-

Inexpensive Proton Exchange Membranes

08/10/2018 at 19:38 • 0 commentsHere is a research update for the project

https://www.sciencedirect.com/science/article/pii/S2405653716300835 - super info

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4385132 cabon as electrode material

increasing surface area = increase mah output

terra cotta as a pem, it looks promising BUT there are many details that are not avail to do this as a DIY home project and in the efforts of OPEN and DIY I will stick with more avail materials

https://link.springer.com/article/10.1007%2Fs00449-013-0967-6

Study on Agar as a electolytic / PEM

https://aip.scitation.org/doi/10.1063/1.5029150

A BI POLAR membrane, two membranes in dual chamber with center transitional chamber

https://www.tandfonline.com/doi/full/10.1080/21553769.2016.1230787

-

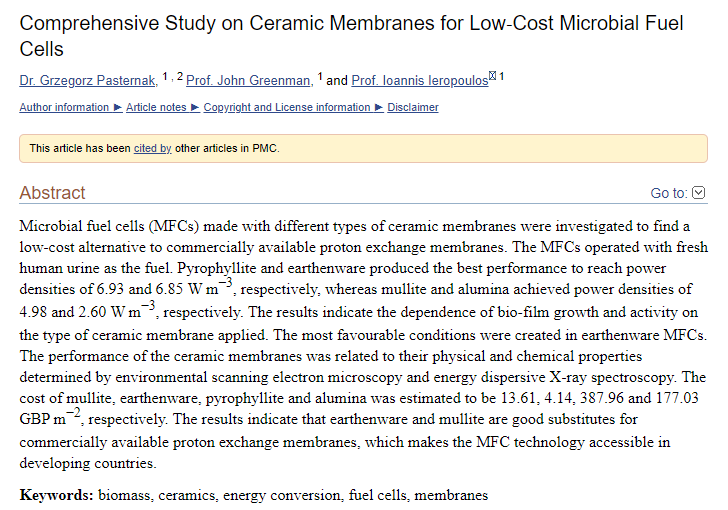

Hacking Low Cost Ceramic for Membranes in Fuel cells

08/04/2018 at 22:13 • 0 commentsSo I have been doing a bit of reading on various materials. There have been studies conducted on earthenware membranes. This was a clever suggestion from Mechanicus. Terra Cotta is one of these. Though I could spend lots of money on custom made film membranes, in the spirit of hackaday I need to HACK something that is both common , repeatable and effective. I believe earth based/ clay membranes would be much better as the cost is less than 10 percent that of a designer membrane from somewhere like fuelcellstore.com for example.

![]()

36 dollars plus tax for 11 sq ft of PEM / Cation Membrane material is a fantastically priced over the designer films

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4744959/

http://www.clays.org/journal/archive/volume%2012/12-1-397.pdf

![]()

![]()

![]()

![]()

![]()

![]()

![]()

https://www.hindawi.com/journals/tswj/2015/864568/ good article related to my setup

-

Tiny update, Researching the next cell design

08/01/2018 at 13:17 • 0 commentsNo building or design as been done at this time while another collaborator and myself research the logical next steps. We are coming up with options for Proton Exchange membranes. Namely what we would like to so is have a membrane that satisfies more than on need or a system that takes advantage of CO2 creating bacteria to feed the requirements of the micro algae on the other side of a cell. Some research must be done to determine is the electrode itself must be in plain view of light.

-

3 weeks Algae Growth

07/27/2018 at 01:19 • 0 comments![]()

A picture doesn’t do it justice because my phone keeps raising the contrast of the picture thinking it is too dark when the algae is centered in the frame. Without this significant brightness increase you can’t see the tubes inside the liquid. Shortly I will get a second Algae Container and Split the current sample I have so I can make a bigger setup in the future for version 2 of the semi permeable membrane upgrade to the design.

-

researching phase two, Permeable membrane use

07/24/2018 at 22:48 • 0 commentsIntroduction

Microbial fuel cell is the promising technology for clean power

generation and has gained lot of attention in recent years. Нe algae

obtained aіer MFC utilization can be further used for the production

of biodiesel, green diesel or bioethanol [1,2]. Complete utilization of

biomass is important for the transition to biofuels and bioeconomy [3].

