-

Uses & Paths

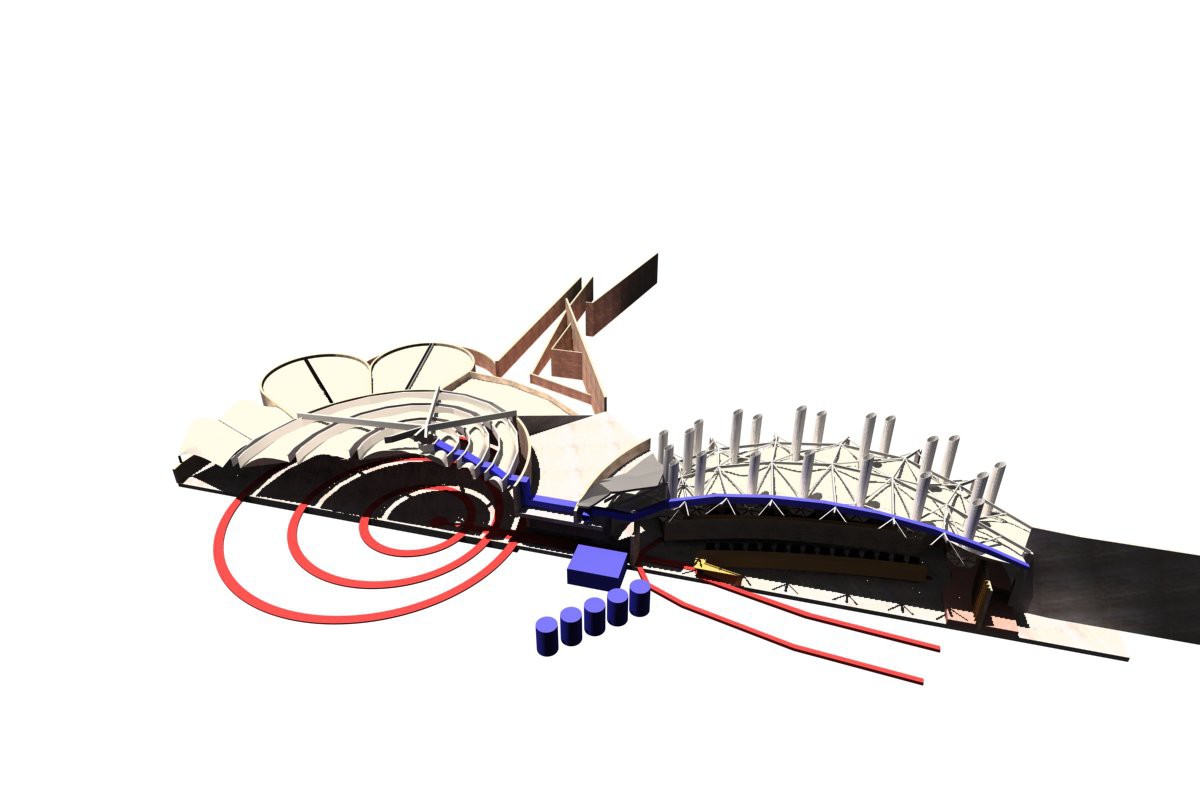

07/16/2018 at 11:55 • 0 commentsWhen I began this project back in late 2008, I was working with Phase Change Materials (PCMs) as latent heat storage systems with architectural applications. while trying to design a latent heat storage system for solar energy, I destroyed my first prototype storage system when the PCM expanded. I had designed the container to have the exact volume of the frozen PCM, and spent a good week scratching my head after the container failure. In retrospect, I am actually kind of surprised that I came up with the idea of creating a hydraulic mechanism over simply enclosing the PCM with a compressible gas; either way, I discovered Wax Thermostats after this revelation. By combining a latent heat storage system with a usable hydraulic cylinder, I was able to come up with an interesting final thesis project.

![]()

