this project uses code that allows between 4 to 256 rectangles to be written in a single instruction or single set of instructions without need for command mode, windowset, pixel address commands for each pixel. this allows effective and efficient spi data transfer of data with minimal command overhead. for 64 rectangle at a time look at program links.

if using the spi optimized driver files and a st77xx display (i'm optimizing for ILI9341 by end of october 2018) you will get incredible update speeds to display. if using a display other than the ones i have mentioned, i have created a wrapper that takes my display commands and translates them into universal drivers for adafruit. you'll get the performance from the reduced command overhead (4-10x) but wont see the 2x-3x boost that comes with spi bursting, memory optimizations as these need to be built into the display drivers)

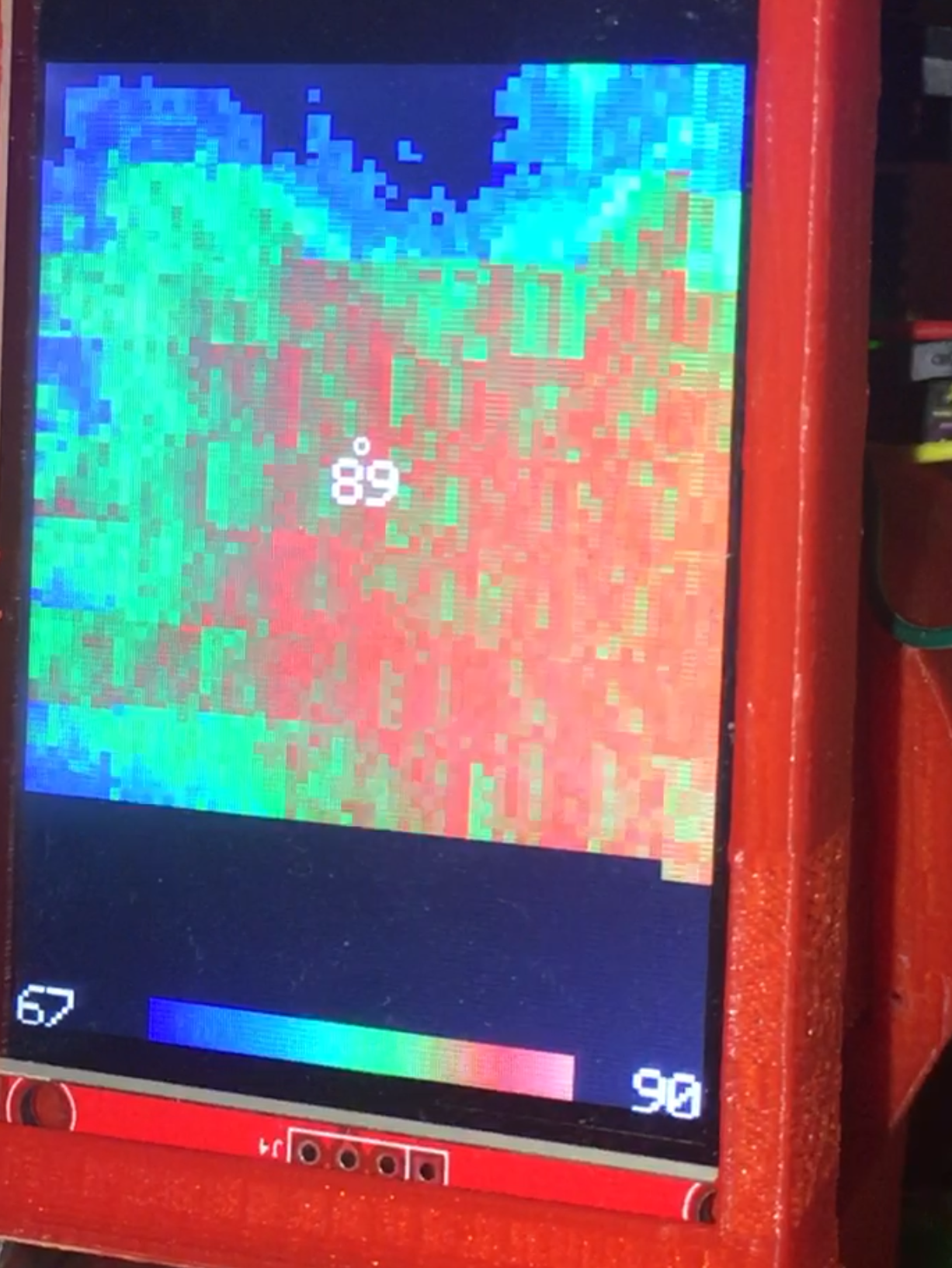

video below shows project details and is only 3-4min. This is just for an article format to discuss methods and ways of speeding up lcd displays that use SPI. It explains why SPI is slow, and methods to increase performance by over 30 times! example of use can be found here https://www.thingiverse.com/thing:3050327 it is a complete thermal pointer, that works at 64x64 resolution on Arduino mega, 64x64 on uno! There is so much overhead to writing pixel information, writing rectangles reduces this overhead, but now a newer method, writing several rectangles at once with minimal overhead. this alone leads to 16x performance for Arduino, where buffering the entire screen is not an option due to limited memory. there is also double speed to SPI on Arduino. SPI bursts are now twice as fast! (with everything it is able to do 64x64 at ~10fps!) newer code is in beta section of my downloads for speed with 64x64.

weird tech jargon below!

