-

7/11 - Assembling the Main Power Module

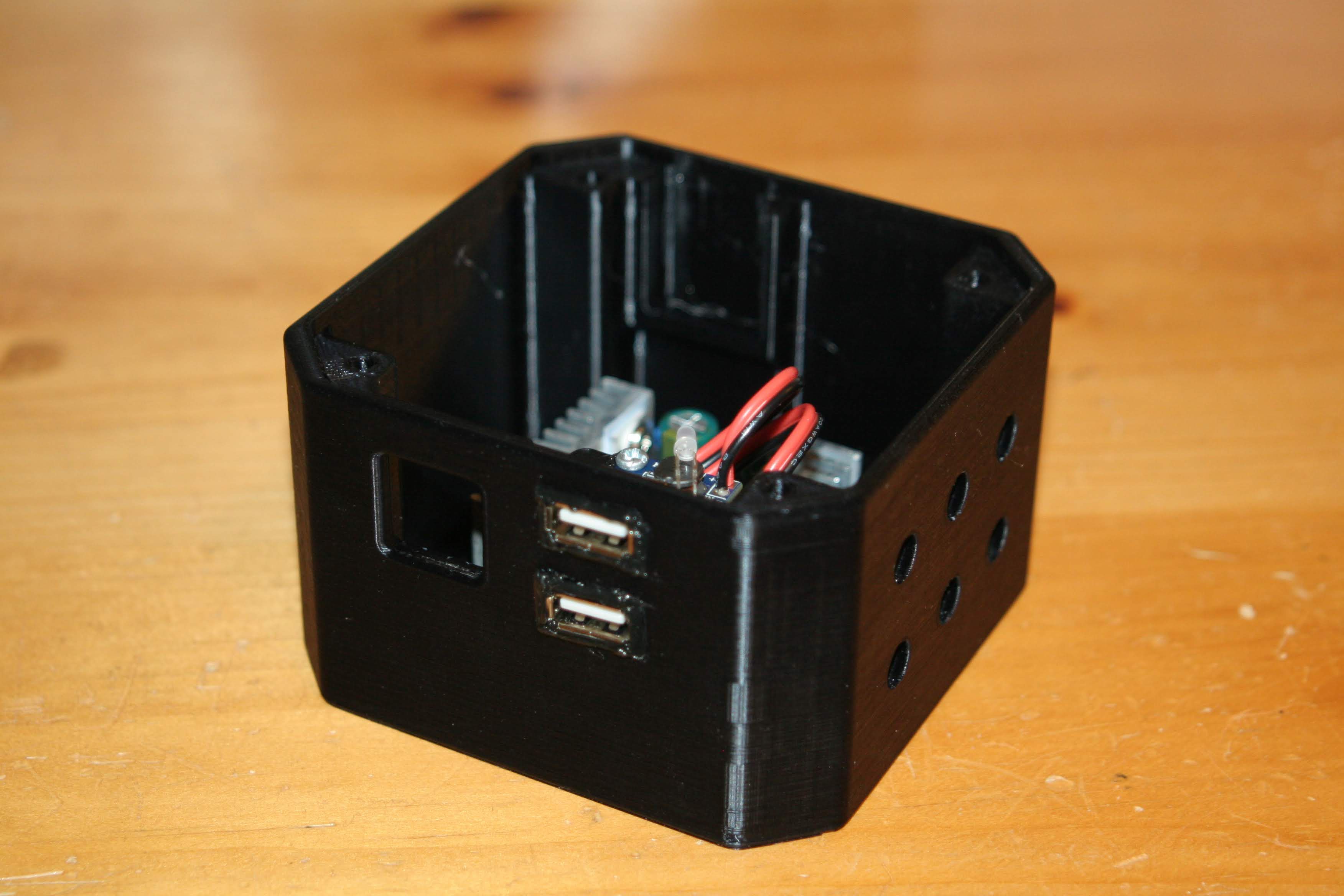

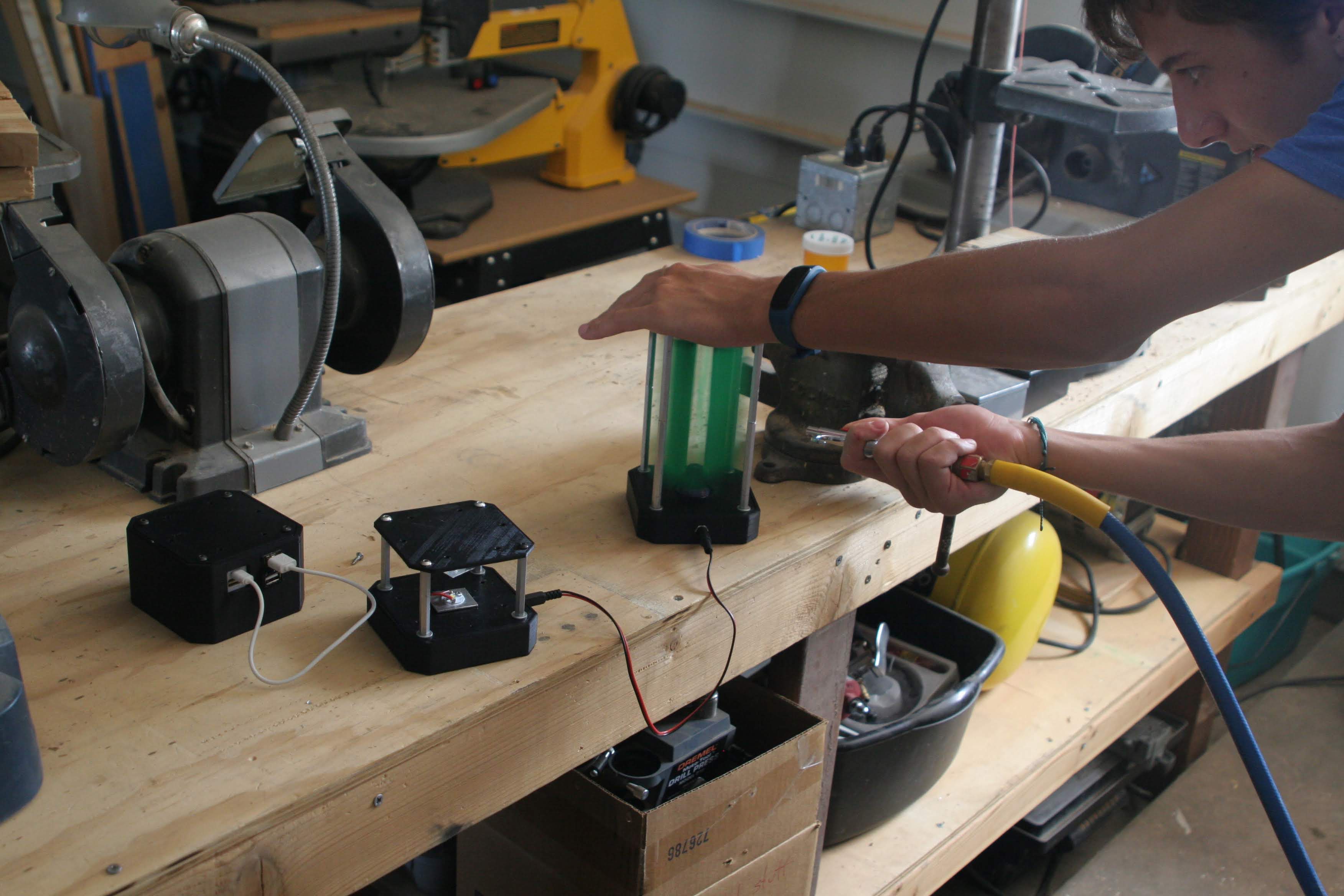

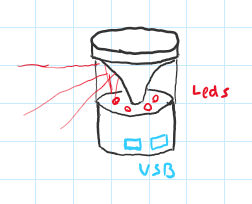

07/13/2018 at 04:32 • 0 commentsToday we assembled the main power module. The power module has 6 barrel jacks for the power generation modules to connect to. The power from these inputs is then regulated down to 5 volts and output to 2 USB ports. There is also an integrated mobile power pack that can be connected to the USB outputs to store the generated energy. We tested the power pack with the water turbine, hand crank, and wind turbine. The crank output a peak of 15V and 0.3A and the turbine output a peak of 22V and 1.1A. We also tested the wind turbine with an air compressor and found that it had an output of 1.8V and 0.3A. We are planning to investigate other motor options for the wind turbine in order to generate more energy.