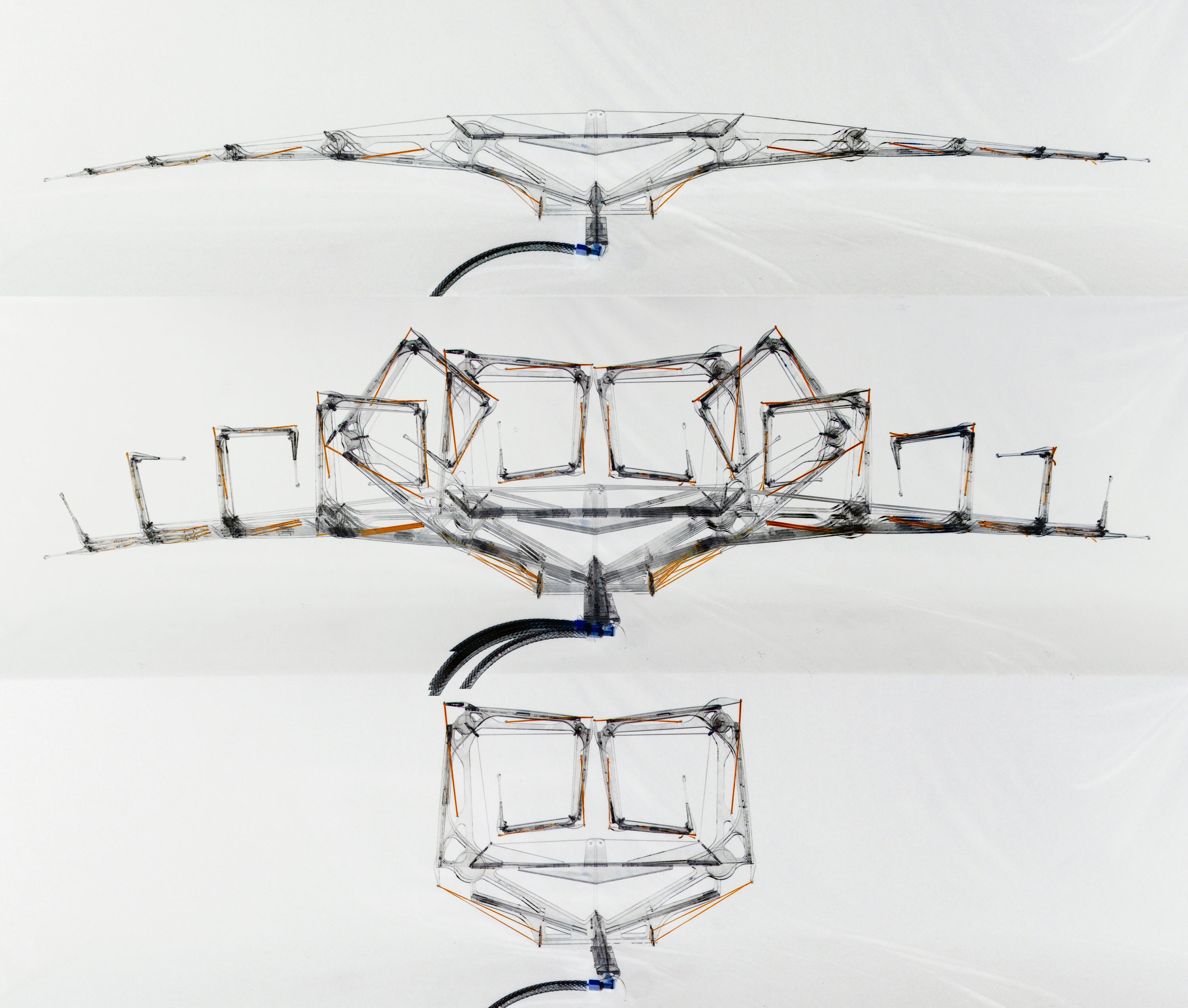

My initial designs were for environmental control systems that would allow buildings to both respond to their environment, as well as store thermal energy. I went a bit off the deep end trying to come up with boolean logic thermal actuators, and otherwise trying to find the limits of the technology. After graduation, I attempted to write a patent for the system, but failed to articulate the limits of the system before the "one year after public exhibition" deadline prevented me from patenting the invention. I burnt myself out on the project, and threw my endeavors into digital fabrication and open source entrepreneurial endeavors.![]()

In the passing years this project has haunted many hours of speculation. I have sketchbooks filled with drawings of skyscrapers that radically change forms with the seasons, walls that prevent conduction when the thermal batteries are full, and rivers that are pumped uphill by daily temperature oscillations. Before these designs can be taken much further, some pretty basic research needs to be done on optimizing the design - hence entering the project in the hackaday prize. I hope that by publishing this project openly on the web, others may explore this simple concept further. -

Moving Forward

07/16/2018 at 11:01 • 0 comments![]() For the next iteration of the design, I decided to machine a basic FDTA out of Aluminum. Previous versions of the device have been made out of glass or acrylic to allow visual inspection of the PCM. Now that I have experience with machining Aluminum, I can explore higher pressures than were possible with glass. I designed this actuator around some scraps I had in my shop, with a usable stroke of approximately 40mm.

For the next iteration of the design, I decided to machine a basic FDTA out of Aluminum. Previous versions of the device have been made out of glass or acrylic to allow visual inspection of the PCM. Now that I have experience with machining Aluminum, I can explore higher pressures than were possible with glass. I designed this actuator around some scraps I had in my shop, with a usable stroke of approximately 40mm.![]()

-

Intermediate thoughts

07/16/2018 at 08:34 • 0 commentsI threw together some videos of the project in the years since I graduated:

-

Project Origin

07/16/2018 at 07:42 • 0 commentsThis project was my graduating thesis from the University of Arizona College of Architecture in 2009. When I saw Thermal Actuators show up on Hackaday, I figured I should dust off the project and have another go at it. When I built my first Fluid Displacement Thermal Actuators (FDTAs), I was limited to my college's laser cutter for digital prototyping. I have since built a modest fabrication laboratory, and am excited to revisit this project with nearly a decade of personal development (and frequent contemplation of the project). When I was working on the project, I did extensive research into Thermal Actuators, and to the best of my knowledge this is a unique design. Of all the thermal actuator patents I sifted through, few used a hydraulic medium, and all of those did so with the assistance of a flexible membrane between the Phase Change Material (PCM) and the hydraulic fluid, severely limiting the stroke length.

![]()

Me, demonstrating the self deploying shade mechanism I designed (2009)

Fluid Displacement Thermal Actuators

Actuators that use a hydraulic medium to transfer material phase displacement as a thermally reactive mechanical force

Andrew Benson

Andrew Benson

For the next iteration of the design, I decided to machine a basic FDTA out of Aluminum. Previous versions of the device have been made out of glass or acrylic to allow visual inspection of the PCM. Now that I have experience with machining Aluminum, I can explore higher pressures than were possible with glass. I designed this actuator around some scraps I had in my shop, with a usable stroke of approximately 40mm.

For the next iteration of the design, I decided to machine a basic FDTA out of Aluminum. Previous versions of the device have been made out of glass or acrylic to allow visual inspection of the PCM. Now that I have experience with machining Aluminum, I can explore higher pressures than were possible with glass. I designed this actuator around some scraps I had in my shop, with a usable stroke of approximately 40mm.