-

Wasp for Grasshopper

08/10/2020 at 22:06 • 0 commentsAn individual named Andrea Rossi filled a critical gap in Geometer's progress and potential.

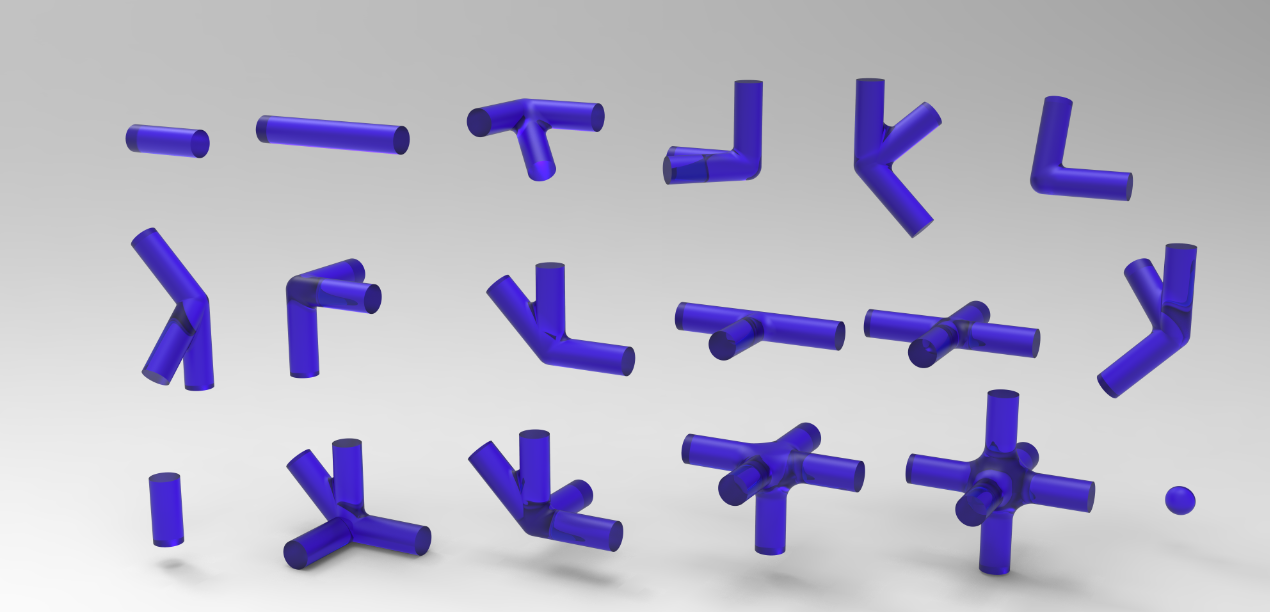

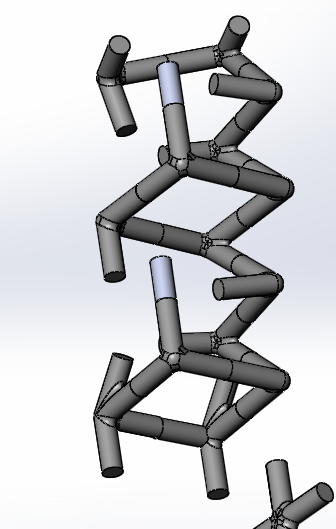

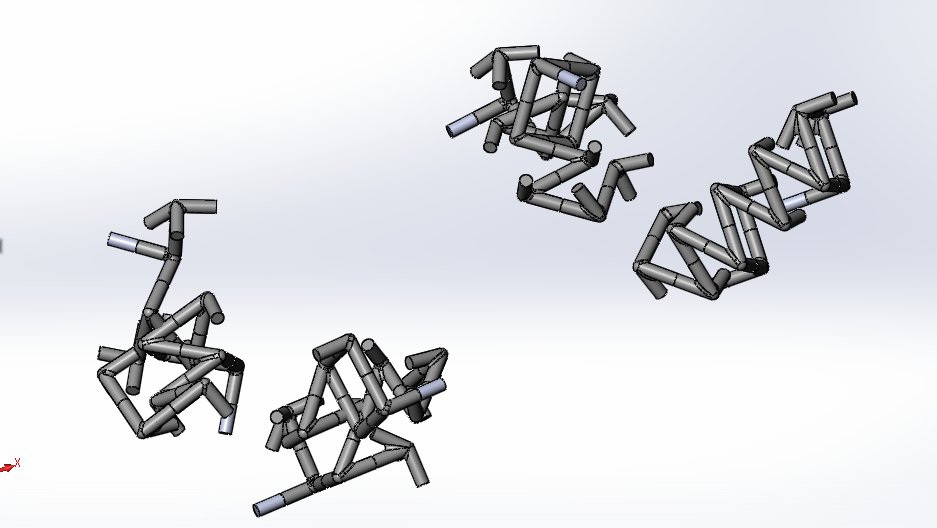

He has developed Wasp for discrete component aggregation modelling based off of simple to complex rule sets. What this means in essence is that combined Geometer components can be assembled/simulated automatically by Rhino and Grasshopper for a number of purposes.

