-

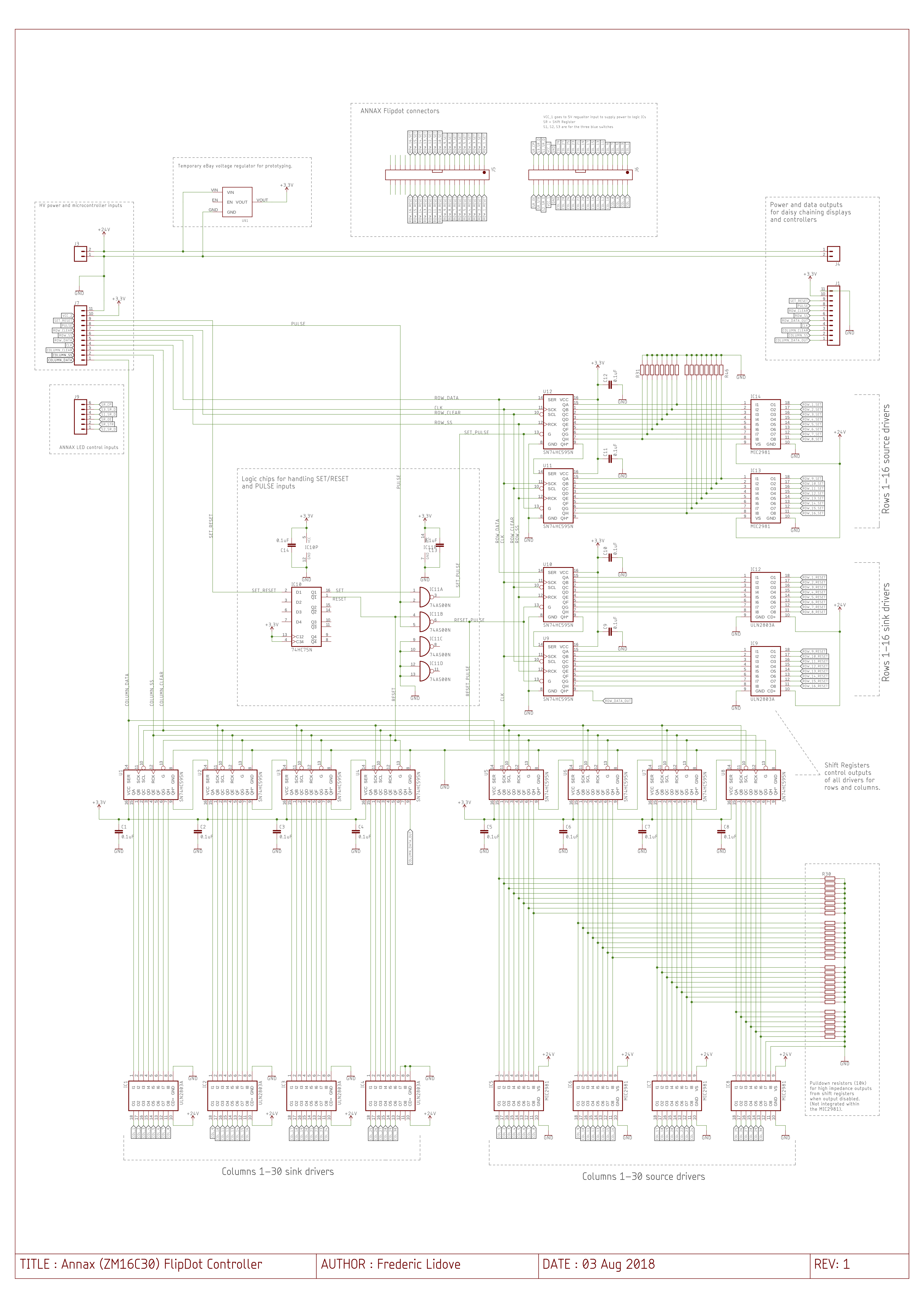

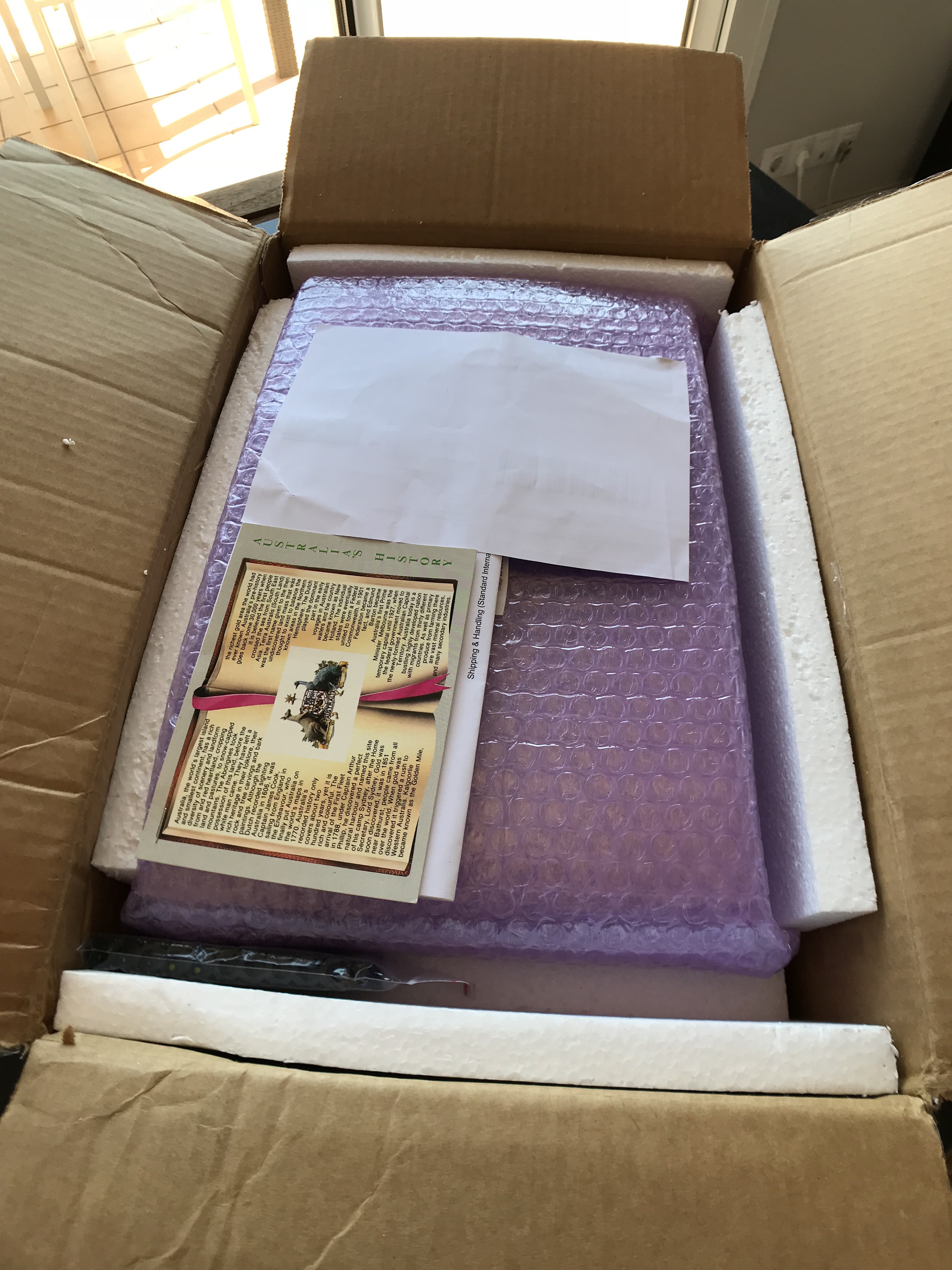

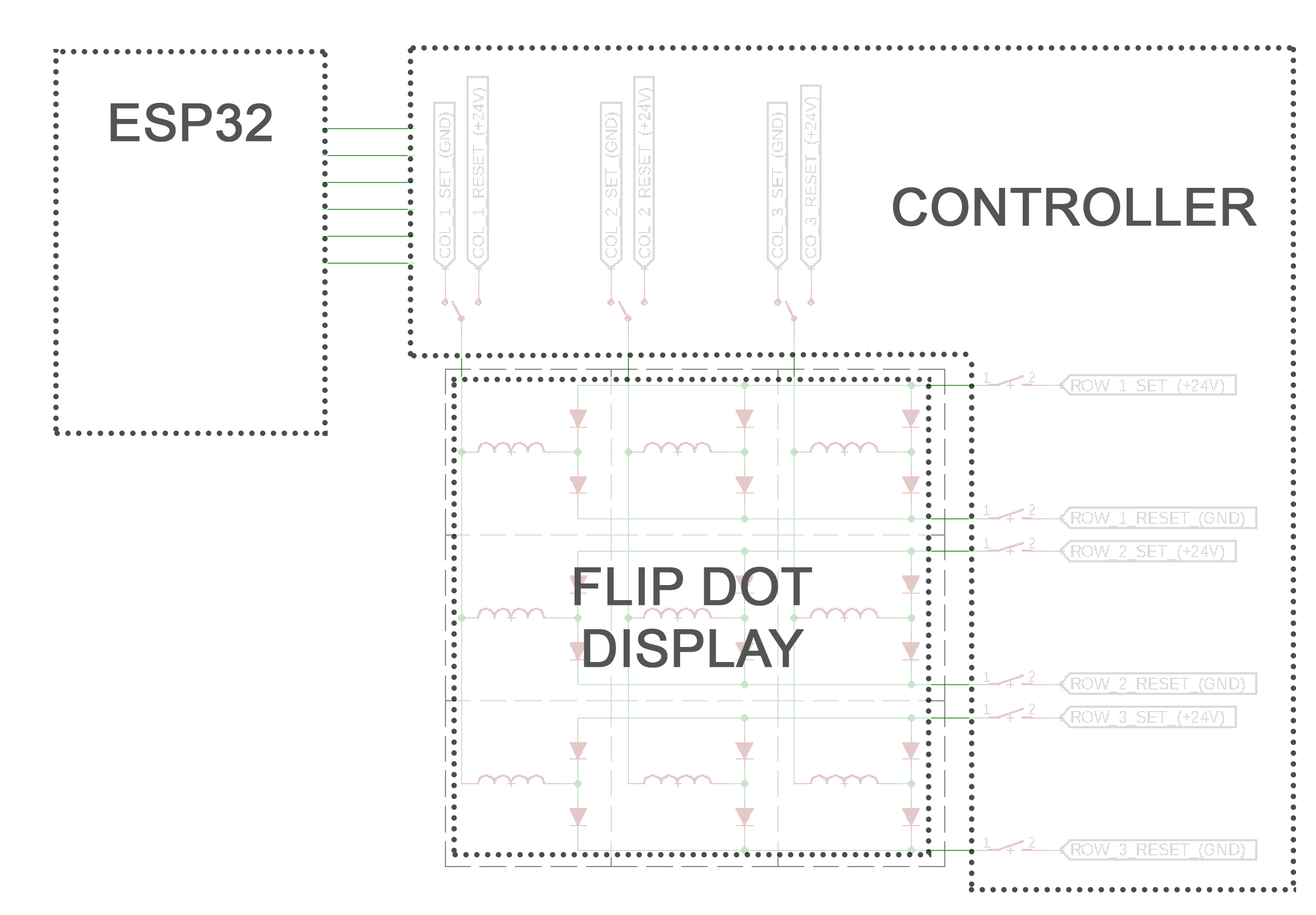

Controller prototype schematic !

08/03/2018 at 09:49 • 0 commentsFinally ! Here comes my strategy to control the flipdot display. This is the control board prototype, and drives ONE display. Each display will have it's own control board and can be daisy chained (ie, only one micro controller needed and it will control all the displays stacked together.

It's still a prototype as I'm not sure it will work (it would be too good if it worked at first try). Also I still have to design the power supply for the board logic chips. For now I'm using a cheap eBay switching voltage regulator to provide 3.3V or 5V to the ICs from the 24V supply, but this will be integrated in the design in the final version. The ESP32 being 3.3V and the chips on the display being 5V, I'll have to do some level shifting in the final design (I keep this for later once I'm sure it works).

I tried to annotate as much as I could to help follow the logic of the board, but next log will go more in depth into the chosen ICs and describe the overall functioning.

Available in PDF version for higher quality.

