-

Arm Rig Update

10/14/2018 at 16:04 • 0 commentsHello,

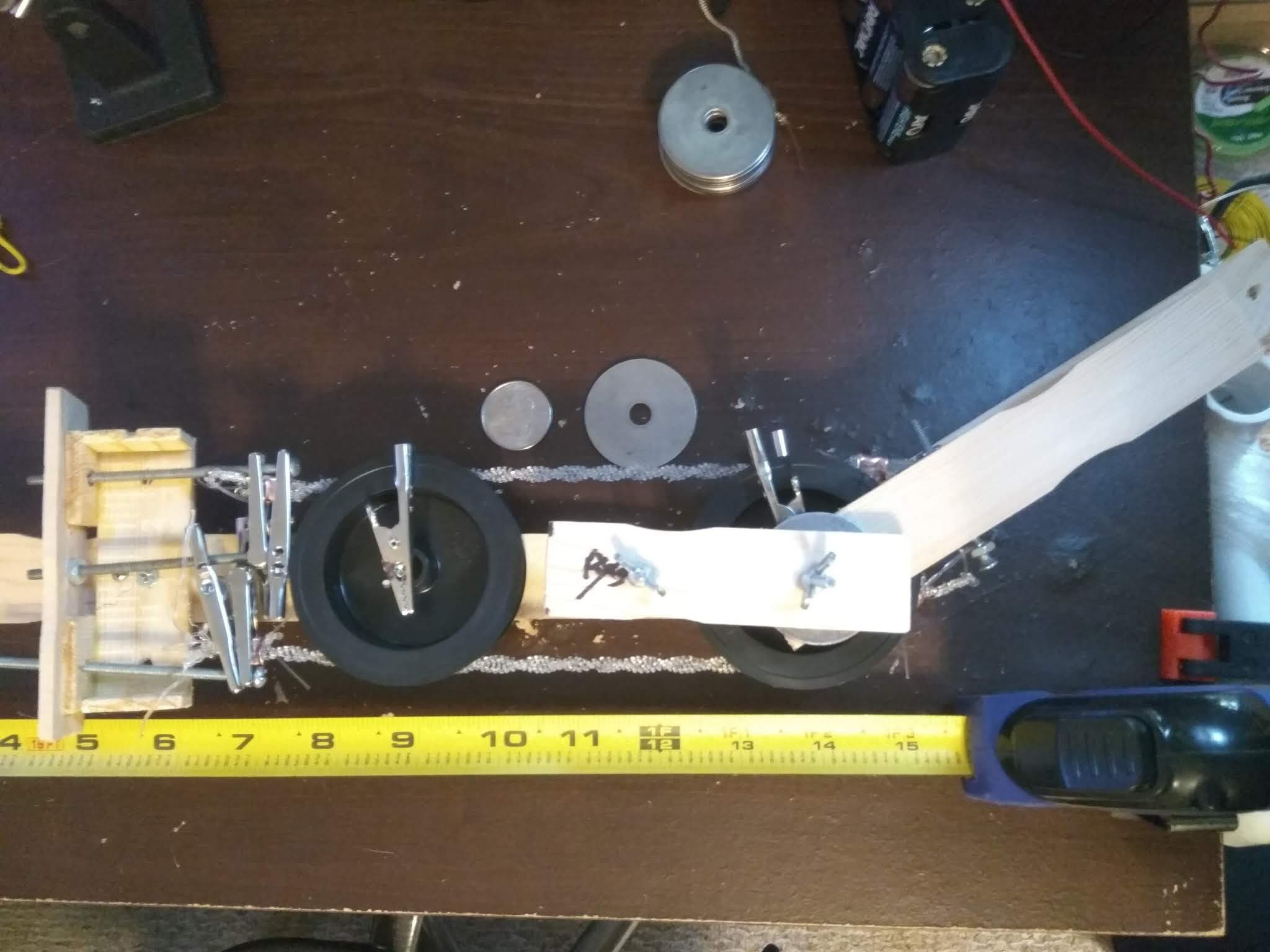

In this update I will list some findings mainly focused in the application of Nylon Helix muscles as actuators and the beginnings of experiments to bring about increased efficiencies. For the former I have constructed a wooden rig meant to mimic a human arm's bicep and tricep (Pictured and filmed below is actually the third version). In the video you can see me powering the bicep and having the forearm move up, it's most easily seen by following the red stick in the bottom right hand corner.

