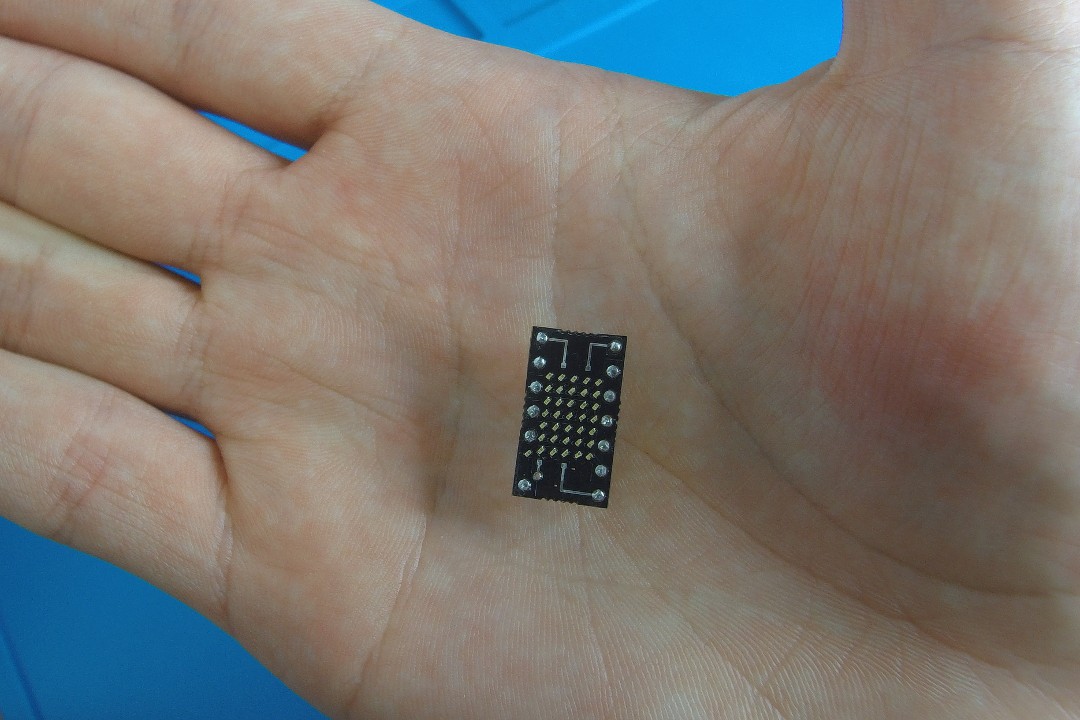

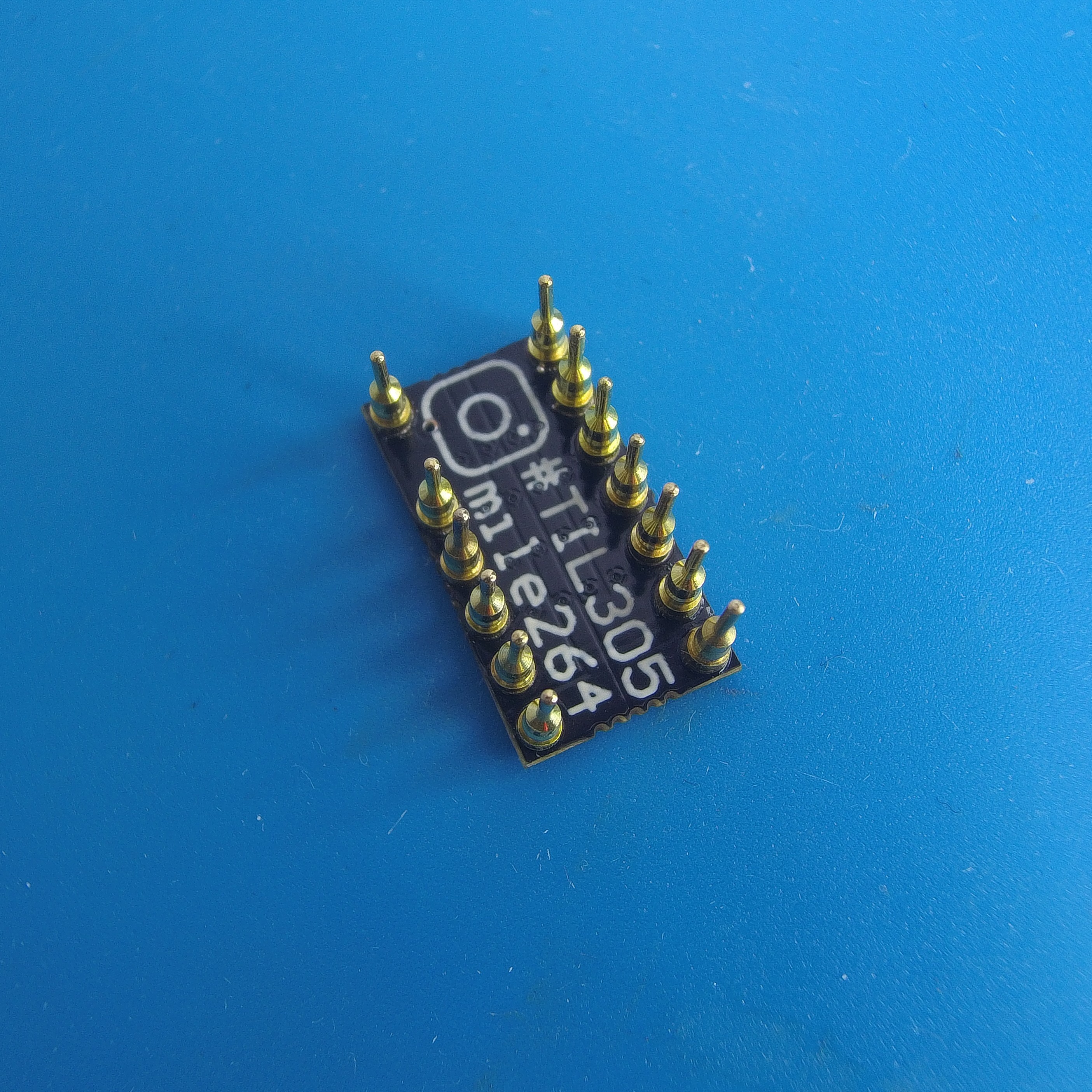

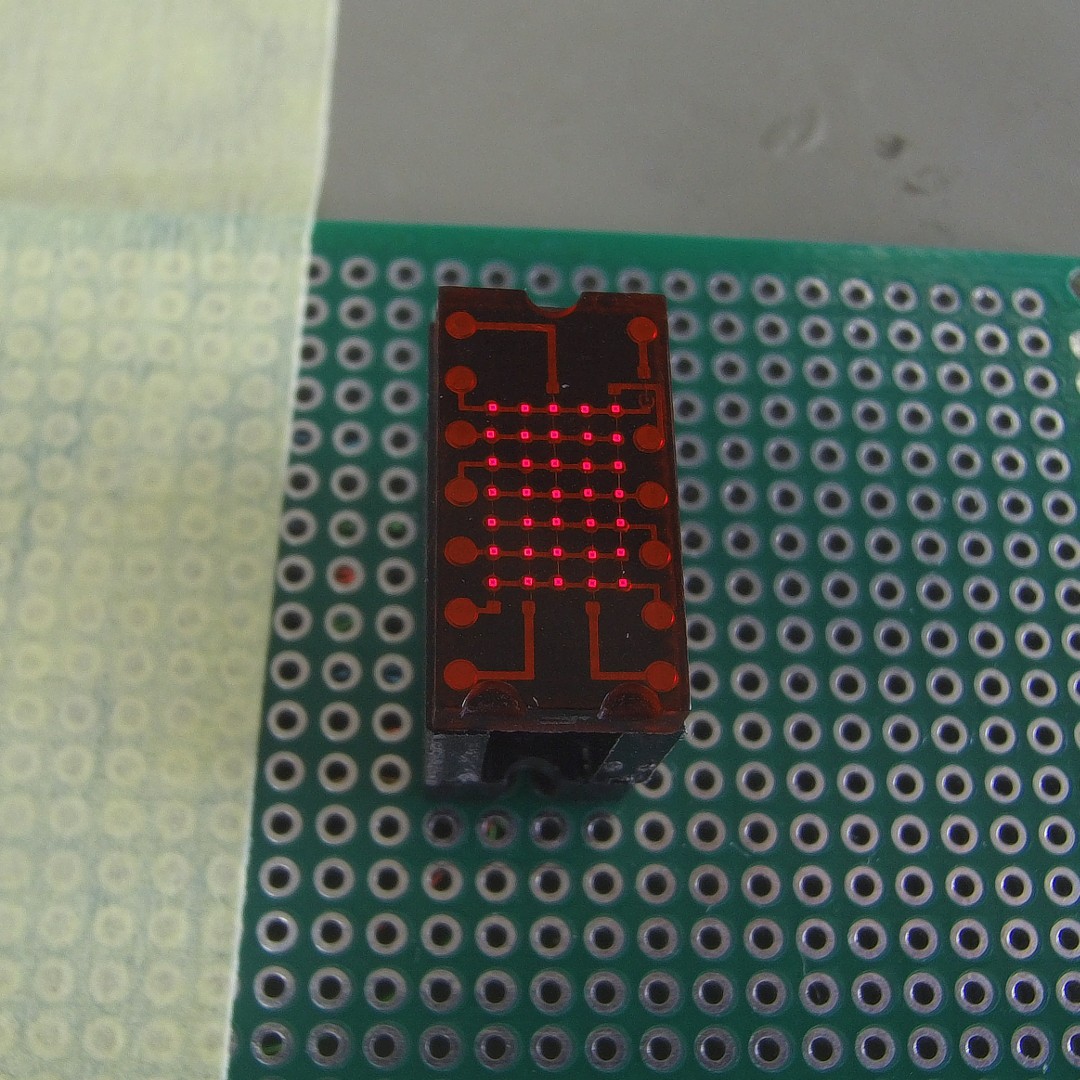

This week I assembled few DIYTIL305 modules. Main problems were: Solder paste that wouldn't go through stencil, leds sticking to tweezers and not being aligned with footprint after reflow process.

First problem was solved by getting finer grain solder paste (in future led footprint will be adjusted). Solution for second problem was to clean tweezers with rubbing alcohol multiple times during assembly process and re-heating leds with hot air gun with addition of flux so they align with footprint (some leds are still misaligned).

