-

automatic nozzle cleaner

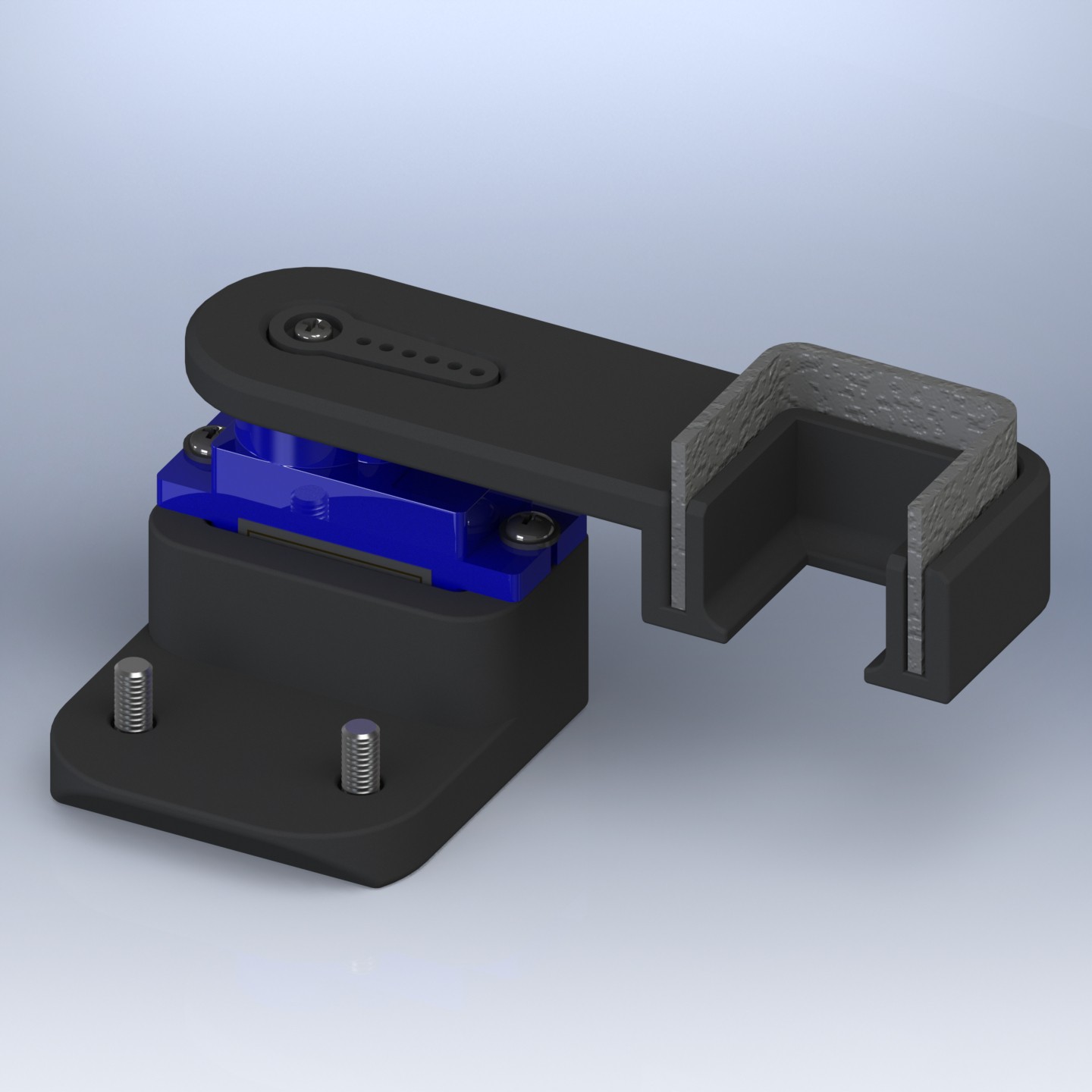

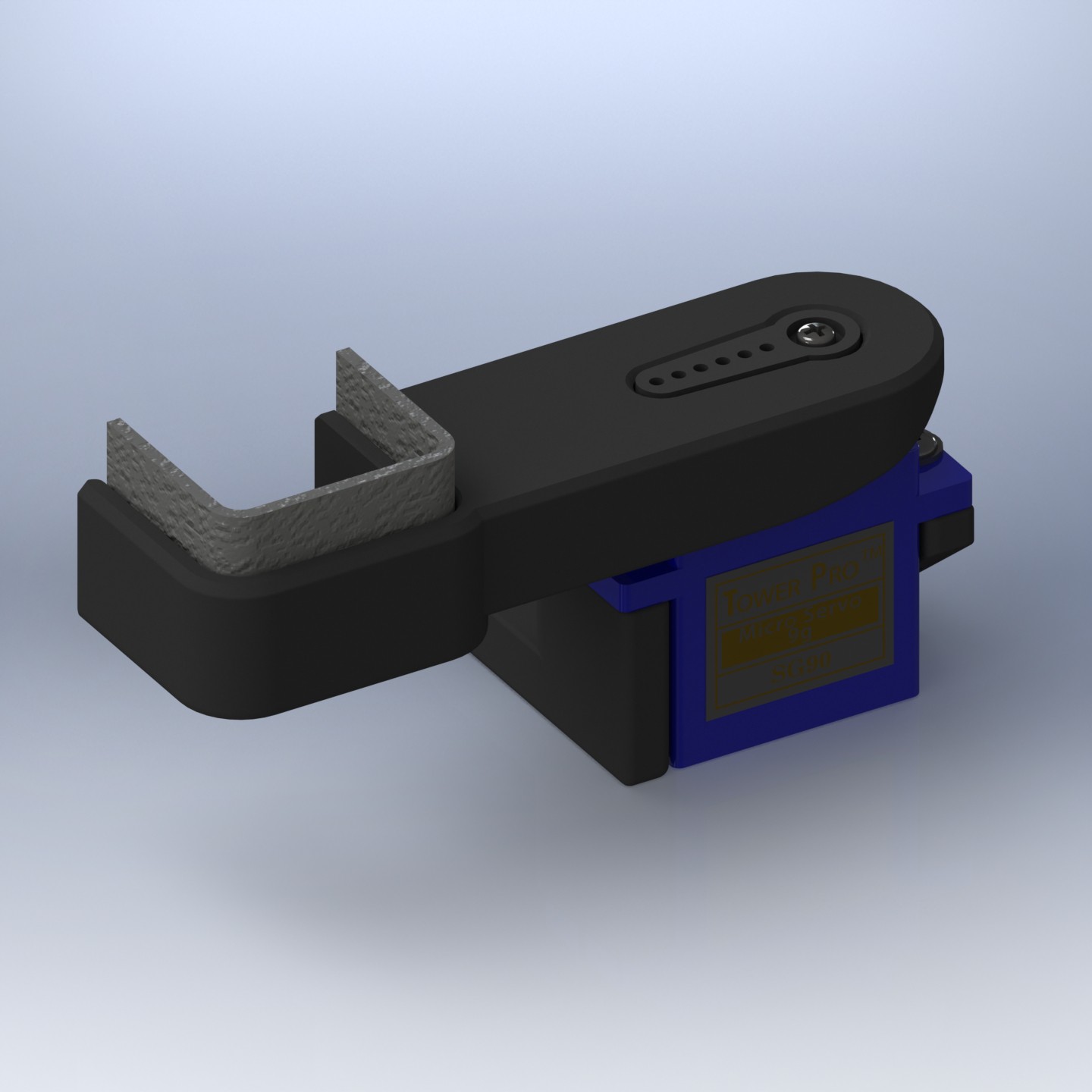

09/17/2018 at 08:08 • 0 commentsI'm using a lot of PET-G for printing. It's one of the most interesting material on the market. Printed parts layer to layer bonding is superb and it's way better than ABS and it can survive almost same temperatures. Printing with PET-G is simple and i think that it's even simpler than printing in PLA... but it likes to ooze.

It was oozing for me to this point when i was very pissed off sitting in front of my printer waiting to heat up and then when the printer was starting to print i needed to take out the oozed string from the nozzle until it reached the build plate...

Now it's automatic in little help of an hobby servo.