Microbial fuel cell (MFC) consists of an anodic and a cathodic

chamber, separated by a proton exchange membrane (PEM). At anode,

organic compounds are oxidized by the microorganisms and electrons

move towards cathode through an external circuit and combine with

an electron acceptor (mainly oxygen) to generate electricity. At

cathode, oxygen is supplied continuously by aeration which is an

energy consuming process. In MFCs, mediators can accelerate the

process of electron transfer [4]. Recently, the concepts of MFCs have

been extended into dLوٴerent technologies such as Bio-Electrochemical

Systems (BESs) which produce numerous useful products such as

formate, [5] methane [6] and acetate [7]. Нe microbial desalination

cell is the most attractive option as this can be successfully

implemented for power generation, treatment of wastewater with the

simultaneous desalination of water [8]. MFCs can be used for the

production of hydrogen gas [9], powering environmental sensors and

digital wrist watch, charging a mobile phone, smartphone and LEDs

[10-13]. MFCs are also coupled with solar cells for power production

[14] which provides opportunities for utilizing solar energy in this

field. Future applications of MFCs may include their use in human

systems as well.

Utilization of microalgae in MFCs has gained interest as

phototrophic microalgae act as biocatholytes as the oxygen produced

by them serves as final electron acceptor, minimizing the energy

needed for the aeration at the cathode. Earlier work from author's

laboratory was reported on the H2 production from algae and its

utilization in carbon fuel cells for power generation [15]. Later work

involved the studies of the potential of power generation from algal

MFCs [2]. In the present study, potential of two strains of a green

colonial hydrocarbon (petroleum oil) rich microalga, Boryococcus

braunii, has been analyzed for its application in MFCs while

generating biomass for oil production. In these MFCs, green algal

strains have been used at the cathode as the source of photosynthetic

oxygen as electron acceptor, whereas sugar industry wastewater with

activated sludge, S. cerevisiae culture alone and S. cerevisiae with

supplementation of methylene blue (350 mg/L) was used at the anode.

НLs technology has great potential to couple the algal and yeast

biomass cultivation for the oil and bioethanol production, respectively,

along with wastewater treatment and power generation. Algal biomass

obtained from MFCs may be used for the production of biodiesel and

for bioethanol production through hydroliquefaction.Materials and Methods

Experimental organisms

Two strains of B. braunii, Udaisagar strain from Udaisagar lake,

Udaipur Rajasthan, India and Loktak strain from Loktak lake,

Manipur, India, were isolated by serial dilution method and plating on

the solLdLfied Chu-13 medium [16] which were grown and maintained

under controlled conditions in an incubator. Saccharomyces cerevisae

(Bakers's yeast), obtained from Indian Institute of Technology, Delhi,

New Delhi, India was revived by adding 1.3 gm yeast powder in 1 L

Sayed et al. medium [17] for 16 h at 27°C temperature in dark.

MFC design and operation

Нe MFC contained two chambers, an anode and a cathode, each of

250 ml capacity with 6.5 cm diameter and 12 cm length and with

electrode area of approximately 30 cm2

. Both the electrodes were made

up of carbon and separated by a proton exchange membrane (1afion).

A digital multimeter (Haqyue) was connected to the system for

continuous measurement of voltage (V) and current (I) at the external

load of 100 Ω. Peak values of current density (µA/cm2

) and power

density (µW/cm2

) were calculated from the values of V, I and A (area

of electrode). In MFCs under study, five sets of catholytes examined

separately with the two strains of B. braunii were

• Algal strains in Chu-13 medium;

• Algal strains in Chu-13 medium supplemented with 0.5 M NaCl;

• Algal strains in simulated sugar industry wastewater;

• Algal strains in simulated soap industry wastewater;

• Algal strains in simulated treated sewage water.