![]()

![]()

![]()

![]() The rig has several problems including the cheap wood flexing under the strain and causing pinching at the joint. Additionally this rig is a little too big for the size of the muscles, meaning a full contraction does not bring the forearm to where a human arm would rest.

The rig has several problems including the cheap wood flexing under the strain and causing pinching at the joint. Additionally this rig is a little too big for the size of the muscles, meaning a full contraction does not bring the forearm to where a human arm would rest.

Also as part of recent work I have been attempting to increase contraction distance and speed. Which means creating a lot of helix and hetero/homeo-cordial muscles. One of my recent findings was that with my new deep sea fishing line annealing actually decreased the Helix contractions from 16.5% unannealed to 13% when annealed for any time.![]()

![]()

As for my next steps I am looking into creating a series of videos that would show someone from beginning until end how I create these material actuators. I am also going to be running further experiments in manufacturing that I hope to increase my contractions to around 20%. After which I will then build an Arm Rig v2, most likely from PVC and get some footage of that out.

Lastly I am leaning towards some sort of crowdfunding, I think with even a small amount of funding I could create some machines that would allow faster experimentation and thus greater potential! And maybe get a prototype material exosuit working. ;) Stay tuned.

-

Another Major Breakthrough and Future Plans

08/30/2018 at 01:05 • 0 commentsApologizes for being gone, I was recently on vacation. Anyways, I spent some time reading more white papers and studying what they have going at HBS Labs including their video on producing Silver Plated TCP.

I recreated their results and was amazed to see that their "2-Ply" or 'helix' muscles combine aspects of the hydrocordial and regular actuators by allowing them to contract against and up the second muscle material they are paired with. This led to a great increase in contraction distance for very little strength loss. I will try to get some hard numbers soon.

![]()

![]()

![]()

Finally I want to go over my longer term strategy, which differs from where many other scientists are moving with TCP. Other scientists are using the resistance of thin conductive wire like silver or copper. But since I am using Nichrome the resistance comes from the material and thus wider material means more heat. Thus instead of scaling down I have plans to scale up! Above with the green background are two pieces of 100lb test fishing line. The top most using 30 gauge nichrome and was yielding 18% contractions with a half duty cycle of 4 seconds. The bottom was similar but much slower to contract for a fraction less distance. This leads me to believe that if I increase the thickness of nylon and nichrome then I will see an increase in efficiency. I do not have have the full numbers for this either yet. But I will work them out soon.

Thanks for all the support!

-

Hydrocordial Conquered

08/01/2018 at 20:23 • 0 commentsAs teased, here are the videos of the hydro-cordial muscles in action. These muscles are created by adding an additional step to manufacturing where before annealing you wrap the twisted nylon around a bolt under tension. Then after annealing it holds the structure of a spring. This was originally discovered by research students at UCLA I believe and the creation of which had eluded me until recently. The point is that it trades some strength for a great deal of contraction. As described if you wrap the material around the bolt in the same direction as the twisted nylon the muscle will contract under heat. If you wrap it the opposite it then the muscle will expand under heat.

