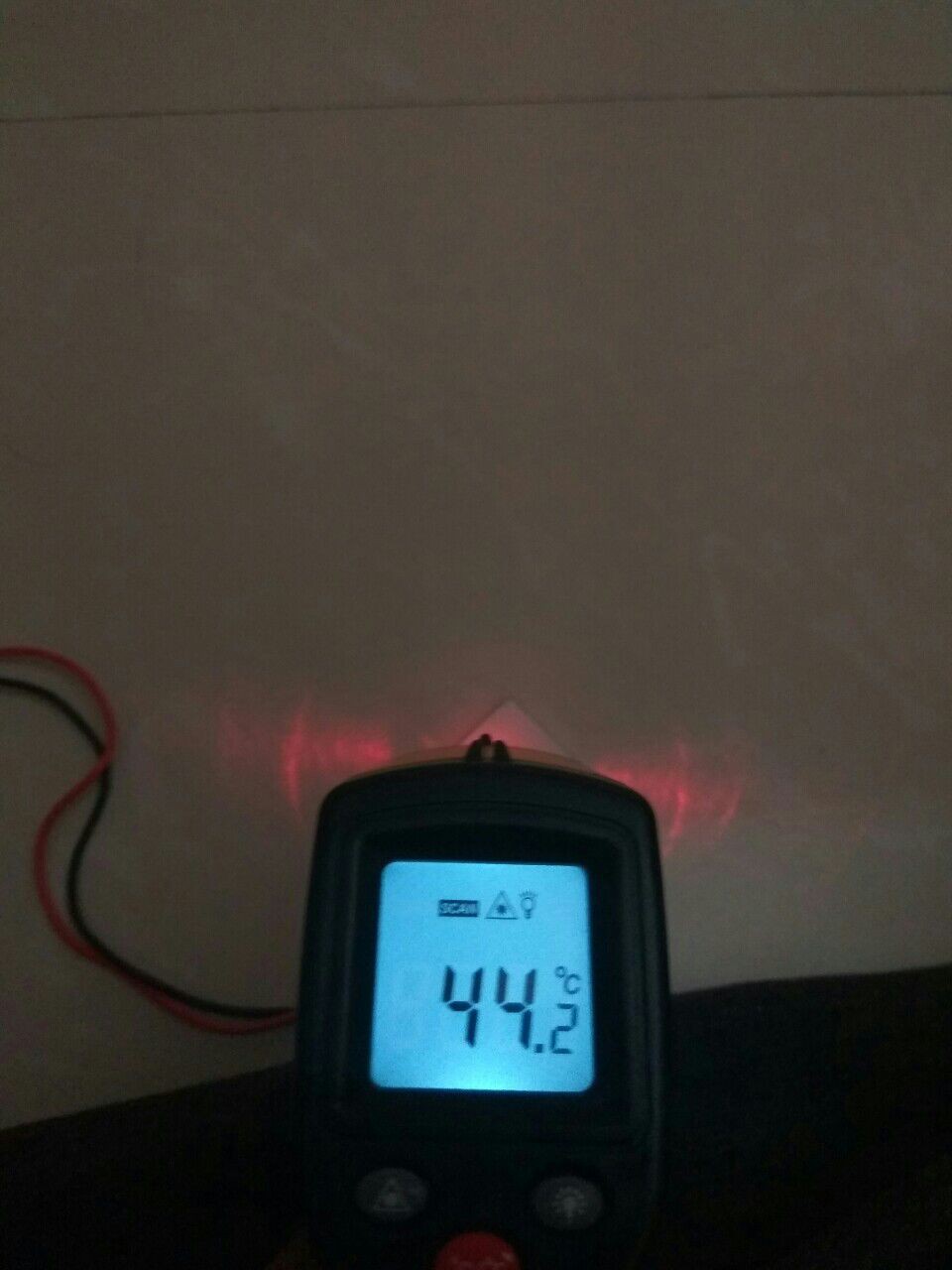

The Thermoelectric module instantly heats up instantly, No Ohm's law here all solid state up here.![]()

It get's pretty toasty, Definitely needs some PWM to control the temperature between some safe limit. In comparison the Litex fabric consumes over 700mA of current at 5V for roughly the same temperature and it takes over 2 minutes to heat up.

We were blown away by the performance of the Peltier element and we plan to use it along side the Litex fabric in our future revisions. -

Prototype done!