![]()

-

In depth ANNAX layout and design

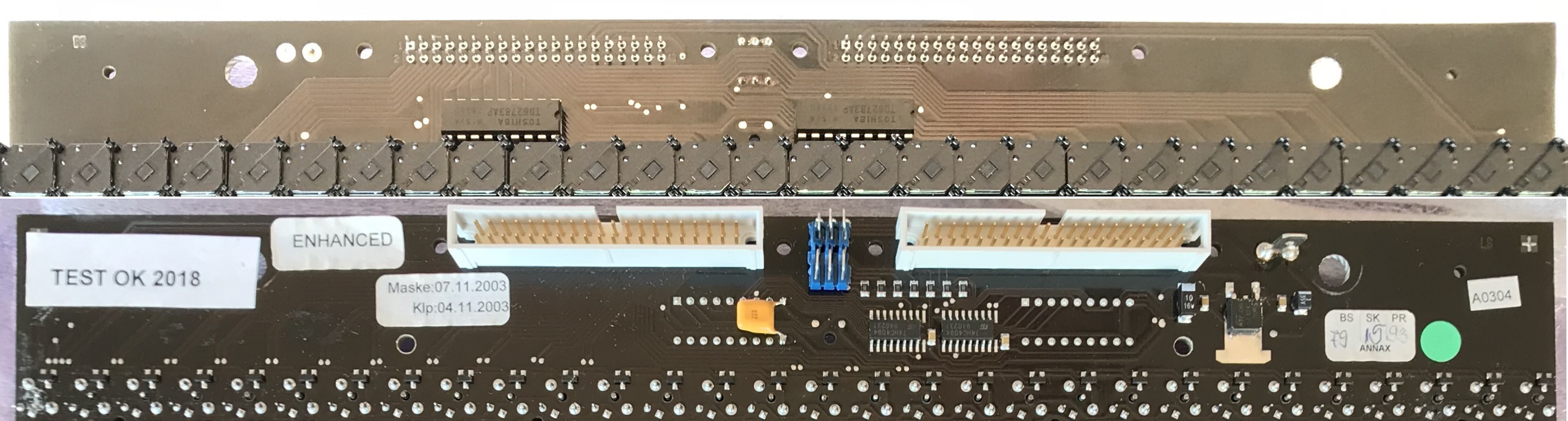

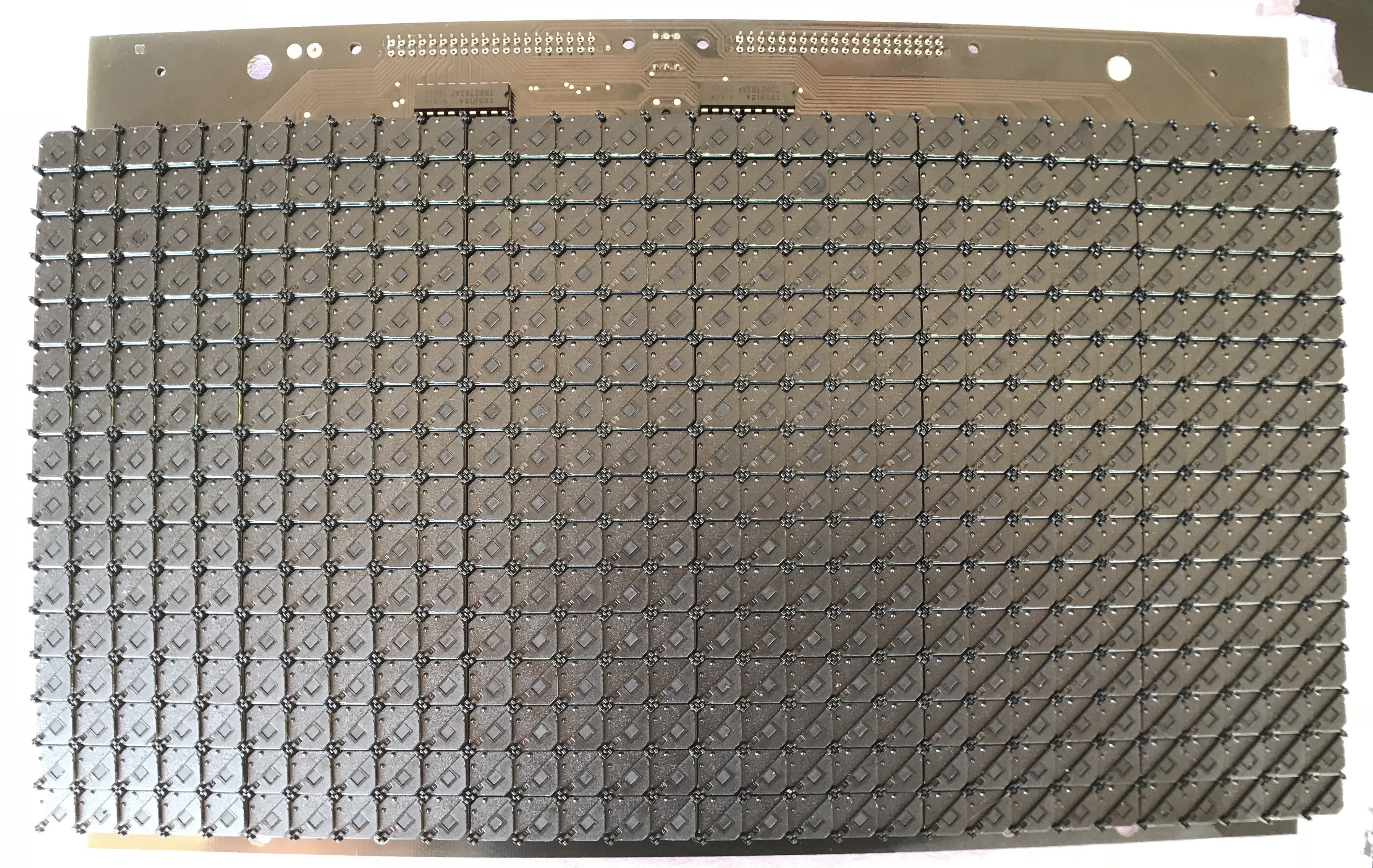

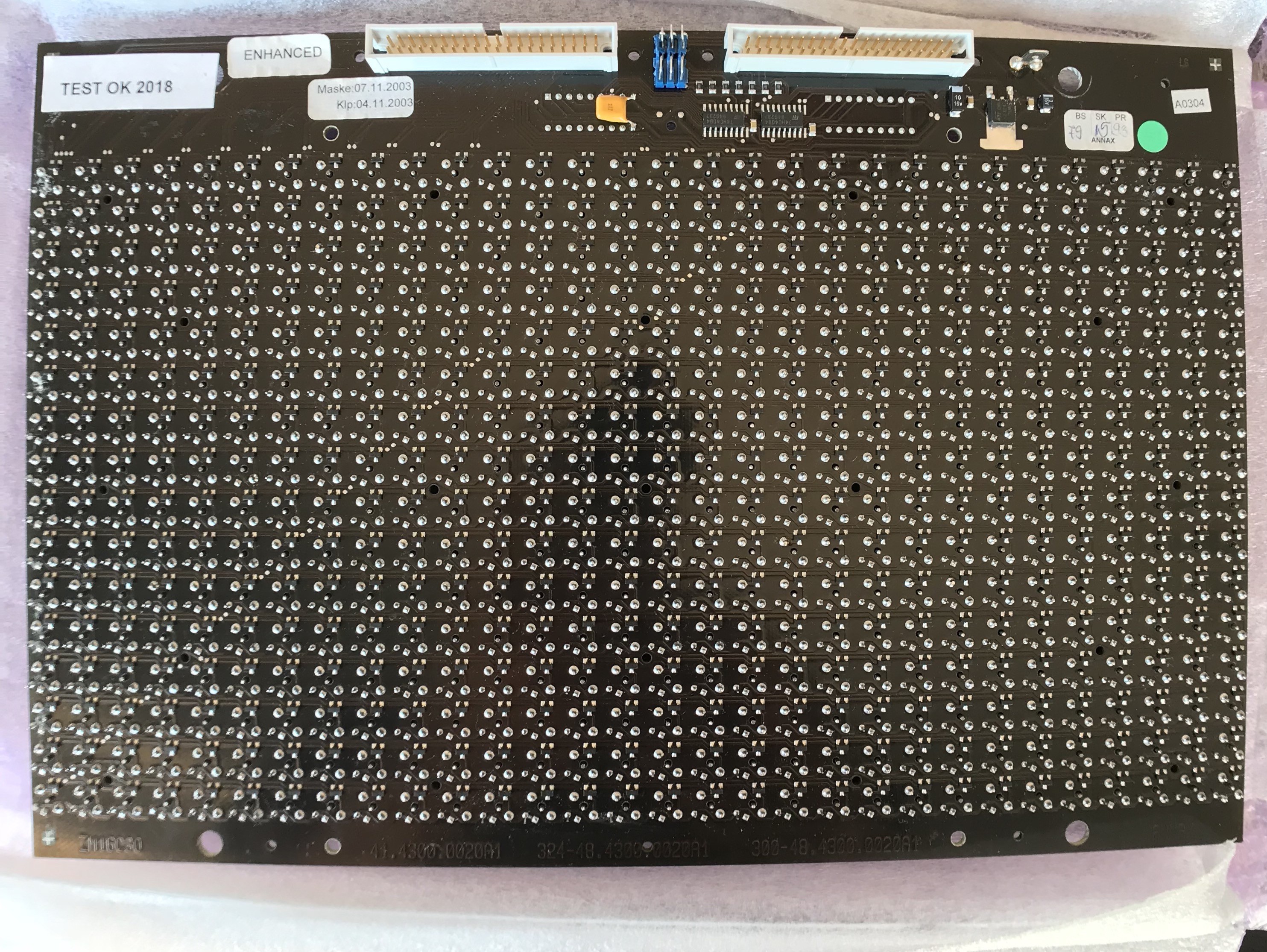

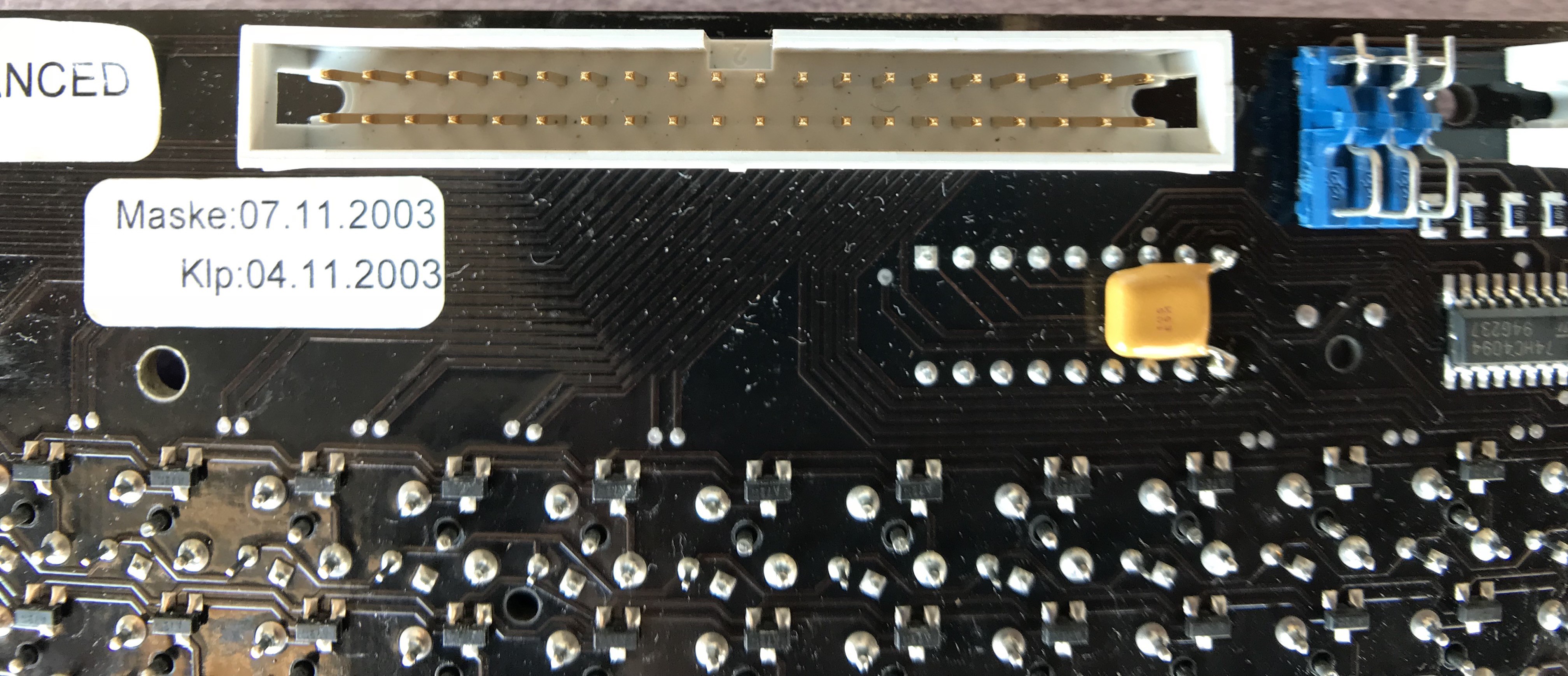

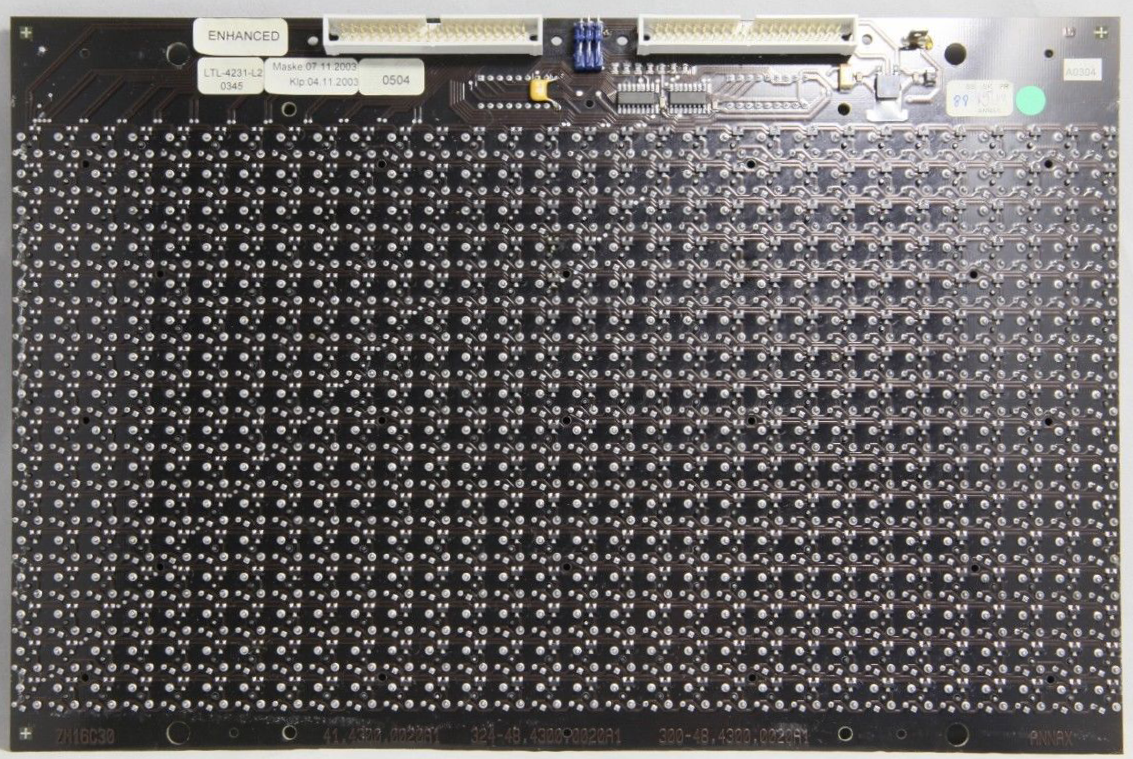

07/29/2018 at 08:20 • 1 commentI had a few hours to spare yesterday, so I pulled out my multimeter and started figuring out the board layout (reverse engineering to sound fancy). I won't go over the matrix layout as it has been covered in a previous log, but I will describe the top part of the front and back board and my findings regarding the pins of the two connectors. Here is a global view of the front and back top part.

![]()

There isn't much to it, and you'll see that the few ICs on there are for driving the LEDs only. The flip dots on the other hand, are connected to the pins of the two connectors at the very top.

