-

Twin bots win second place

06/04/2018 at 11:26 • 0 commentsApril 2018.

This year, we built twin robots: Order and Chaos, using our modular ecosystem of CAN boards.

Each robot contained 18 boards (1 beacon, 1 adapter, 1 sensor, 3 IO, 12 motor).

We won the second place at the Swiss national competition (SwissEurobot).

Read our full blog post for more details.![]()

-

Let's make this bot smarter!

06/04/2018 at 11:20 • 0 commentsMarch 2018.

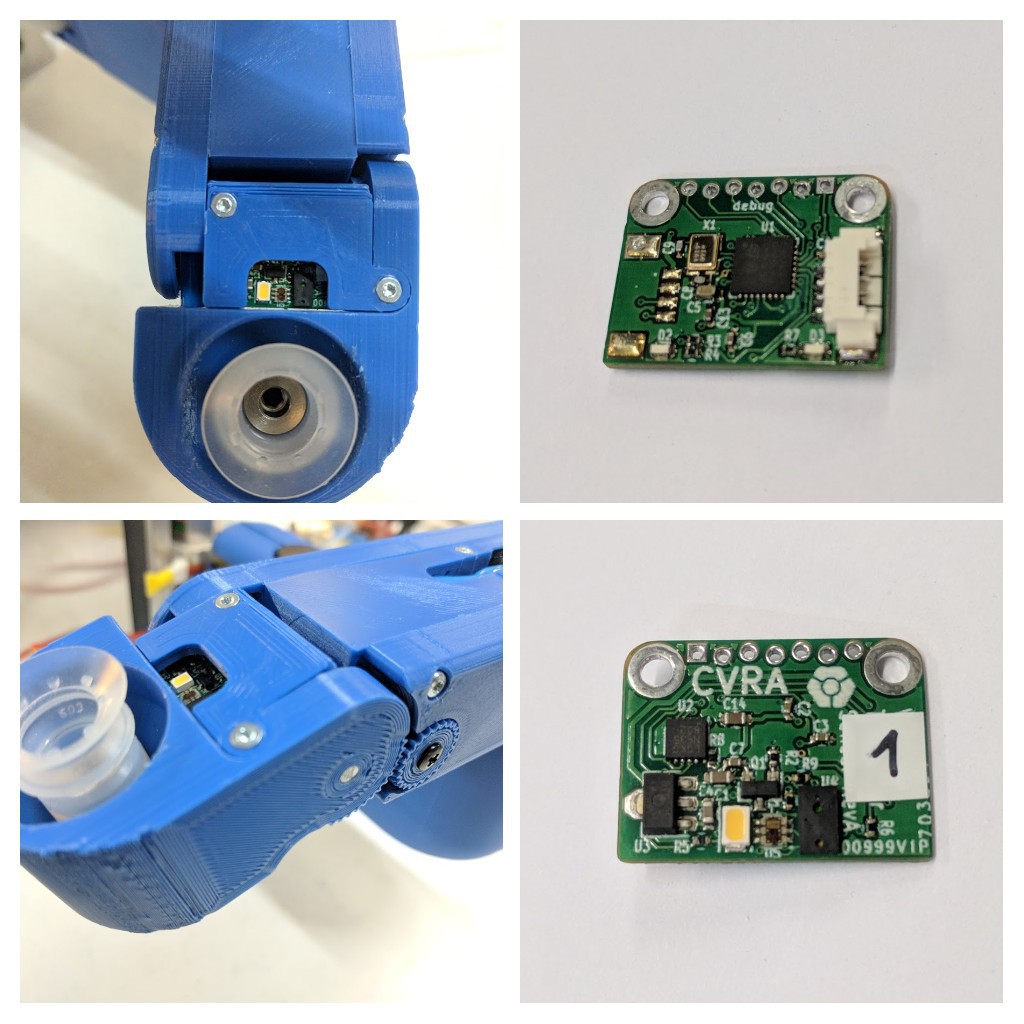

First use case of our new sensor board: we put one at the end of each arm.

