-

Heat and volt test on cloudy day noon

07/27/2018 at 17:15 • 0 comments.928 volts half submerged in water on a 85 degree day at 1 pm , cloudy. Highest temp today I read at the center was 54 degrees C about 127 degree Fahrenheit.

![]()

-

Testing under heatlamps

07/26/2018 at 01:52 • 0 comments![]()

I put two 500 watt halogen directly in front of the solar collector. It hit a temperature high enough to scald you if you touched the black plate a couple seconds.

I need to buy a new meter since mine got rained on so I can check the voltage and amperes.

-

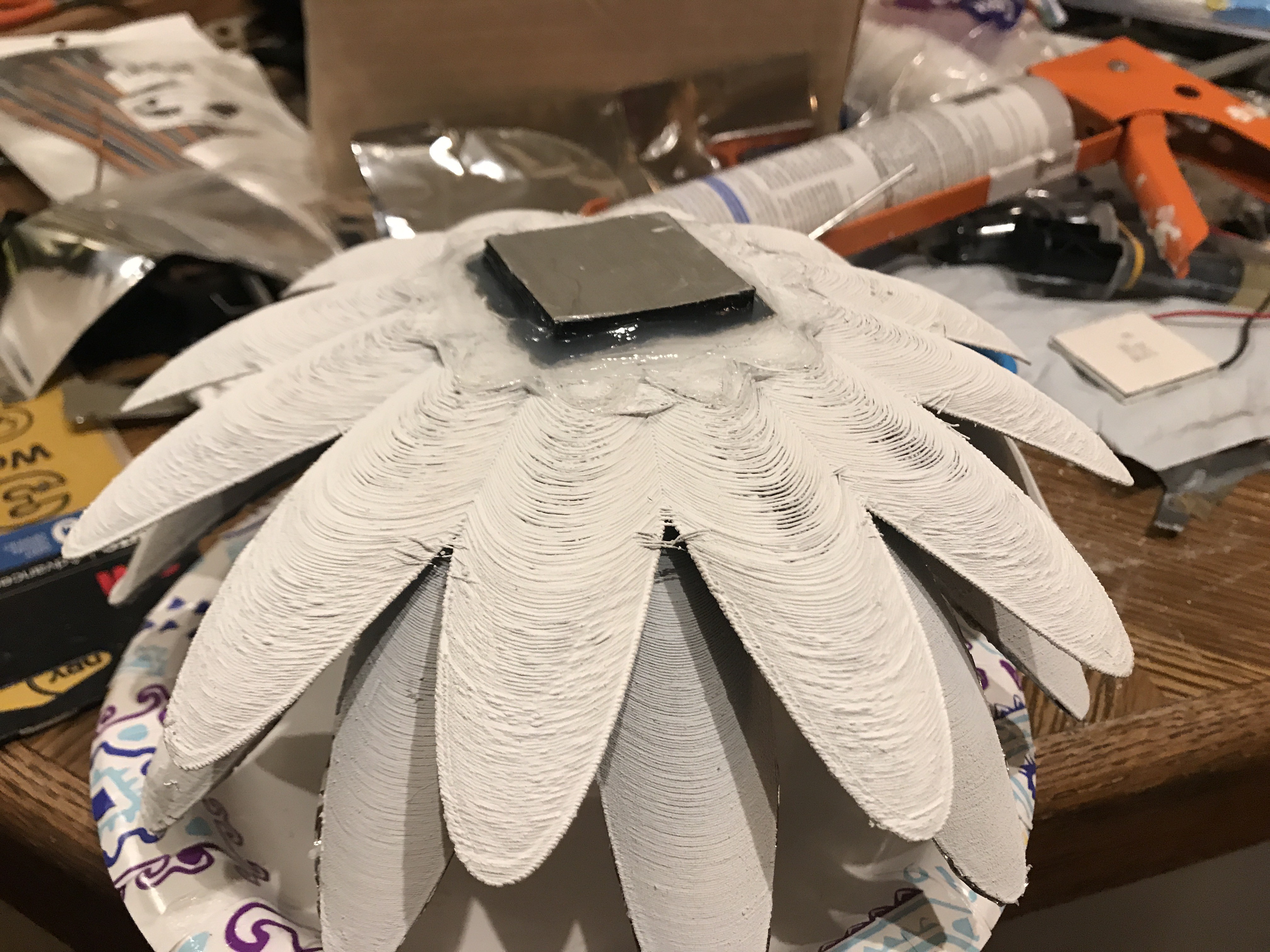

Finishing up

07/25/2018 at 14:55 • 0 commentsOk so the TEG module has been adhered using thermal adhesive. Then sealed up with 100 percent silicon all the way around. All that is left is to get a foam disc from hobby lobby. Paint green , cut the hole for the heatsink to drop through and the floating heat collector will be operational as intended!