The front part is pretty empty, and not much to say besides the two TOSHIBA TD62783AP 8 Channels Source Driver.These will source current for the LEDs for all 16 (2x8) rows.

![]()

We can also notice the trace routing going from the left connector (when looking at the front of the display) to each column. This is indeed the columns lines that will either source or sink current according to whether we set or reset the pixels.

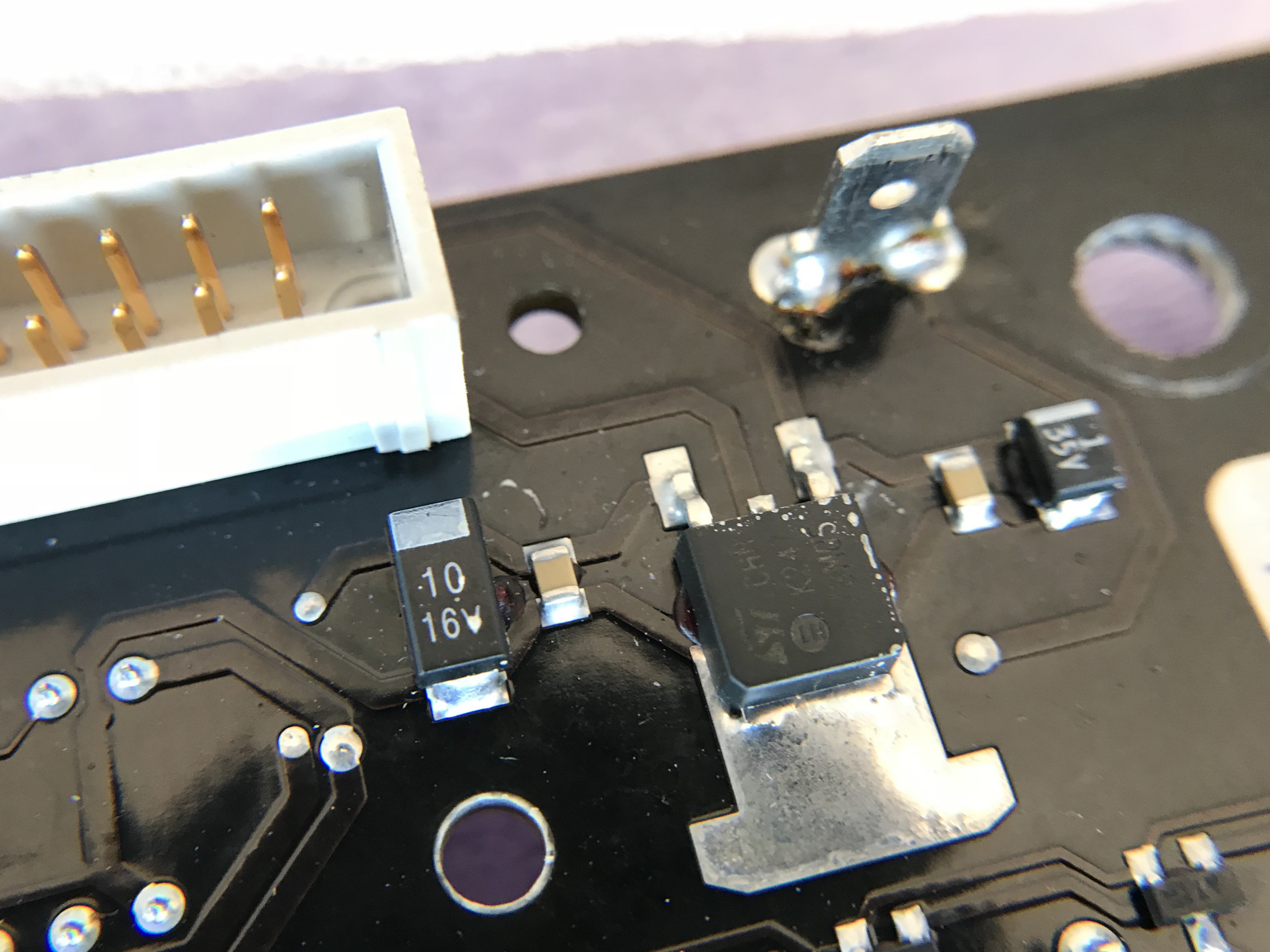

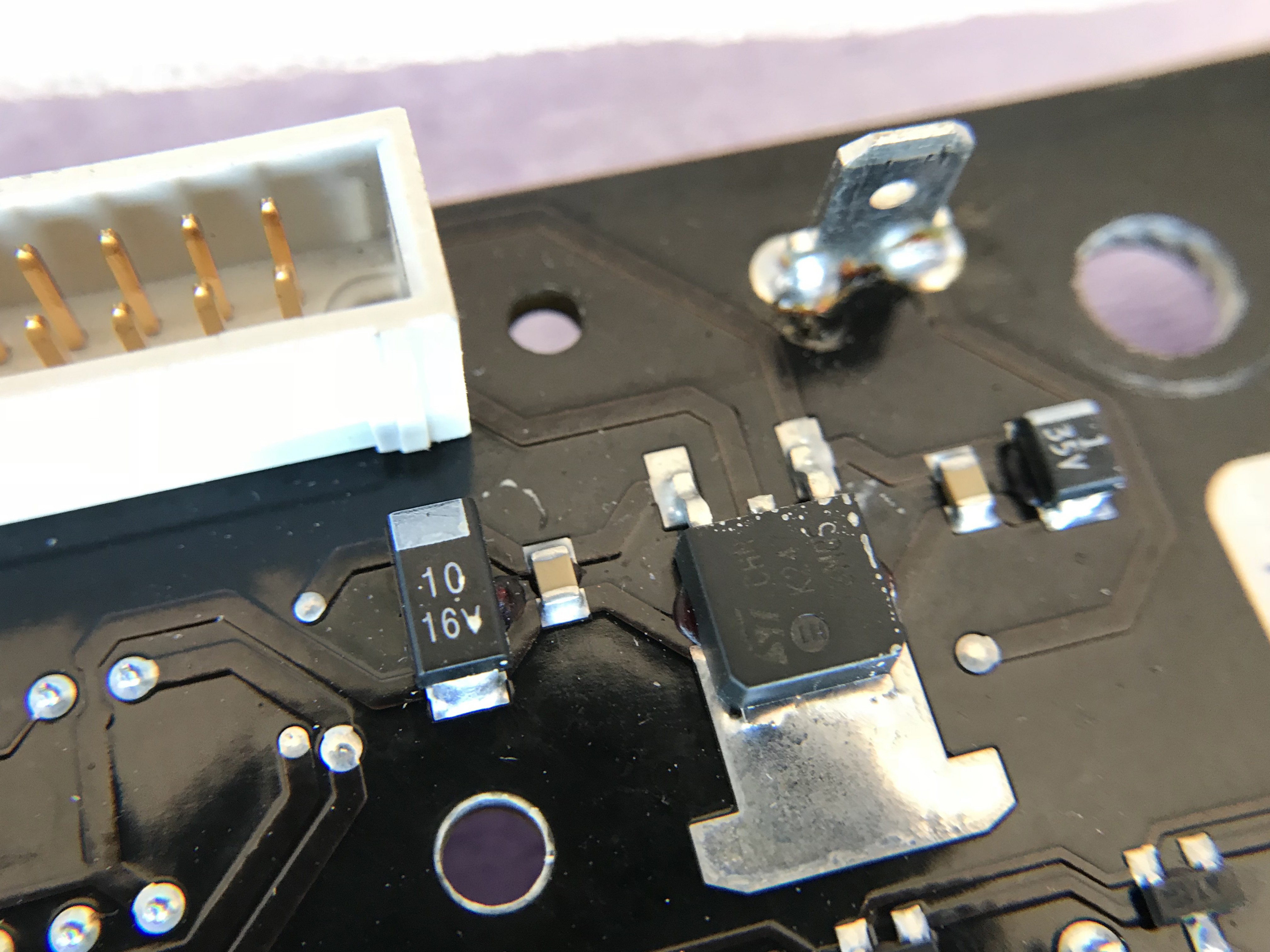

The back part is more interesting. From right to left :

On the top right you see a tab connector. This one is for the LEDs power source, as its line goes directly to the two TD62783AP pin 9 (VCC) mentioned above.