Whereas the three anolytes used were, S. cerevisae culture in Sayed

et al. medium [17]. S. cerevisae with 350 mg/L methylene blue (MB) as

mediator and sugar industry wastewater (198 ml) (obtained from

Saraswati Sugar Mills, Yamunanagar-135001, Haryana, India) with

activated sludge (22 ml) (obtained from the sewage treatment plant

Vasant Kunj, New Delhi, Delhi-110070, India). Нe experiment was

conducted in an incubator under controlled conditions of 27 ± 1°C

temperature, 1.2 ± 0.2 klux light intensity and 16L:8D light:dark cycle

to support microalgal growth and photosynthesis for 21 days which is

the best harvesting time for B. braunii strains.

Figure 1: Schematic diagram of the experimental set up of microbial

fuel cell with algal growth chamber as the cathode and yeast or

sugar industry wastewater with activated sludge as the anode.

Нe working volume of microbial cultures in both the chambers of

MFCs was 220 ml. During operation, the anodic chamber was covered

with a black paper to avoid any exposure of light to check the growth

of algae [18]. It was made anaerobic by sparging nitrogen gas before

the operation and connected to a conical flask filled with distilled

water through a rubber tube for the exhaustion of gases formed by the

microbial metabolic activities. Нe mouth of the cathodic chamber was

covered with a cotton plug to facilitate aeration. For both B. braunii

and S. cerevisae cultures, pH was adjusted to around 7 using 1 N KOH

and 1 N HCl, respectively. Нe schematic diagram of the experimental

set up has been shown in Figure 1.

Chemical Oxygen Demand (COD) Measurement

COD of the sugar industry wastewater sample in the anodic

compartment of MFC was measured on 1st and 21st days of the

experiment by APHA (American Public Health Association) standard

methods [19].

Simulated wastewater

Simulated treated sewage water and simulated sugar industry

wastewater were prepared in the laboratory as per the composition

devised by Poddar and Sahu; Yoshioka et al., Yadav et al., Yetis et al.

[20-23]. Simulated soap industry wastewater was prepared aіer

analyzing the wastewater obtained from soap industry. Calcium,

magnesium and nitrogen were analyzed by EDTA titrimetric method

and semi-micro-kjeldahl method, respectively [19]. Phosphorus was

analyzed by Olsen's method [24]. Amount of glycerol was added on the

basis of the composition given by Israel et al. [25].

Results and Discussion

Earlier work in the author's laboratory was performed on the

successful utilization of urine for the generation of power through

microbial fuel cell [26]. However, presently it was decided to utilize

algae along with sugar and soap industry wastewater in MFCs. Driving

aim was to study the use of B. braunii in algal MFCs, boost the growth

of algae by utilizing industrial wastewater, to treat the sugar industry

wastewater in MFCs, utilize the algae for production of biofuels aіer

its growth in MFCs and above all avoiding the use of costly hydrogen

in the fuel cells. Two strains of B. braunii biomass in the cathodic

compartment of the microbial fuel cells in five dLوٴerent media (Figure

2) were coupled with the three types of anolytes.

6LgnLficant results of voltage, power and current densities were

obtained with all the combinations of catholytes and anolytes (Tables 1

and 2) in MFCs and the best results were obtained with S. cerevisae

supplemented with the mediator methylene blue as the anolyte in

combination with the five catholy -

Test unit charging a phone!

07/16/2018 at 15:39 • 0 commentsThere are 8 cells I setup as proof of concept. I still needed more materials and cellophane as a permeable membrane to allow ions and oxygen CO2 exchange between half cells. When I qualify for the next round I will upgrade the setup with more appropriate materials and stuff

-

Algae Cultivation at 9 days and ready to res-pirate

07/14/2018 at 19:13 • 0 commentsThe algae is getting darker, almost too dark to see even the air hoses or pump inside. Another day and it will be pumping through the microbial fuel cell setup. :)

![]()