![]()

-

7/7 - Finishing the Generation Modules

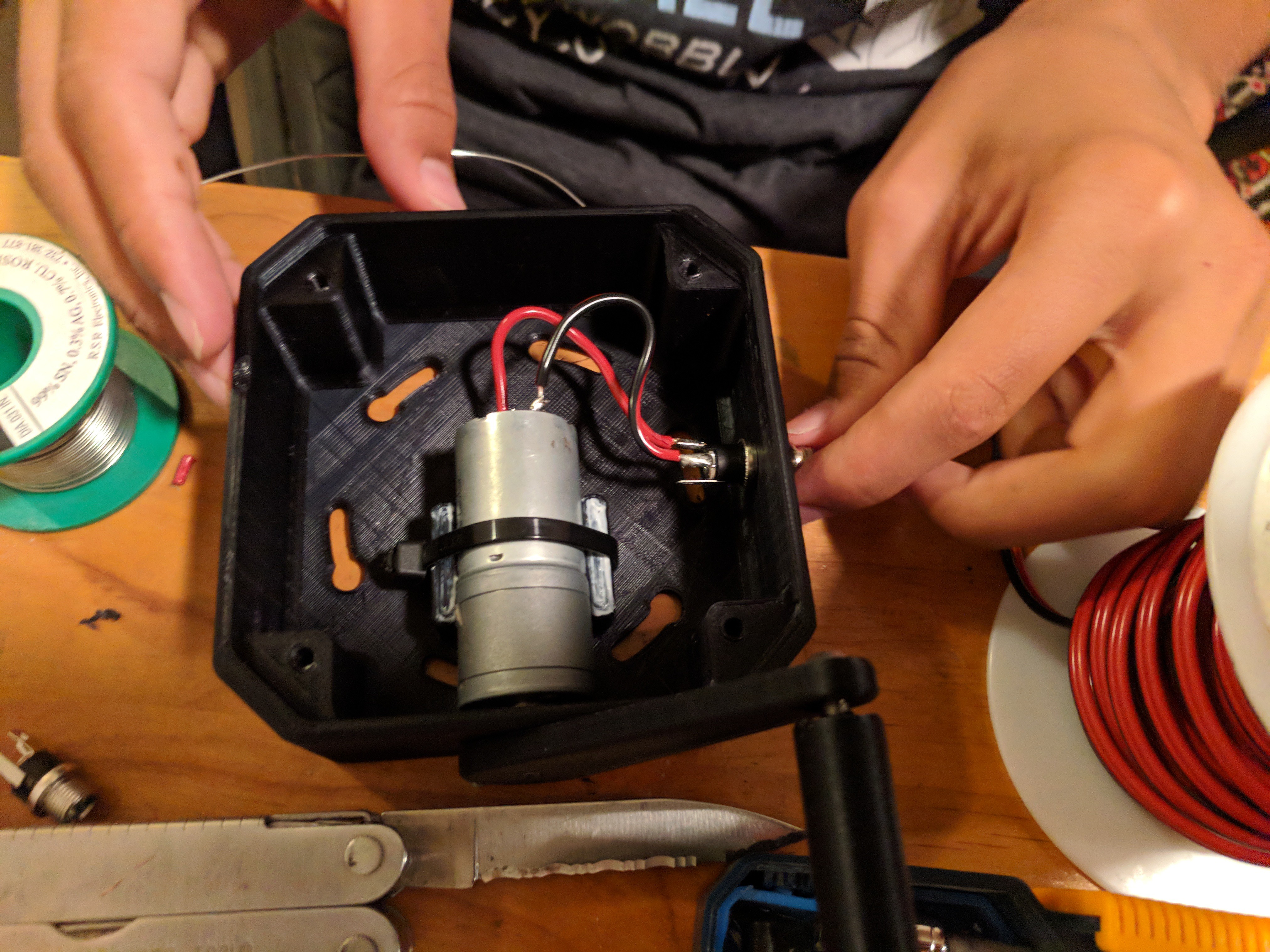

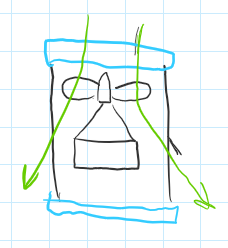

07/12/2018 at 17:02 • 0 commentsToday we finished all of the modules with the exception of the main power module. We installed a reverse voltage protection diode in the hand crank and lantern modules. The lantern was also assembled and wired. The water turbine module was wired waterproofed and assembled. We then concluded the meeting by testing the turbine. It outputted a peak of 17v and ran constantly at 15v. It easily powered the lantern module and could just as easily charge a phone.