-

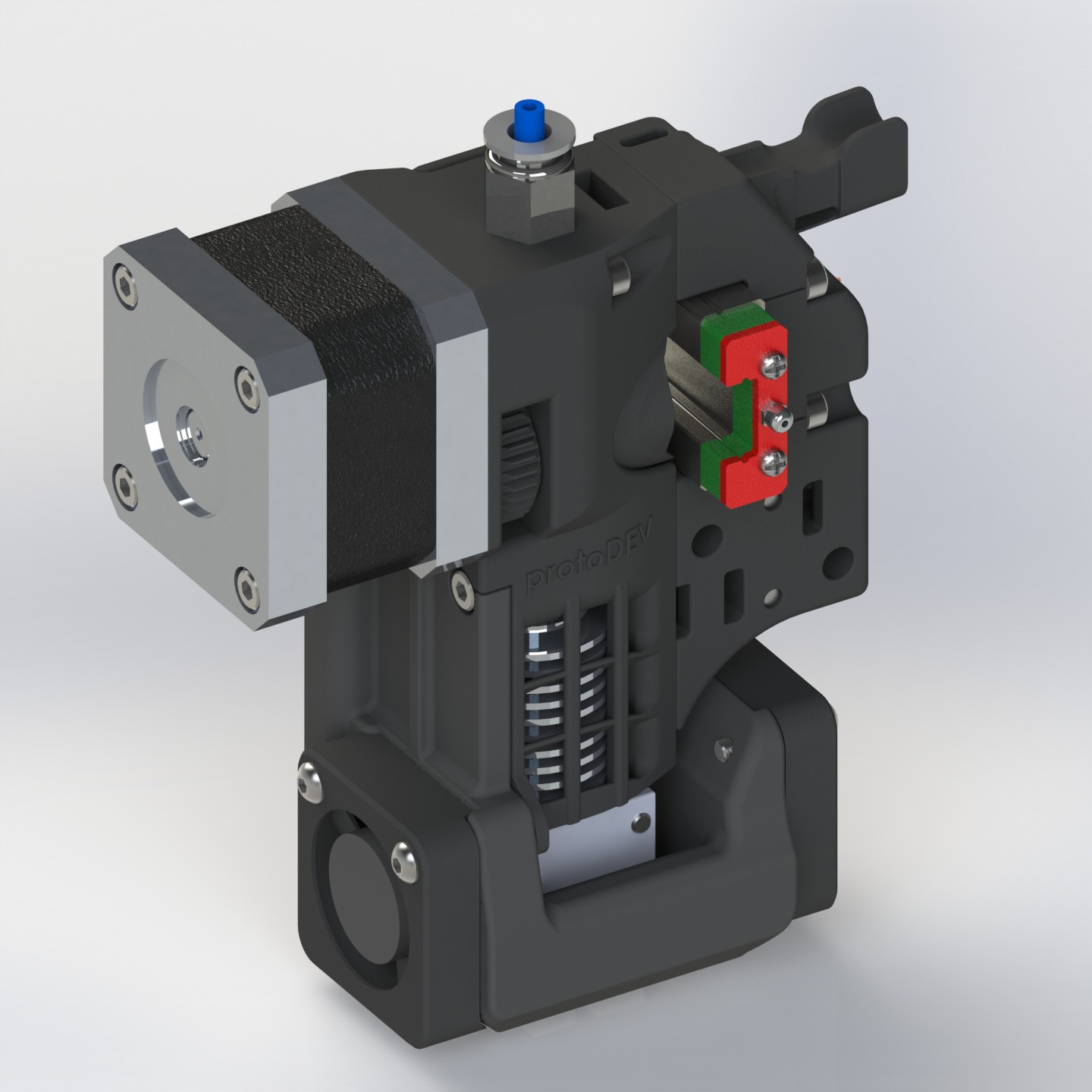

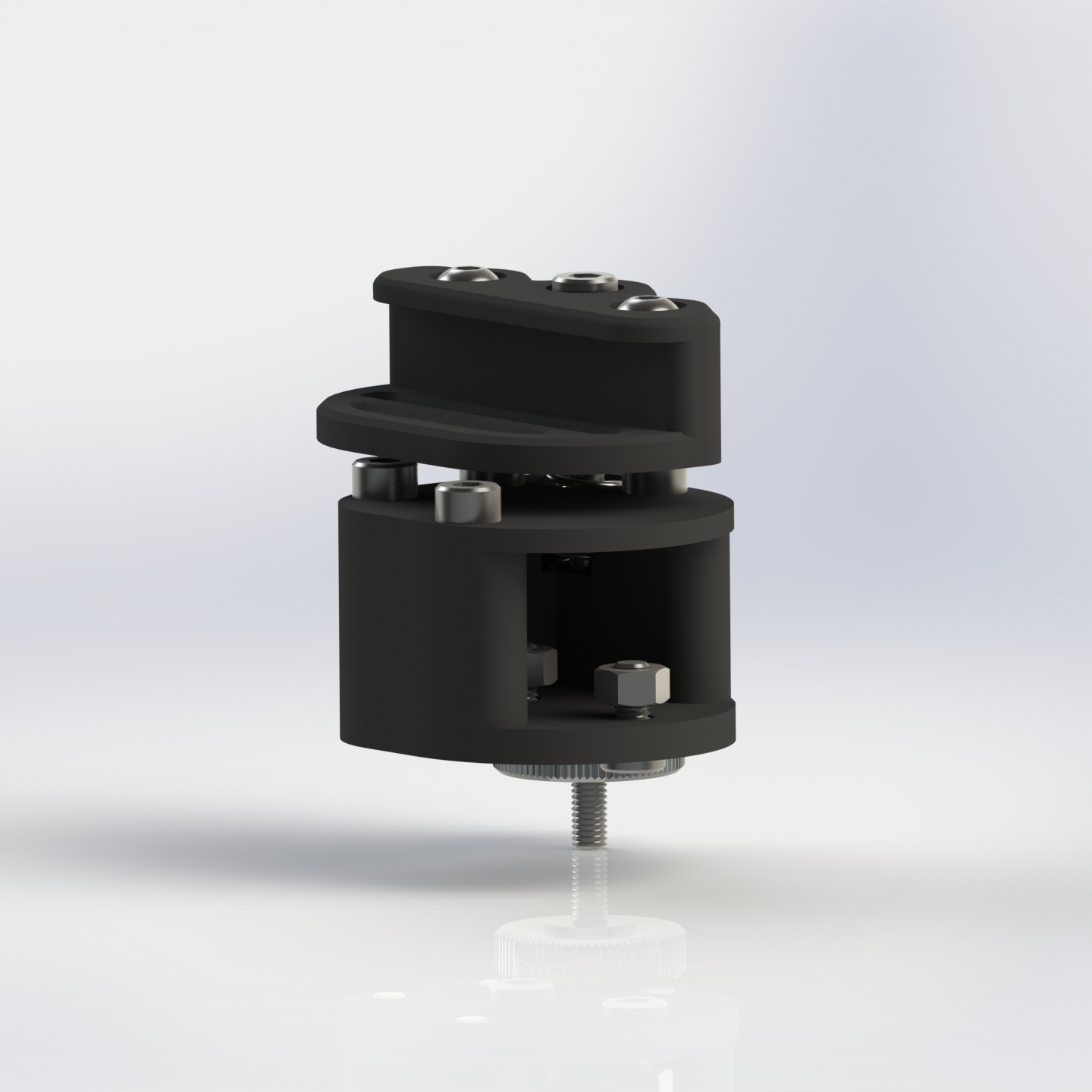

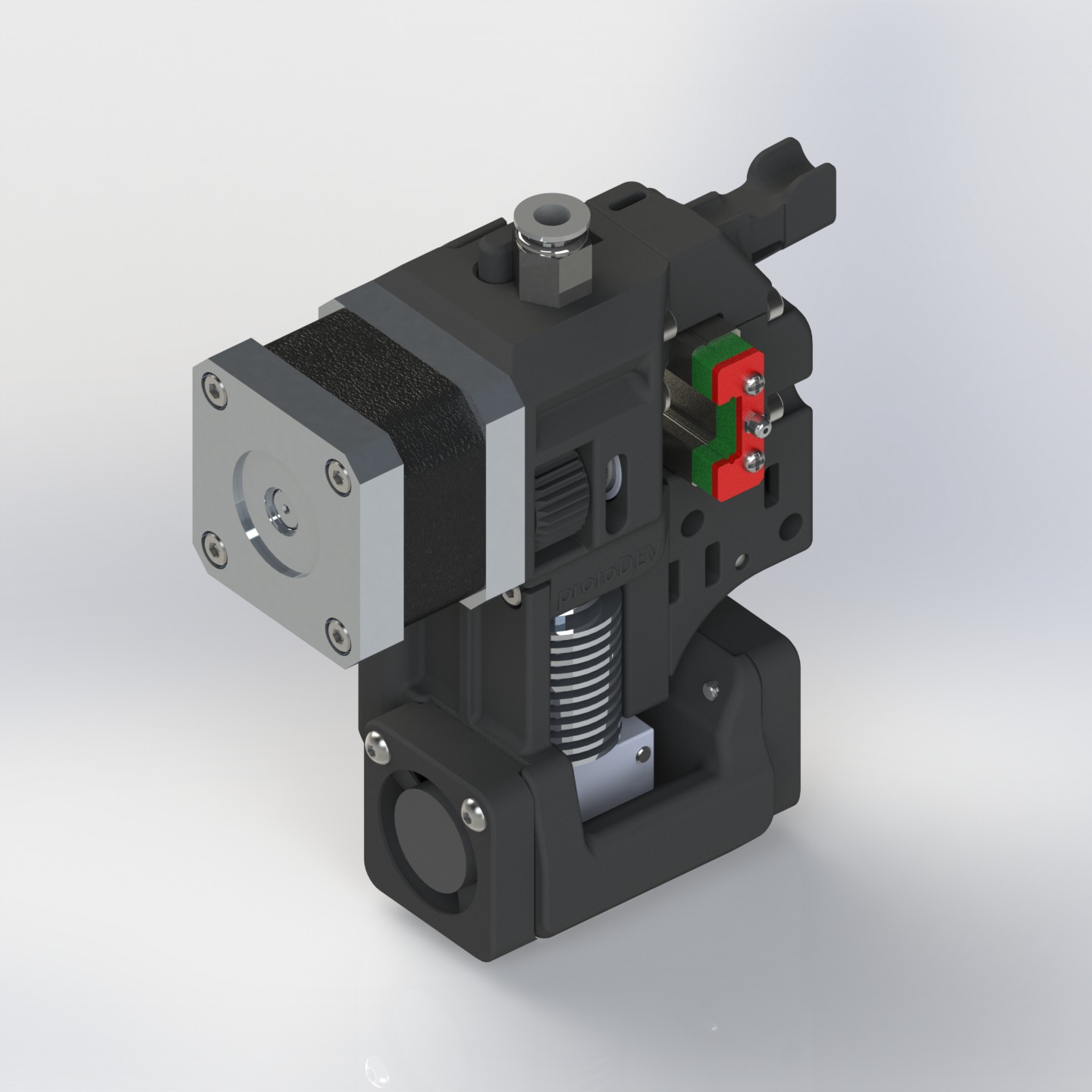

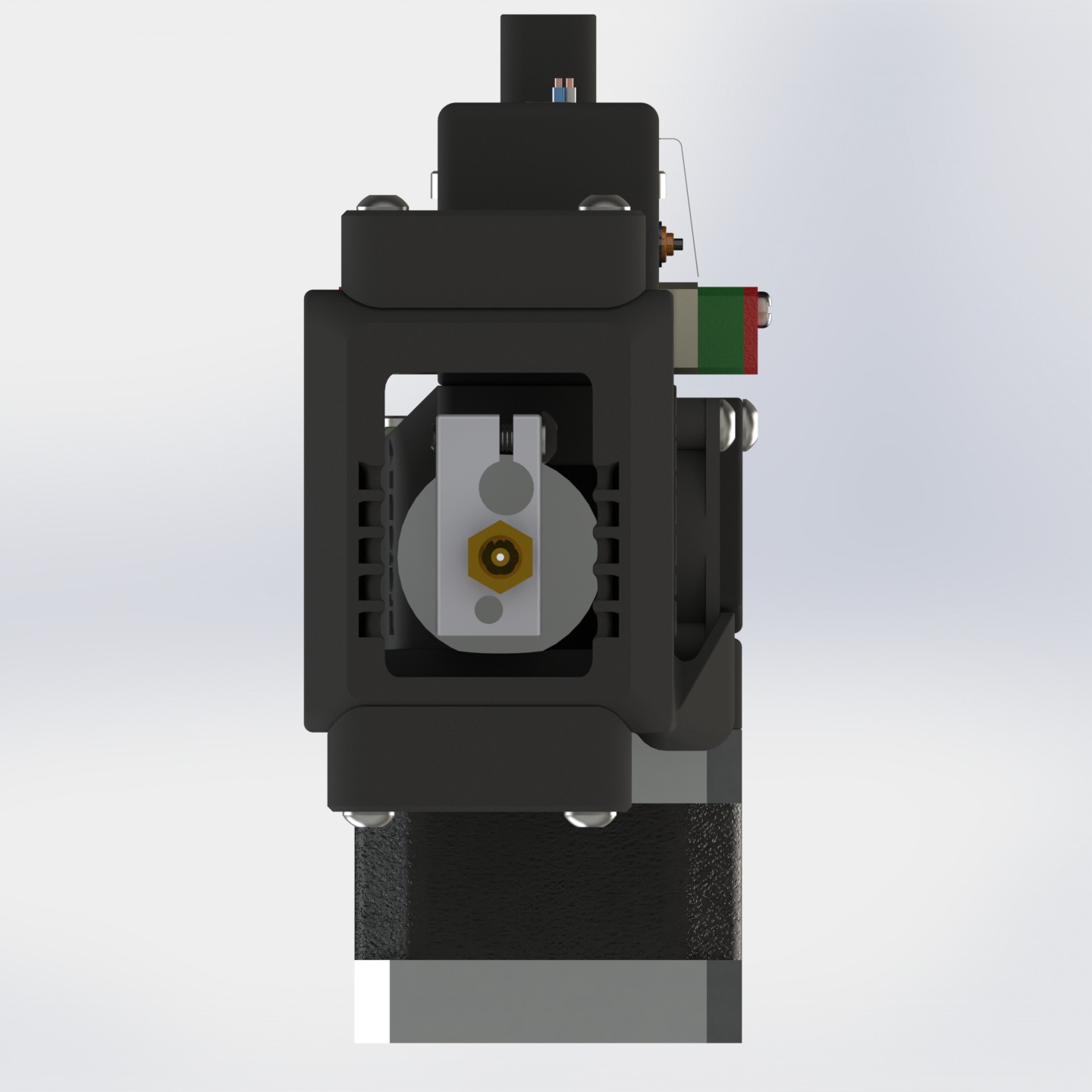

UPDATE! - Bontech extruder design

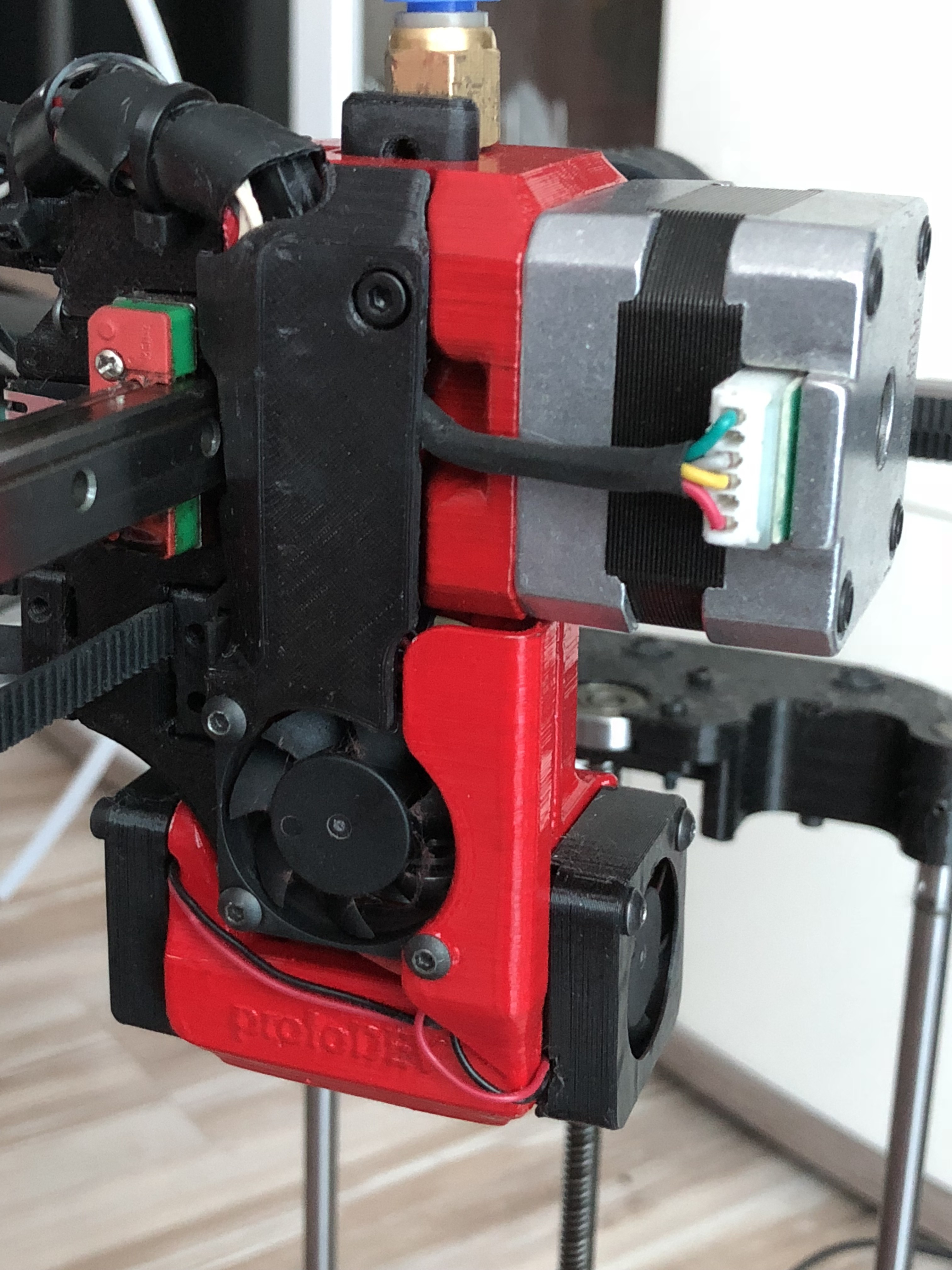

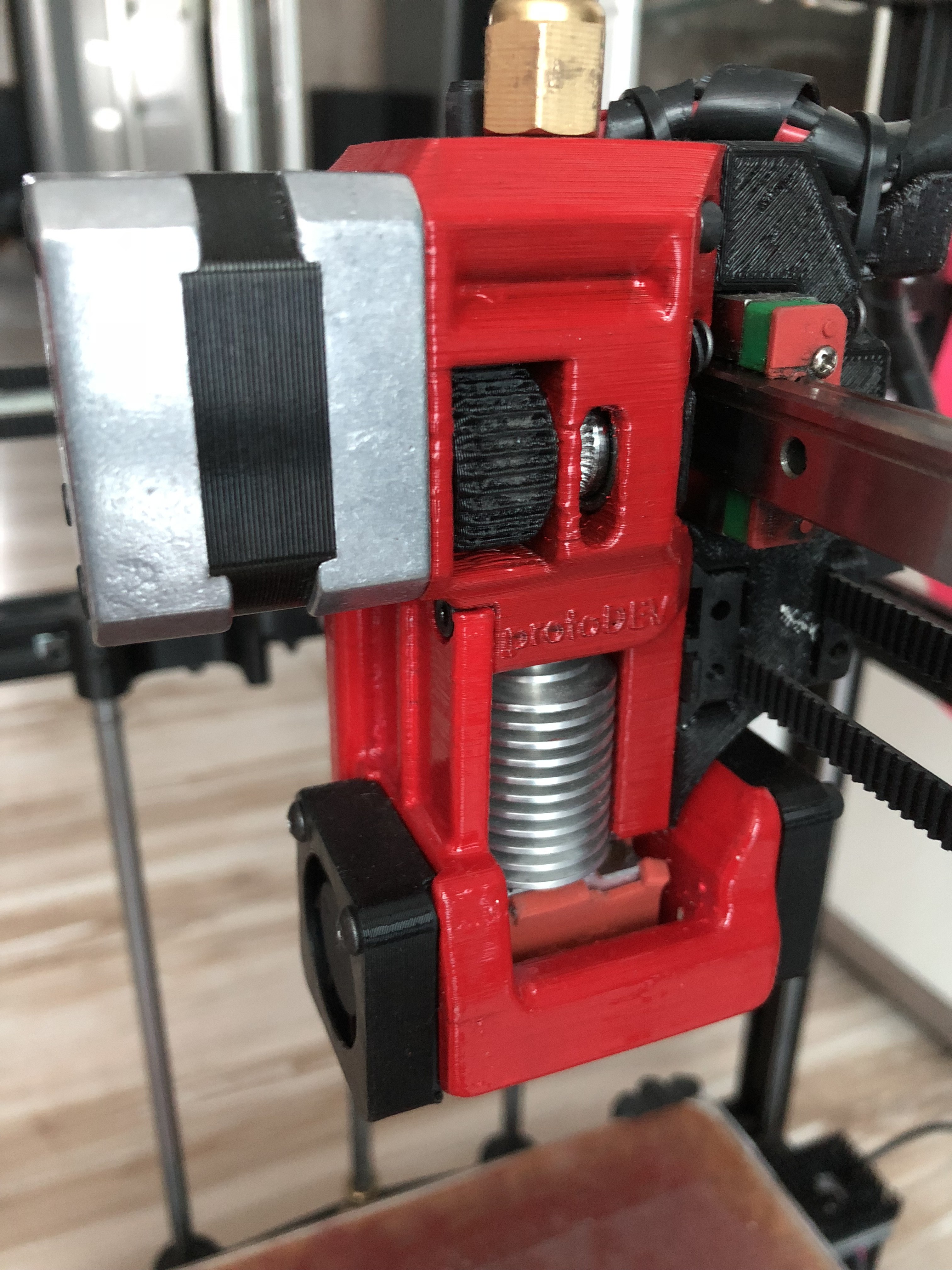

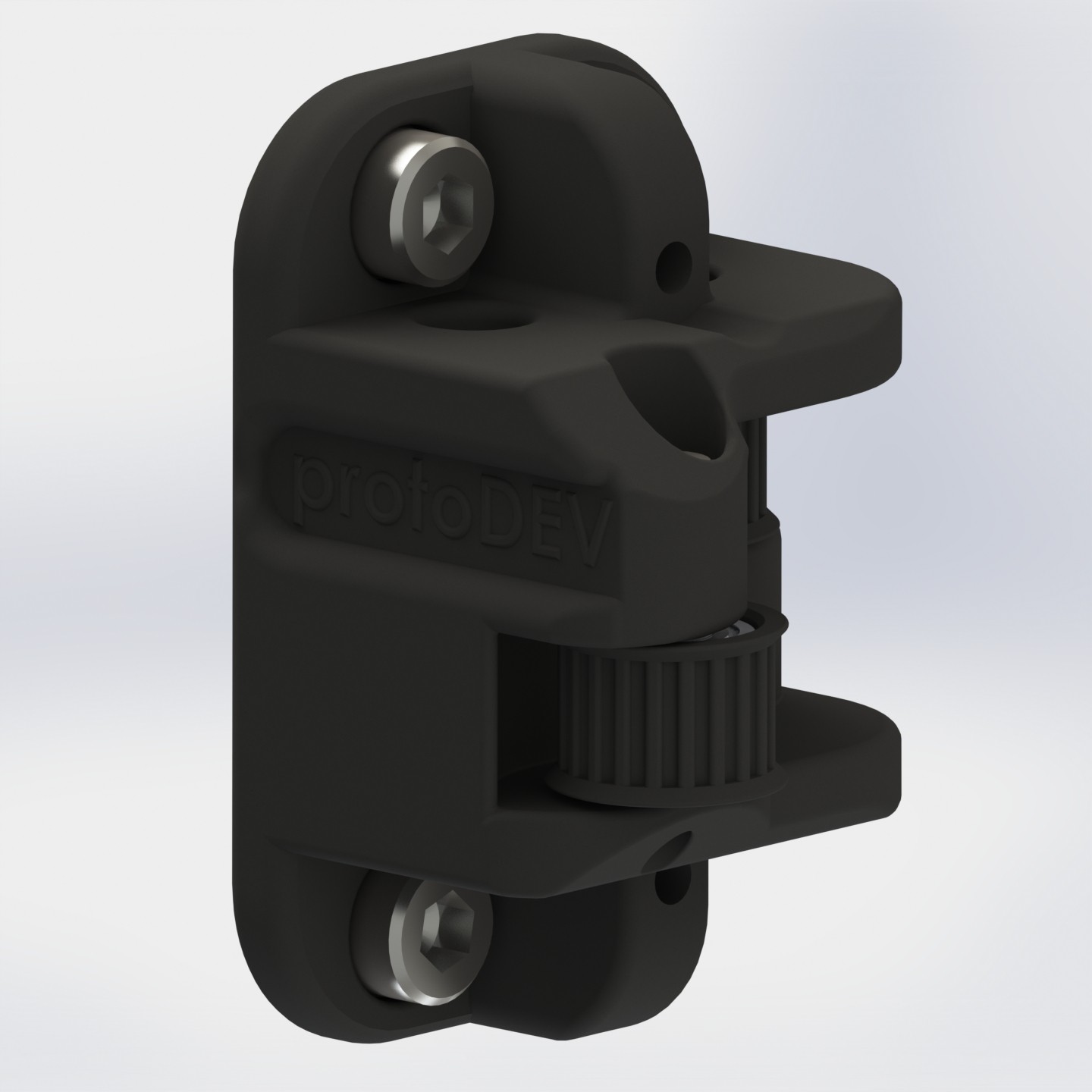

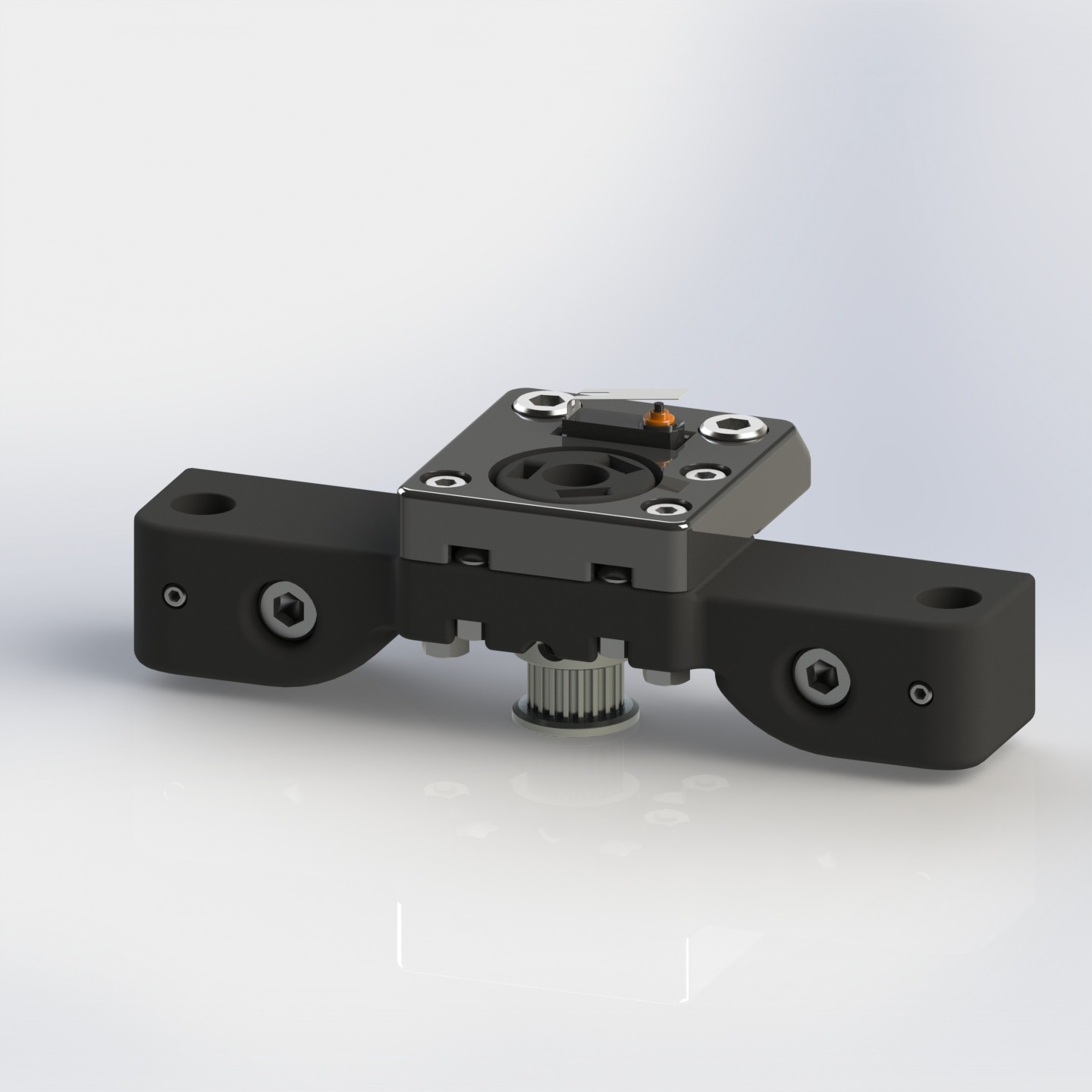

09/13/2018 at 14:47 • 0 commentsFinally i've got my hands on bondtech dual drive gears :) The quality of parts is excellent... if most of parts on market was made with quality like that i think we would have 3d printing heaven on earth.