-

Improved Nylon Muscles

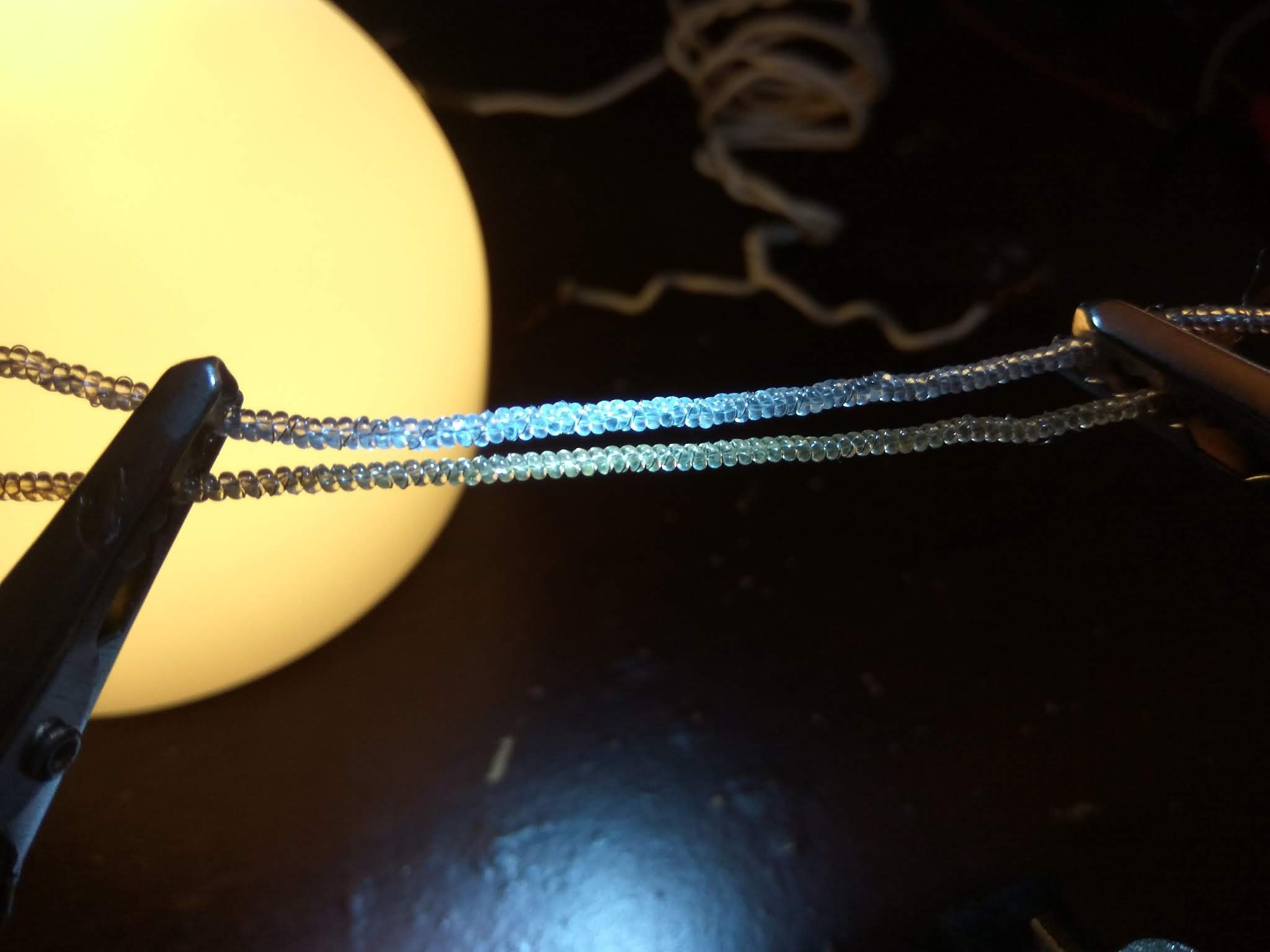

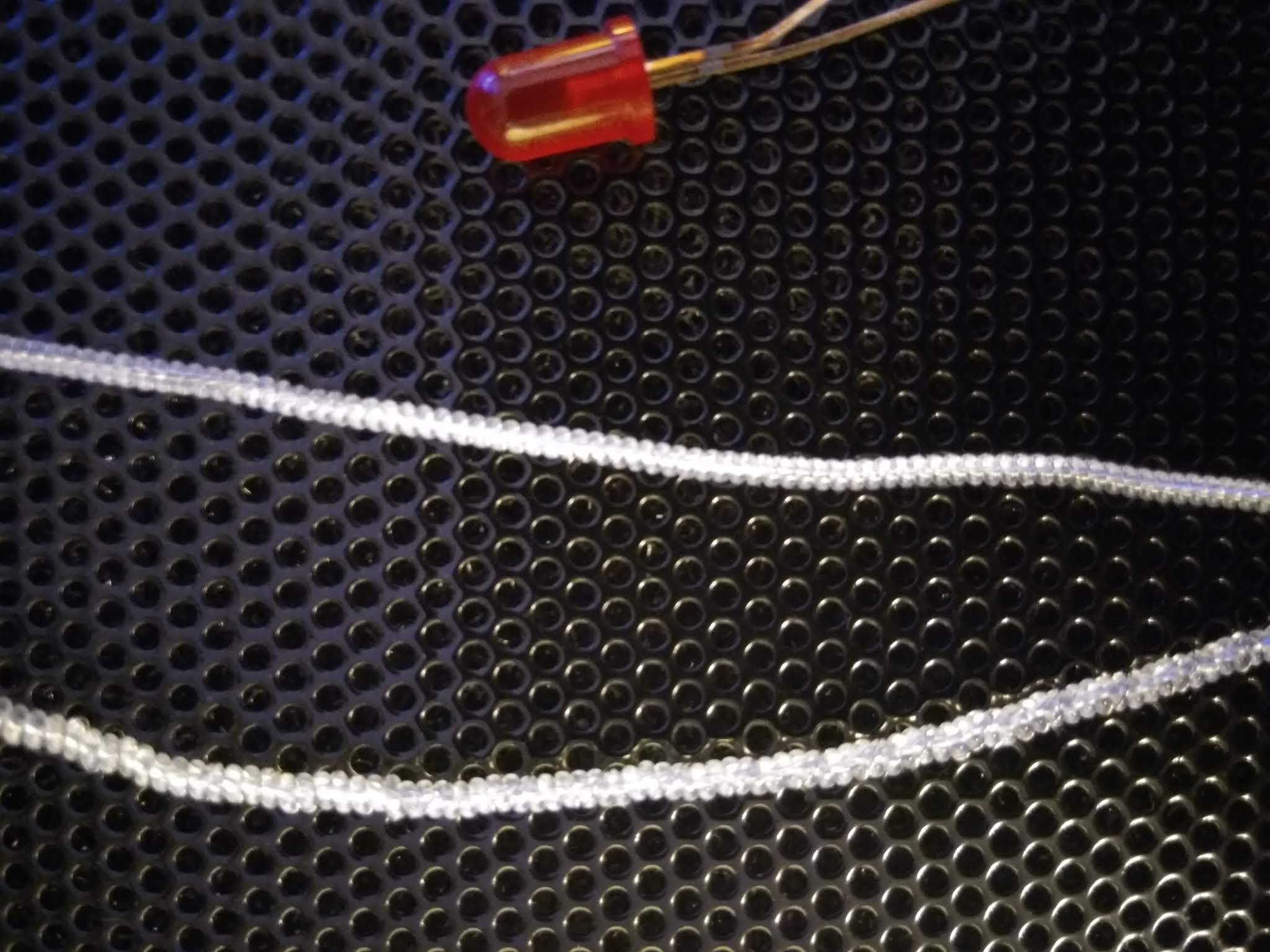

07/31/2018 at 01:15 • 0 commentsWhile trying to automate my twisting process I sped up the RPM of my drill and found that it produced a much more uniform set of wraps. (See picture with LED of higher RPM versus lower RPM.) Additionally after rereading some white-papers I found that the annealing temperature of 275F was far below what the paper suggested, 350F. When I switched to this latter temperature the muscle that produced was stiffer, tighter and contracted more. (See picture with alligator clamps for difference between two temperatures.) Between both these advancements I have been able to create much more efficient single strands.

I will update at the end of the week with some videos of new Hydrocordial muscles in action. I am saving up for a higher quality camera so I can make some end-to-end videos about producing your own muscle as these white papers over complicate the process.

![]()

![]()

-

Breakthrough: Now using multiple muscles in sequence!

06/21/2018 at 21:08 • 0 commentsSorry no update for a while, this one will be kinda long due to the scale of my breakthrough. Found reliable ways to produce both nichrome wrapped and regular twisted nylon muscles from 50lb mono filament. I was able to pair together numerous AAA batteries in order to get the amperage needed to contract a muscle quickly. I found I could contract about 10% in 30 seconds with 9 amps when weighted with about a pound.

My great breakthrough was getting multiple muscles working together because unshielded they could touch and create shorts. I first tried to insulate them with silicone conform coating purchased from amazon. But that failed because it restricted movement quite a lot but may be something I come back to.