-

7/6 - Finishing touches on the Hand Crank and Wind Turbine

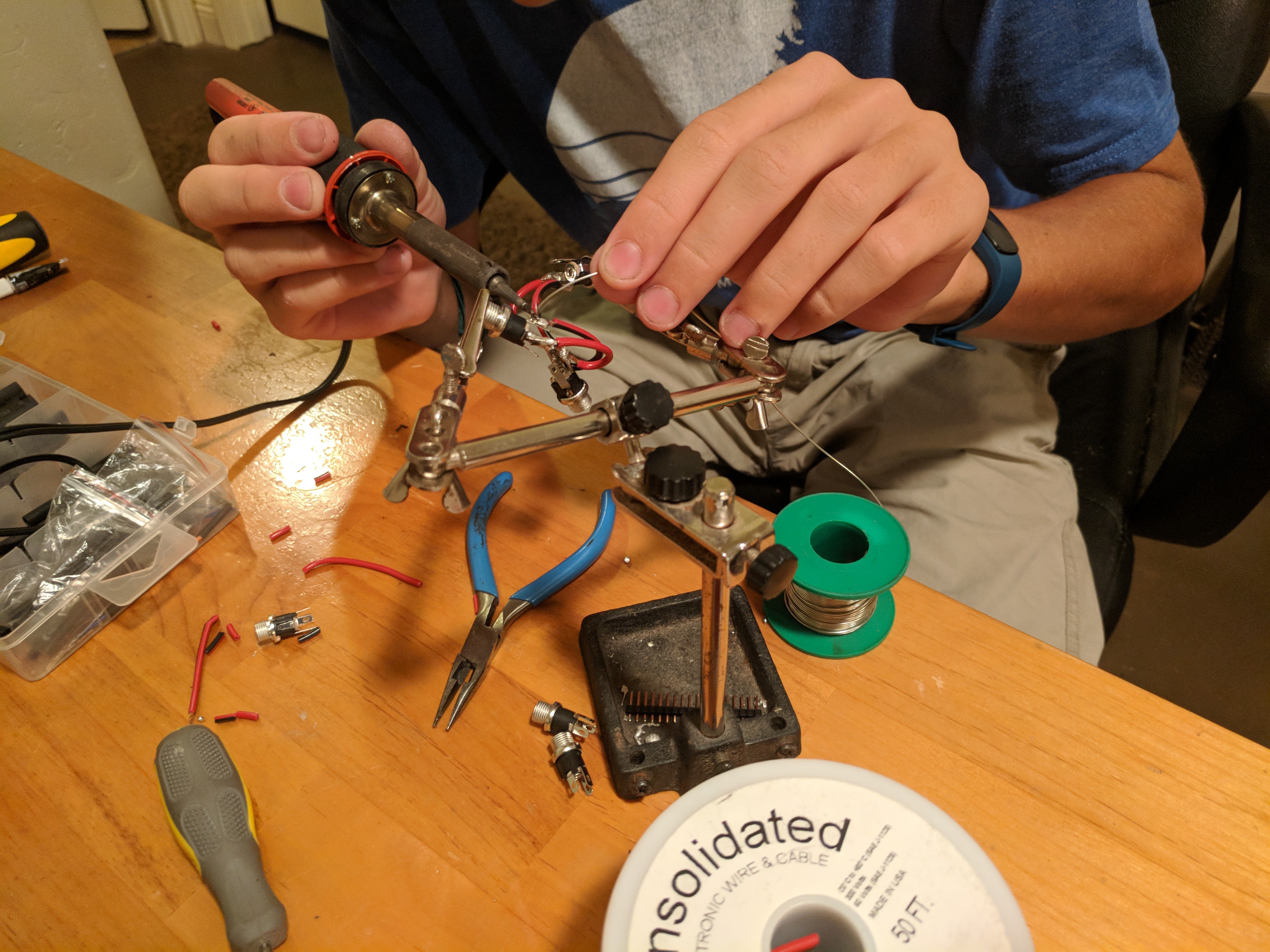

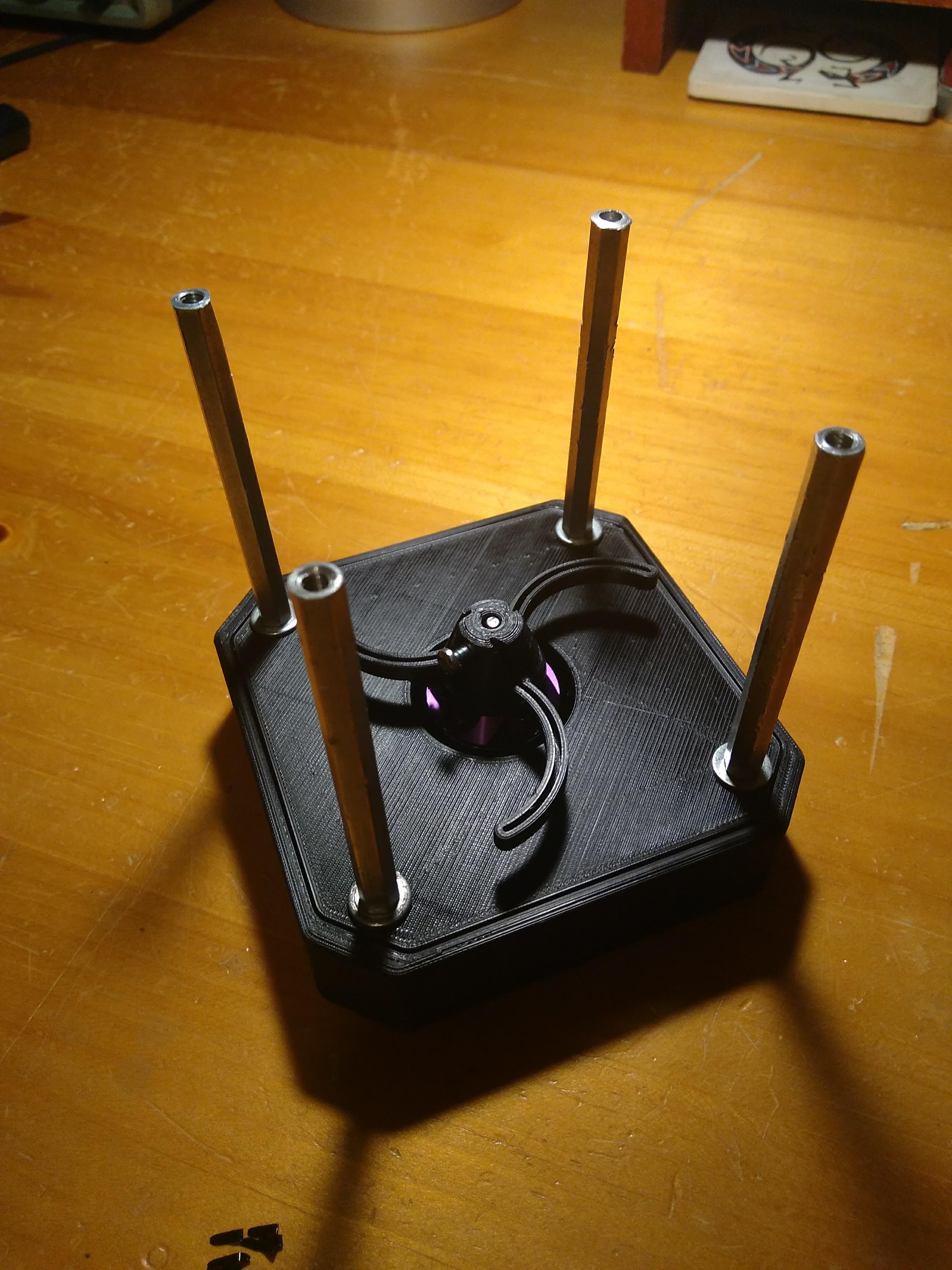

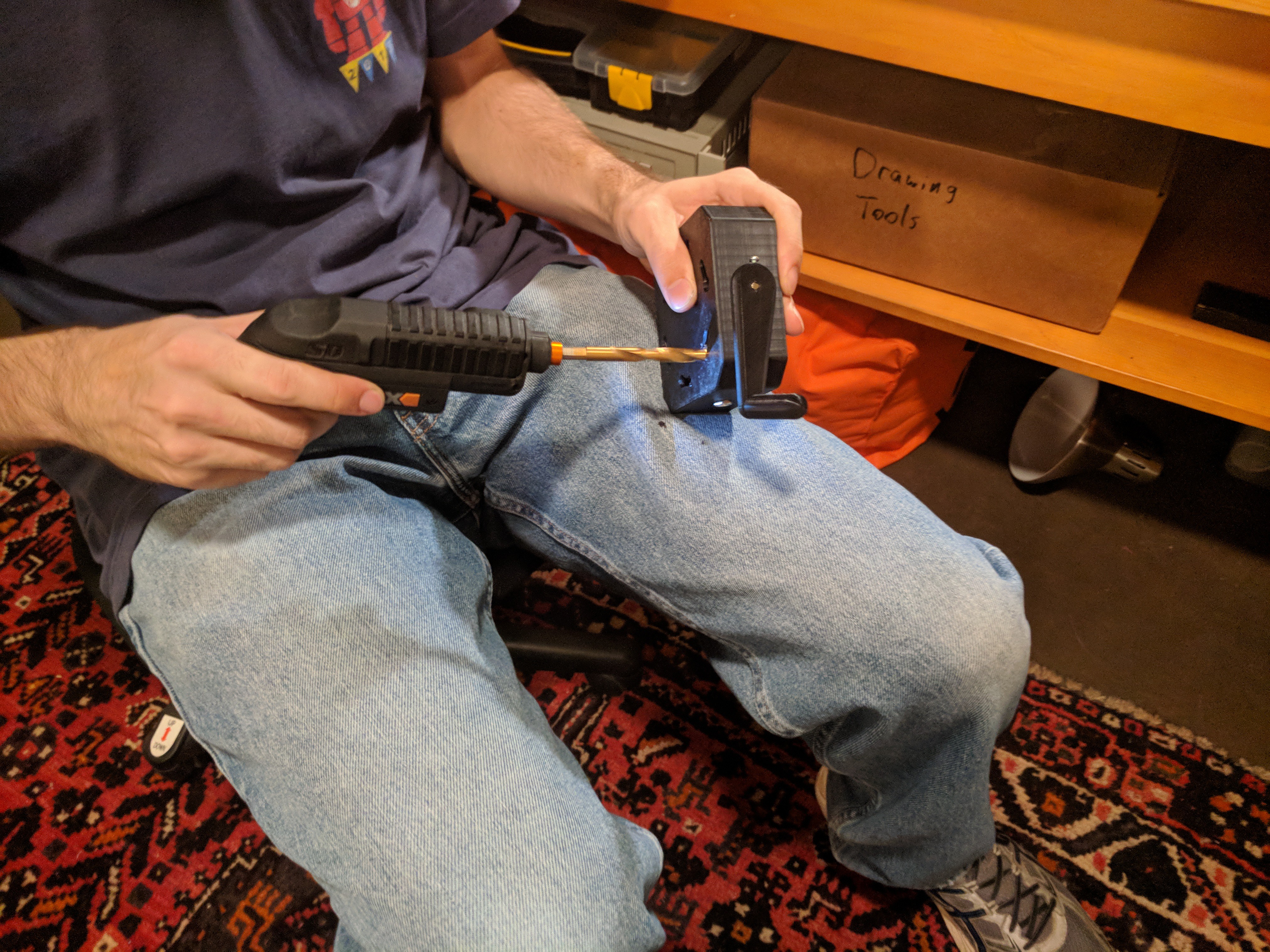

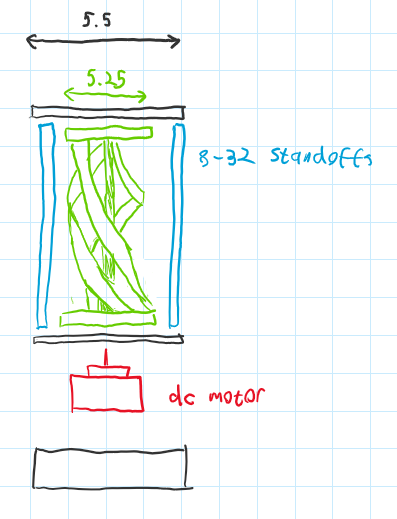

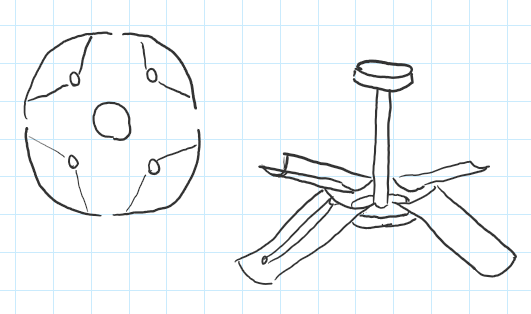

07/11/2018 at 16:36 • 0 commentsWe finally made the blades for the wind turbine module out of paper and sprayed them with polyurethane to make them more durable. We did some tests… the motor we chose is a bit too hard to turn for ordinary winds (i.e. not from an air compressor) so we are working on finding a new motor. On the water turbine module, we were able to mount the turbine assembly to the brushless gimbal motor. This module seems like it’ll generate a lot of power: just spinning the turbine with our hands was enough to generate a volt. Once we mount the blade guard, we can really test this in real conditions. The lantern module just got finished as well: we mounted the high-power LED to the upper part of the lantern and the reflector to the bottom. It looks great, and testing on that will begin shortly. Lastly, we soldered up some three-phase rectifiers in advance for the brushless motors.