When was working on the extruder design i had many problems to make it backward compatible with the system but it's way simpler to fix or mod parts right now without re-printing tons of parts.

![]()

![]()

-

enclosure, print cooling, tmc2208, irProbe...

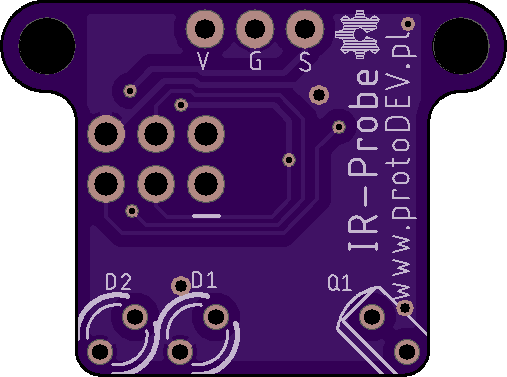

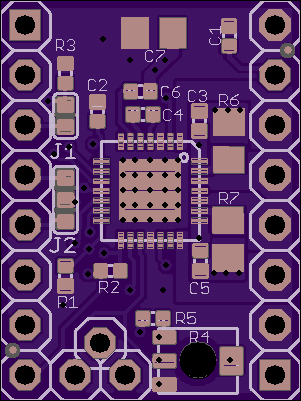

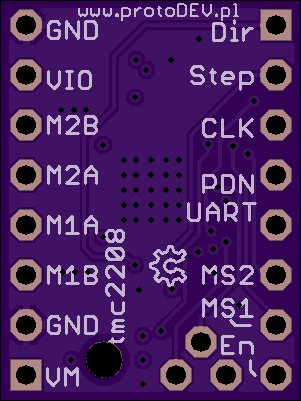

08/08/2018 at 21:45 • 0 comments1. Working on a pcb for Ir-Probe based on dc42 schematic. Any suggestions about pcb manufacturing company? Right now thinking about oshpark.

Additionally will order an additional pcb's (watterrot board layout) for my tmc2208 sample chips from Trimatic. Got also tmc2224, 2130, 2660 sample chips so will try to make pcb's for them.