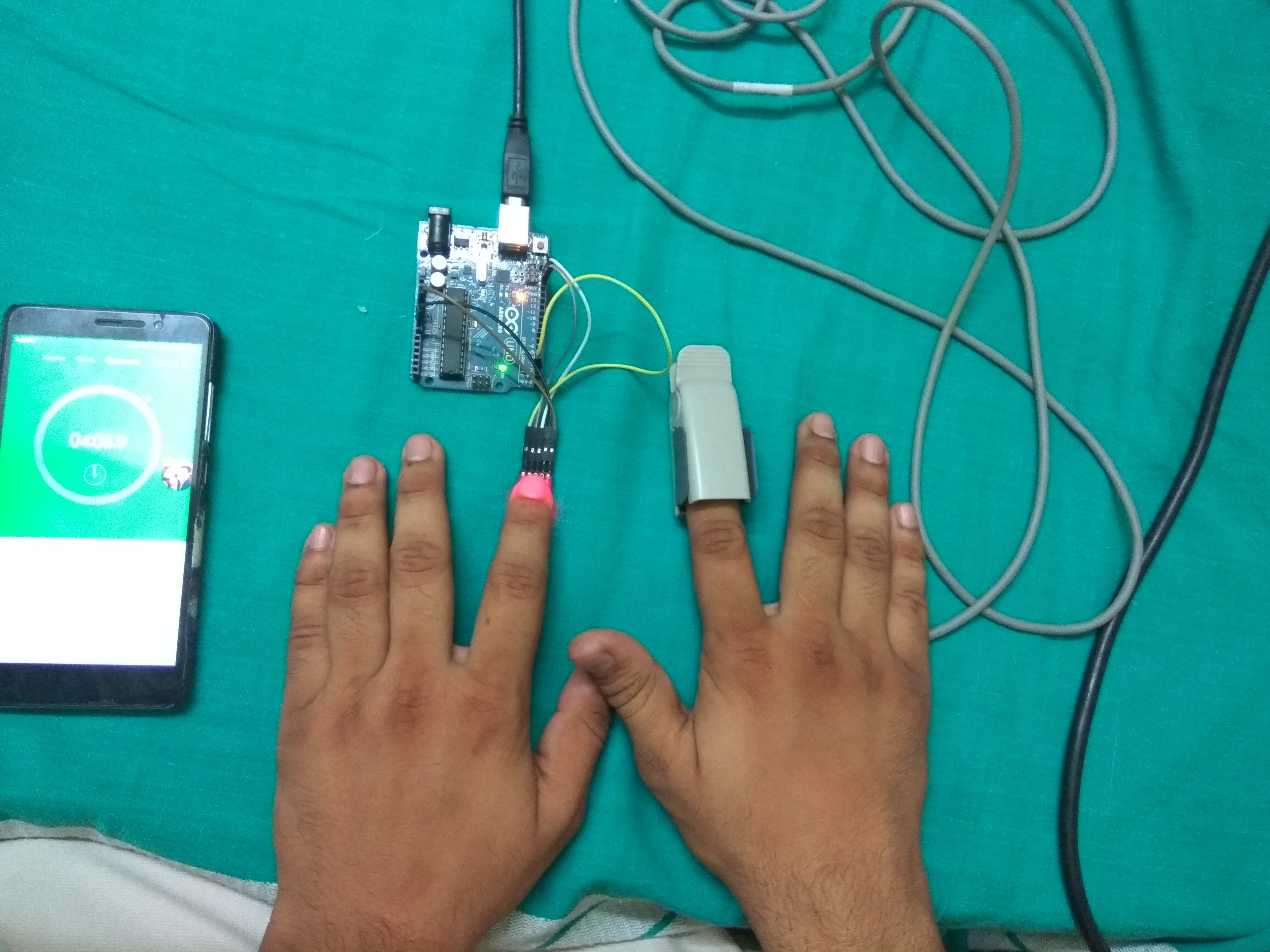

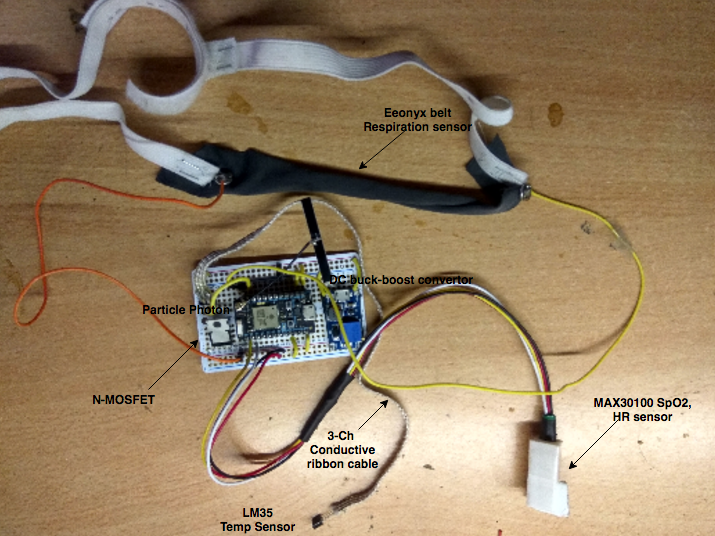

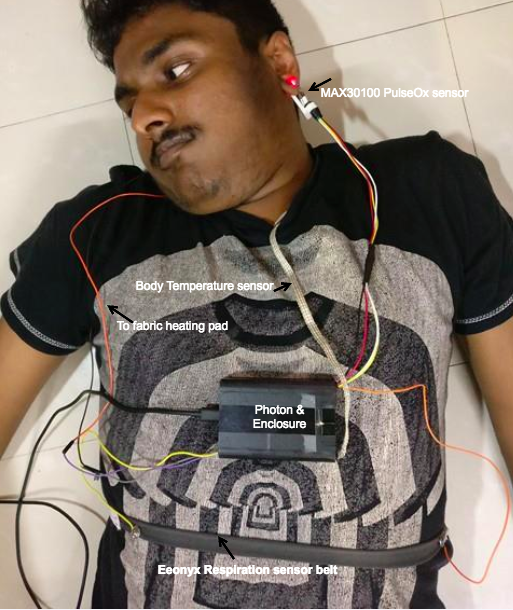

10/02/2016 at 12:04 • 0 commentsWe got the first prototype done, We interfaced the respiration sensing belt, Pulse Ox & Body temperature along with some early PWM controlled Textile Heating Pad.

![]()

An IRFZ44 N-mosfet was used to drive the Heating element using PWM control. We have a cheap USB boost regulator for giving a solid 7V supply for the Heating pad.

The respiration sensing belt is interfaced using detachable 10mm snaps. We have a 3-channel conductive ribbon cable soldered to an LM-35 temperature sensor too.

We soldered all of it into a half breadboard sized Adafruit Perma Proto board, We used one channel of power line for 7V supply and the other for 3.3V regulated supply from the Photon.

One glad coincidence with the permaproto is that the 55mm protoboard perfectly fit into one aluminium enclosure from Aliexpress I had lying around. Now a new problem arose as the enclosure would cover the chip antenna causing EMF sheilding. This was an easy fix thanks to the uFL antenna option given by the guys at Particle. I used a 2.4Ghz PCB antenna that was lying around.

<Incoming Cringe>![]()

As live baby trials were out of question for now, I had to test it on the brave Ser.Vignesh.

As you can see the belt is comfy to wear, The system is powered using a USB powerbank for now. Making a custom LiFePo4 battery pack is on my priority list.![]()

This the back view of the system, We have a Fabric heating to warm my upper back with wires running to the MOSFET. Also you can see our custom 3d printed enclosure for PulseOx sensor, Will upload the STL files soon.