![]()

![]()

![]()

-

Mounting Cold Side Heat Pipe Heatsinks

07/25/2018 at 02:44 • 0 comments![]()

![]()

![]()

![]()

-

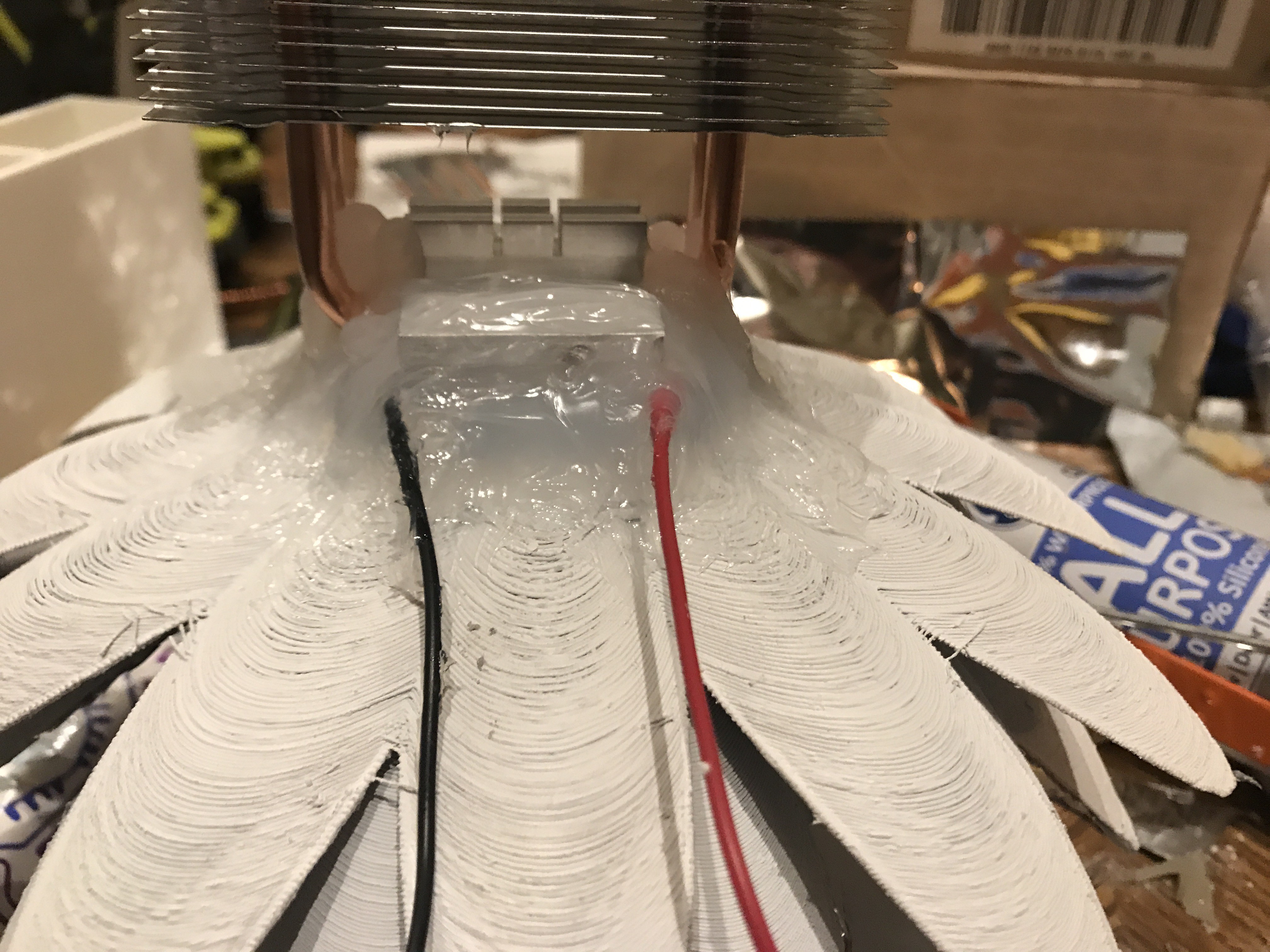

Installing the TEG

07/25/2018 at 02:42 • 0 comments![]()

![]()

the heat transfer tower is siliconed in place filling the gaps around the metal

-

Heat collector painted and siliconed

07/25/2018 at 02:39 • 0 comments![]()

![]()

-

Upside down collector and heatsink

07/24/2018 at 13:16 • 0 comments![]()

![]()

-

Building the thermal transition tower

07/24/2018 at 13:05 • 0 comments![]()

![]()