-ir probe:

![]()

![]()

- tmc2208 stepstick (watterot board layout):

![]()

![]()

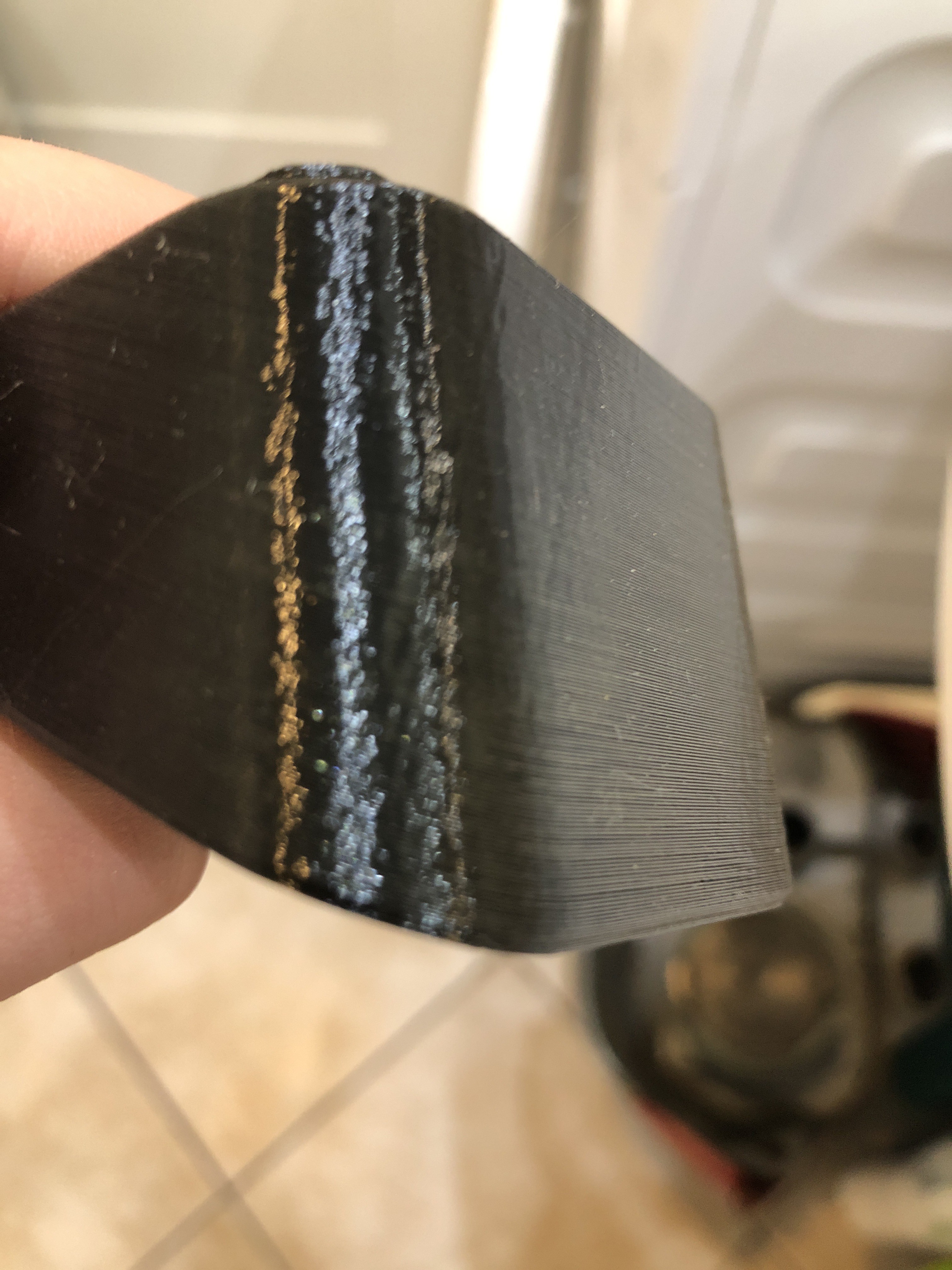

2. Print cooling fan duct update. Added a steel sheet to make an additional thermal barrier. Air flow can be much bigger without any heater temperature change.

![]()

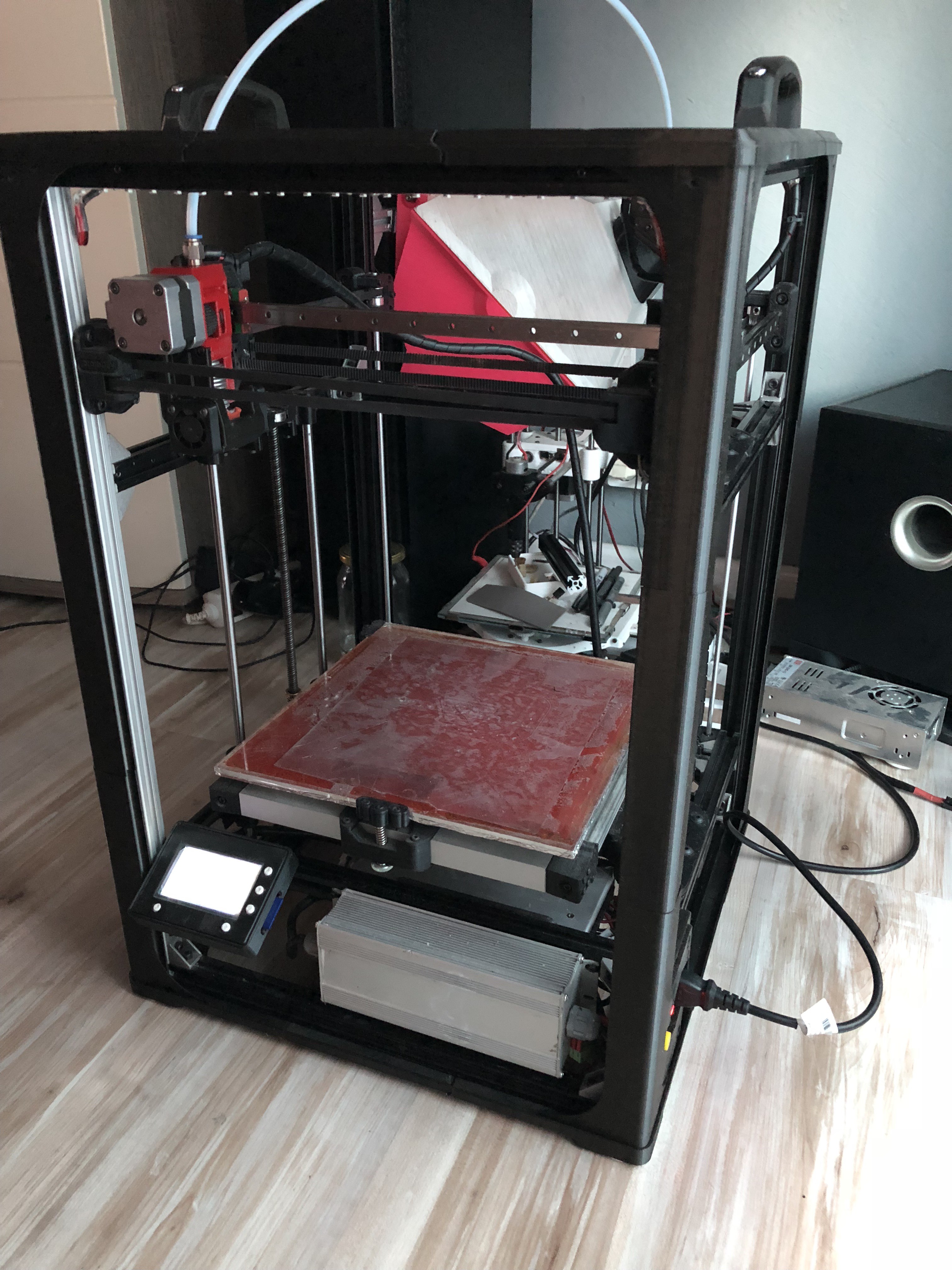

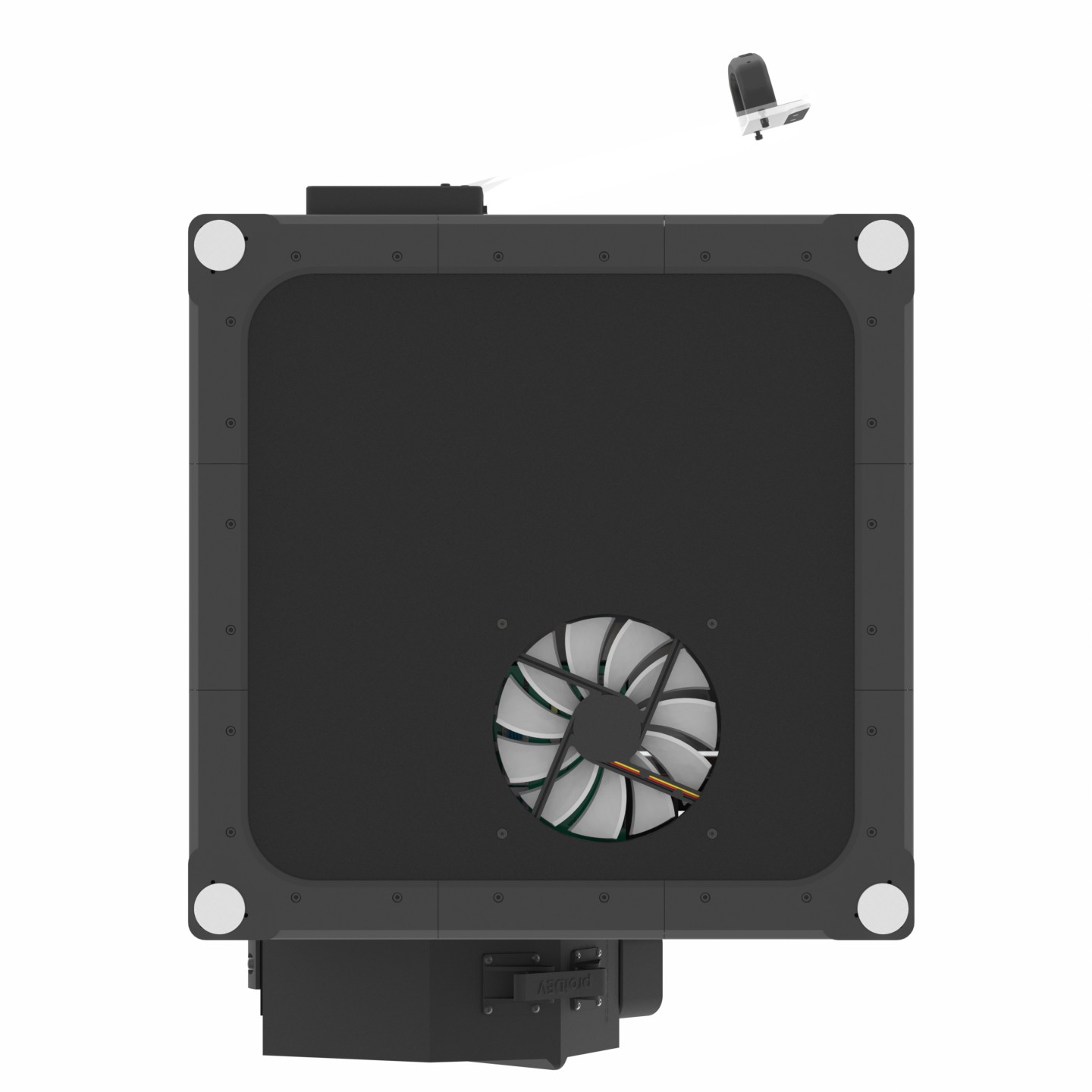

3. Enclosure project in progress.... All latest files added to github

![]()