Below it is an L78M05 voltage regulator. It takes power from the 40pin connector, regulates it to 5V and powers the other ICs on the board. The few caps around are quite common on power supplies, mainly for decoupling.

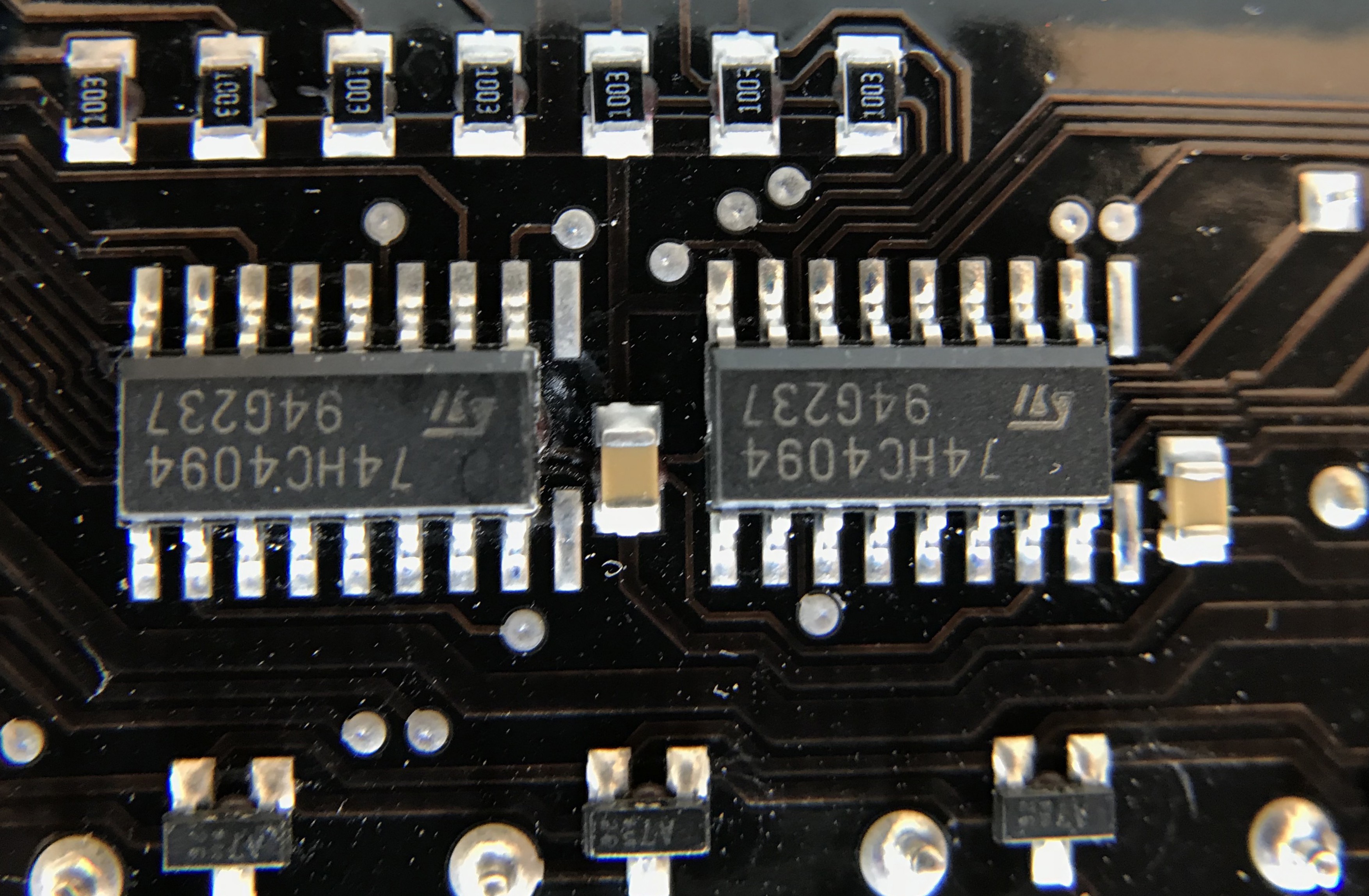

Next come the two 74HC4094 shift registers. Those are controlled from some pins on the 40 pins connectors, and their outputs go directly to the Toshiba source driver on the front. Together they control the LEDs power on each of the 16 rows.

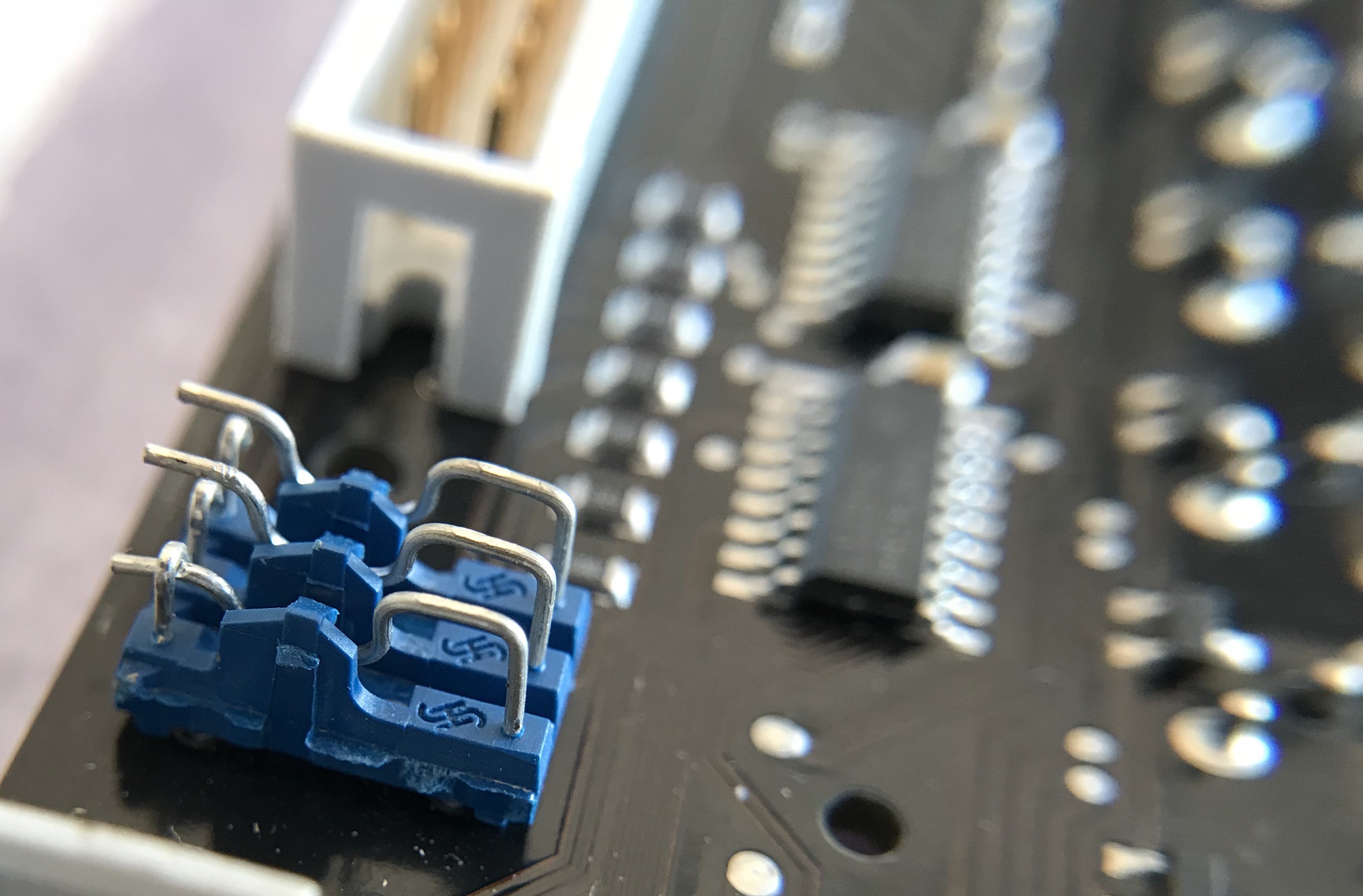

The blue thing here are three switches. On the photo you can see switch 1 is closed (the left lug goes below the hook, making contact), whereas the other two are open. Each switch connects one different pin of the 40 pin connector to the DATA (D line, PIN 2) of the first shift register (the second shift register gets it's data from the output of the first shift register. My belief here is that those switches allow to selectively control several displays LEDs with different data lines.

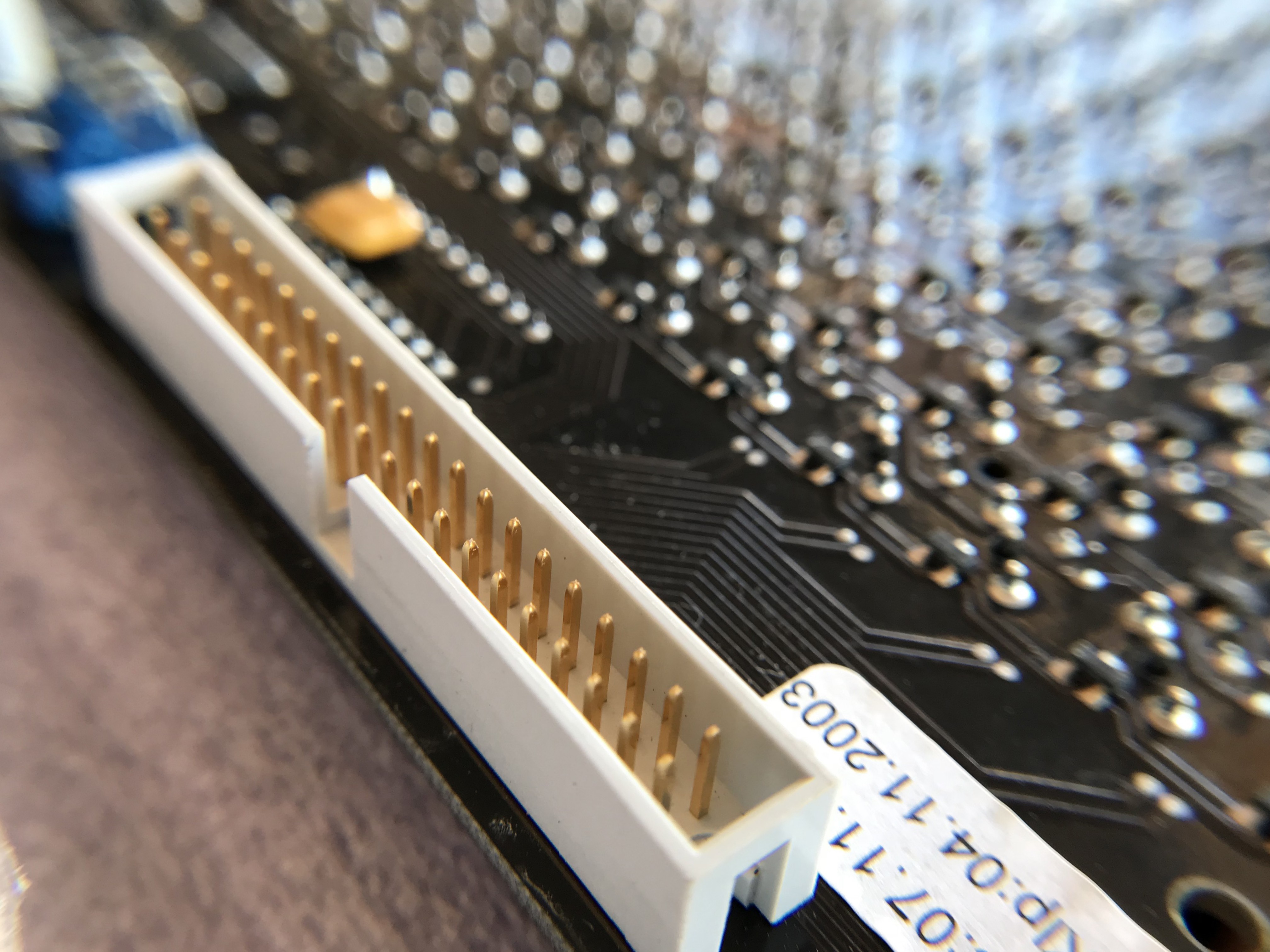

Finally, the most important and interesting part for the controller, are the two 0.1" pitch IDC 40-pins connectors.And here are what each pin is for :

![]()

This view is as seen from the back of the board, ie. pins going towards us.