At its most basic, random rules are applied to three of the twenty plus modules with a limit of one hundred and twenty-two elements.

As additional modules are added along with rules Geometer will become a robust problem solving tool for limited component set manufacturing.

An example; a vague form of a chair can be populated with Geometer components with individual component number restrictions, if you only have thirty "F" molds and thirteen "I" molds, you'll be able to tell the system that and solve for possible configurations within a given boundary region.

Stay tuned for enhanced functionality; a new library, grasshopper scripts and installation instructions.

Up to this point anyone could do what I've done, feel free to fork towards your own purpose!

-

Mentor Session

05/17/2019 at 15:39 • 0 commentsSince Geometer is participating in the Hackaday Prize I had the opportunity to present my work and get some feedback on potential directions. See a recording;

-

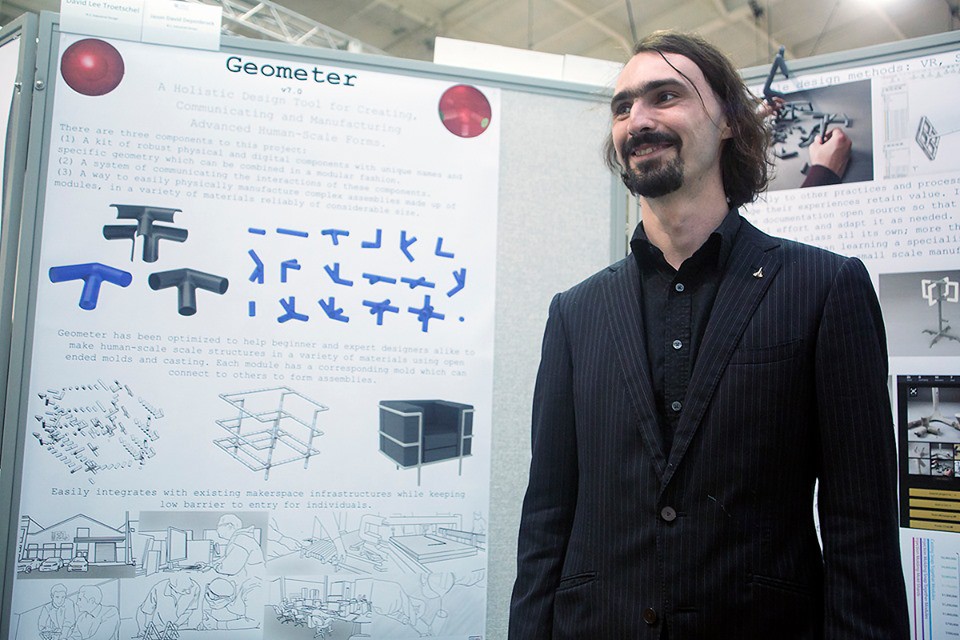

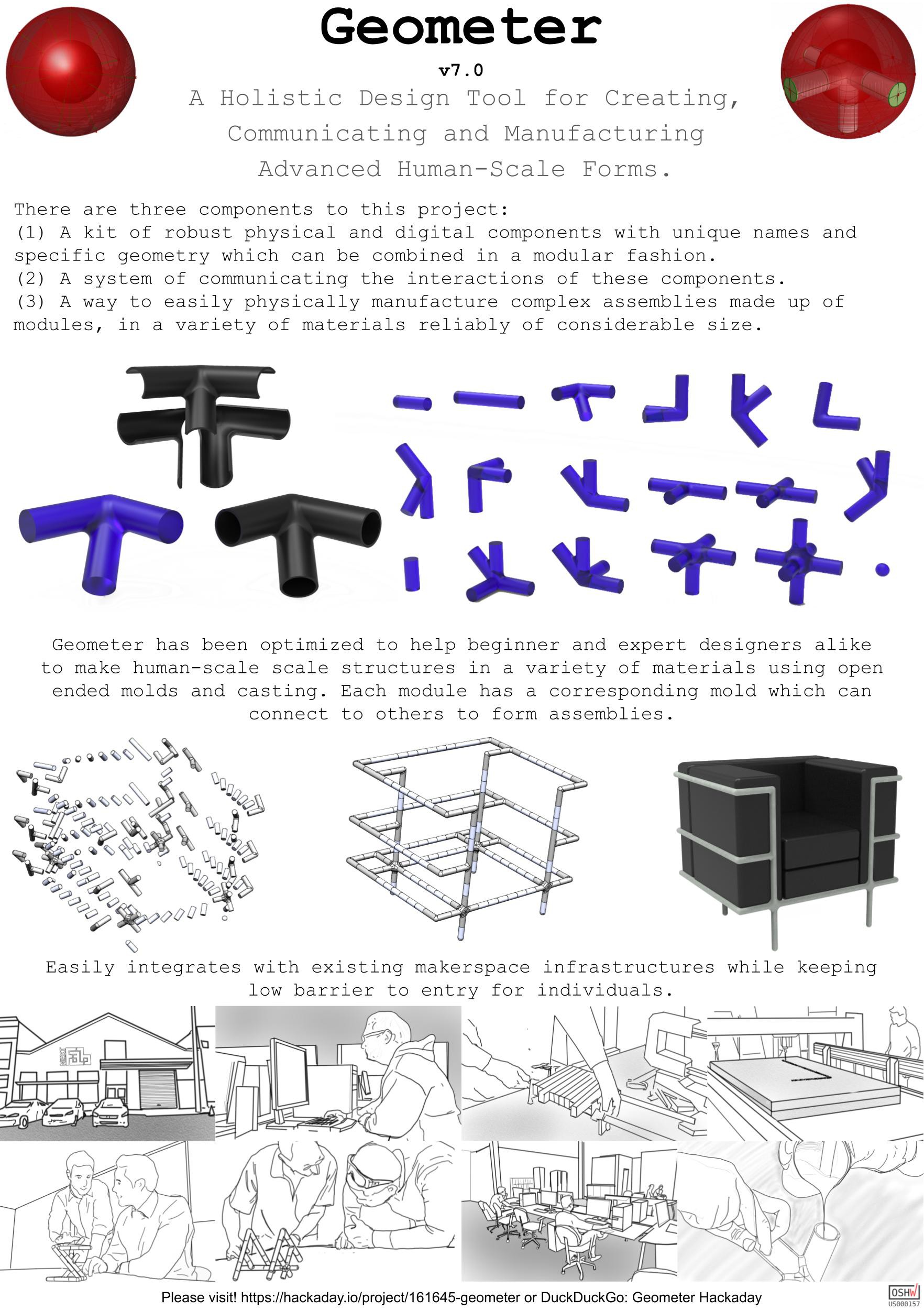

Senior Show Posters

05/02/2019 at 21:48 • 0 comments![]()

And the actual posters:

![]()

![]()

-

Final presentation

05/02/2019 at 18:44 • 0 commentsOn the 29th we completed our final (at school) capstone presentation.

Our powerpoint with annotations, is available in the downloads section.

A video recording is on youtube:

A higher quality version may follow.