-

Heart Rate and Blood Oxygenation sensor

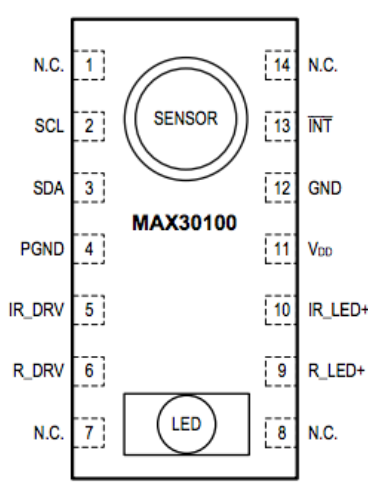

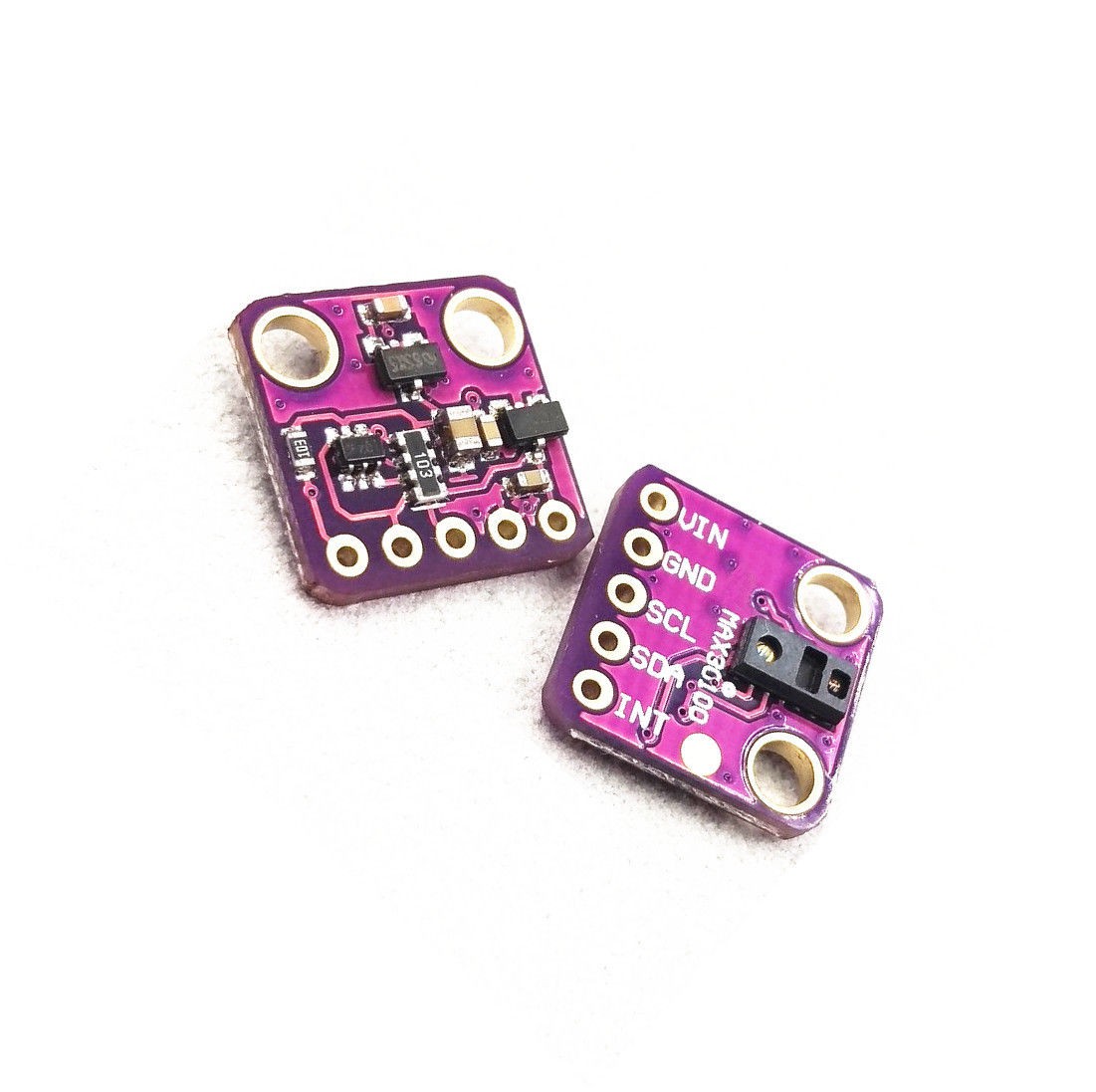

10/02/2016 at 05:15 • 0 commentsPhotoplethysmography (PPG) and Pulse Oximetry (SpO2) are carried out by a single sensor which is used to measure reflectance of two LEDs of different wavelengths. SpO2 is found by measuring the reflectance of 650 nm light in comparison with 940 nm light. We are currently using the Maxim Semiconductors MAX30100 to reduce the size, cost. The sensor has an integrated amplifier, Analog to Digital Converter (ADC) and inbuilt LED's and LED drives (940nm,650nm). The price takes the cake for this part (3.31$ for a qty of 100)

Neat eh? Guess we have the Smart watch revolution for this. To get started I planned to originally get the MAX30100 Click board from Microe but it was too big for what I had in mind. I eventually bumped into a cheap small MAX30100 breakout board.![]()