The arm of the robot is used this year to build towers. These are made of 60mm cubes of different colors. We use this board to verify if cubes are picked up properly, and if the tower is build according to the plan.![]()

-

We need more sensors

06/04/2018 at 11:15 • 0 commentsMarch 2018.

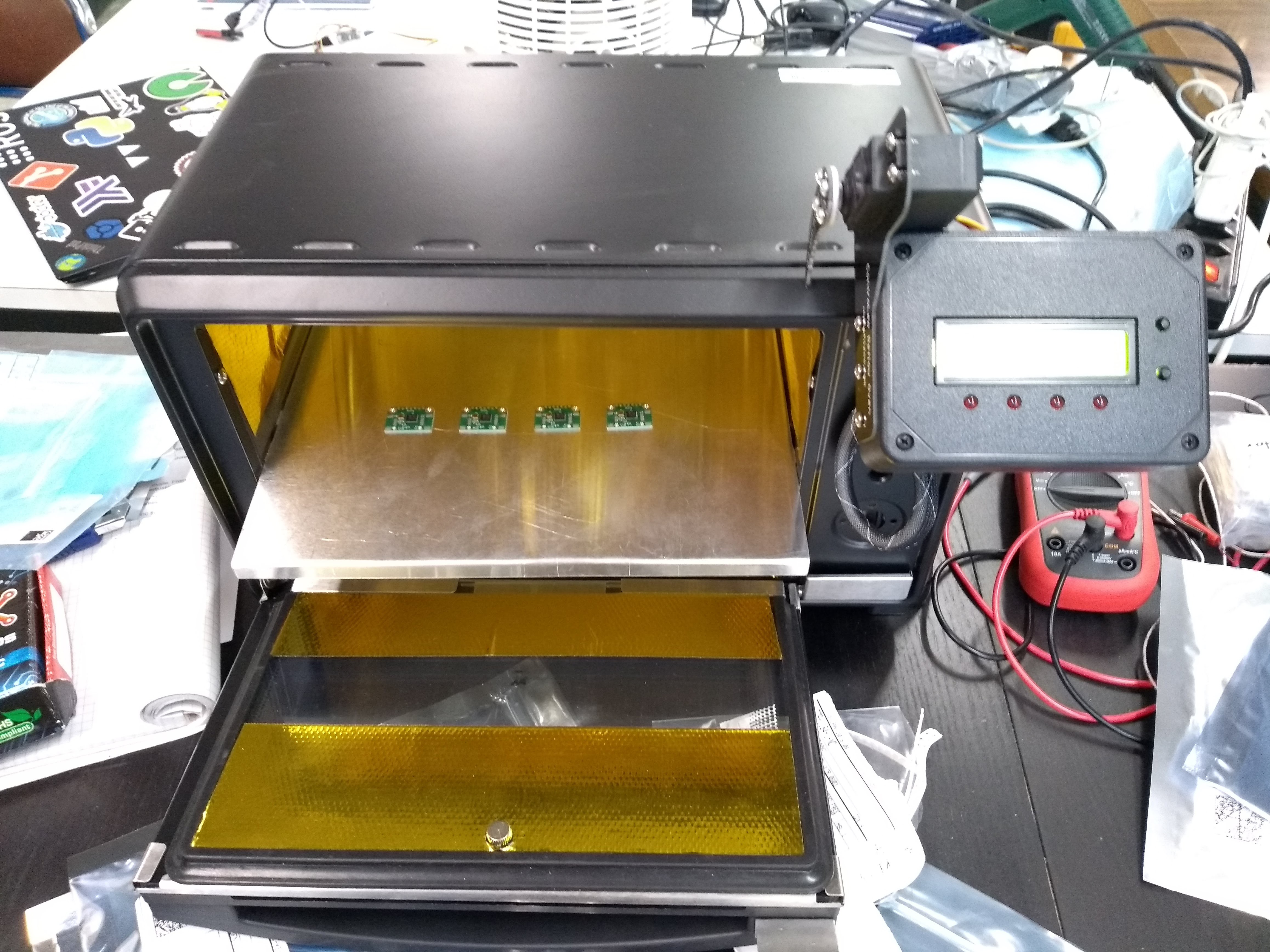

A new member to the family: sensor boards.