-

Open Source Hardware Association Certification

05/02/2019 at 17:57 • 0 commentsWe're officially certified now!

![]()

https://certification.oshwa.org/us000157.html

What a journey!

Set seven is the current release, let us know if you make anything cool or have questions!

-

Final presentation

04/29/2019 at 15:25 • 0 commentsThings have been crazy the last couple weeks since we've been preparing for our final senior presentation. Most of our time has been writing a cohesive narrative and figuring out things like financial simulations and build examples.

After we are done with everything we will do a time warp in the following days and update our project log.

Set 7 is live!

Set 7 is alive and well, stable modules in many formats ready to use! Share what you make!

Files may get sporadic updates and formatting in the next twenty-four hours or so. Licenses have been applied and registration for the OSHWA https://certification.oshwa.org/list.html is pending!

Of particular note are our example business model in the set 7 module directory and spreadsheet. One interesting estimation is that for a half million investment up to six million dollars profit can be made with a huge margin for safety if this system is adopted.

Final presentations, with hopefully a video and audio will also be available.

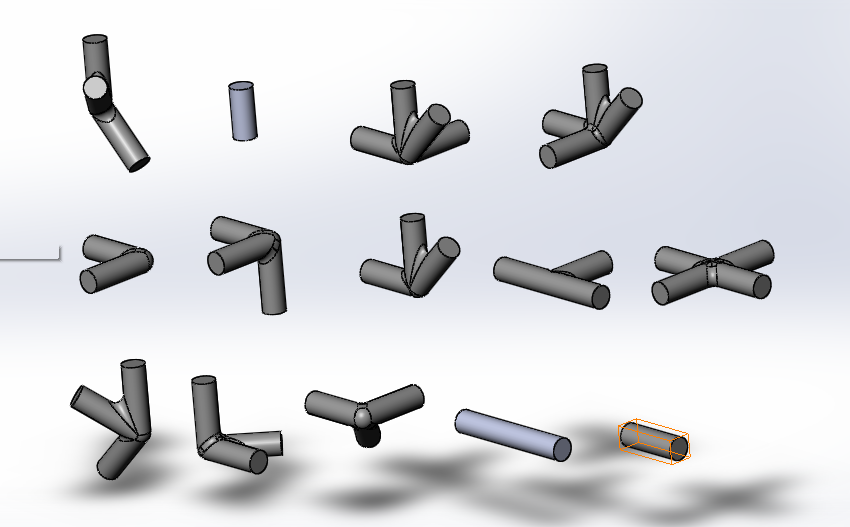

All set 7 modules rendered:

Mold to fabrication:

![]()