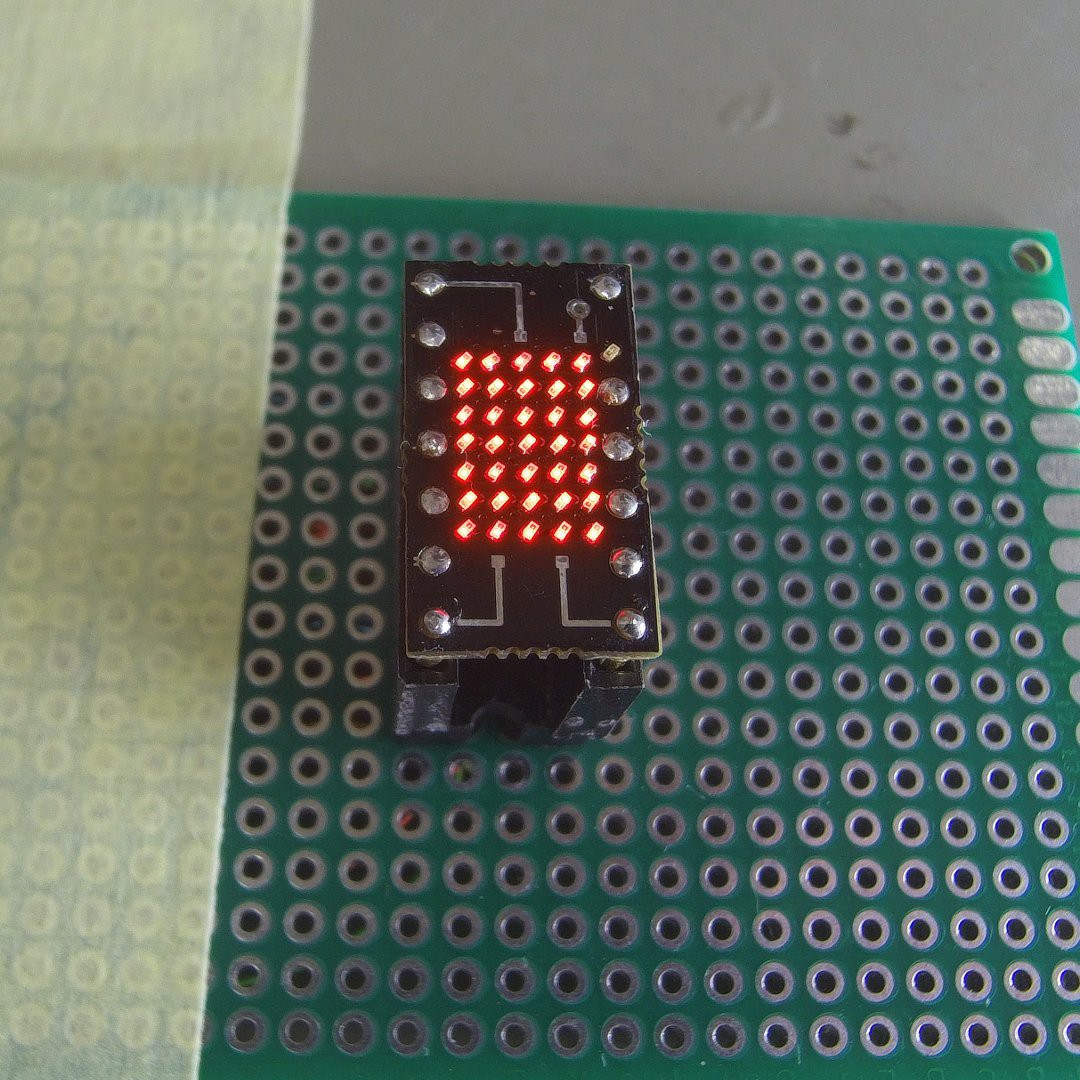

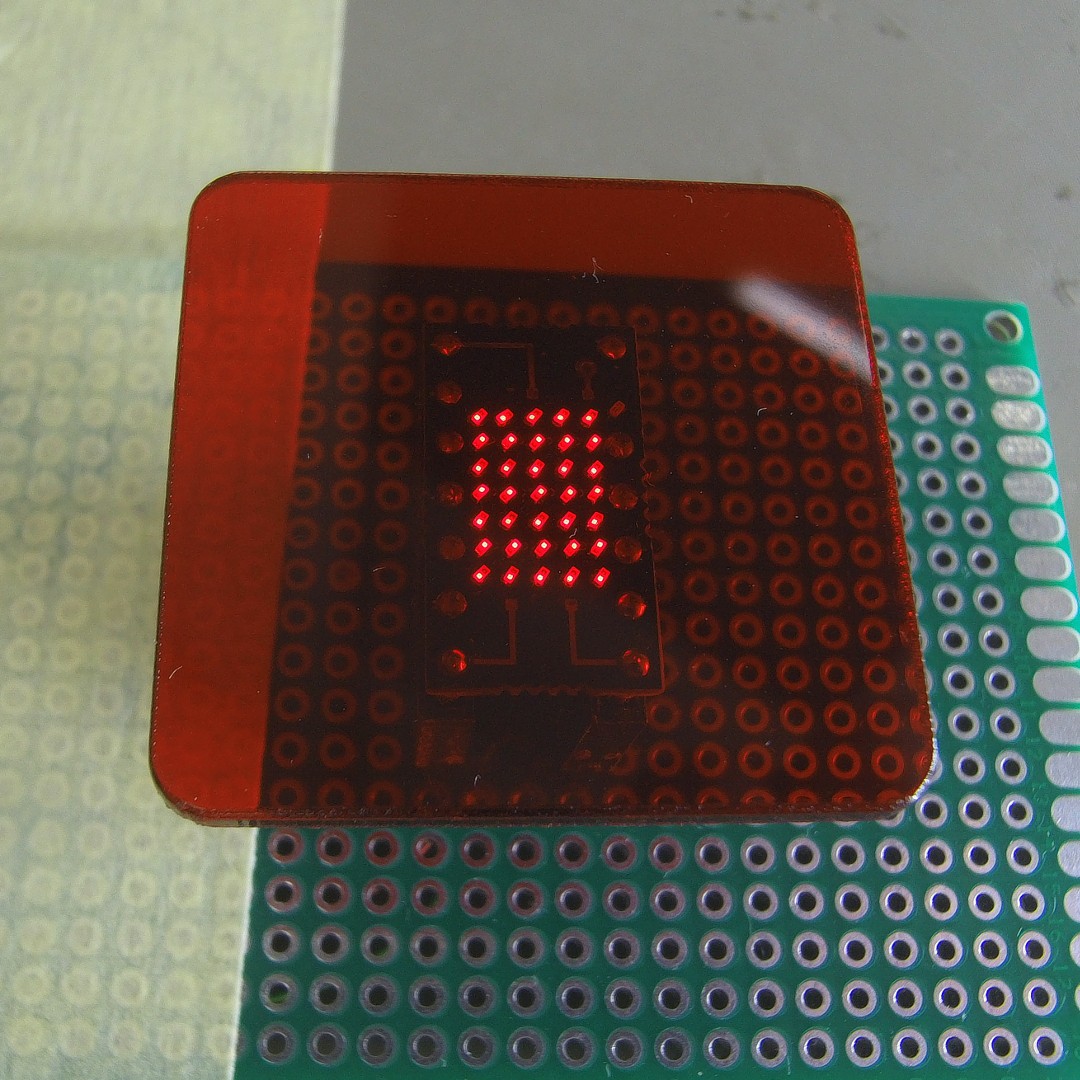

Afterwards I did some comparison between DIYTIL305 with red transparent acrylic and original TIL305 (last two pictures). In those pictures DIYTIL305 consumed 1.27mA and TIL305 15.78mA.

|  |

|  |

Mile

Mile

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

any updates on this project?

Are you sure? yes | no

Hi Dave

Don't worry, I haven't forgot about this project :)

Are you sure? yes | no

dandy! looking forward to an update!

Are you sure? yes | no

fantastic! i assume you switched from type3 paste to type5?

Are you sure? yes | no

LEDs under the acrylic sheet really look fancy! I like that they're brighter than the original ones. A bit more pointy would be nice but I guess thats just a side-aspect!

An added 0,8 or 0,6mm thick drilled PCB could act as a template for that?!

Are you sure? yes | no

cool :)

Are you sure? yes | no