These are going to be useful for short distance measurement and RGB color detection.We made a small batch of 5 boards to start, and got to use our new modified toaster oven with a pre-programmed reflow profile.

![]()

![]()

-

Time for expansion

06/04/2018 at 11:08 • 0 commentsApril 2016.

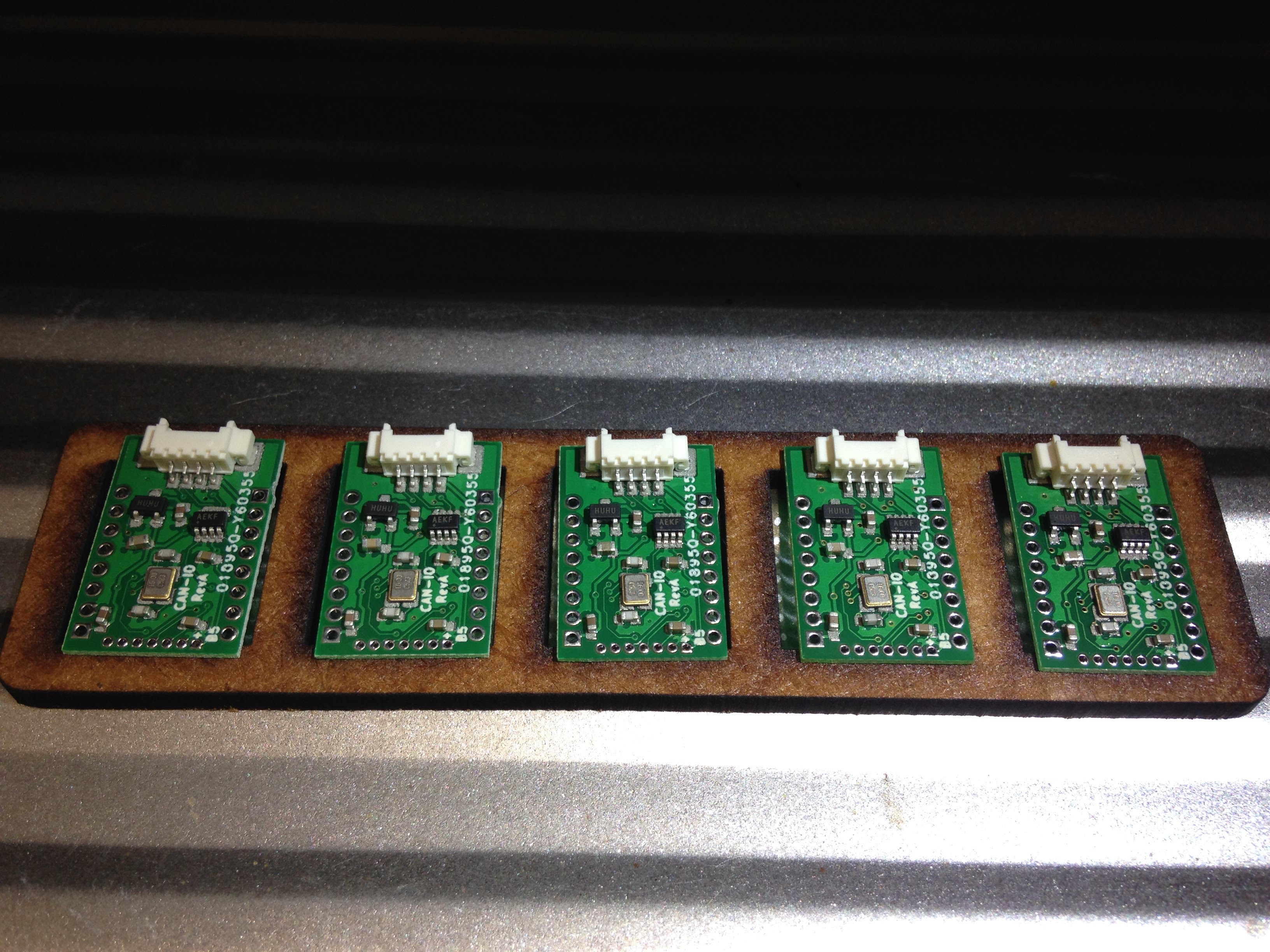

This year's new addition is an IO board. It's cheap, small, and connected, what else?