-

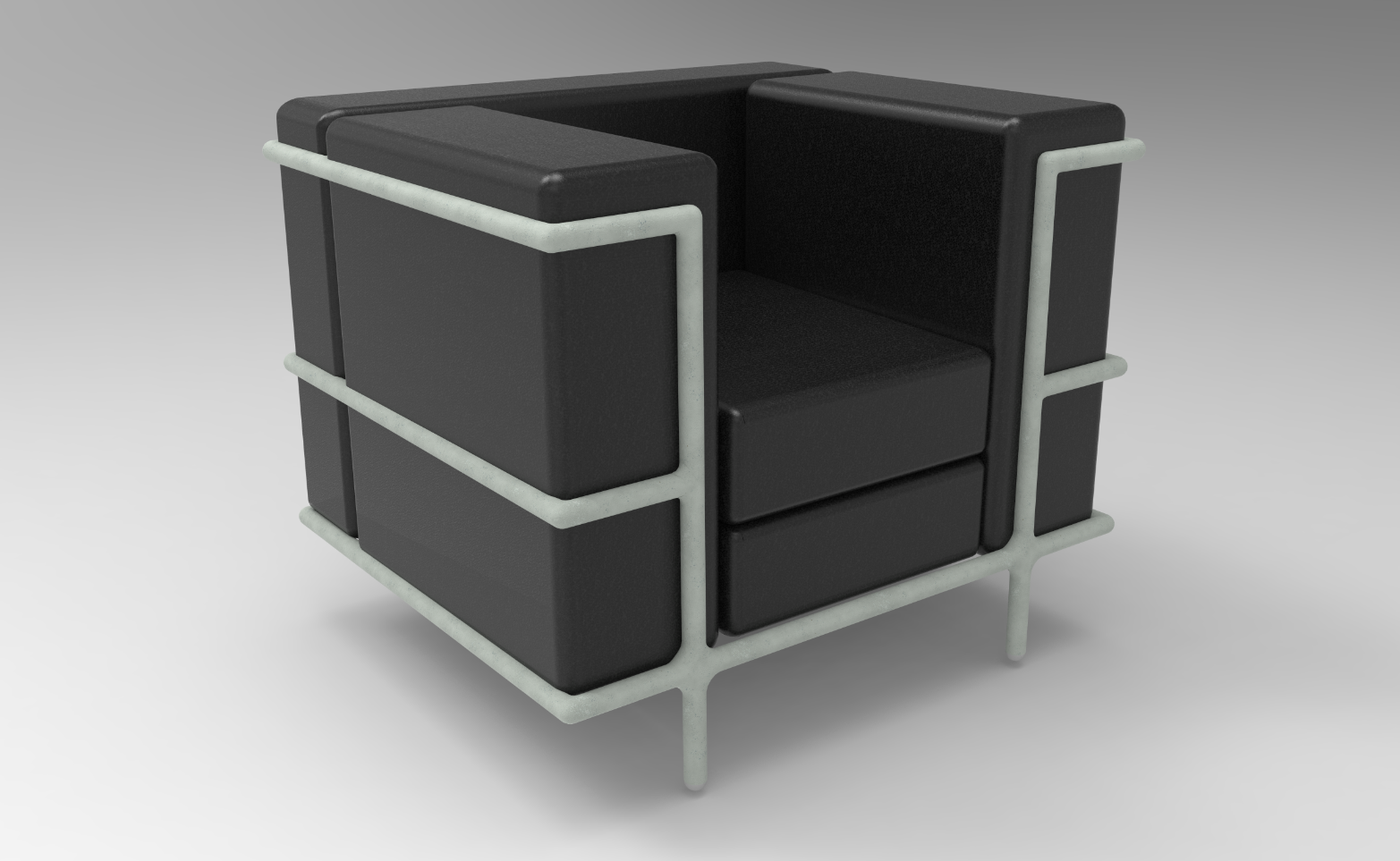

Renderings

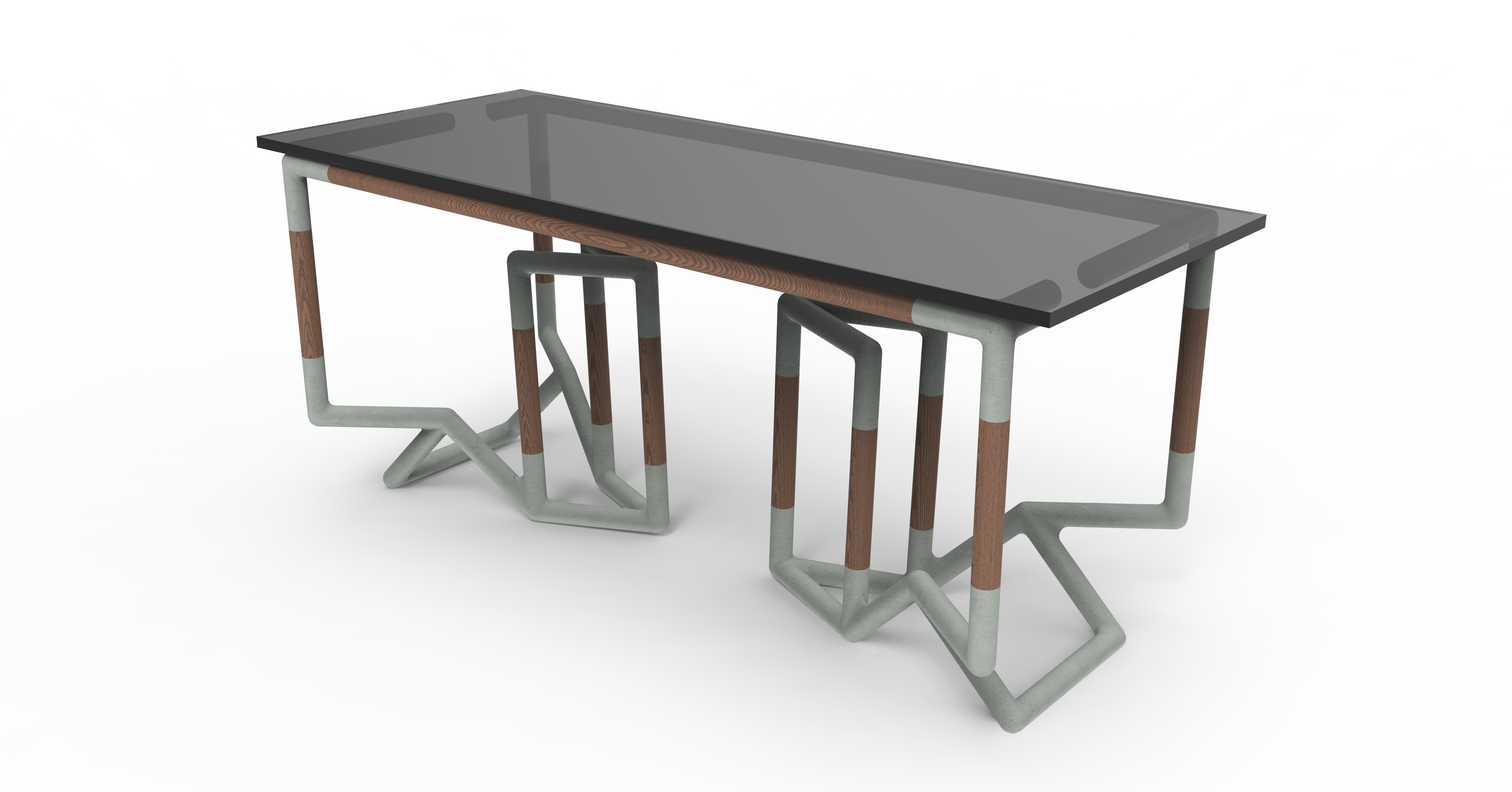

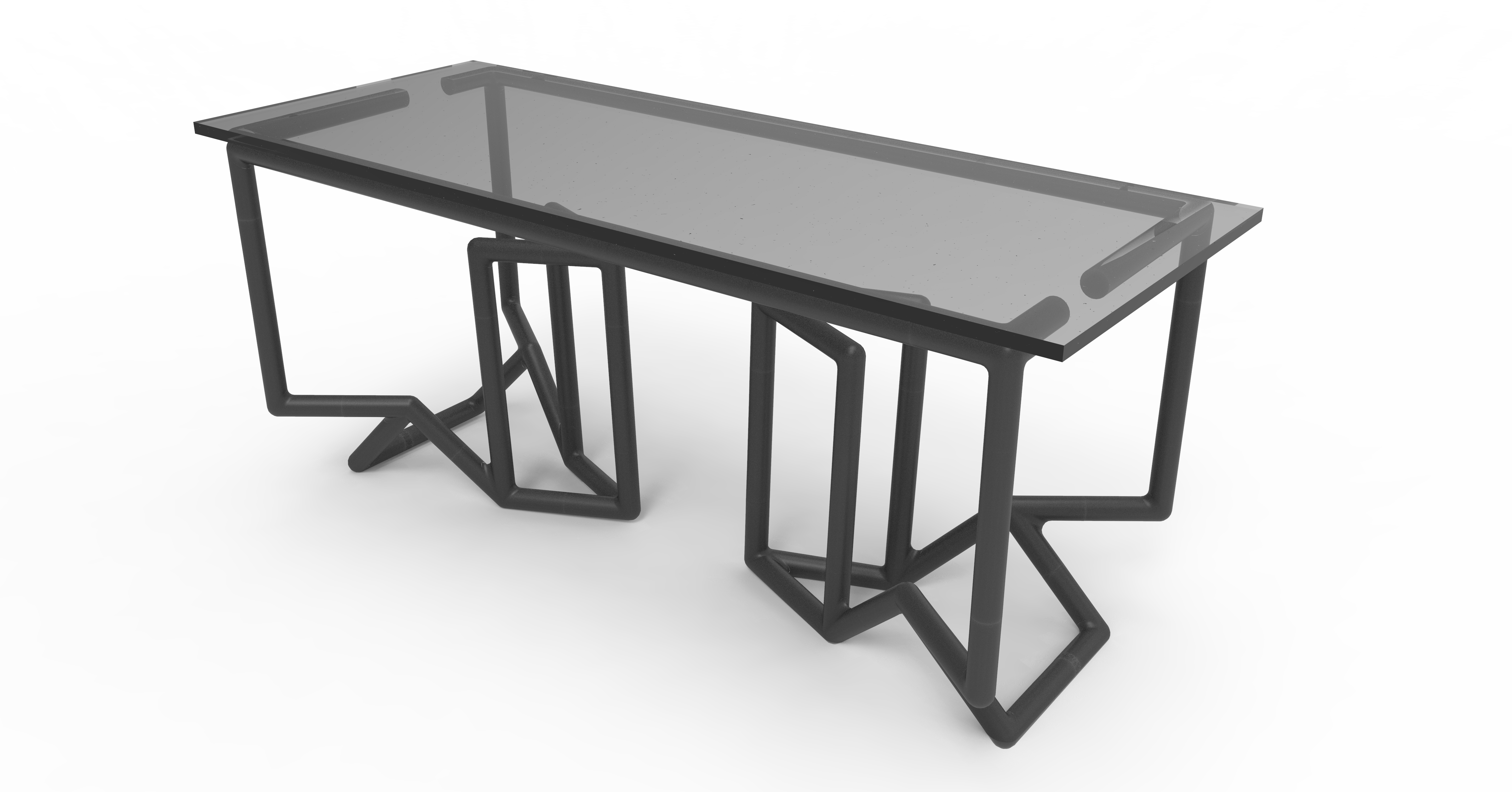

04/09/2019 at 19:06 • 0 commentsSome renderings were made to further explore some preliminary designs:

![]()

![]()

![]()

![]()