(Photo is of the Hand Crank module on top of the Wind Turbine module)![]()

-

7/5 - Hand Crank and Wind Turbine Assembly

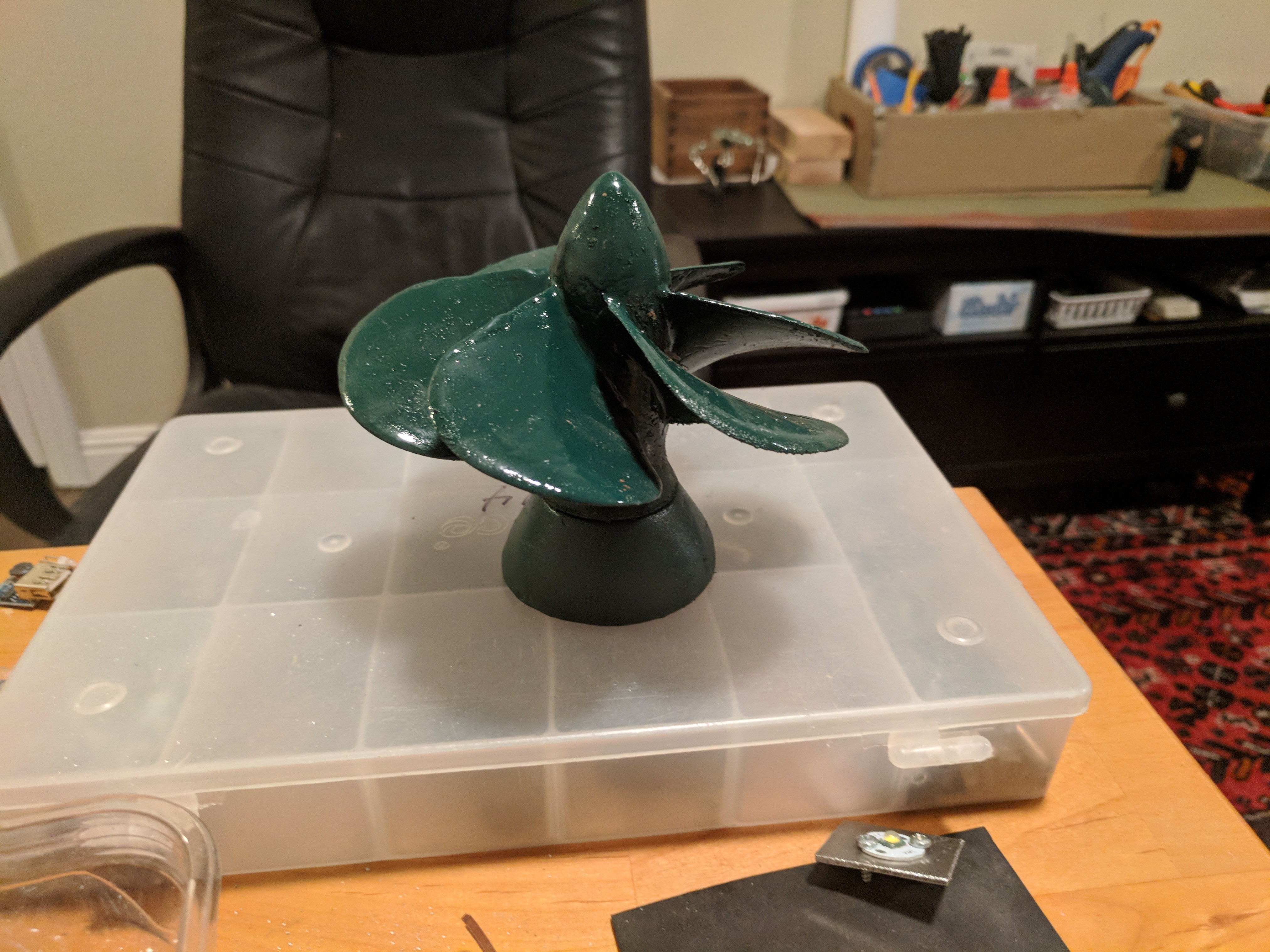

07/11/2018 at 02:25 • 0 commentsToday we worked on assembling the wind turbine and hand crank modules. The hand crank works very well, however the 3D printed crank handle broke during testing so we will need to fabricate a new handle out of aluminum to replace it before our next meeting. We also began assembling the wind turbine today. We decided to make the blades out of paper and only 3D print the hubs to reduce weight. However, the motor we ordered to generate power from the turbine has more resistance than expected, so it is unclear if the wind will be able to turn it. As we still need to make the turbine blades out of paper we were unable to test the turbine today. Additionally, we began work on the lantern module and finished sanding and painting the water turbine.