-

Enclosure preview

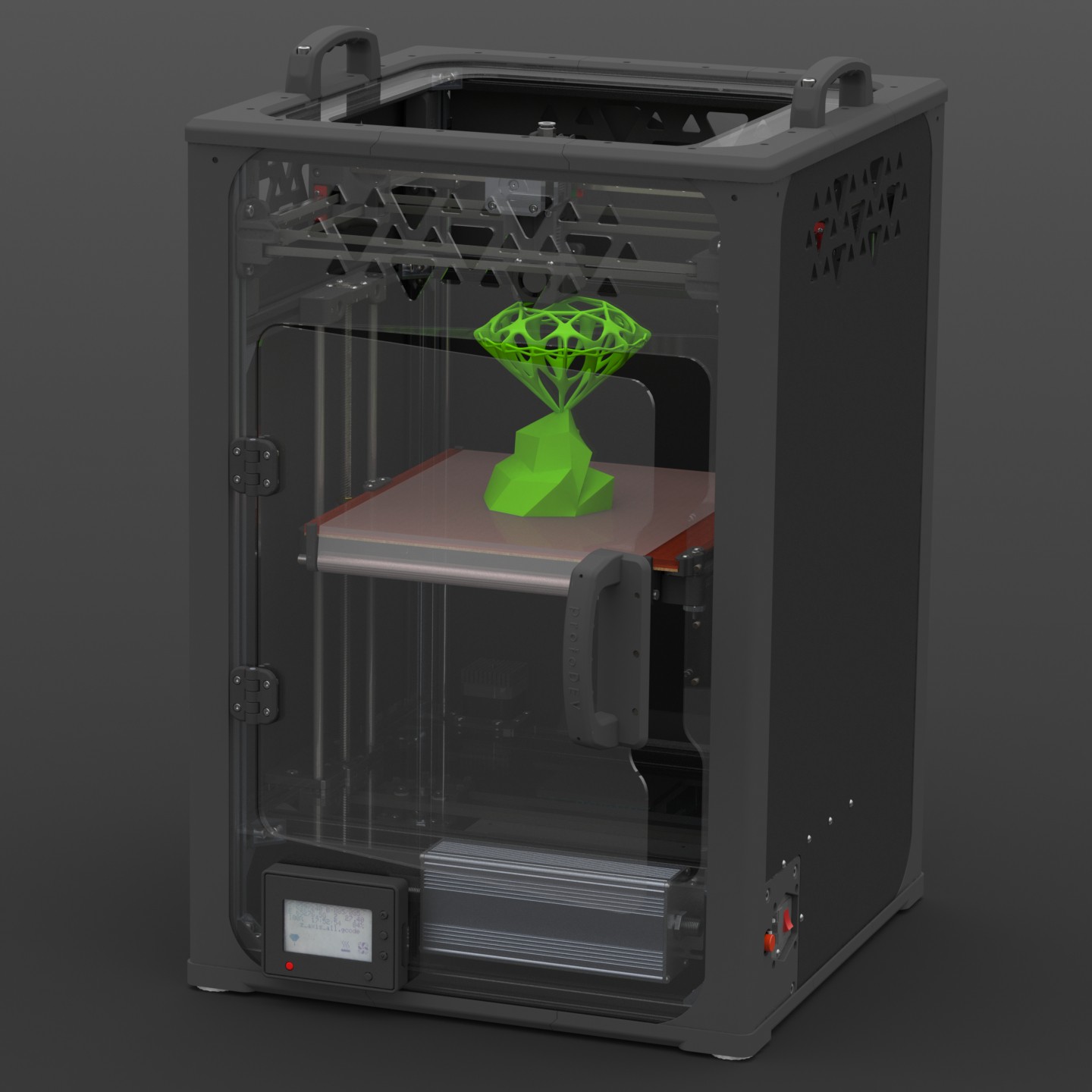

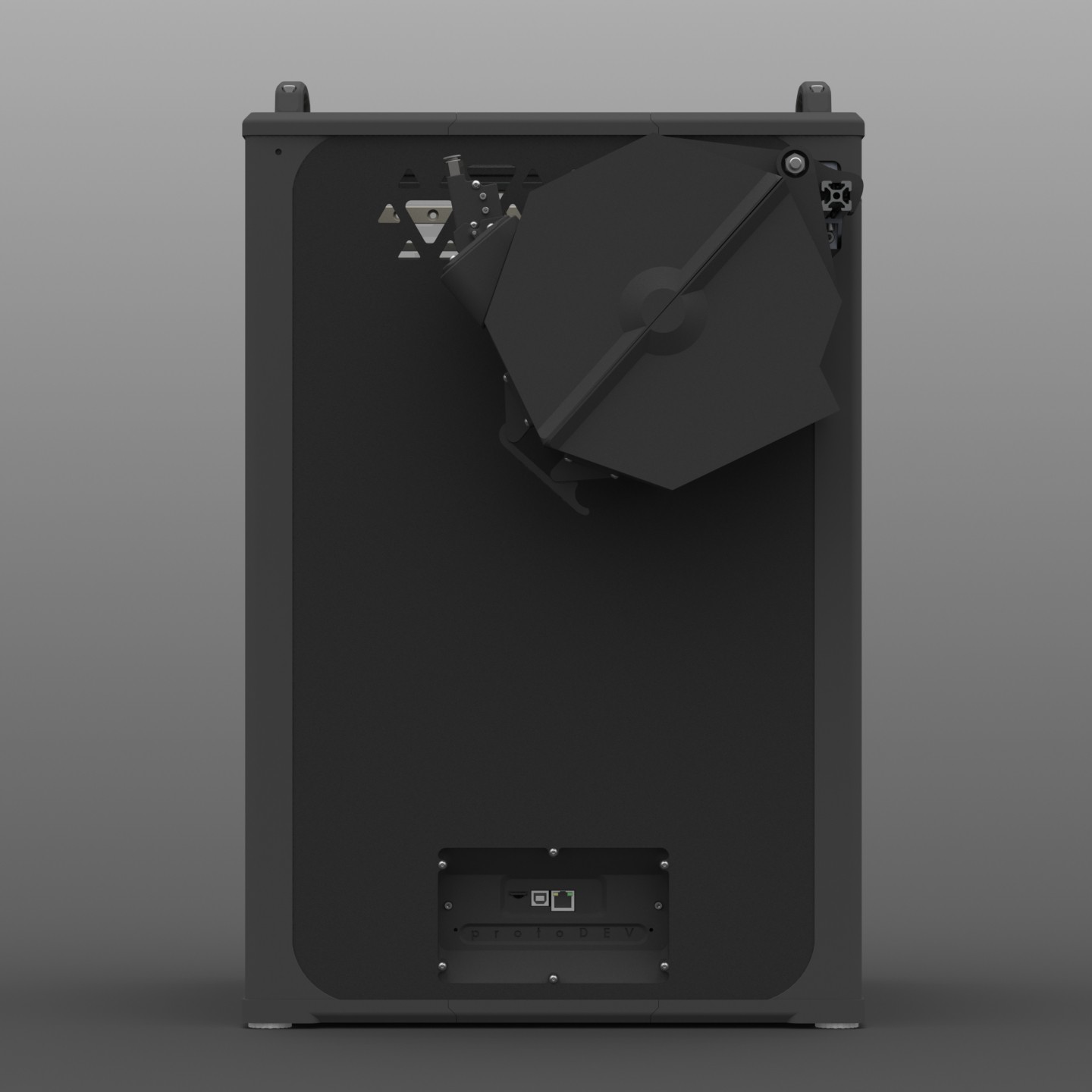

07/11/2018 at 22:50 • 0 commentsWas working on the enclosure concept and made the first design. Here is the preview:

-

Another day, another... fail

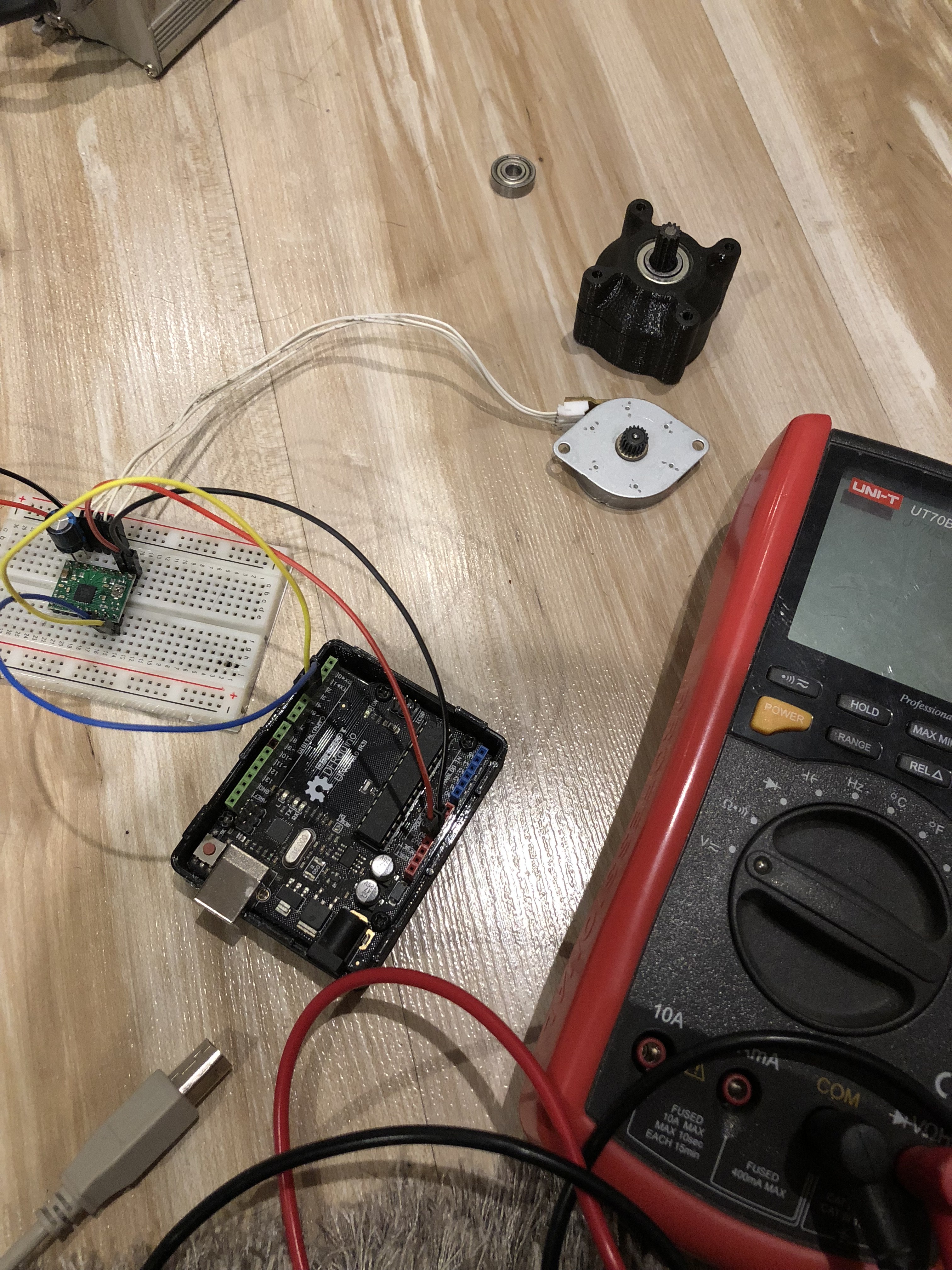

06/27/2018 at 22:18 • 0 commentsWhen i got my hands on a small stepper motor from old scanner thought that i need to try it as an extruder motor...

Downloaded the datasheet and the spec wasn’t promising: 96 step, 24V, 15ohm, small torque and the worst part... pull-in torque and speed significantly different to pull-out.

Hmmm nice begining. But i didn’t want to buy any parts for experiments right now - got my eyes on bondtech dual-drive extruder gears and after making five different 3dprinters projects my hobby piggy bank is dry as an desert...