-

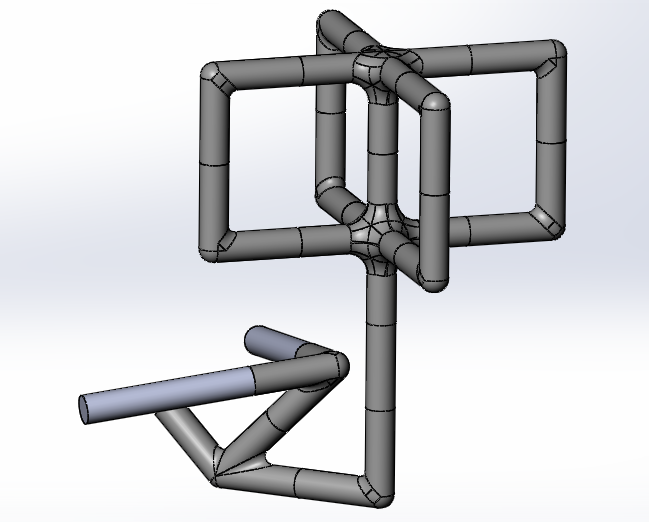

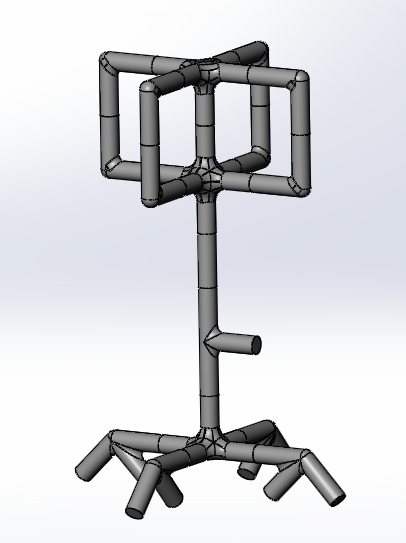

Solidworks form finding

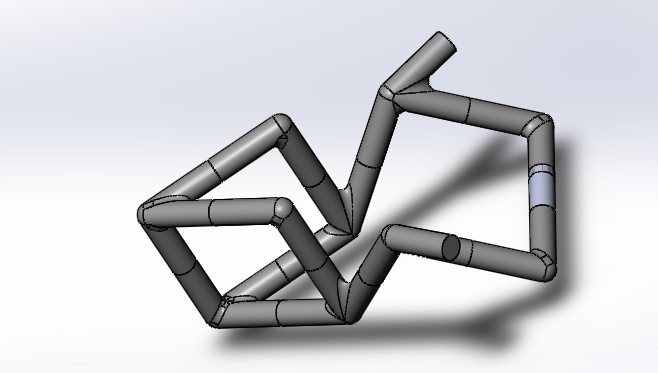

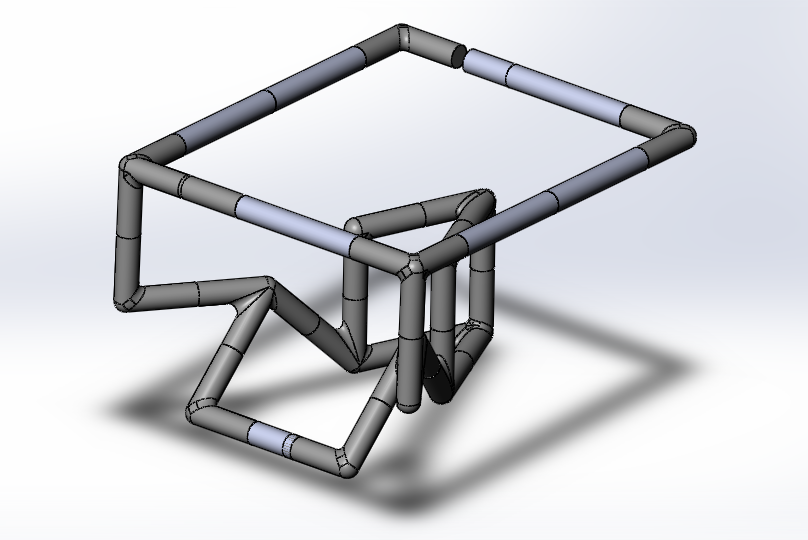

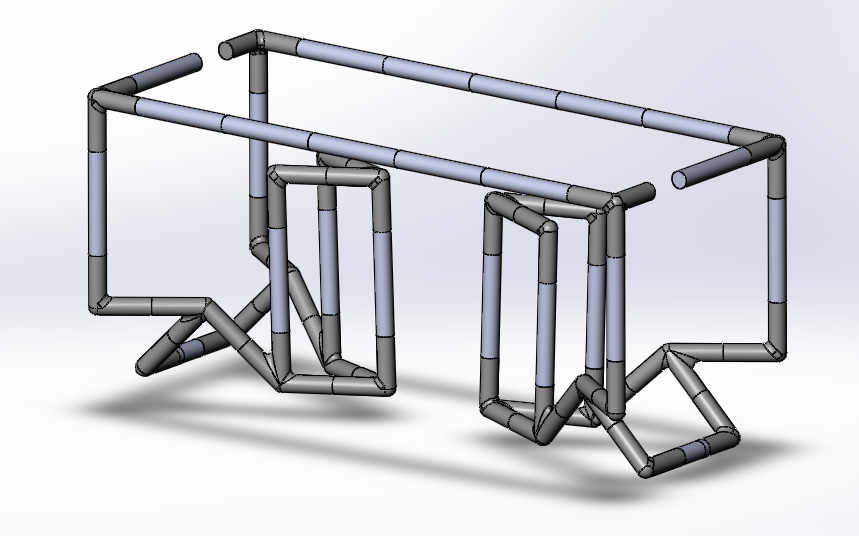

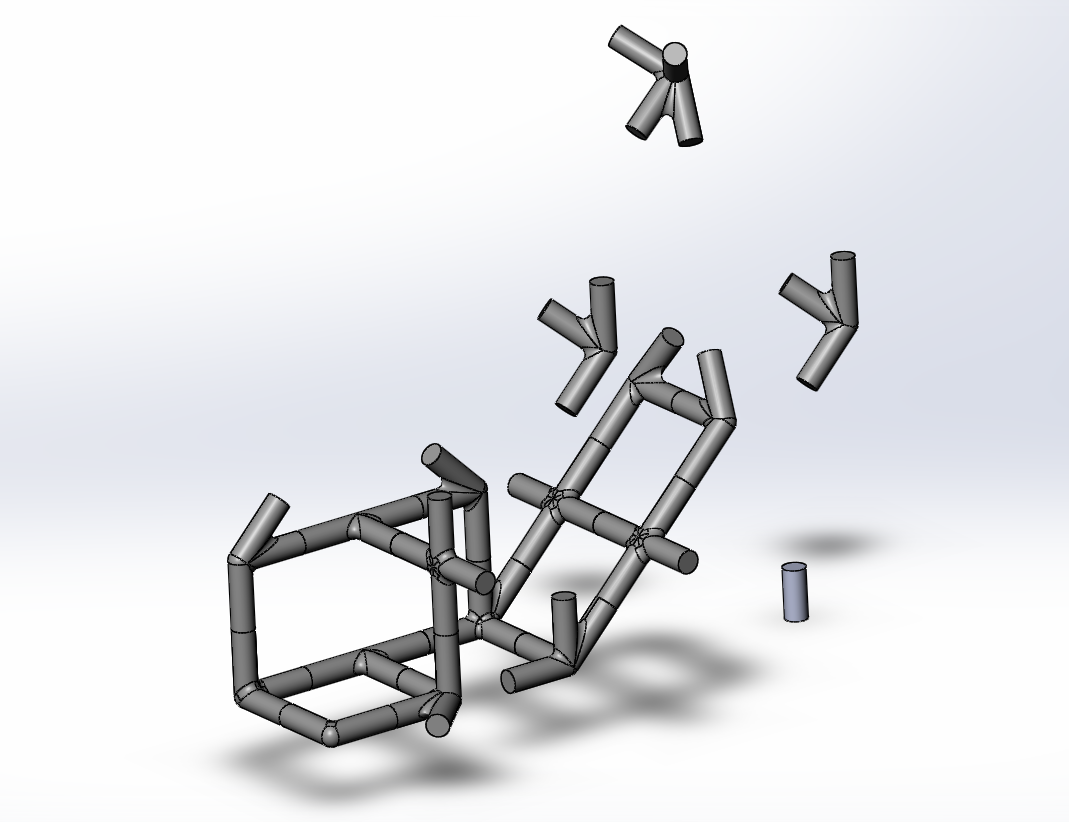

04/08/2019 at 14:45 • 0 commentsMates definitely help speed up the digital form finding process.

An example of a wall light and then its transformation into a desktop model.

And then using the same structure to inspire a table, initially too small but slowly growing to have correct proportions.

There are overlaps and several gaps which presents us with a unique opportunity. We can make a small insert module to take up these 1/4-.5" gaps and such or we can follow along with the natural troubleshooting method of our modules by inserting more modules and expanding dimensions until things line up correctly. Fortunately we can more or less cut and past and reorganize until things work but its definitely an interesting design process. You have an intention and find a module which will approximate it but due to its constraints it naturally guides the form into a specific form factor or increment thereof.