Don't they look great fresh out of the oven?

-

First robots with motor boards

06/04/2018 at 11:01 • 0 commentsJune 2015.

Wiring of the robots went well, although we had a lot of motors to wire.

If you didn't trust us when we told you the board fits on the back of an RC servo, here is a picture of the main robot's arm featuring three grippers each driven by a hobby RC servo modified using our motor boards.Our new modular robot concept won the jury award at the Swiss national competition.

-

Motor boards manufacturing

06/04/2018 at 10:57 • 0 commentsApril 2015.

The firmware is all done, or at least good enough for now.

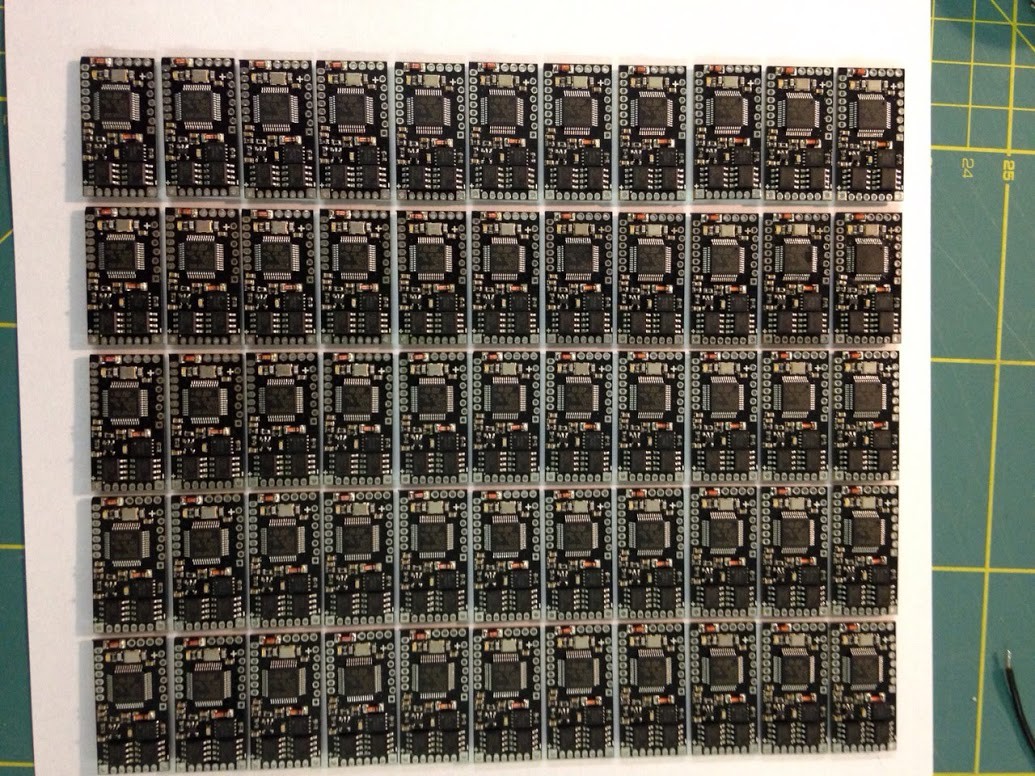

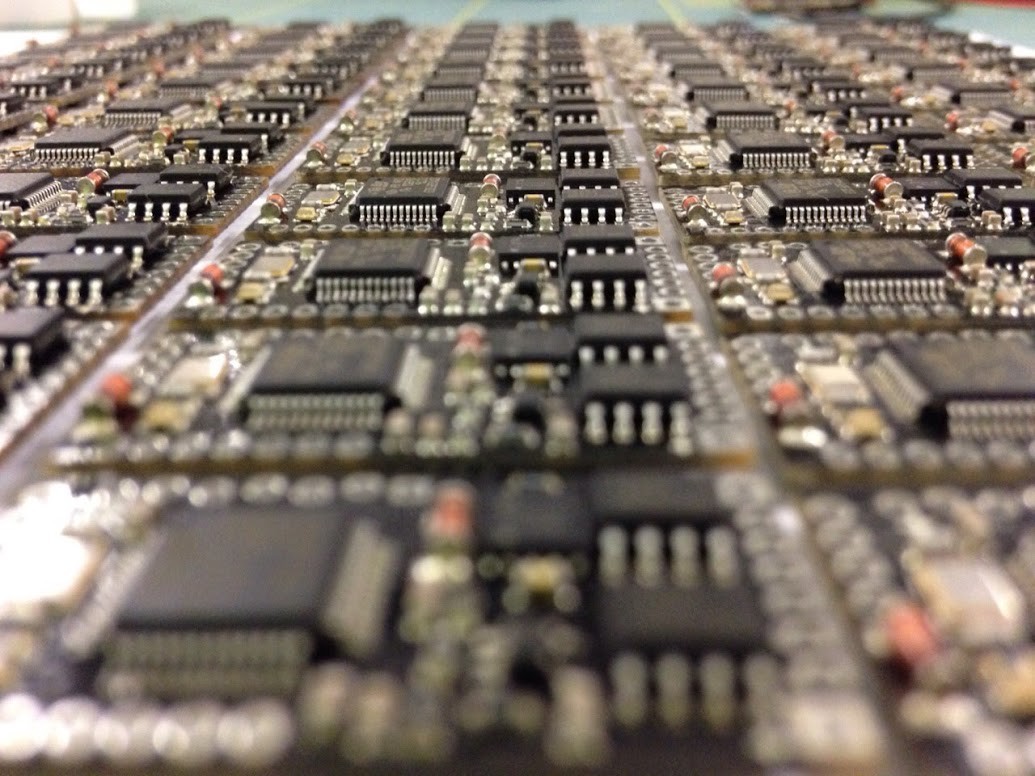

Four of our members spent 20 hours over a weekend to assemble the remaining 55 boards.We split tasks with one person testing boards, and the three others applying the solder paste on the boards using a stencil and placing the components on the board.

We turned this space into a Shenzhen factory.![]()