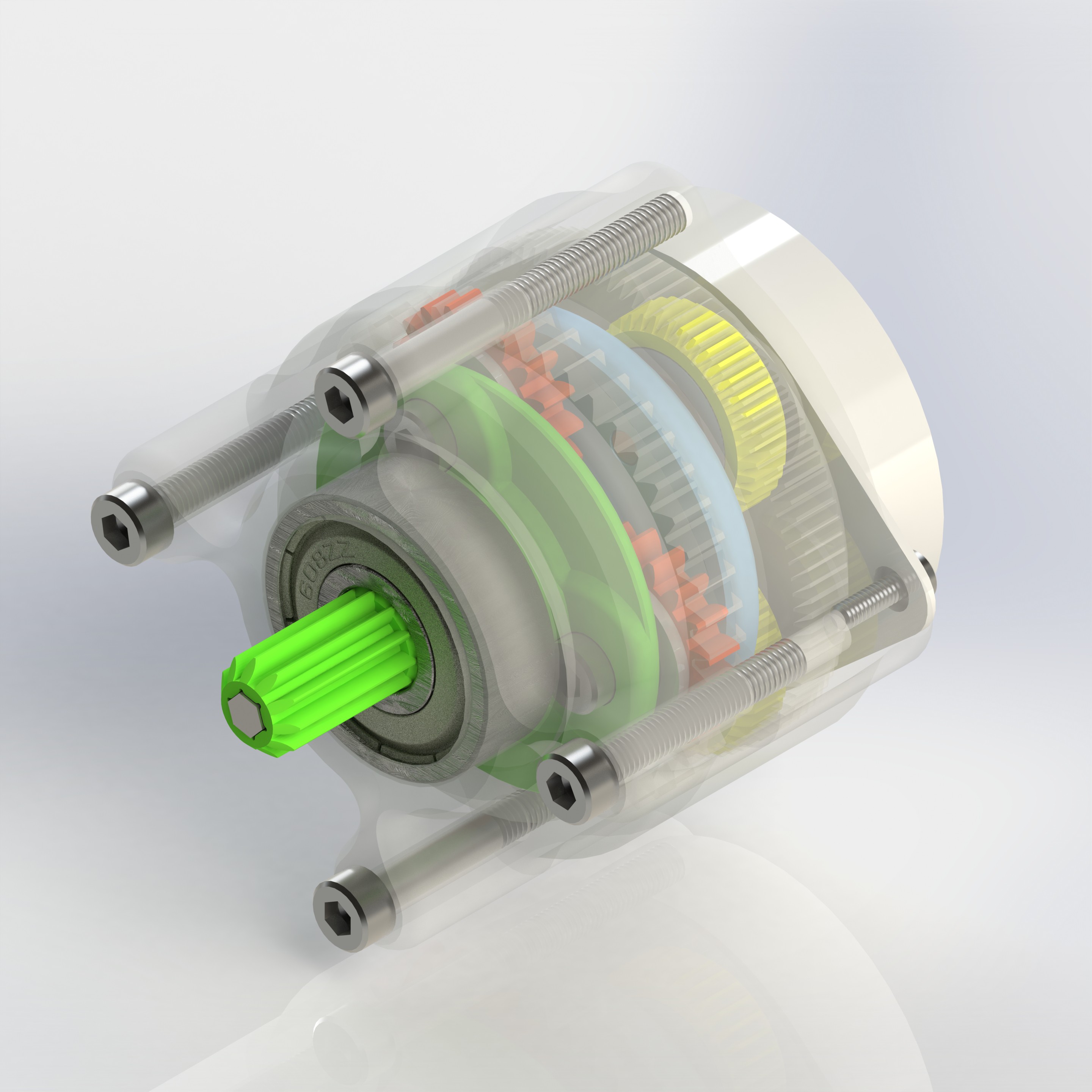

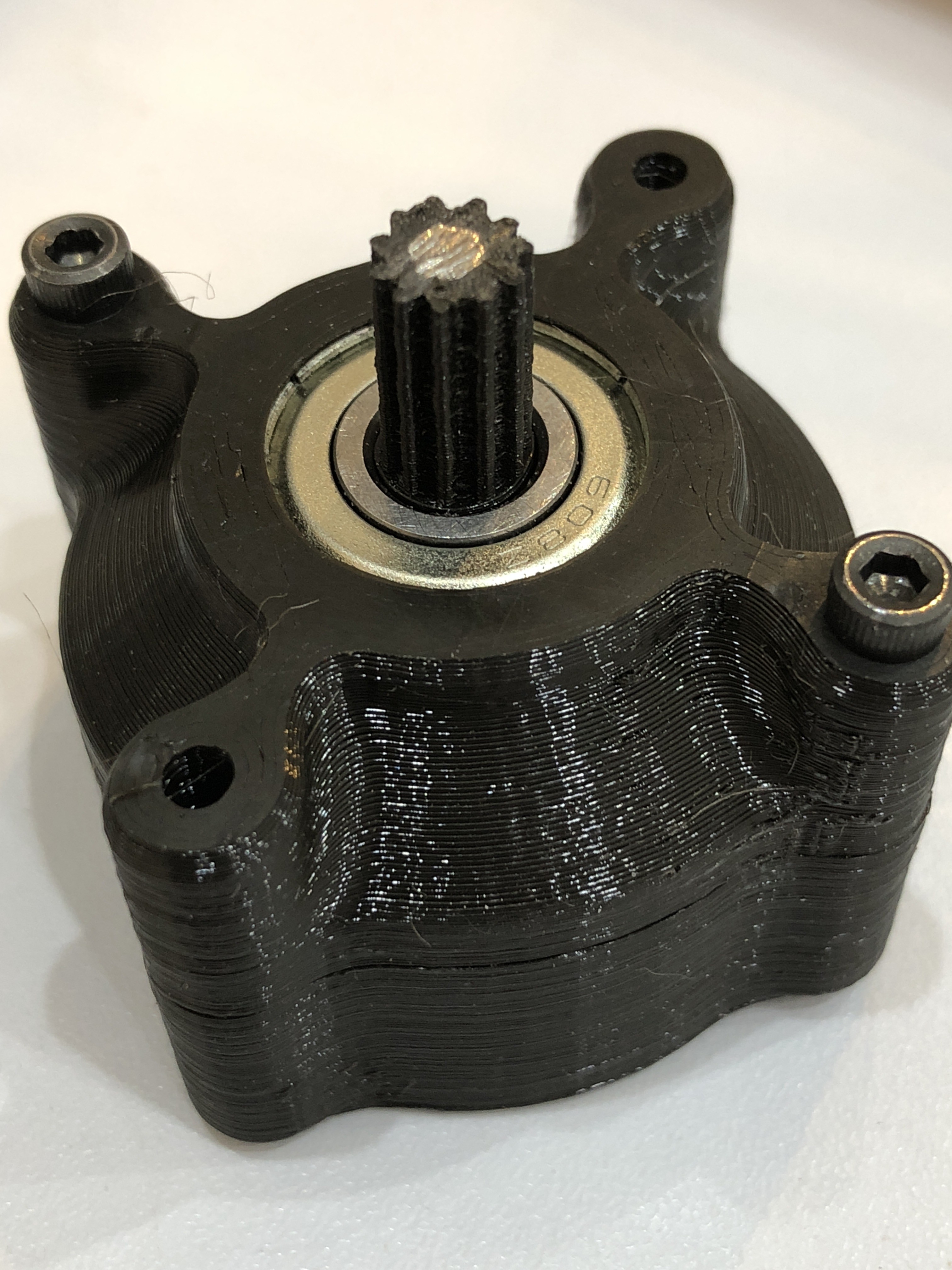

So... Designed a 21:1 planetary gearbox.

![]()

3d Printed all parts with PET filament, assembled and oiled everything. Without the motor attached there was an nasty friction when turning the gearbox so i’ve spinned it untill the friction got lot lower.

Mounted the motor and it was spinning... few times and got very hot - so hot that i didn’t bother to test it in my 3d printer... the current was set as low as the motor could turn... Epic fail :(

![]()

![]()

![]()

-

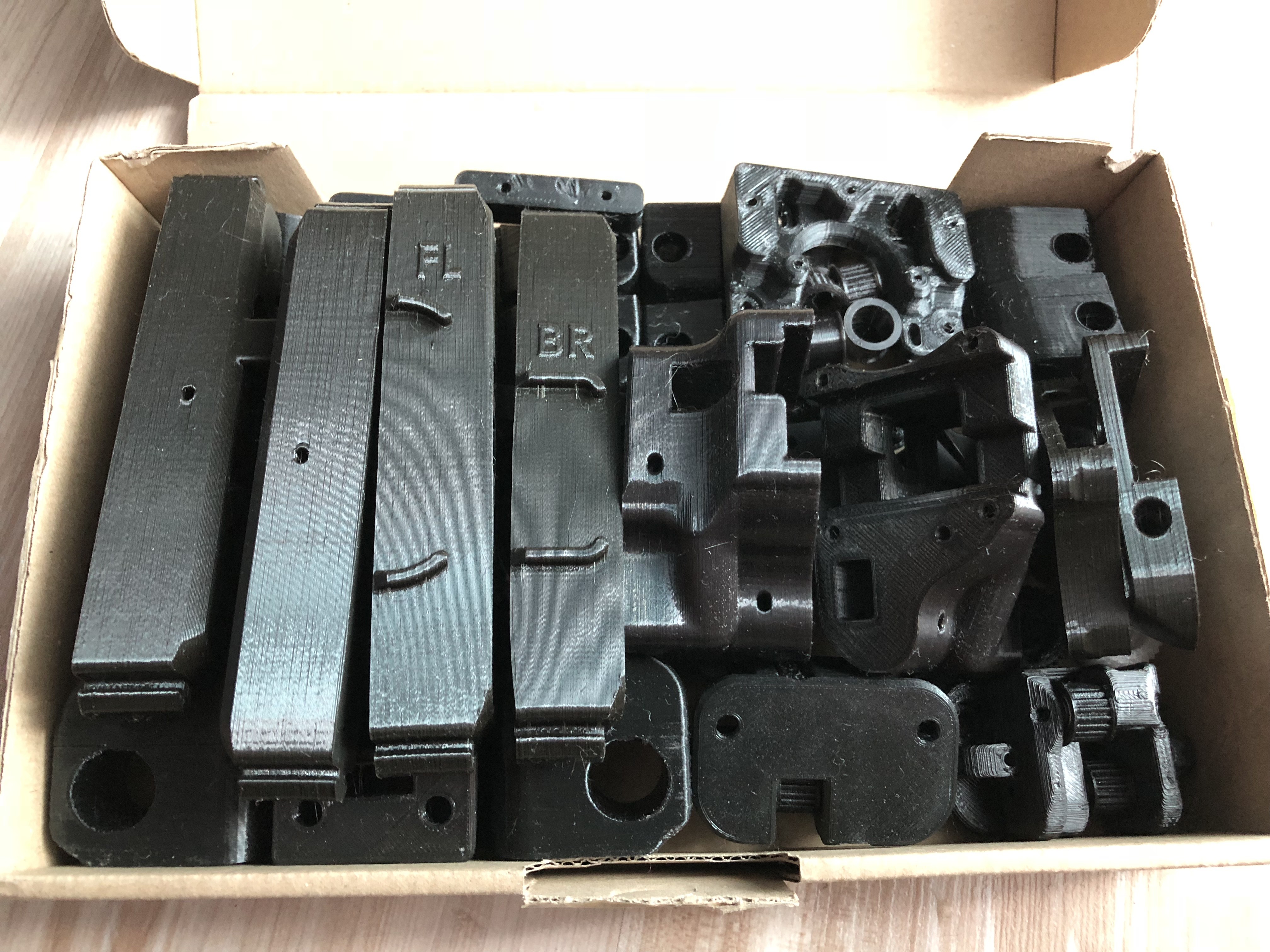

Work accumulation... and some system fail

06/25/2018 at 08:51 • 0 commentsBox of upgraded parts needed to be installed...

![]()

![]()

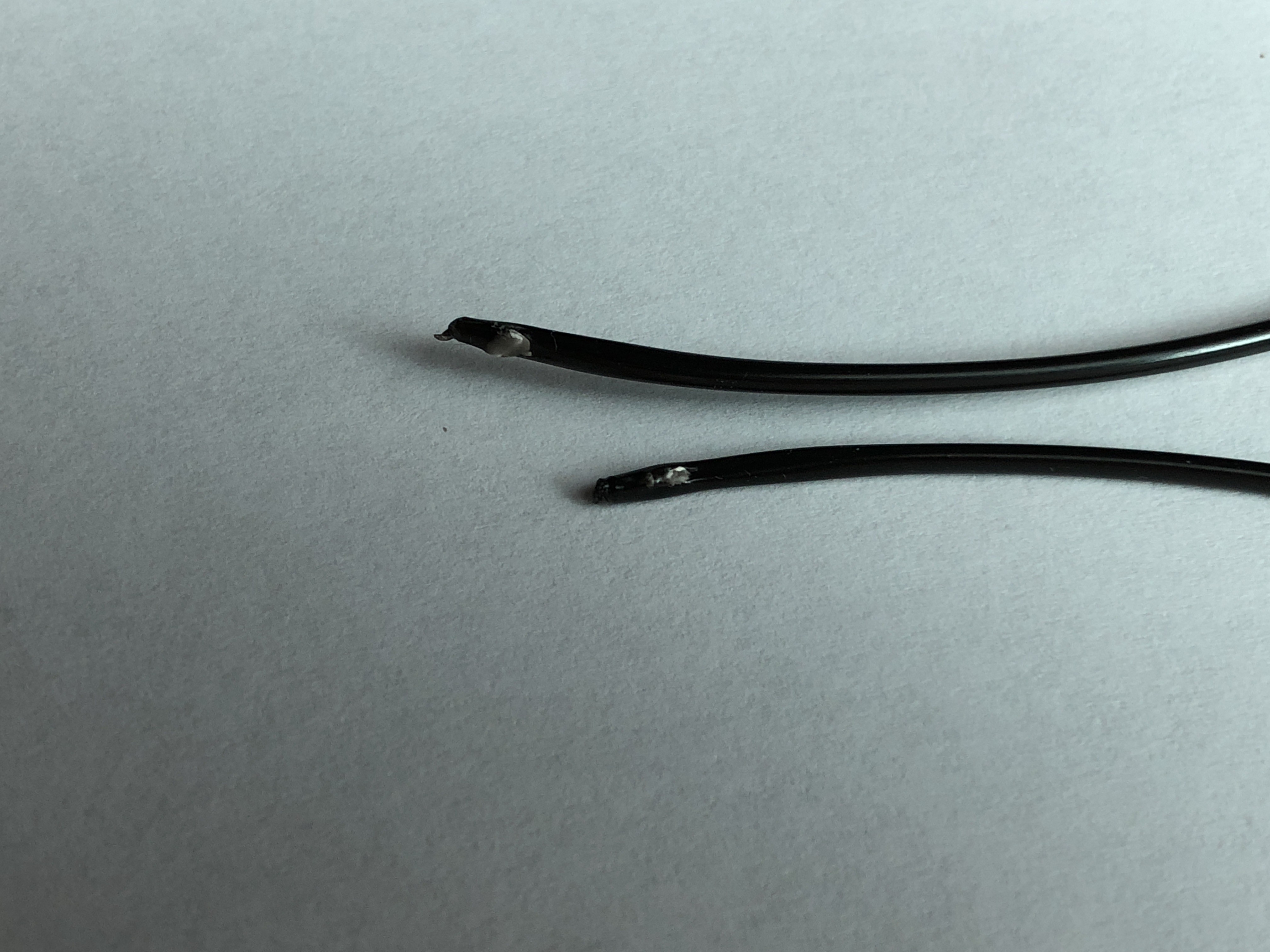

When printed some casual stuff for setup testing the nozzle got clogged. Very unusual i thought and then i realized that got some „quailty” fillament... PrintMe 1Kg Black PET-G.

When You look at the photos there are some small white particles in the fillament that are big and hard enough to jam everything on it’s way...