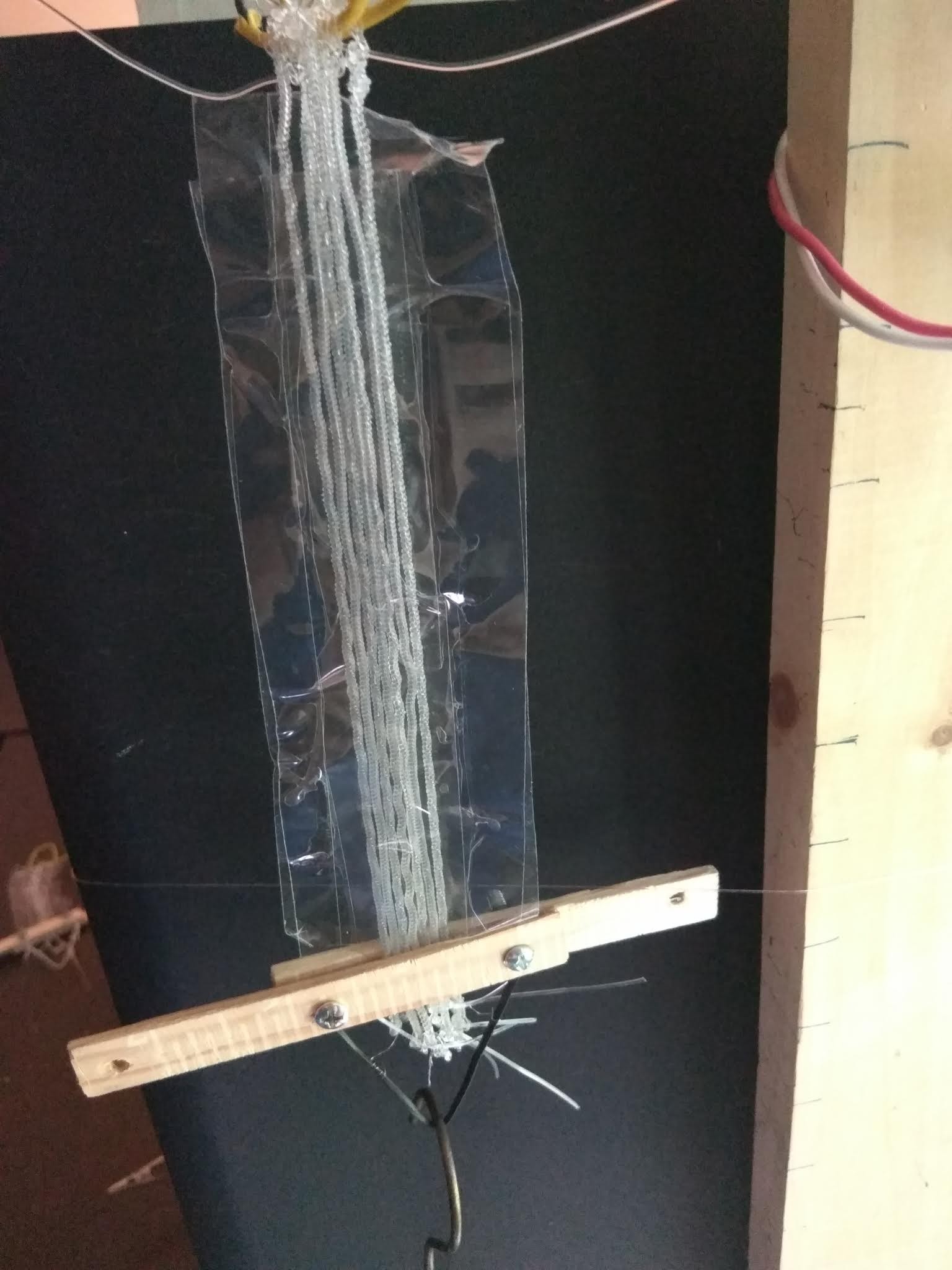

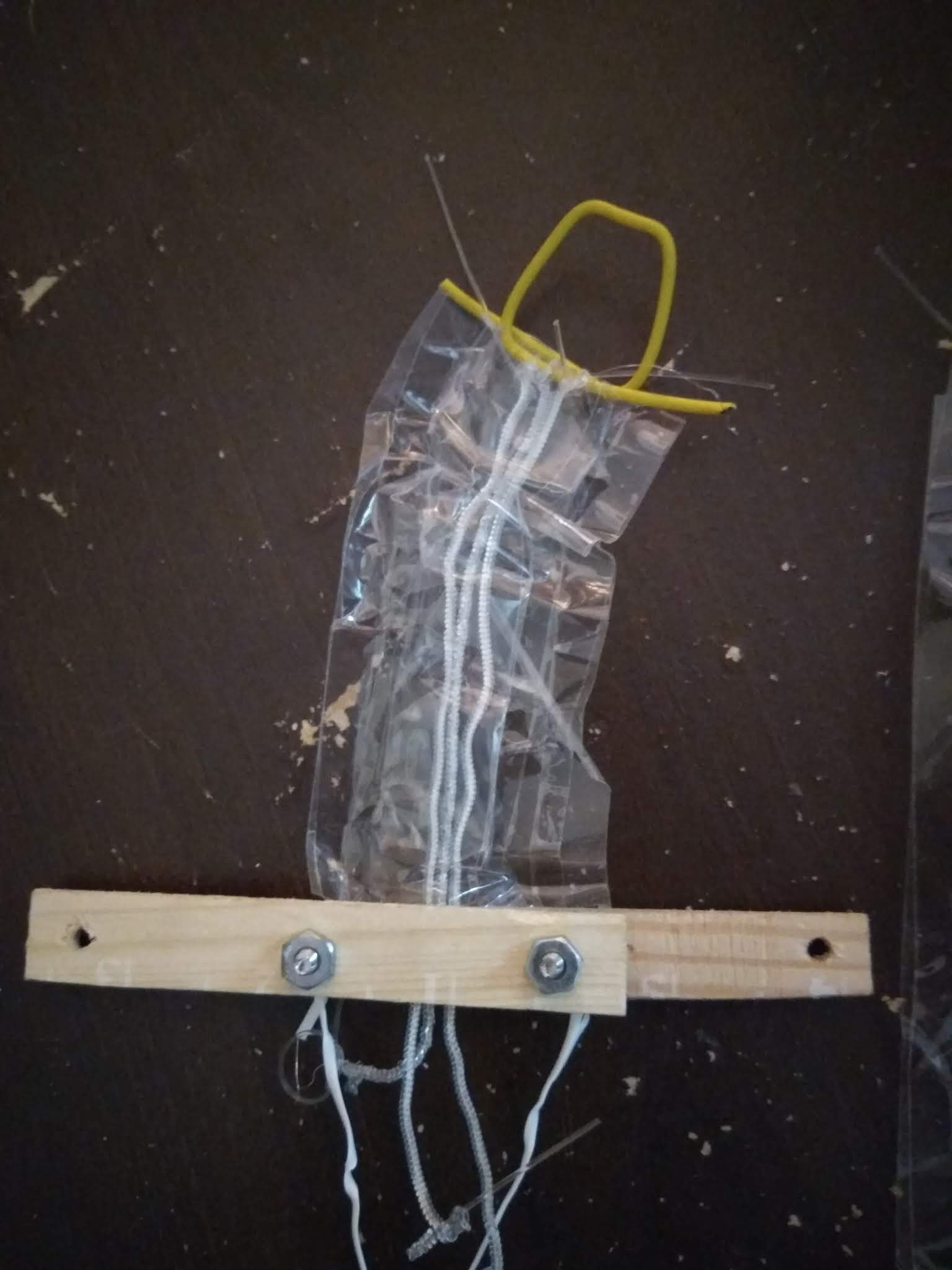

I found that if I lined up non-wrapped and wrapped in an alternating pattern the non-wraps would insulate the wraps from each other while being heated by their neighbors. To keep the multiple strands at the same tension I put them under load and then 'tune' then until they all appear the right space apart. Following that I clamp them with a small piece of wood and seal them loosely in plastic wrap. I've included some pictures below. My first attempt was with 3 muscles and is a bit stubbier, my second is much longer and with 7 muscles.

More to come soon!

![]()

![]()

![]()

![]()

![]()

-

Project Log #3

05/31/2018 at 22:21 • 0 commentsWell I ended up using all my Nichrome wire last weekend so I had to order more and due to time constraints I do not think this project will be any where near ready for the Hackaday Challenge this year.

My current go forward is to complete a Proof-of-concept robot forearm and hand of limited motion all powered by groupings of twisted nylon actuators and using sweat like evaporative cooling . I was unable to find a suitable waterproofing yet but have ordered Silicon conformal Coating which should work along with my order of additional 36 gauge nichrome wire.We will see how that goes next week!