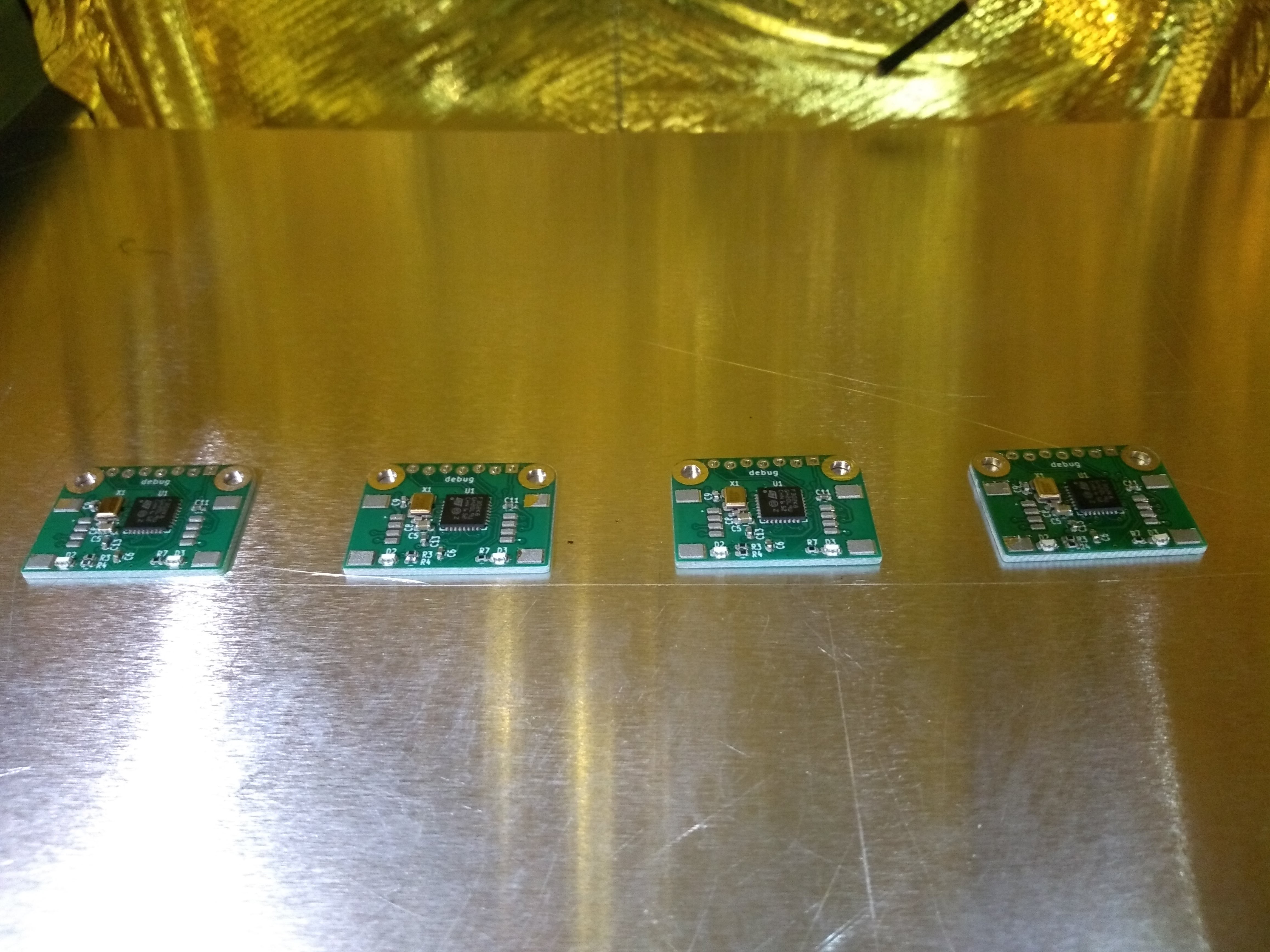

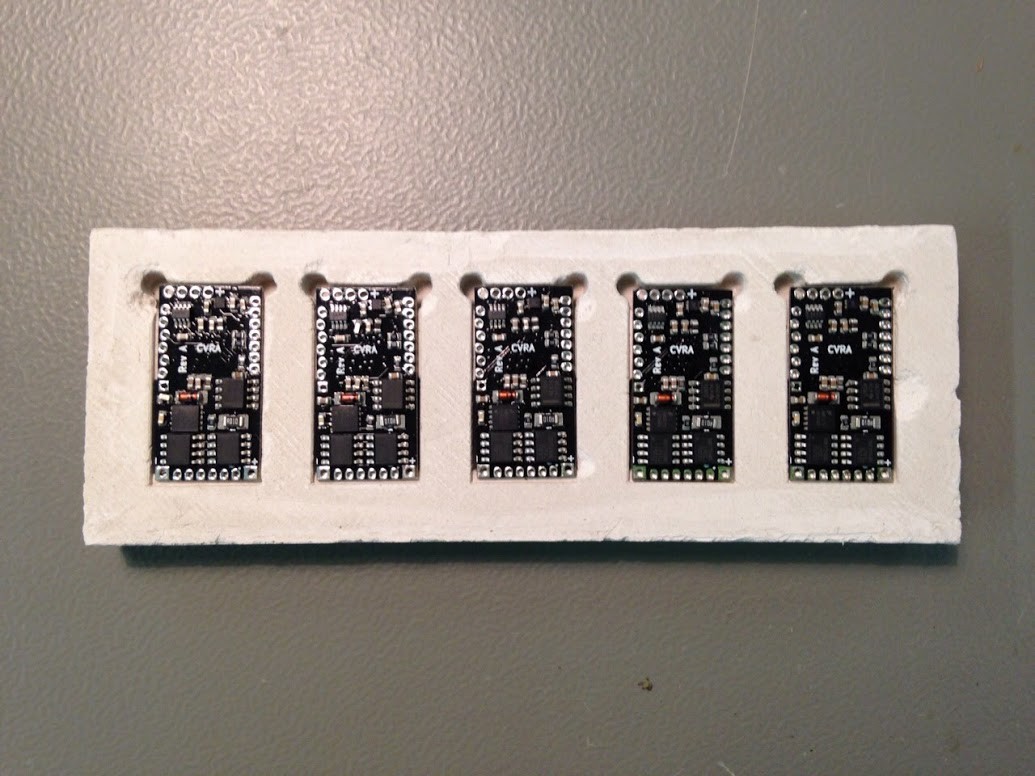

We made a board holder out of plaster so we could easily solder boards in batches of five in our toaster oven.

![]()

And here they are, fresh out of the oven, 55 motor boards soldered and tested.

![]()

Don't stare too much or you might get hypnotized!

![]() All 60 boards are done. Time to build robots!

All 60 boards are done. Time to build robots! -

Motor board design is done

06/04/2018 at 10:53 • 0 commentsJanuary 2015.

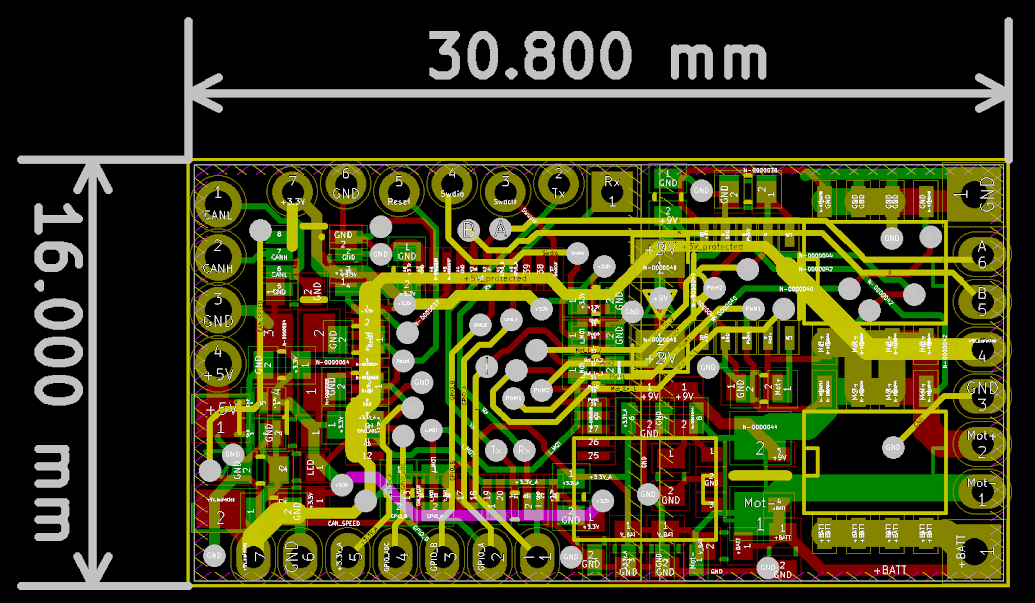

The board design is done!

It passed review, and we ordered 100 PCBs and components for assembling 60 boards. We only need about 40 boards for our two robots, but we need spares too, better safe than sorry.The final version is 30.8mm by 16.0mm and fits on the back of a big hobby RC servo.

![]()

Schematics, gerber files, and KiCad files are all available on Github.

CVRA's Robotics CAN Ecosystem

An open-source panoply of UAVCAN connected boards to enable smart sensors and actuators for modular robotics development

Salah Missri

Salah Missri

All 60 boards are done. Time to build robots!

All 60 boards are done. Time to build robots!