-

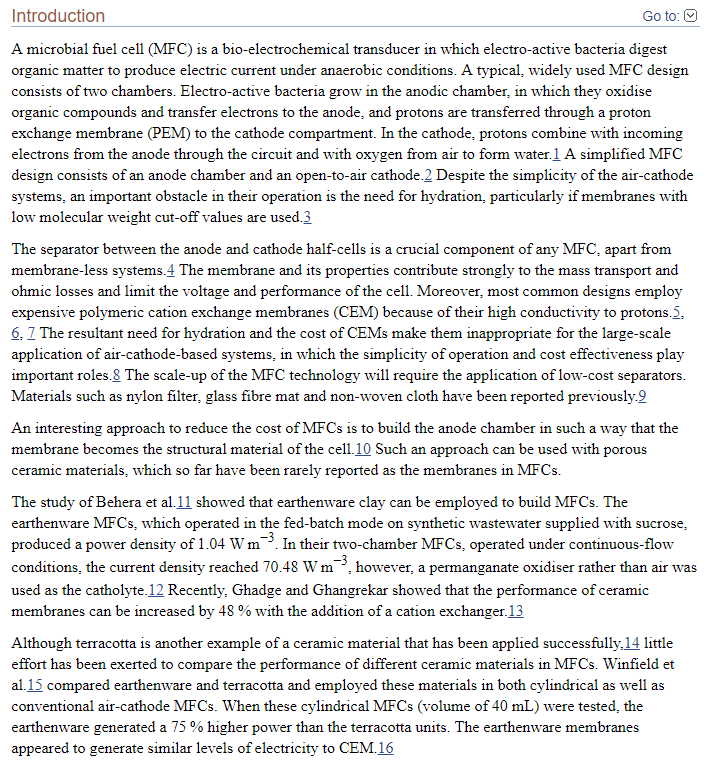

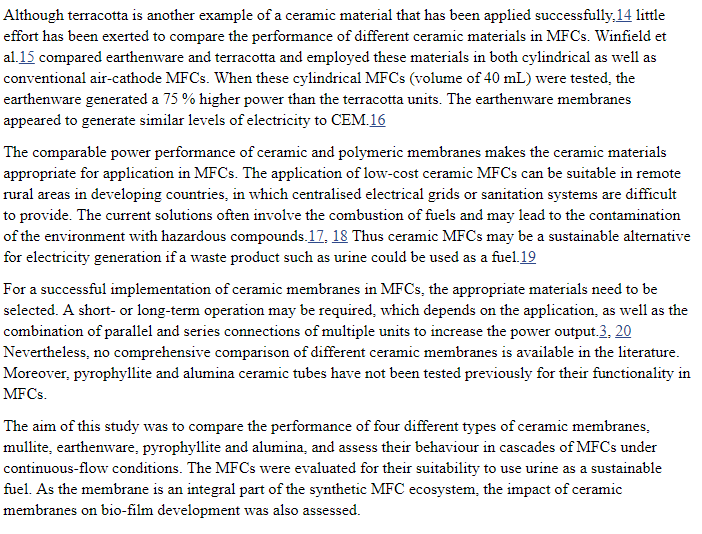

24 Cells Plumbed Bacteria / Algae Respirator

07/14/2018 at 16:28 • 0 commentsThis is the actual setup I plan on building tomorrow on my day off so it can be demonstrated on video for the hackaday project submission. This is version 1. Version 2 will use a Selectively permeable membrane to allow the electrons and oxygen / Co2 exchange through the membrane only carrying the ions from cathode to the anode.

![]()

![]()

![]()

-

salt bridge test 1.7 volts, Yeah !!

07/13/2018 at 15:13 • 0 commentsTesting out the gel salt bridge , it functioned great but then the gell started melting. Sad times. I may do a rope . fabric salt bridge as a replacement. 1.7 volts while the salt bridge was intact. :)

-

Comparison My Cell versus Their Cell

07/13/2018 at 15:10 • 0 commentsNot my video , but I wanted a direct comparison to other types of microbial fuel cells out there. This little guy produces .200 volts or 200 mv , which is not enough to power much as far as voltage goes , but if he made several cells and scaled them he could power an led perhaps. SO FAR with only a half cell we are getting 5 times with microbial cells voltage. When I tested both cells with a salt bridge I get 1.7 volts which is 8-9 times the voltage. Also the amount of volume required is about 1/10 this , so that could be a good thing.

Phytoplankton Power ! - Hybrid Microbial Fuel Cell

Turn home wastes like food scraps into sustainable electricity production. Using Anaerobic Nitrifying bacteria, Photoplankton and the sun!

Josh Starnes

Josh Starnes