-

Project Log #2

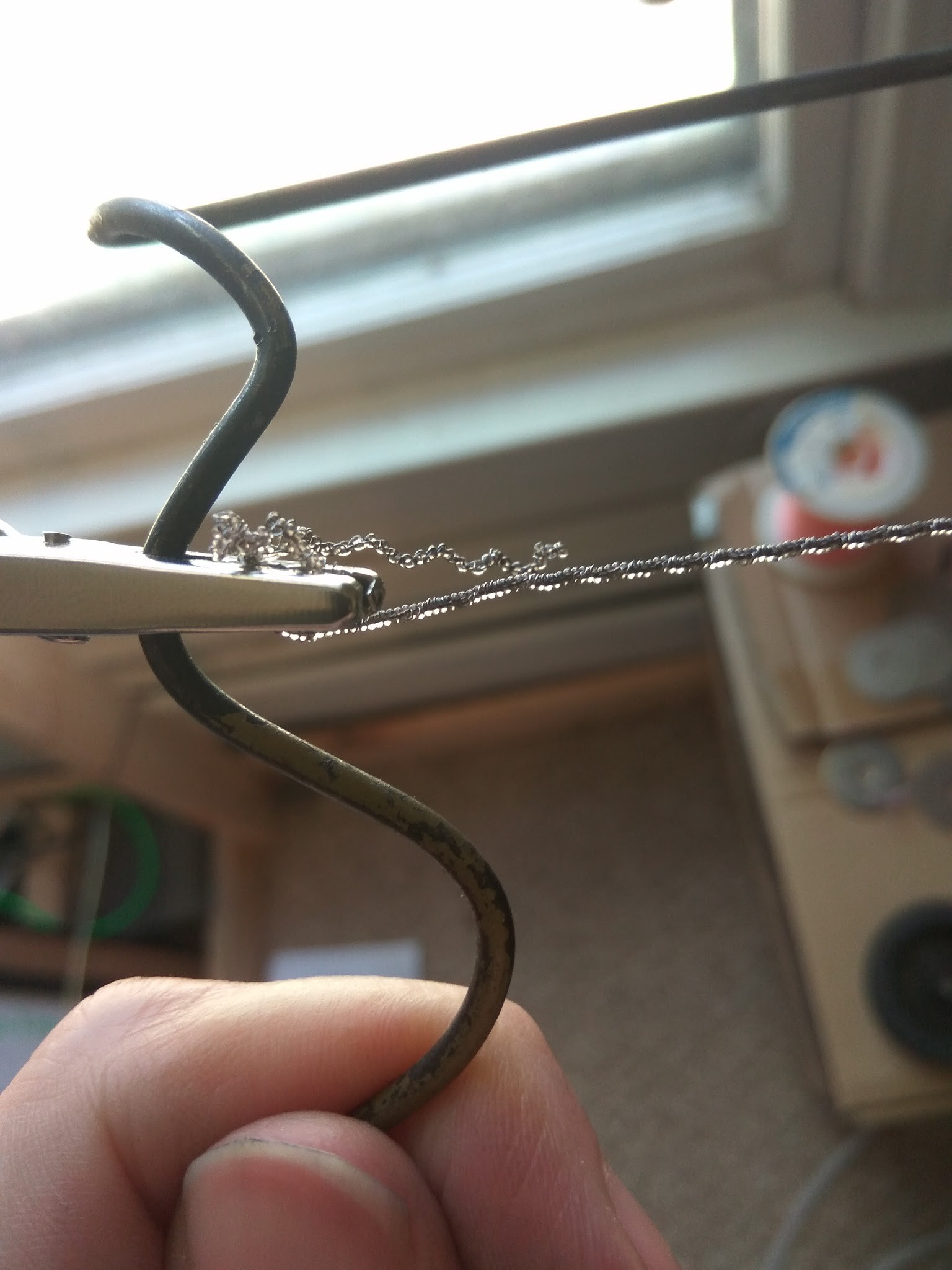

05/14/2018 at 21:59 • 0 commentsThis weekend I spent time experimenting with Nichrome Wrapped Hyper Spun nylon actuators. Do do this I follow my regular process of laying out a some 8lb fishing line, under some weighted tension provided by some metal washers. Then I pin some wire of roughly the same length to the nylon with some alligator clips and allowing the hobby motor spin until hyper wound. I found that lightly wetting the nylon with lubricant stopped the nylon from tearing mid spin.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Please enjoy some pictures I took during the experiments.

Material Linear-Actuator for Robotics

Basically you can turn regular fishing line and nichrome wire into a linear actuator that can contract much like a human muscle.

The rig has several problems including the cheap wood flexing under the strain and causing pinching at the joint. Additionally this rig is a little too big for the size of the muscles, meaning a full contraction does not bring the forearm to where a human arm would rest.

The rig has several problems including the cheap wood flexing under the strain and causing pinching at the joint. Additionally this rig is a little too big for the size of the muscles, meaning a full contraction does not bring the forearm to where a human arm would rest.