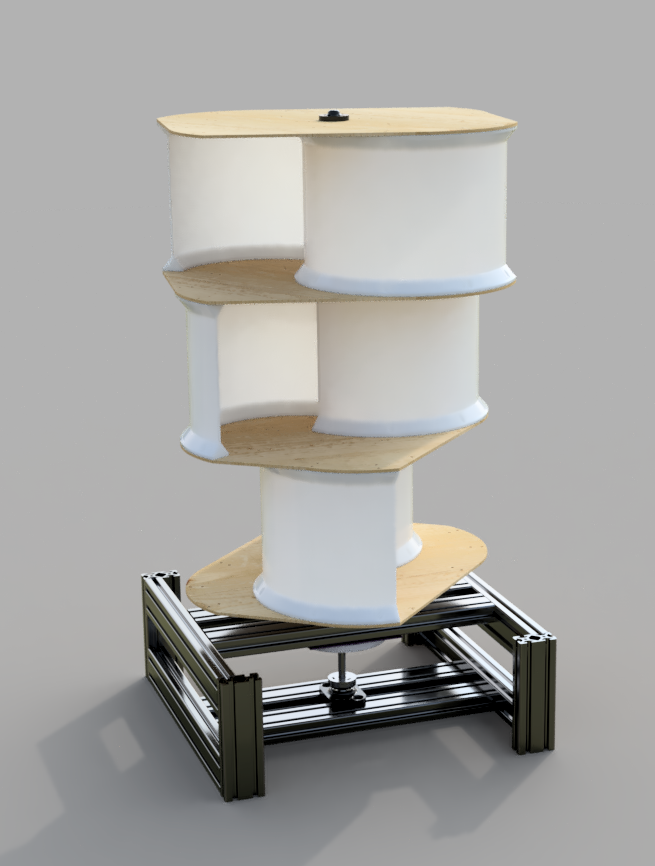

This has been the biggest project I've done yet with Fusion 360, and I've learned quite a lot.

- Always start each new document with "Create -> New Component". This lets you separate your model into pieces-- each with its own history-- and move them around separately.

- Copy and paste components to make multiple copies of a component. This allows you to make design changes to the original component, and have all the copies of it update automatically.

- Use the CAM tool to output profiles for laser cutting. That's what I did for the "plates" between the blades.

- McMaster Carr puts 3d models of their entire catalog online, which you can easily import into Fusion 360. This is amazing.

I still have a bunch to learn. When doing a design, do you put the nuts and bolts in, or is that too much detail? Should I be setting up joints?

Also, Fusion 360 has a really nice rendering engine:

Laen

Laen

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.