From there, let's make a controller.

-

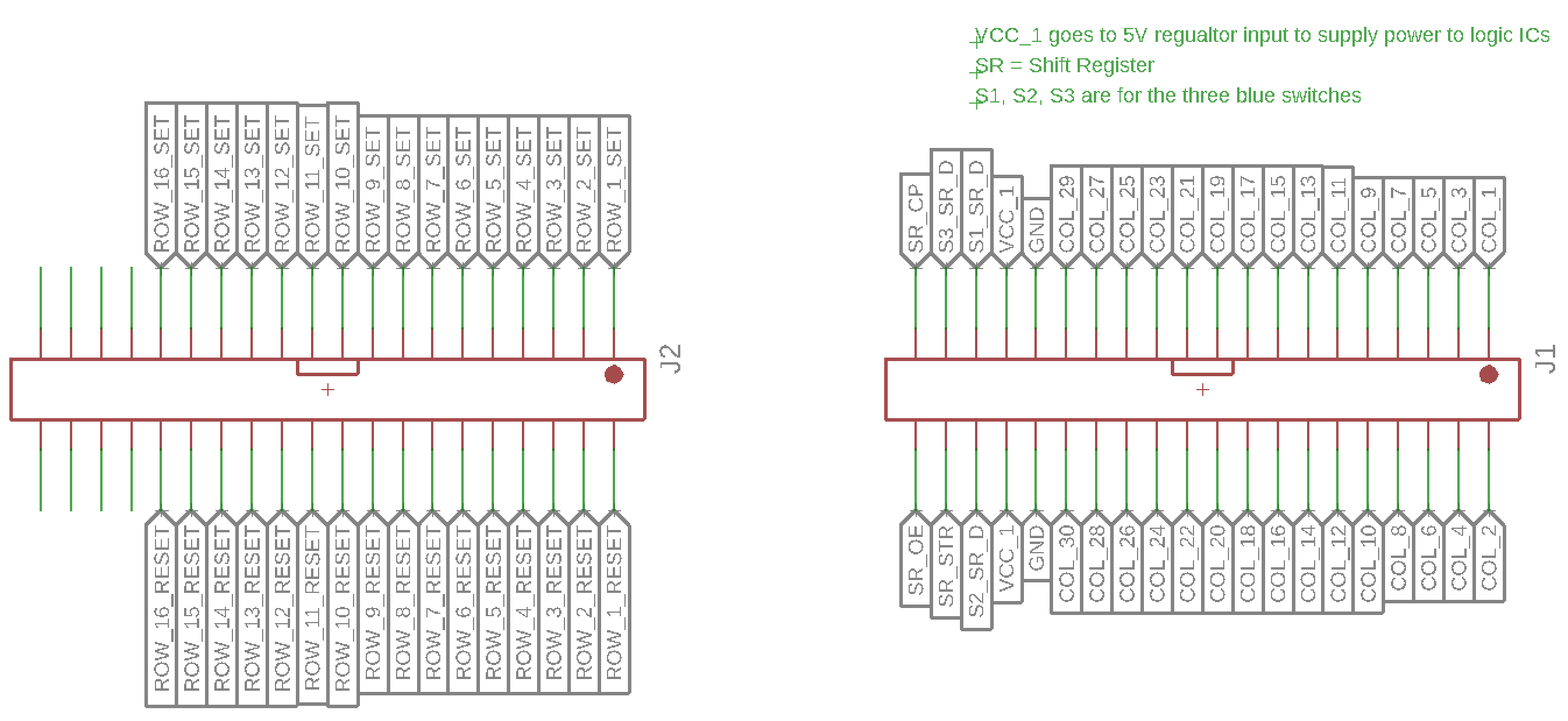

Unboxing the ANNAX Flipdot display

07/26/2018 at 17:20 • 0 commentsFinally, after a few weeks of waiting, I received this morning my two ANNAX ZM16C30 flip-dot displays. I'm extremely pleased with the packaging. Several layers of styrofoam, bubble-wrap, and foam sheets kept the precious boards and flippy dots secure during this journey across the globe from Australia to Spain.

Came with a personal note on a postcard :

And a small bag of several replacement dots. Some don't seem to be usable directly as some are missing their magnet. But nonetheless very appreciated and could be very useful to make some repairs at later stage.

![]()

Double wrap in bubbles and foam :

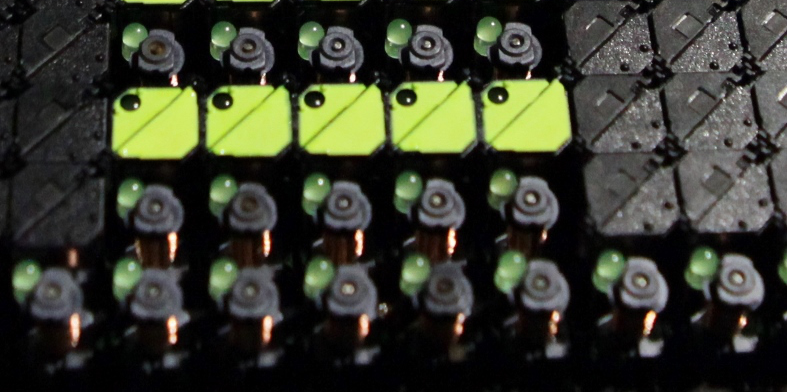

High quality manufactured board and clean dot matrix. Pretty happy with the product so far.

Some close up shots.

Now will start the reverse engineering. The board comes with two 40pins connectors, and a few other chips on it as seen above. I'll try next to find out what they are for, and which pin of the connectors go to which columns and rows. Stay tuned !

-

Matrix layout and controller's job

07/14/2018 at 07:57 • 1 commentFlipping a dot isn’t too hard, but how do you proceed when you have to control hundreds of them ?

![]()

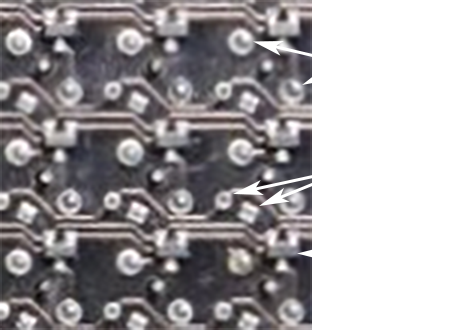

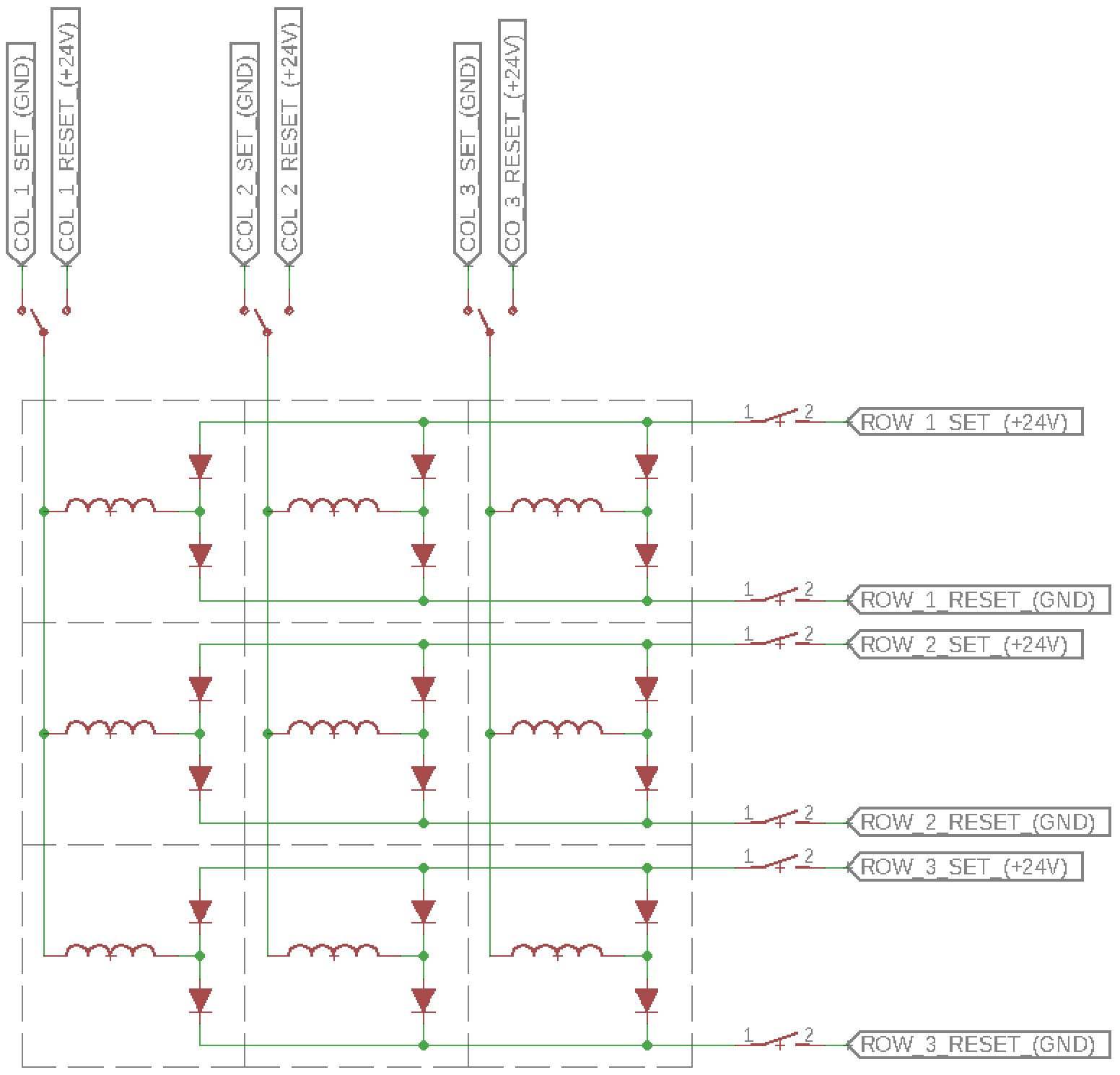

If you look at the picture below (sorry for the poor quality, I can’t take pictures of it myself as I haven’t received the displays yet), you can see the display's back board. I extracted a 3x3 dots area.