![]()

![]()

![]()

![]()

-

6/29 - Starting on Water and Wind Modules

07/10/2018 at 23:48 • 0 commentsToday we began working on the water and wind turbines and worked on finishing the CAD design for the remaining modules. We epoxy coated the water turbine in order to waterproof it. The turbine still needs to be sanded and painted at the next meeting. Additionally, we tested the wind turbine we had 3D printed. Unfortunately, this design did not work well. We will need to design and print a new wind turbine design. It also became clear that we will need to make the modules larger than originally planned.

![]()

-

6/22 - Brainstorming a New Project

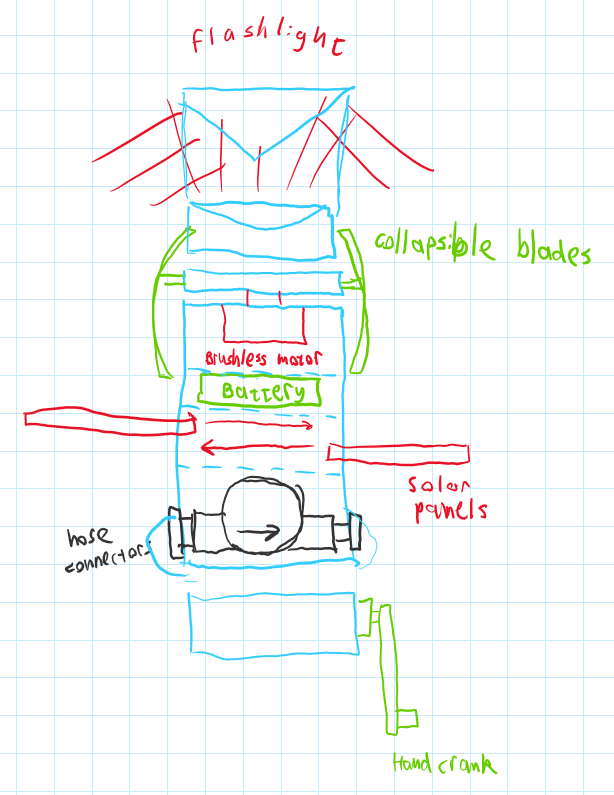

07/10/2018 at 19:49 • 0 commentsToday we brainstormed new project ideas. We settled on creating a modular device that could simultaneously harvest power from a variety of sources. We are planning to make the device about the size of a large water bottle when collapsed so that it is easily transported. We then brainstormed the different modules that we would want to create. Some of the possibilities we brainstormed for power generation include a wind turbine, a water turbine, photovoltaic panels, CSP panels, Peltier modules heated using fire, and a hand crank. In addition, we decided to create a lantern module and a battery module to store power until it is needed. We also began creating a CAD model of the module connection system.

![]()

![]()

![]()

![]()

![]()

-

6/20 - Finalizing the Design & a Problem

07/09/2018 at 20:59 • 0 commentsDuring this meeting, the some of the team members finalized the CAD design while the others researched the availability and cost of the necessary parts. However, after thoroughly examining the specifications on the appropriately sized hydroelectric generators, the team members became concerned that the system would not generate meaningful power. With this concern in mind, the team performed the necessary calculations based on the quantity of water, the weight of the car, the stiffness of the tube that the water would flow through, and the size of the generator. Unfortunately, it was determined that the system would not generate a meaningful amount of energy and the team decided to go back to the drawing board.

-

6/15 - Brainstorming & Preliminary Design

07/09/2018 at 17:34 • 0 commentsDuring the first meeting, the team discussed a variety of different ideas that would capture power. About 1/3rd of the way into the meeting, the team decided to prototype a speed bump that would generate power when cars drove over it by using the car's weight to force high-pressure water through turbines. This power could be stored in a battery and could be used for a number of purposes such as a street lamp. Next, the design was mocked up in CAD; however, there wasn't time to finalize the CAD design and order parts during this meeting.

Power Generation Modules

Modular power generation system for powering and charging small electronic devices

Cole B

Cole B