![]()

![]()

![]()

-

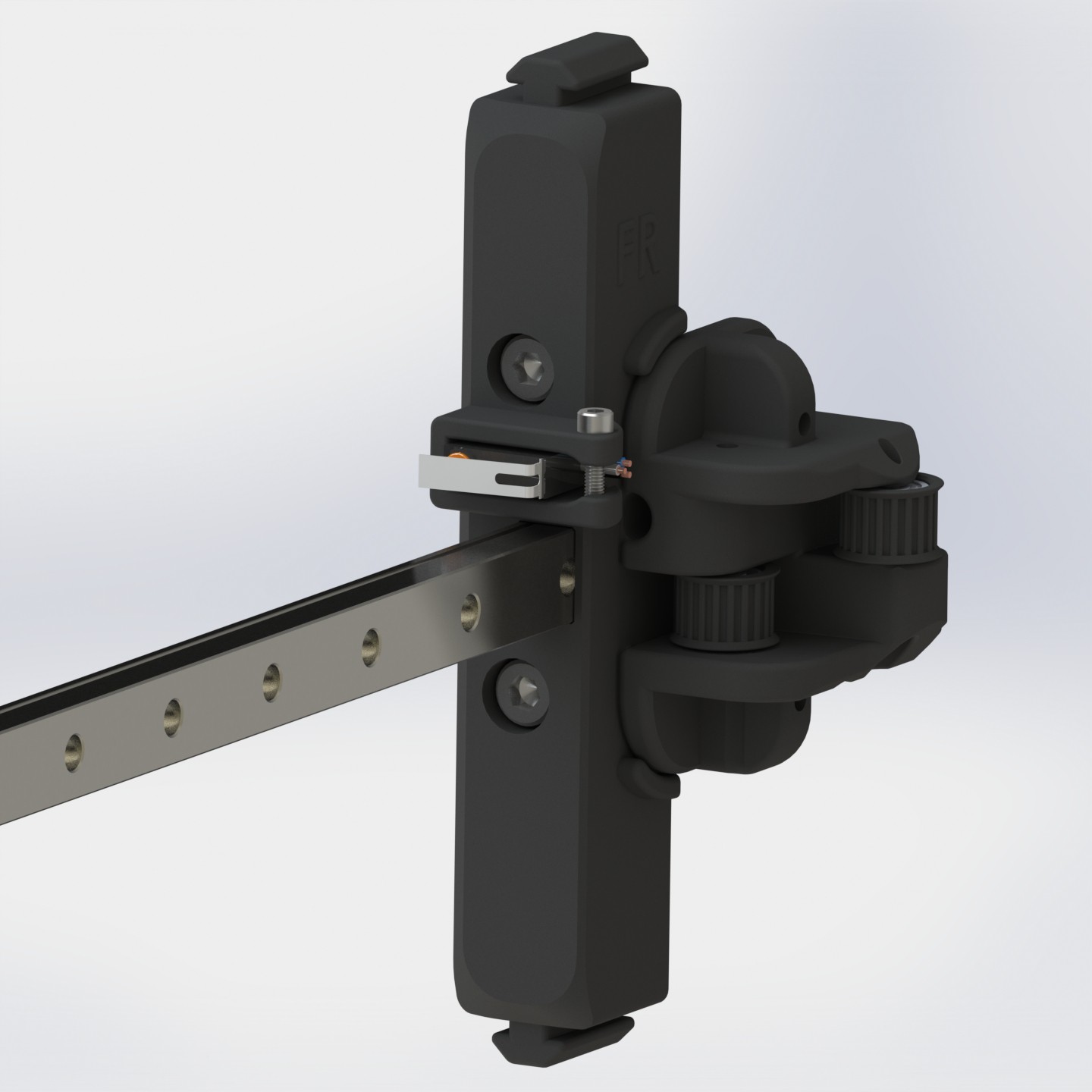

New addon parts and test printing log

06/22/2018 at 10:21 • 0 commentsWhen changing the fillament spool you needed some tricks and it wasn’t simple as it should be. It really was pissing me off.

Figured out a very simple solution.

Added an magnetic connection between spool system and the filament sensor. Now it’s changing spools is super simple... You can even take out the whole spool system.

![]()

![]()

-

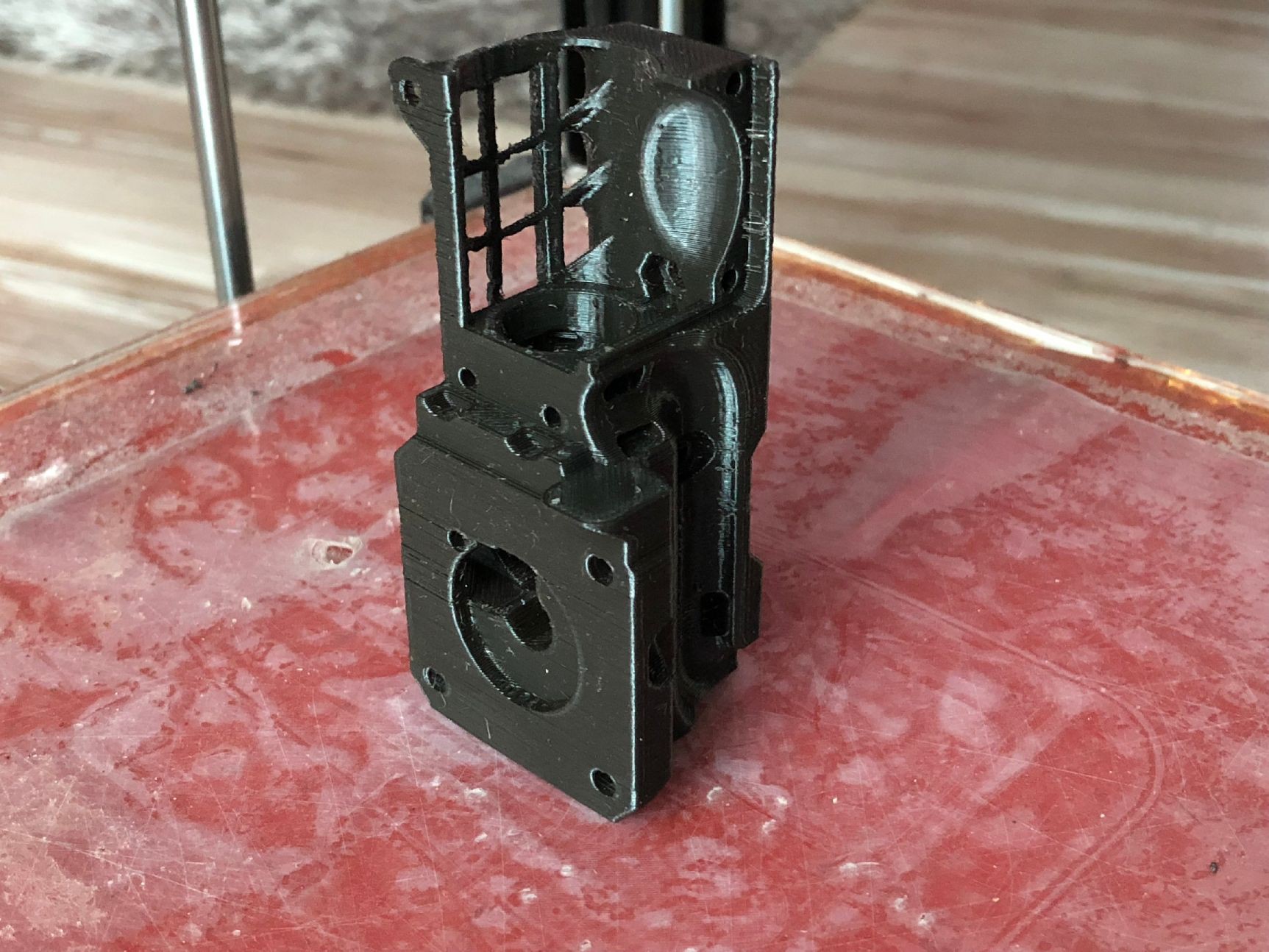

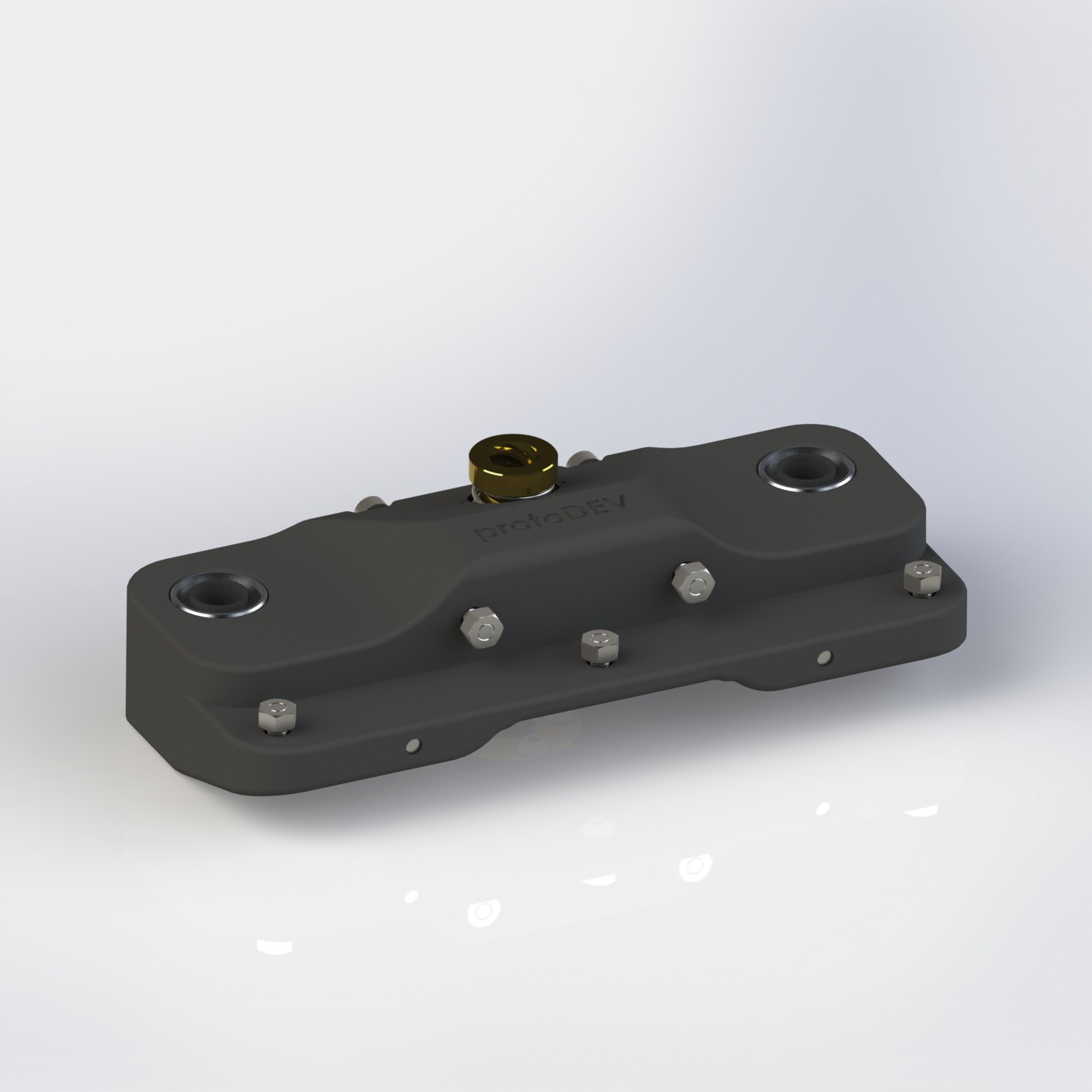

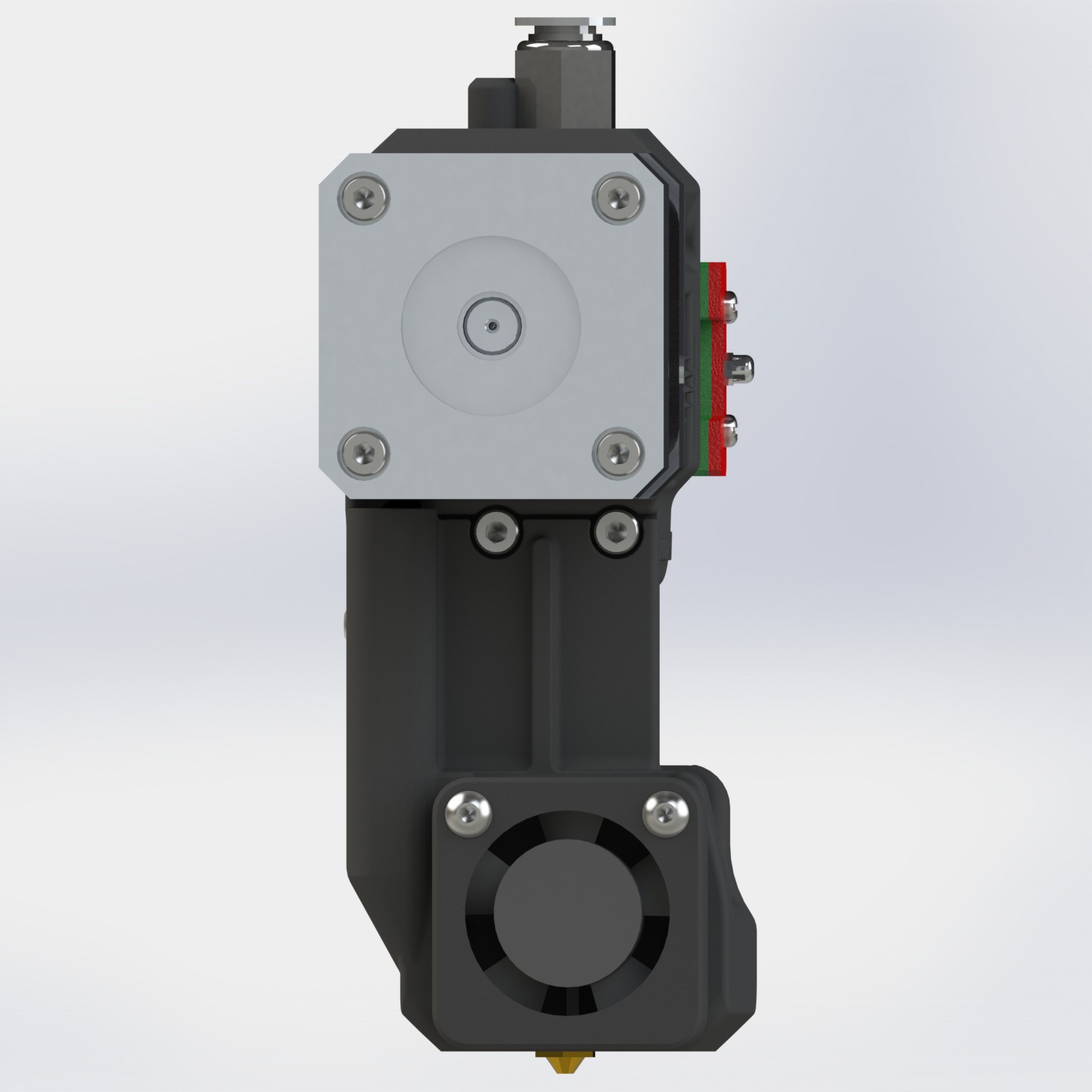

Better airflow and spray painted PET parts test

06/21/2018 at 22:39 • 0 commentsFrom 3d cad to reality...