![]()

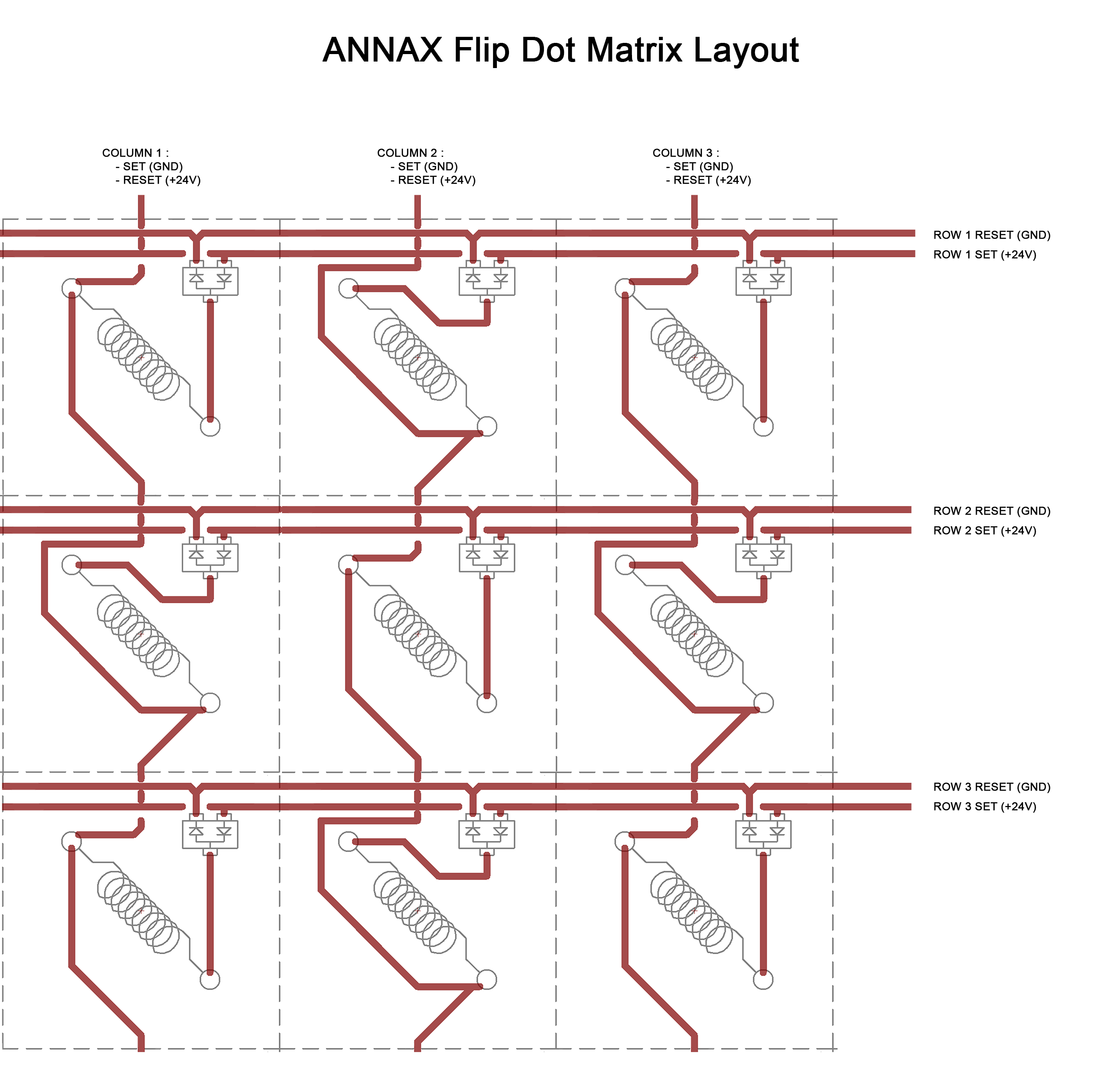

You may be able to distinguish the connections. Below is a drawing of it to make it clearer (I omitted the part associated with the LEDs). Also the columns connections are not visible on the picture as it seems they are on the other side of the PCB.

![]()

Drawing of 3x3 dots above Below is an equivalent schematic, but clearer and easier to work with :

![]()

Simpler equivalent schematic of 3x3 dots

From now on we’ll stick with this schematic and look at the theory of flipping dots in such an assembly.

Each column can either be connected to GND or to +24V (respectively SET and RESET the dot).

Each row has two separate inputs, +24V to SET the dot, and GND to RESET the dot.

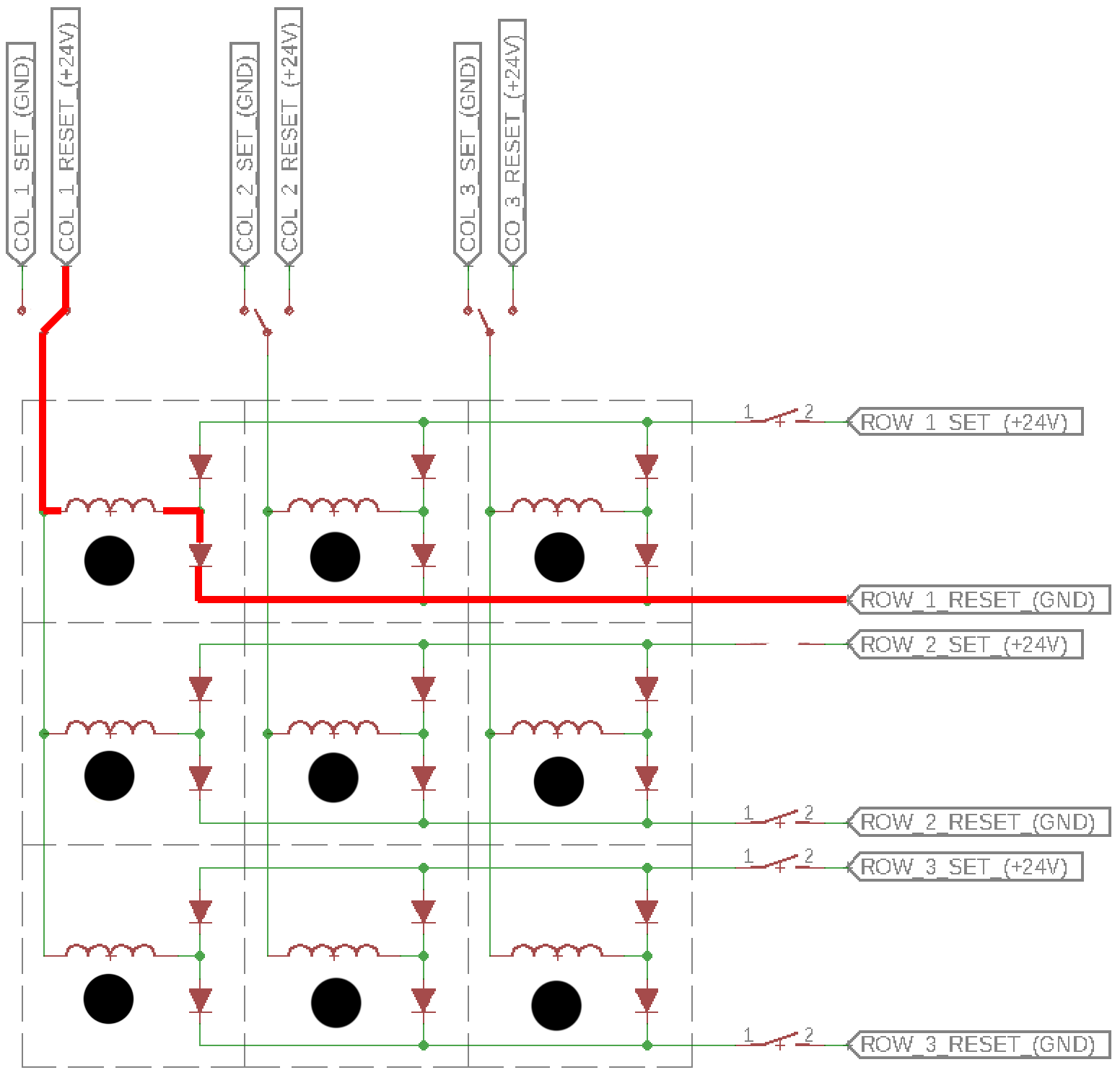

Let’s consider a blank (black) display and we want to flip the upper left dot (column 1, row 1). We should connect ROW_1_SET to 24V, COL_1_SET to GND, send a pulse of 24V, and open the switches again. Current can only flow through the first dot, as it is blocked by the dual diodes (those are required otherwise the current will be free to flow through every other coils) and open switches elsewhere.

![]()

To UNSET it, we have to reverse the direction of the pulse through the coil. So we connect the column to +24V and the row to GND.

![]()

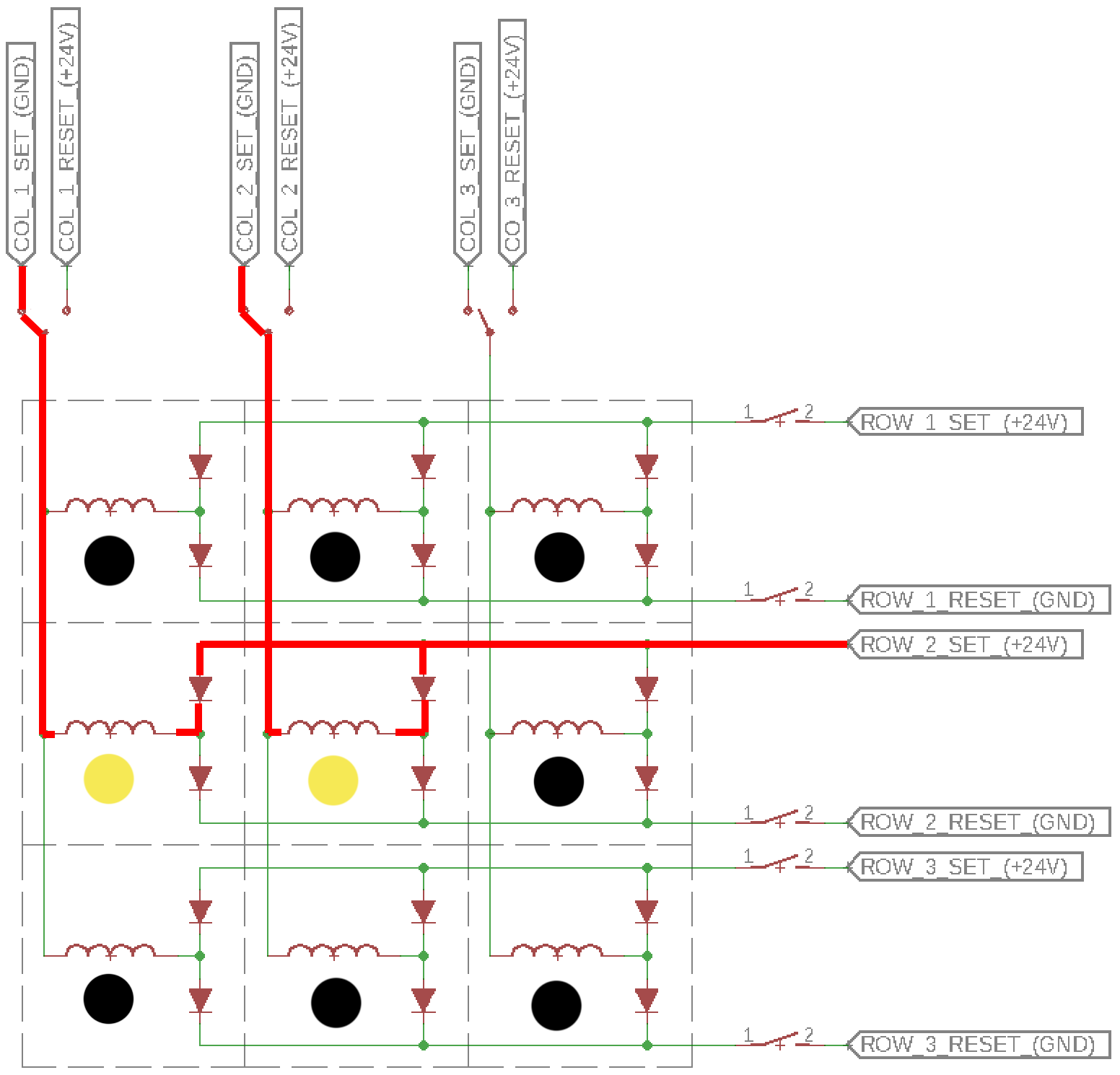

To flip several dots at the same time, for example (column 1, row 2) and (column 2, row 2), we can connect COL_1_SET and COL_2_SET to GND simultaneously, and send a pulse through ROW_2_SET.

