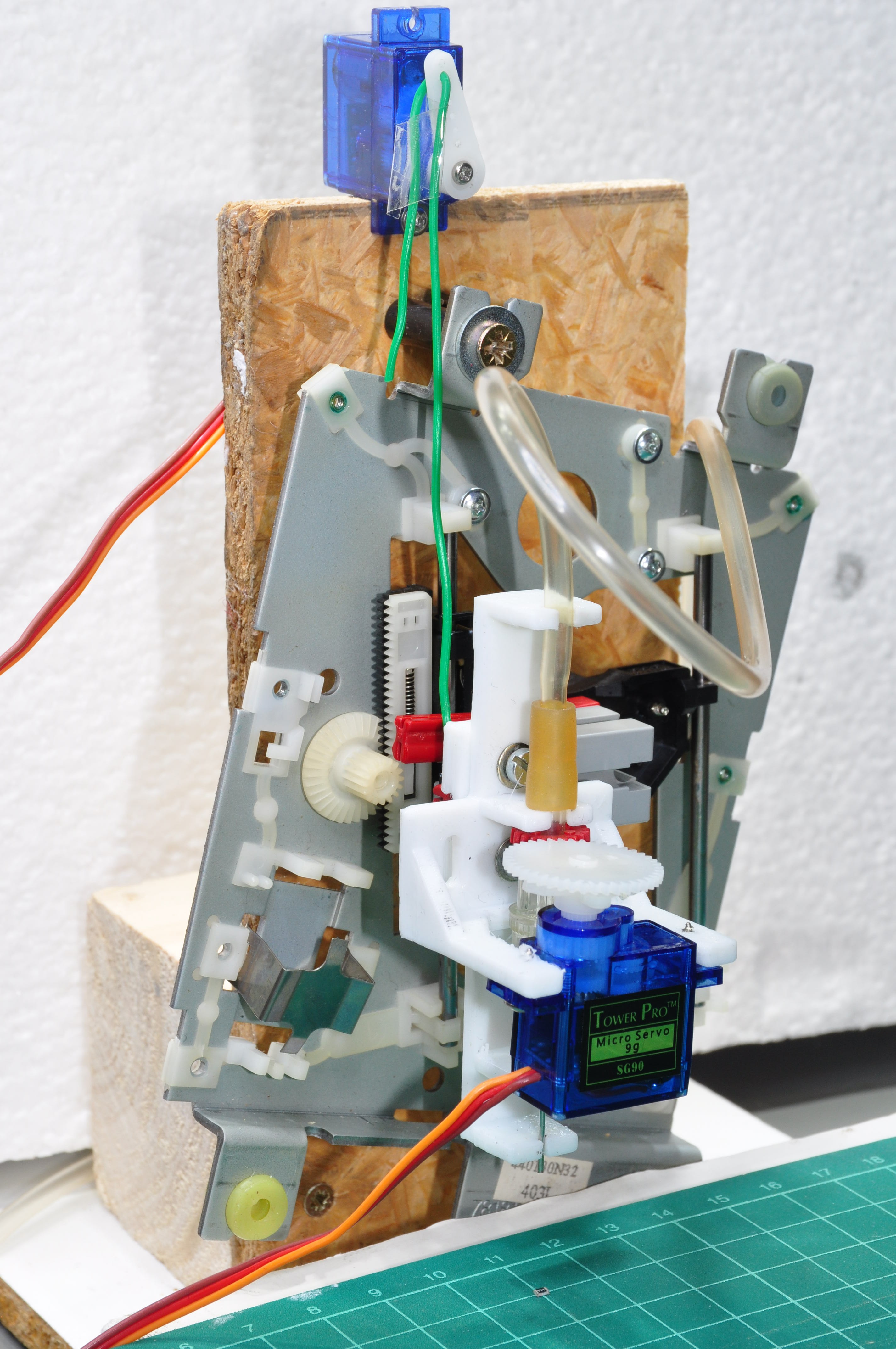

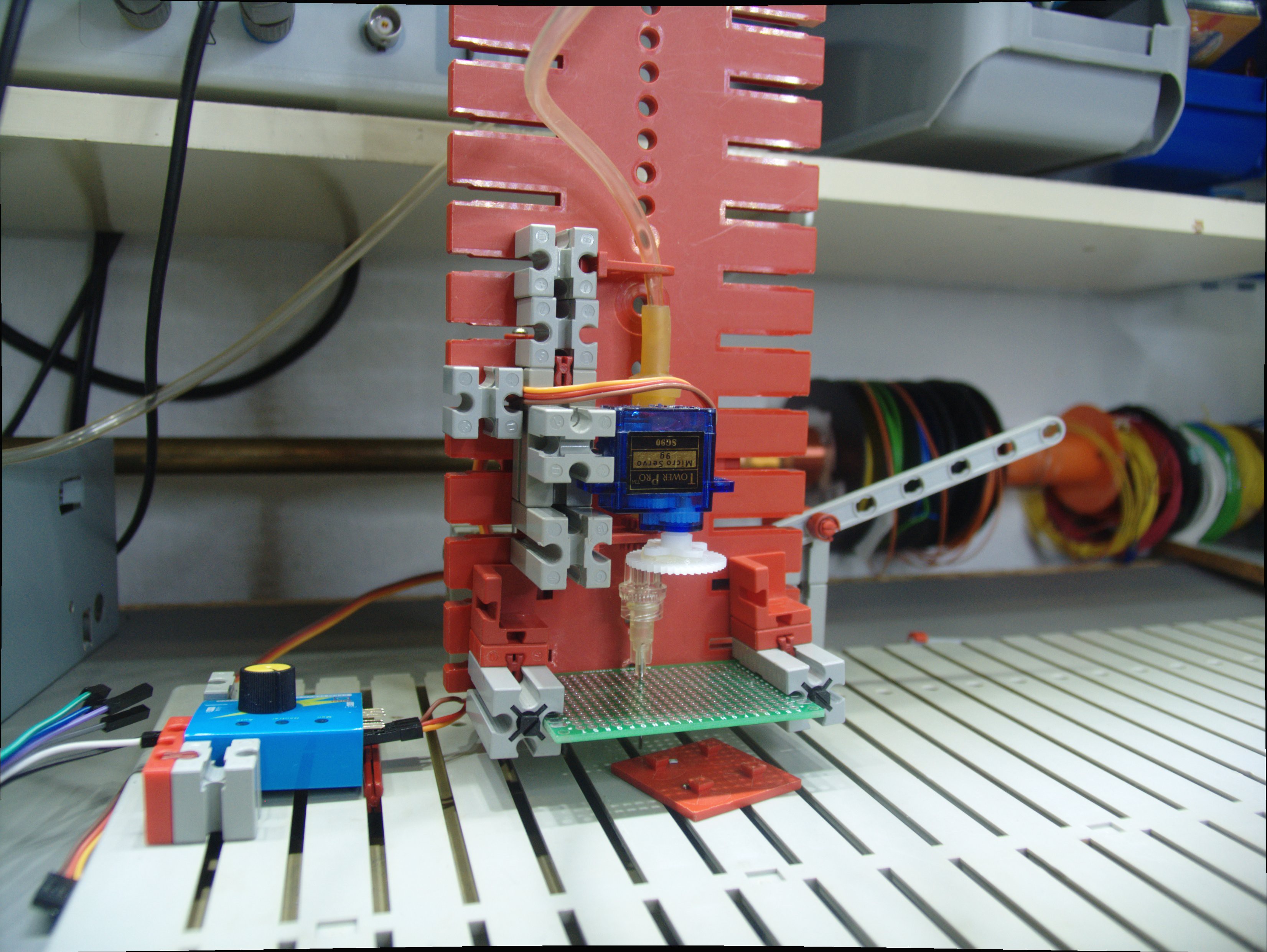

current status: 3D-printed first prototype. Result better than expected, maybe even usable. Working on a simple control logic now.