Yes some people use buffers but the spi transfer itself is also not optimized. There is often a lot of overhead other than pixels for display of data.

originally code was written per pixel, and being that Arduino code didn’t know where pixel was, each pixel needed an address, so 2 bytes for x, 2 bytes for y address, and for color data, in 16 bits it required 2 bytes of data. Only one time was window size defined, at initialization, or at start of lcd use, the window size was set to full display size.

On Arduino buffering of the entire display is often not possible as the memory requirements are a lot.

There has been a really clever method that came out and it was to write rectangles, as long as data had same color it is faster to write areas of the display. Set windows size commands that takes 6 or more bytes, set start address, and then write same color 2 byte data, again and again.

The display is usually set to a mode that automatically advances pixel location after color data is sent. This seems faster, but the closer the information gets to the display resolution the slower this method becomes because of the overhead to set the starting positions of the window size for the rectangles. At reasonable resolutions the display update rate gets down to a few frames a second.

What I have is a possible solution to the speed of spi, using the rectangle command to draw several rectangles at once, utilizing the set window command, but allowing rectangle command to write several rectangles within the larger rectangles with individual colors, and only uses up to an additional 32 bytes of ram, but speeds up display writes by up to 16 times because overhead is only used every 4 or 16 pixels, instead of each time!

Also removing the wait of spi. Spi data is usually checked to ensure that the write of serial 8 bit data is complete. Why do we have processor stall and wait for this to complete....

Read more »