![]()

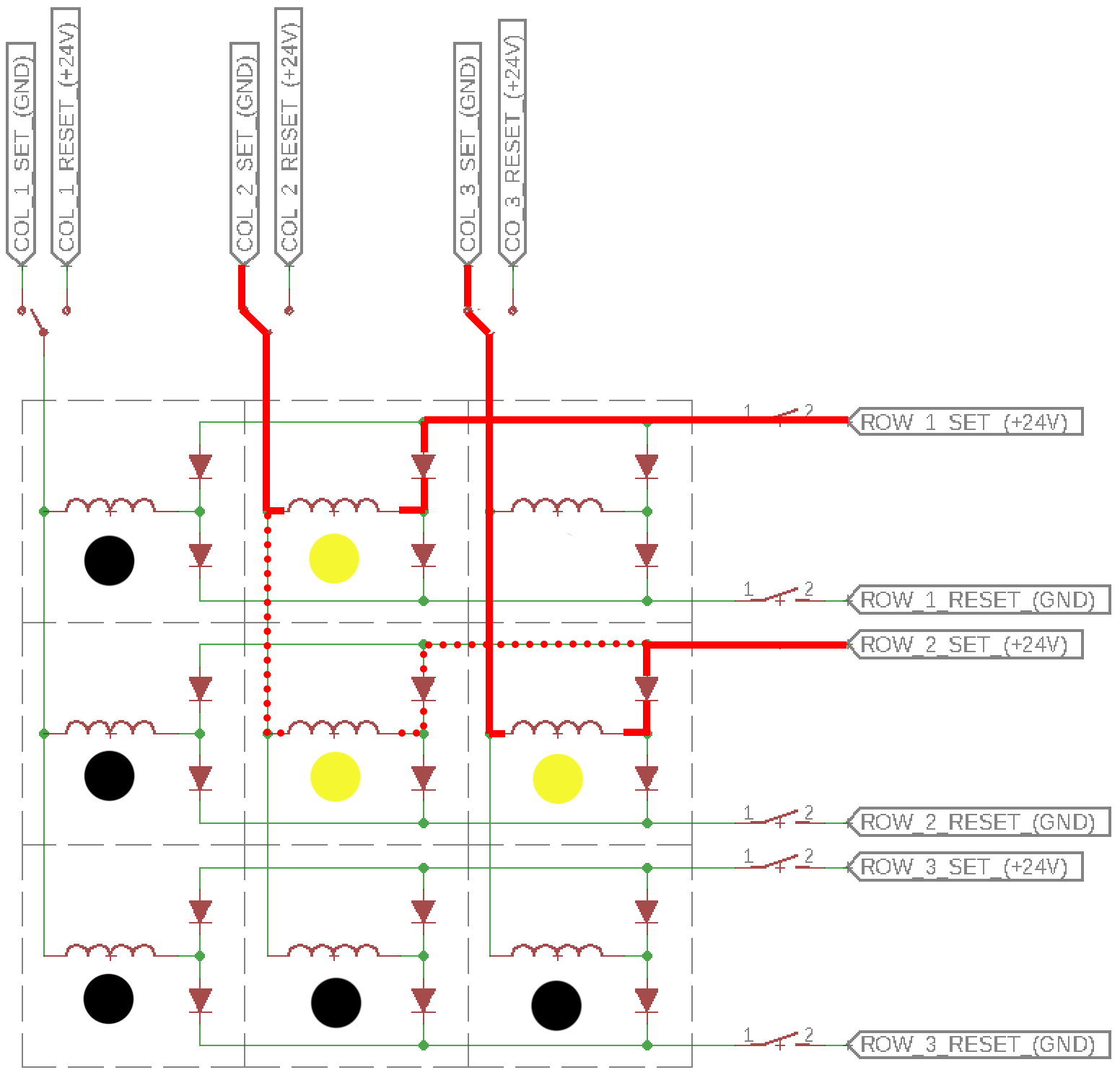

Note that NOT ALL combination of 2 or more dots can be set at the same time. We cannot simultaneously set dots that don't share the same column or same row without affecting other dots on the board. Below an example of trying to set (col 2, row 1) and (col 3, row 2).

![]()

You can see that the middle dot (col 2, row 2) will have current flowing through it and will be SET even if we were not targeting it in the first place.

It's obvious that a mishandling of the switches may easily create shorts and turn the flip-dot in a smoke generator, eg. by closing ROW_X_SET and ROW_X_RESET at the same time.

We established how to flip each dot of the display by a careful combination of connections on each row and column. Moving those switches will be the job of the controller which will be commanded by the code (driver) on the ESP32.

![]()

-

Single dot anatomy

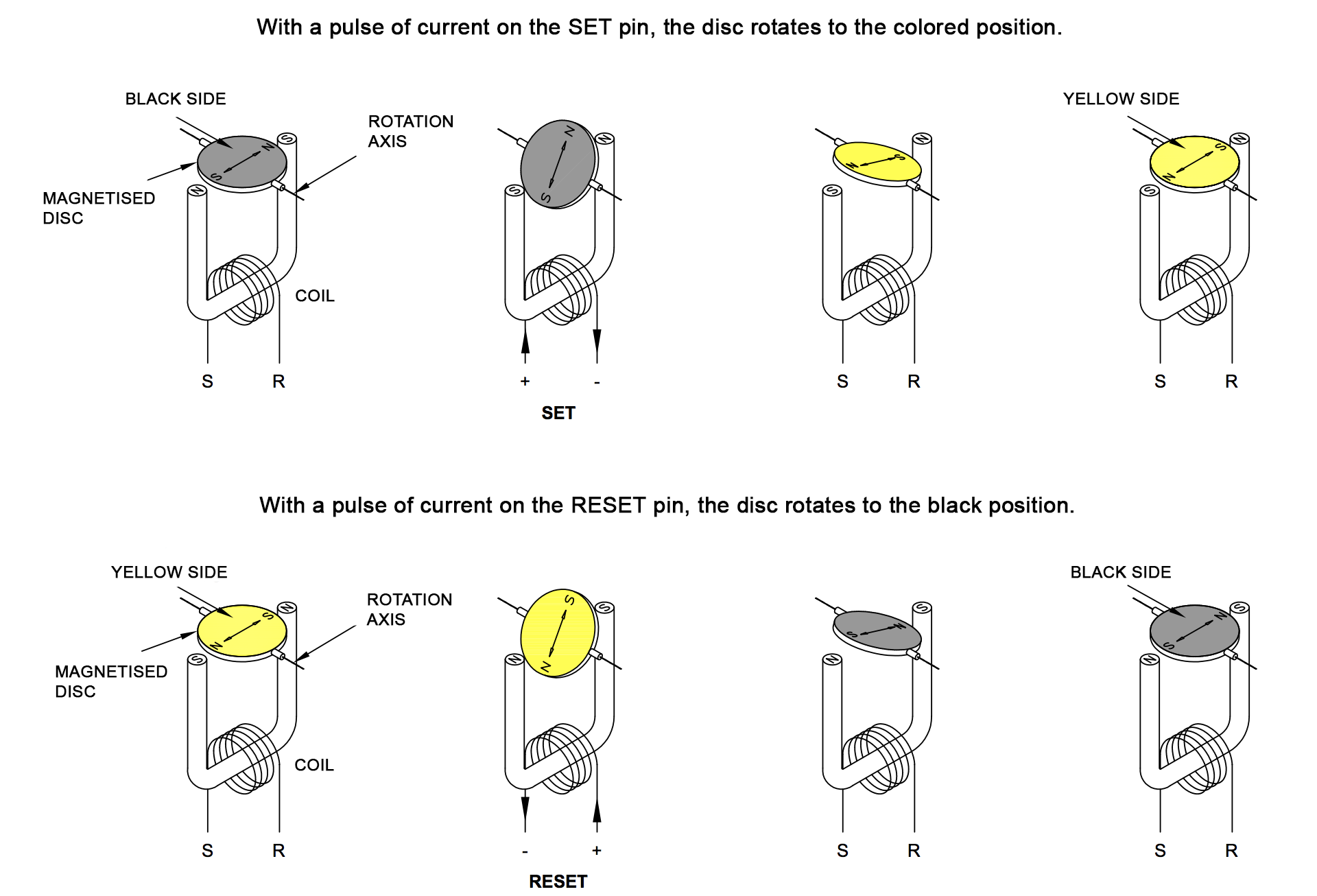

07/13/2018 at 07:45 • 0 commentsI will quickly cover how a dot flips before looking at the bigger picture.

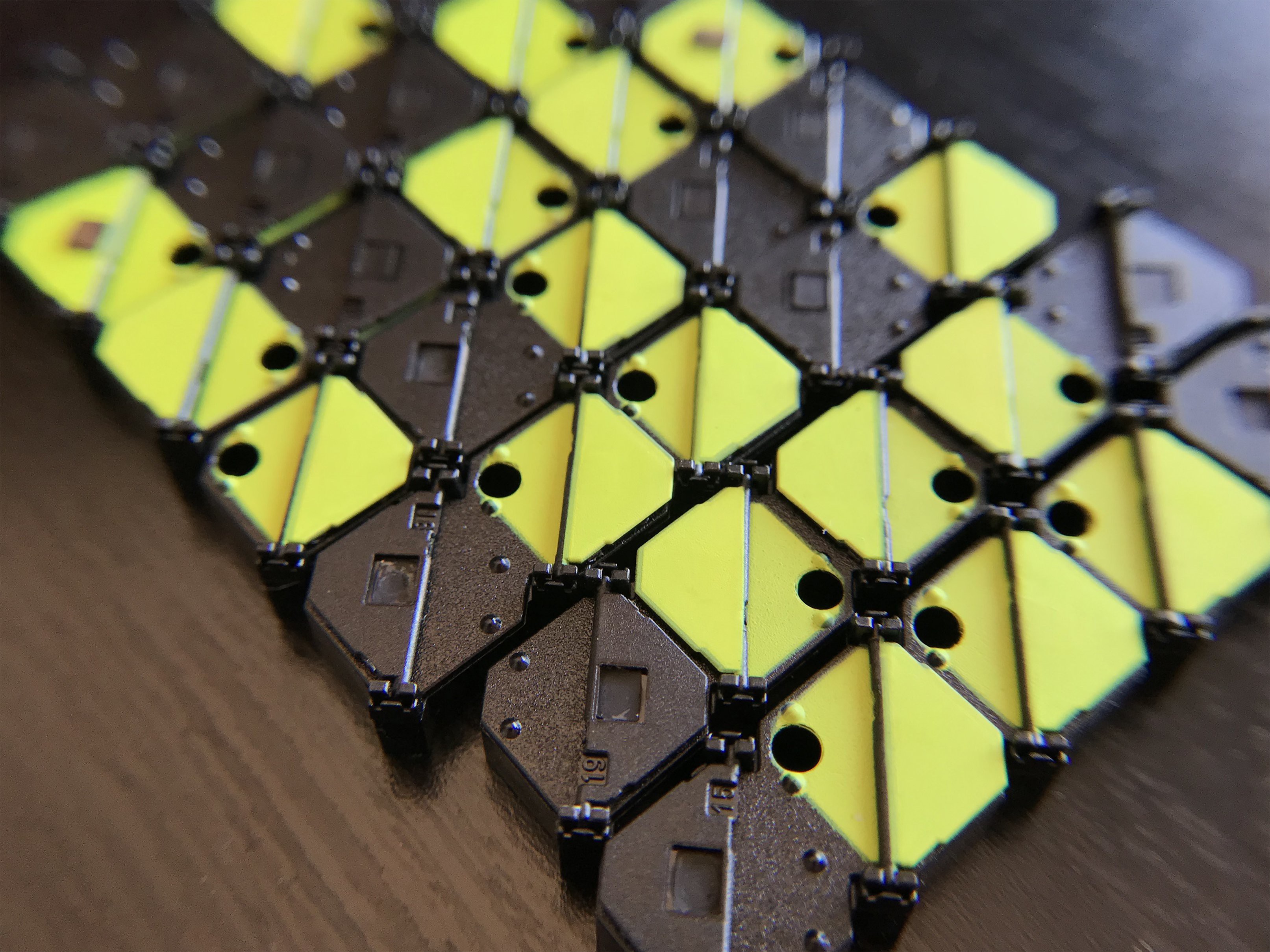

![]()

Each dot contains a permanently magnetised moving surface (usually a disc, or a triangle in my case), usually black on one side, and yellow on the other.

To turn the disc, ie. flip the dot, a coil is placed underneath, along a rod (core) of ferromagnetic metal. When a short pulse of current goes through the coil, the metal core becomes magnetised, with a polarity depending on the direction of the flow of current through the coil during the pulse. Once the pulse is over, the core will retain it's polarity until a new reversed pulse is applied.

When magnetised in either direction, the metal core will attract or repulse the permanent magnet on the yellow and black surface, hence flipping the dot and locking it in it’s new position.

![]()

(Pay attention to the polarity of the core tips, drawings from Eldi datasheet)

Why does the core retains it's polarity once the current is removed you may ask (as opposed to electromagnets) ?

Well, I'm not an expert but I believe the core is made of a metal with specific magnetic properties, such as high permeability (its ability to become magnetised when subjected to the magnetic field of the coil), and high remanence (its ability to remain magnetised afterwards).

This would turn the ferromagnetic core into a permanent magnet once magnetised by the coil, and it would remain so until the next opposite pulse through the coil.On the picture below you can clearly see:

- The permanent magnets (small squares on the upper-left black triangles)

- The vertical copper coils underneath each dot

- The tip of the ferromagnetic core that sticks out from the center of each coil.