simple pick-and-place head

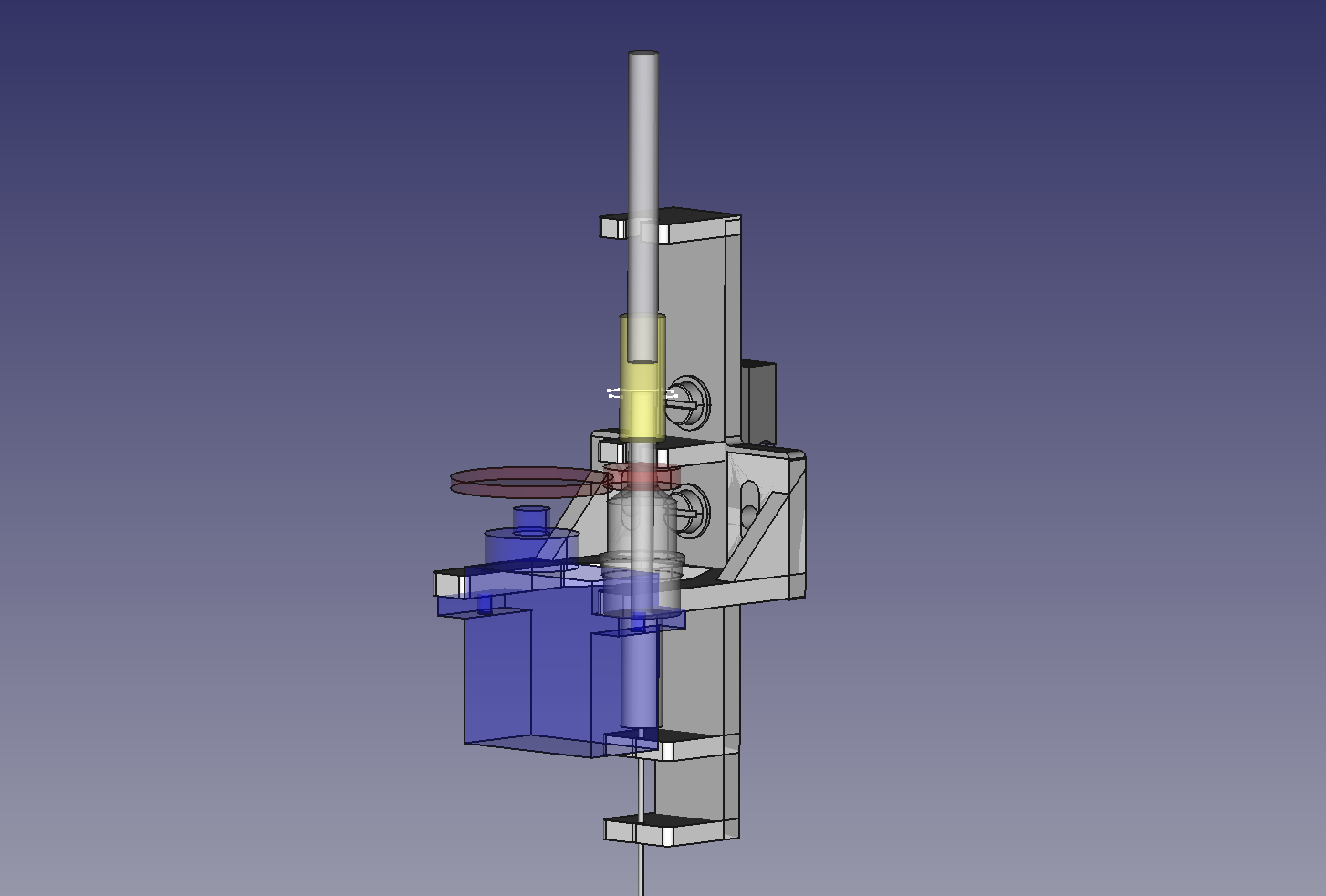

A study for a simple pick-and-place head using a servo and an injection needle instead of a hollow-shaft stepper motor and a standard nozzle

Michael Mayer

Michael Mayer

Just fro me to be sure : from yours description : "I expected small misalignments and added 1/2 teeth pitch (~0.8mm at M0.5)" >> misalignment s is distance between center of servo and center of rail ?

I found that backlash at cheap Chinese cheap gears is about 1 - 0.5 degree.

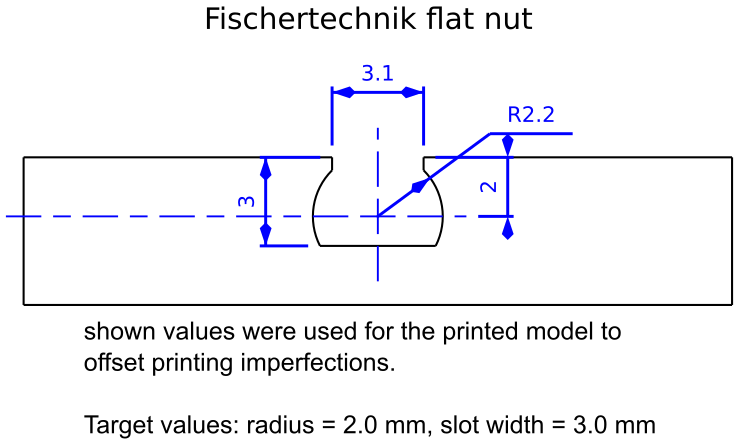

I am just curious : on yours 3D printer , when you make components like this , how precisely they can me made??

I am planing to buy my 3D printer , any recommendation from point of tolerance of product??

thanks

ivo