-

More snap together modules

04/04/2019 at 17:20 • 0 commentsWe still don't have one of each module since we added a few recently; expect file updates soon as fillets and molds are completed.

Interacting with the snap together modules is enjoyable though and we are quickly troubleshooting small problems:

![]()

![]()

![]()

![]()

Solidworks is interesting since the mate tool helps line up modules very quickly.

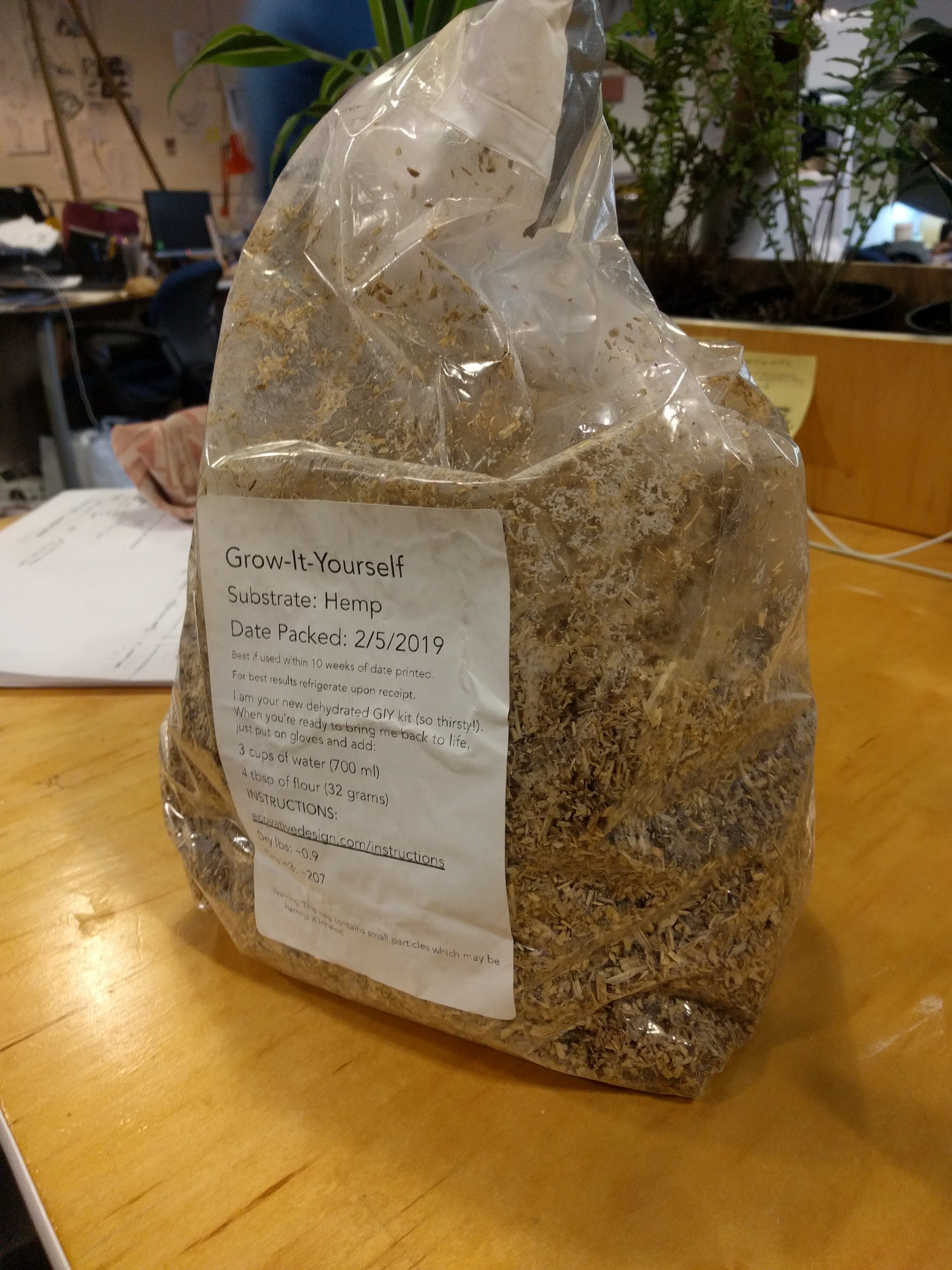

We also started a new bag of mycelium today to be ready for the final presentations.

![]()

Our older bag is looking a little funky now considering its been three weeks or so.

![]()

Kinda scary looking haha. So, we really need to stop wasting material and move it to molds or something.

-

Solidworks Form Finding

04/03/2019 at 15:42 • 0 commentsUsing the mate tool in Solidworks assembly is very fast for form finding, although it is a little annoying to undo a mate if you change your mind often. A quick start file will be created for those with Solidworks 2017 or higher once module files are finalized.

We still haven't gotten to try out Mindesk for Solidworks since we do not have Solidworks 2019.

The above assembly took less than five minutes to put together.

Geometer

A Holistic Design Tool for Creating, Communicating and Manufacturing Advanced Human-Scale Forms for Design Pioneers and Producers

David Troetschel

David Troetschel