- An associated LED for each dot on this specific display

![]()

ANNAX flip dot anatomy (source)

One advantage of these displays is that you can remove all current and the display will remain as is, hence very cost effective for static messages.

We'll discuss later the power requirements to flip 1 or more dots simultaneously but for now, let’s take a step back and look at how a whole display is made.

-

A bit about pricing and sourcing

07/12/2018 at 09:58 • 3 commentsSo, one morning, I wake up, scroll through some Reddit posts (one of the bad habits I have), and stumble upon a guy posting about his flip dot display.

Well, it didn’t take me long to figure out I ‘needed’ one. Before that day, I had never heard of those displays, though probably I had seen some on busses or at airports, but never thought about it from a technical point of view.

I browsed internet and found that these things are pretty expensive. Especially when you include the shipping fees.

You pretty much have 3 possibilities discussed below:

- Buy a brand new display with a driver ($$ - $$$)

- Make your own display from scratch ($$$)

- Buy a used display with or without a driver ($ - $$, my case)

BRAND NEW DISPLAYSThe brand new route is probably the easiest (and least fun) route, but it will guarantee you get a working display with a proper controller quickly. Though, it comes at a price :

AlfaZeta makes brand new displays, with a controller board. Their XY5 displays (14x28) sells around 500€ (VAT and shipping included). That’s 1.27€ per pixel, but you get the comfort of having a working, brand new, customisable display with a driver/controller board included.

Another high end brand, Breakfast LLC provides plug and play displays for professionals, but their website suggests those would be at a price waaay beyond what I'm willing to put, so I didn't bother asking for a quote :

Breakfast LLC Flip Discs

MAKE IT FROM SCRATCH If you want to make your own board from scratch, ie. buying flip dots new from a supplier, then make your own PCBs for the display and controller, be ready to break the bank. Each dot is a relatively complex component with coils and moving parts.

These are a few suppliers I could find :

I'm waiting for the quotes of the last two, but Magsign made me a quote for 1000 dots for 3500$, so 3.5$ per pixel, and this doesn't include the manufacturing of the PCBs, controllers, and other required components to make it work. Their dots seem to be of very high quality though, and are rated for more than 100 million flips !!!

Even if I would have liked the flexibility and challenge of making it all from scratch, the price (and the perspective of making a schematic and soldering of 1000 dots + 1000 dual diodes) put me away from this solution.

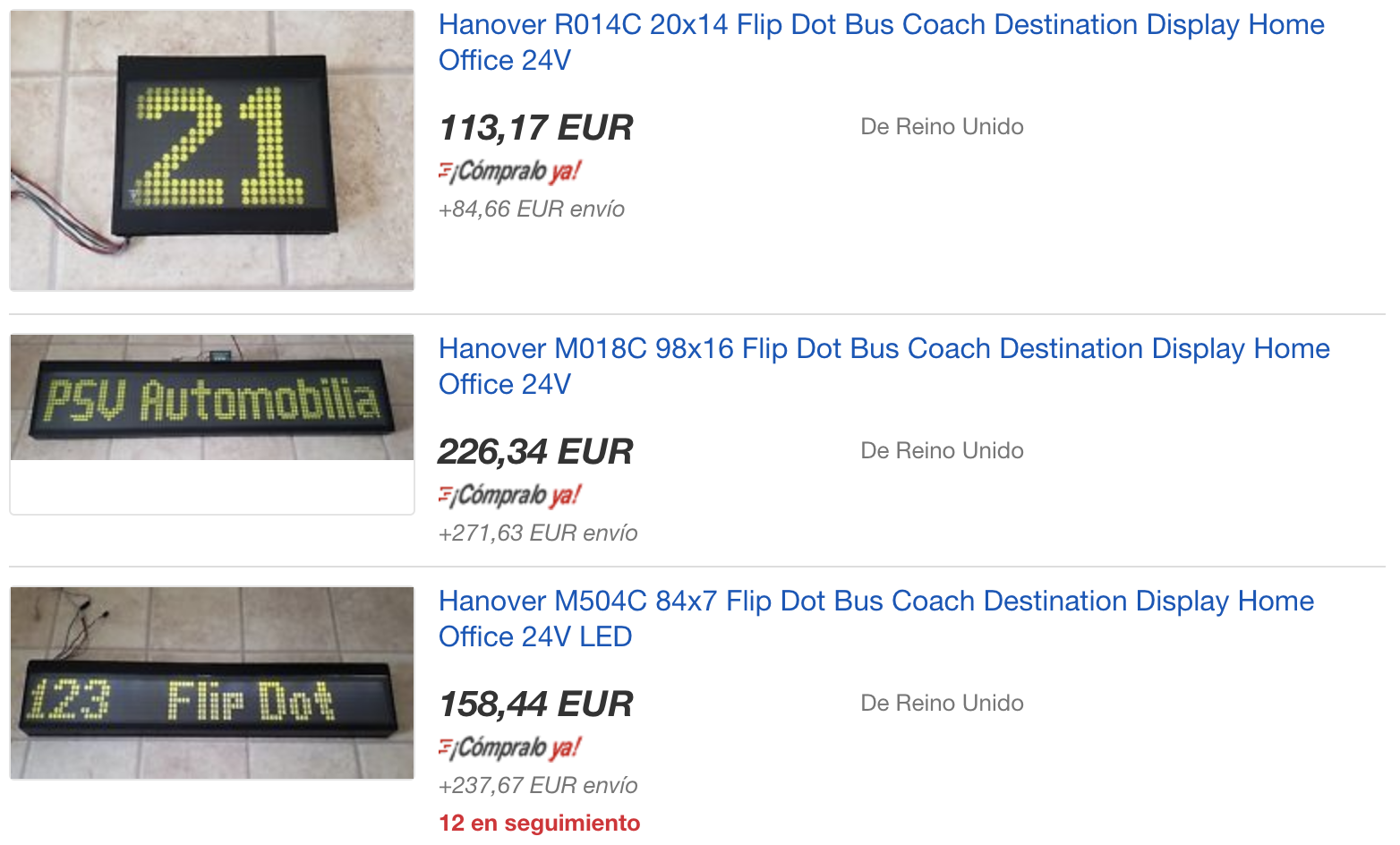

GET A USED DISPLAY Most used displays come from urban busses. Either the bus got scrapped and spare parts end up on the market, or they are being retro-fitted with the more modern LED displays.

Some specific reseller offer those displays, such as Rollsign Gallery, or PSV Automobilia.

Common brands include Hanover, Luminator, and ANNAX and eBay is the easiest place to find flip dots displays, though watch out for the delivery and import fees as it may double the advertised price.

At the time of writing, a used Hanover display sizing 98x16 can be found on eBay for 220€ + 270€ for shipping (seller psvautomobilia). That’s 0.31€ per pixel, but that’s a bit too big for my use.

![]()

A Luminator (16x28) sells for 100$ + 30$ shipping (USA Only). That's 0.25€ per pixel (at today's USD-EUR rate). (Seller frankie615us11).

![]()

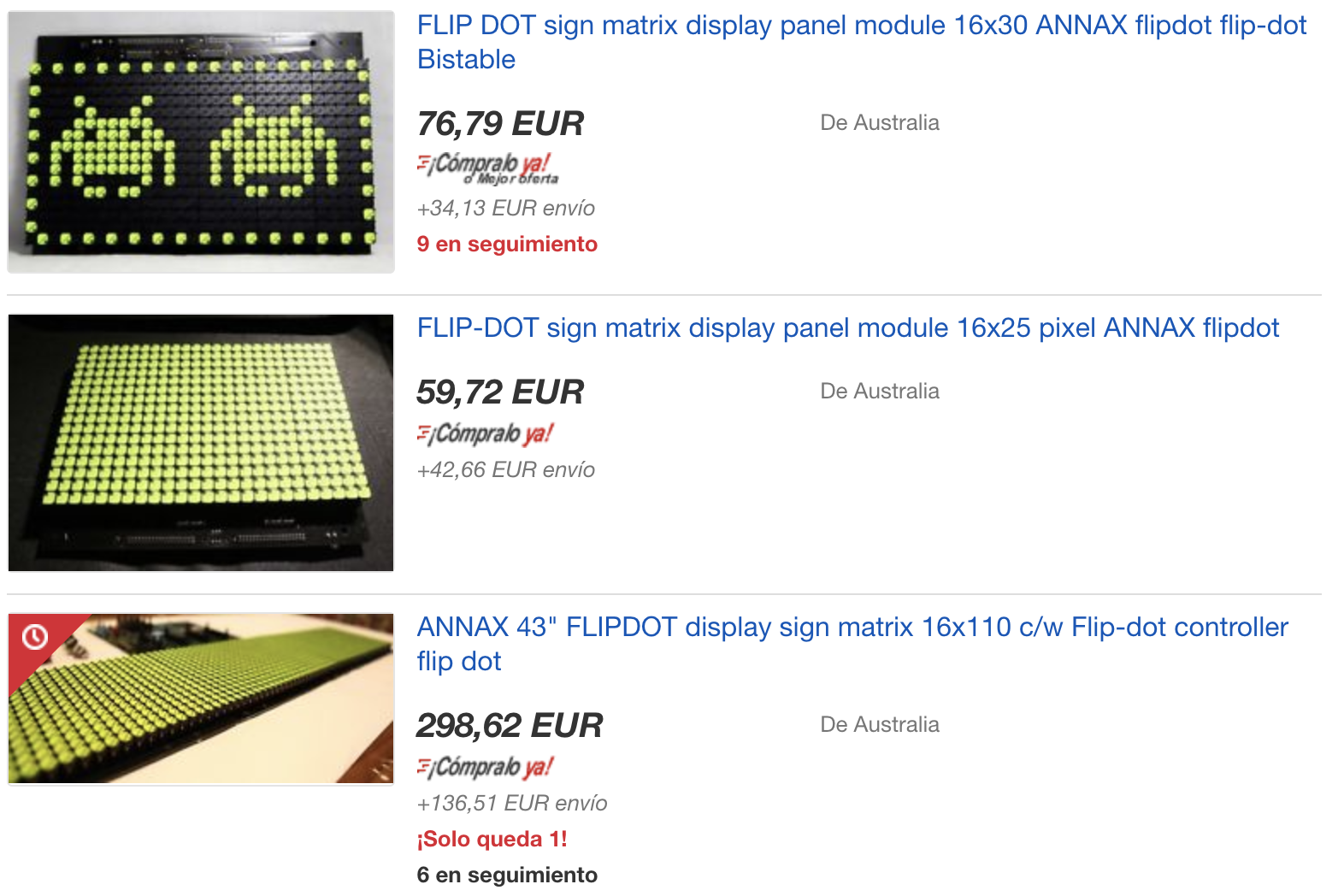

A bit further down on eBay I found some ANNAX displays, 30x16 pixels, for a total of 110€ shipping included (seller discountbuys_2012, open to offers). That’s 0.23€ per pixel, best I could find so far, so I took one, and half a day later I decided to take a second one. That’s twice more fun right ?

![]()

I should end up with a 16x60 dots display, which will be big enough to display a wide range of stuff (not sure what I'm going to do with it yet, I'm open to suggestions).

The pixels are pretty square and with very little clearance, which makes it cleaner, and the integrated LEDs on each dot would make it possible to read the display at night, although it will require more coding and wiring.

NOW THE FUN PART. Those come without any controller board or driver (available separately on eBay at... 160€!). Which is what this project is about: Designing the control module, by reverse-engineering the flip dot display, and use a micro-controller (ESP32), to drive the whole thing.

-

Disclaimer

07/12/2018 at 08:20 • 0 comments![]()

Ok so I thought I should warn you now, I DON’T KNOW WHAT I’M DOING.

Be ready for any outcome. Maybe I’ll end up having a working flip-dot display, maybe I will end up in jail for burning down my building doing activities outside of my insurance coverage.

Though I passed most smoke tests successfully over the past few years playing with Arduinos, I don’t have any formal training in electronics and I cannot guarantee that what you see here will fall in the best practices category.

I rely mostly on what’s available online from fellow hobbyist, and guess what, there isn’t much about flip-dot displays out there.

I’ll do my best to make it work and hope to get some useful feedback from more knowledgable/experienced people out there, and if anything, help somebody else with their flip-dot displays.

Alright, enough talking, let’s get into it.

Frederic L

Frederic L