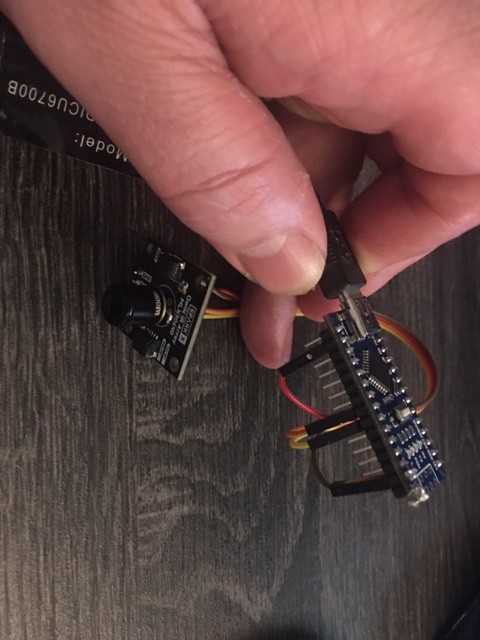

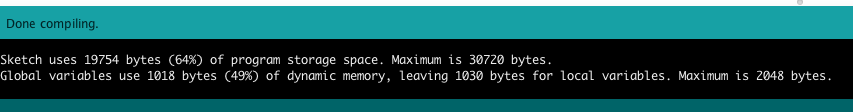

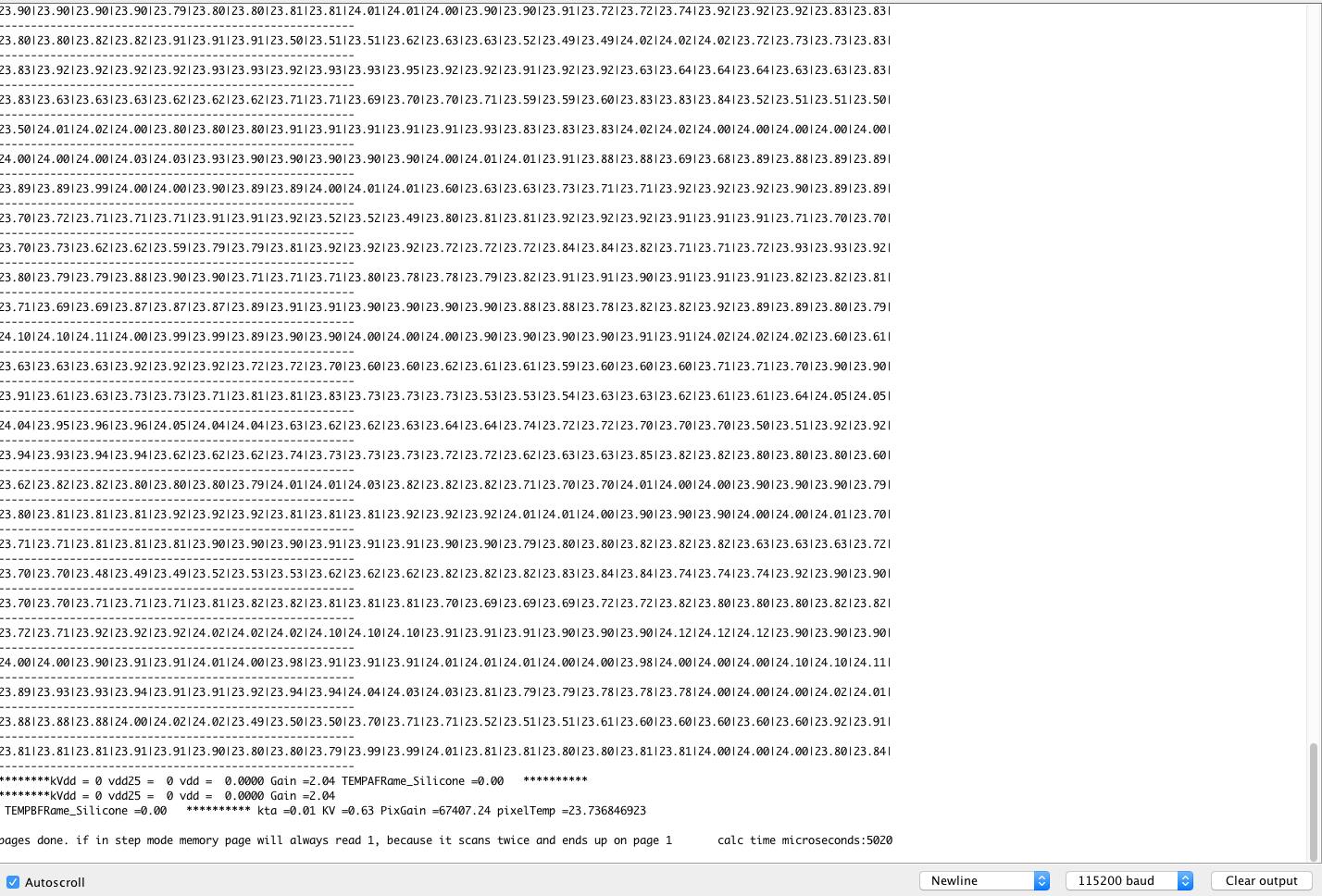

mlx90640 sensor now reading degrees c in array mode thru terminal. working on optimizing and simplifying math and cleaning up routines. then making it work with thermal cam code