![]()

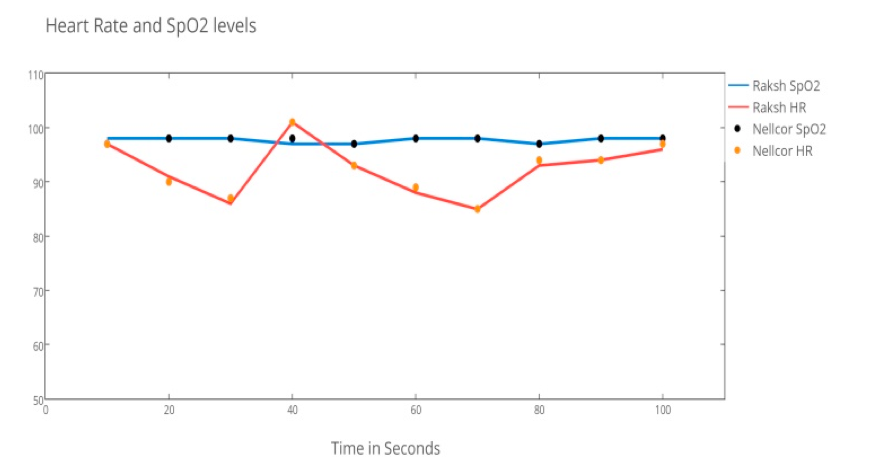

Oxullo interscans made a neat library acquiring some data from the MAX30100, After giving it a whirl. I got it ported to the Particle photon you can get it here.![]() I had it compared against a Nellcor NBP-290 commercial medical grade pulse ox sensor.

I had it compared against a Nellcor NBP-290 commercial medical grade pulse ox sensor.![]()

The data was staggeringly accurate, Fantastic what we can accomplish in a few years as an industry.

![]()

-

Respiration Sensing

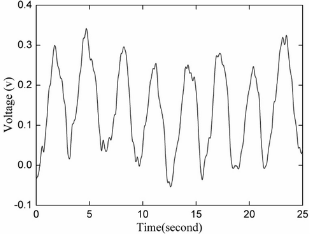

10/02/2016 at 04:36 • 0 commentsRespiration is an important parameter in preterm birth children as they are more suseptible to lung problems and apnea. We were toying around with the idea of Impedance Pneumography but then due we read that the electrodes used in impedance pneumography often caused skin irritation in children.

Respiration sensing using a belt seemed like a viable method to sense a child's respiration.

Eeonyx Corparation has some neat textile sensors which works by the principle of Piezoresistivity, The process by which the textile element changes it's resistance depending on whether it's stretched or it is pressed on.

We made an elastic belt using the same material to measure the resistance of the sensor.![]()

The resistance varies from 60k-100k Ohms when stretched, This value is accurately measured using a wheatstone bridge.![]()

Here instead of the strain gauge we have our eeonyx belt.

I had the output voltage measured and plotted and the result was an accurate respiration plot.

A bit of peak detection can enable us to find the respiration rate accurately by measuring the Inter Breath Interval and the breathing frequency. Timers would measure the time diff between consecutive peaks.![]()

-

Existing Systems

10/02/2016 at 03:35 • 0 commentsExisting Systems:

- GE Healthcare - Lullaby baby-warmer

- Ease of use

- Uniform heat distribution

Con's:

- Stationary unit

- Expensive in comparison to other solutions

• Embrace

![]()

Pro's:

- Inexpensive (25$)

- Doesn't require power

Con's:

• Passive in nature

• Cannot detect emergency situations like Hypoxia(Lack of oxygen)

We wanted to build a system that would bridge the two while also being inexpensive and rich with features. - GE Healthcare - Lullaby baby-warmer

ADITI:Affordable Diagnostic Thermal Incubator

Aditi is a connected bodysuit heating enabled incubator for preterm infants measuring Heart Rate, SpO2,Temp & Respiration comfortably.

Manoj kumar

Manoj kumar

The net current consumption (Including sensor&MCU power) was about 550mAh with the heater on and total power consumption was a 2.75W.

The net current consumption (Including sensor&MCU power) was about 550mAh with the heater on and total power consumption was a 2.75W.

I had it compared against a Nellcor NBP-290 commercial medical grade pulse ox sensor.

I had it compared against a Nellcor NBP-290 commercial medical grade pulse ox sensor.