![]()

![]()

-

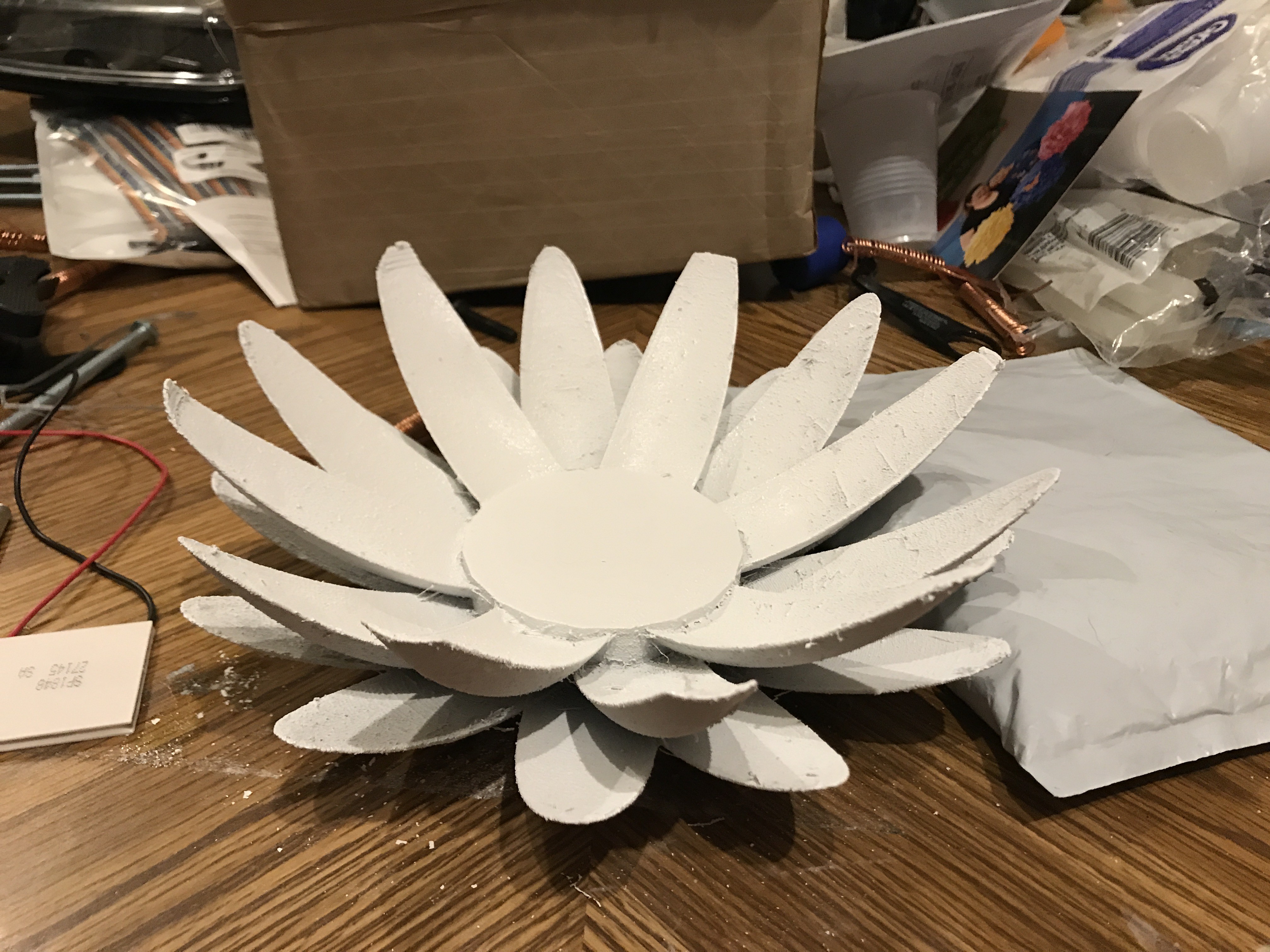

Cutting out thermal collector base

07/24/2018 at 13:02 • 0 comments![]()

![]()

-

Painted prototype with reflectors

07/24/2018 at 02:45 • 0 commentsOk update on ongoing progress, the reflection Mylar film is glued to the petals. I am disappointed that in pictures it looks like tin foil, but this is because the Mylar has zero give to stretch into place to smooth and wrinkles. I think this would work much better with reflective window film because it can be formed and has ah adhesive layer as well. Anyways functionally the wrinkles should not make any difference at all.

![]()

![]()

![]()

![]()

Lily Power Pods, TEG + Concentrated Solar

Thermal Electric Generator from concentrated solar, designed to float in water, small scale power anywhere in the world.

Josh Starnes

Josh Starnes