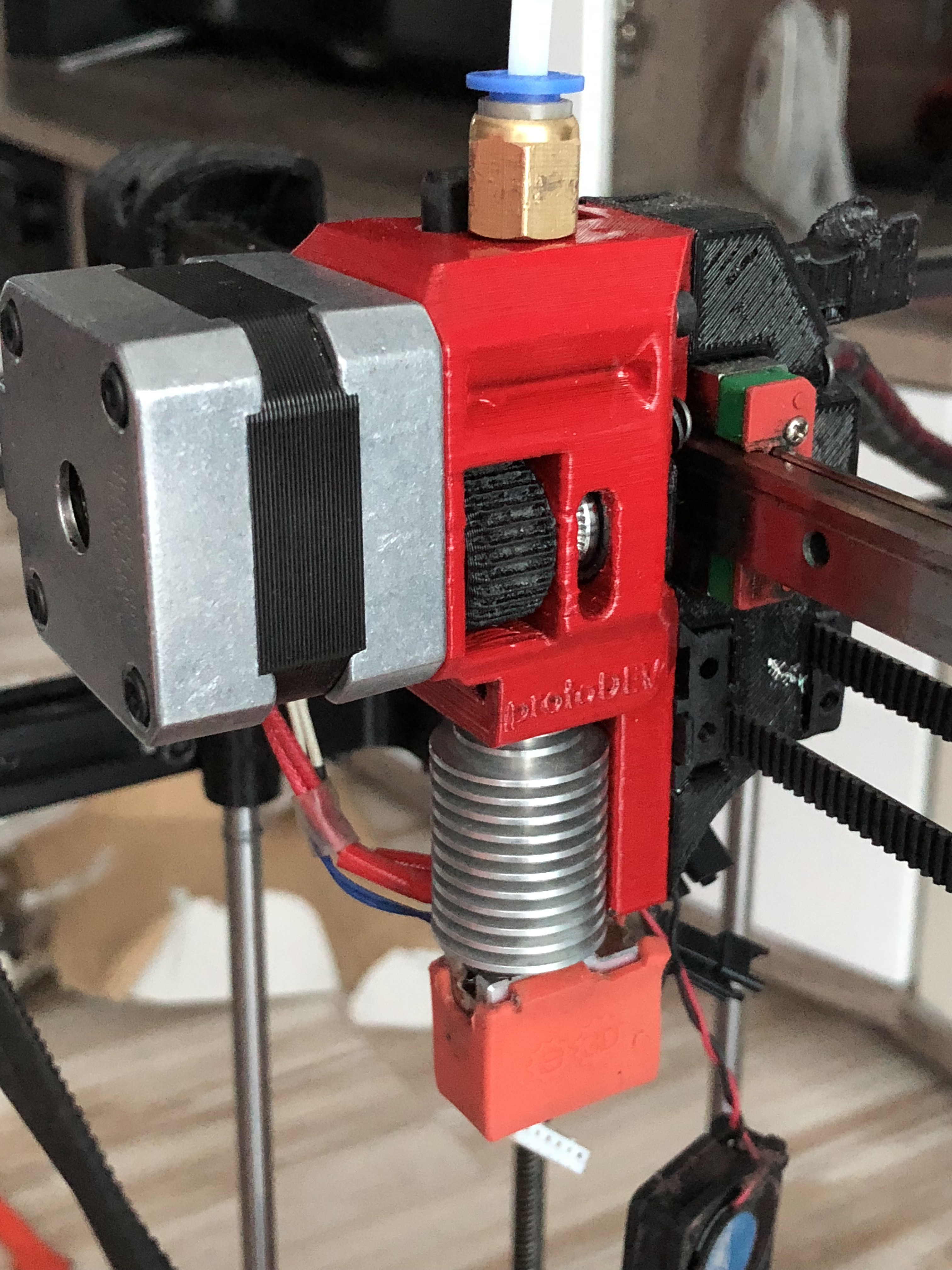

-updated fan duct design for better airflow.

- tested painting new PET parts with spray.

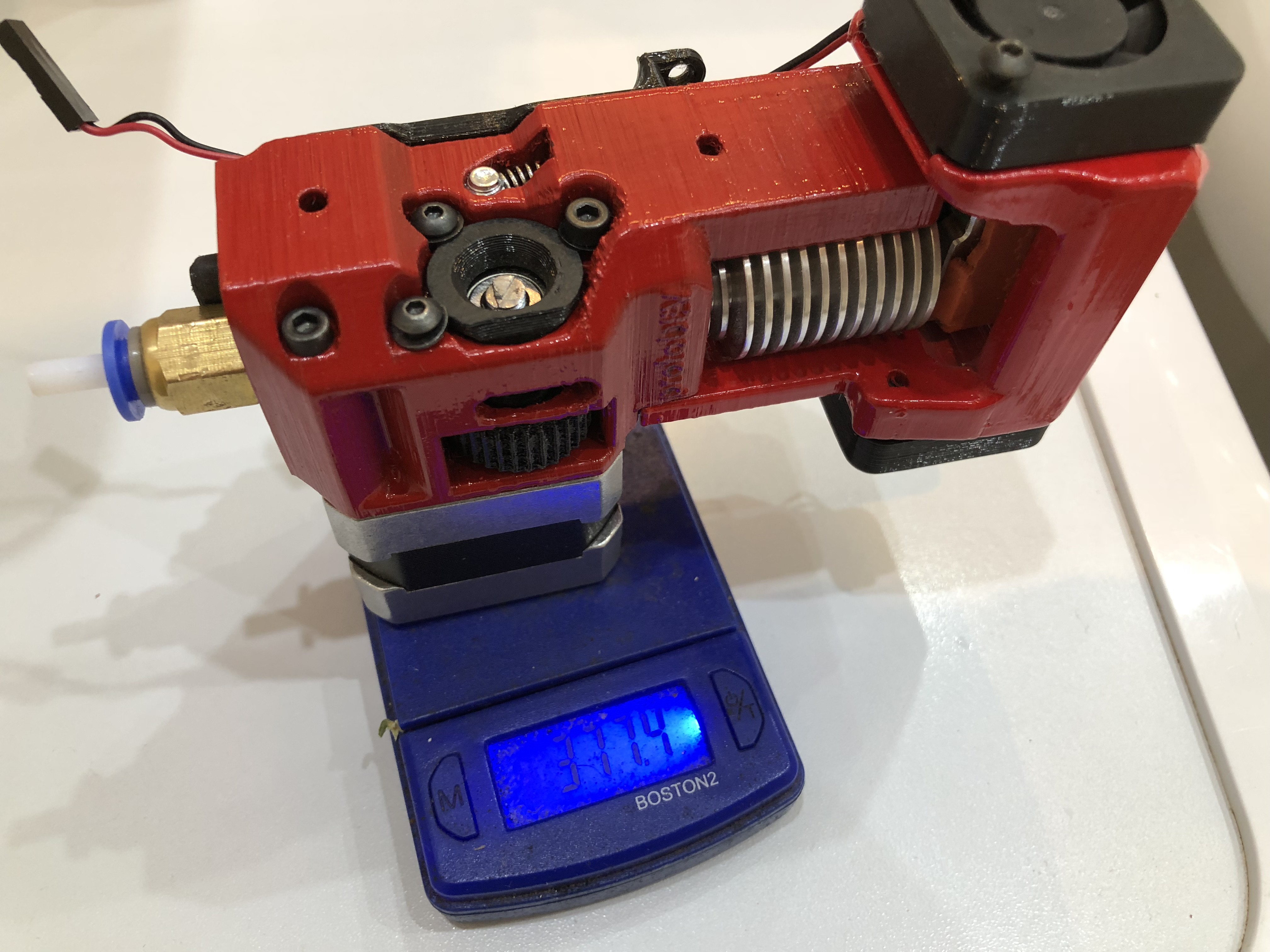

Complete extruder with hotend and all other parts weights now about 377,4g.

- working on some new files if everything works after testing will add all new files soon.

![]()

![]()

![]()

![]()

-

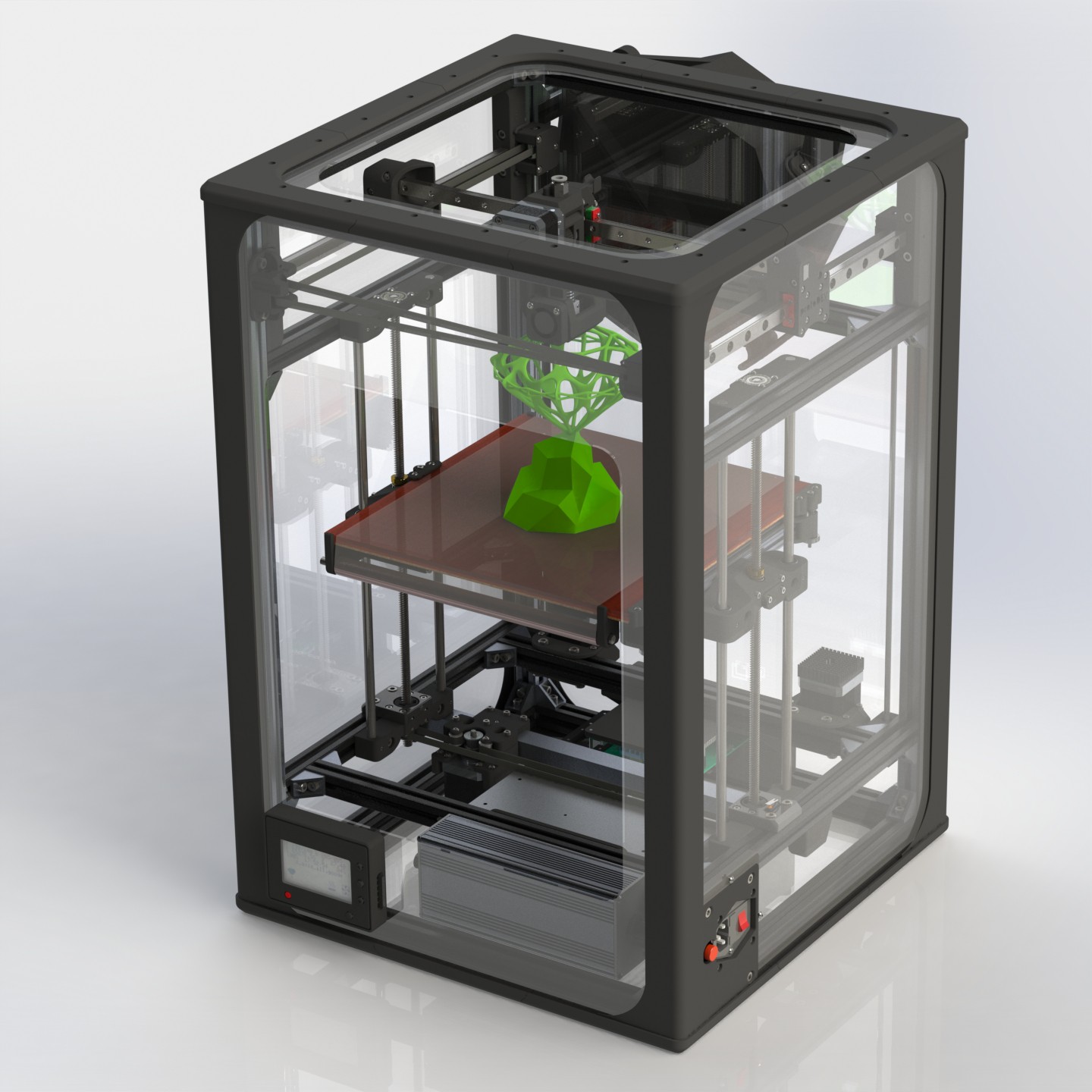

assembly renders & some little updates

06/10/2018 at 18:41 • 0 commentsMade lots of new assembly renders... Now it's simpler If anyone want to try and build the printer on it's own.

You can find the new assembly render files on github (plus some additional files like datasheets).

Finally i had ended months of testing all of my stepper motors in real life and chosen the best for this system (i think :P):

- for all axis: Wantai 42BYGHM809 - 400 step/rev, 20tooth gt2 pully, TMC2208 driver with spread cycle on, max current set at 1.2A, 1/8 microstepping with 1/256i, with these steppers and setup this coreXY setup can run at 395mm/s and 3500 acceleration without missing steps... plz don't print at that speed... damn it's ugly.

- for extruder: Jugetek 17HS1070-C5X - it's not heavy, just 34mm long, and without the 5.18:1 ratio planetary gearbox you got an nice small stepper that has an shaft with 11 tooth that's perfect for my geared 3:1 direct extruder.

-

x axis carriage design update

05/27/2018 at 20:56 • 0 commentsLatest x axis carriage design update. Reduced weight by 6g. Didn't like the fan duct "horns" so I've redesigned it...

Added cable cover and cleaned some surfaces... Getting closer to a point where the design can pleasure my eyes... not only pissing me off :P It's very hard to do something with small budget ( 400 euro ) and nice spec/design.

Michal Wojciechowski

Michal Wojciechowski