-

Final version

08/01/2022 at 10:04 • 0 commentsFinal version is done. Under the following link you can see the video of the demo run.

I hope this is an inspiration to others. Remember, credit goes to HumansSince1982. It is protected by copyright and I can and will not share some critical information. The documents/information you find in this project documentation is also information which is available on other project logs.

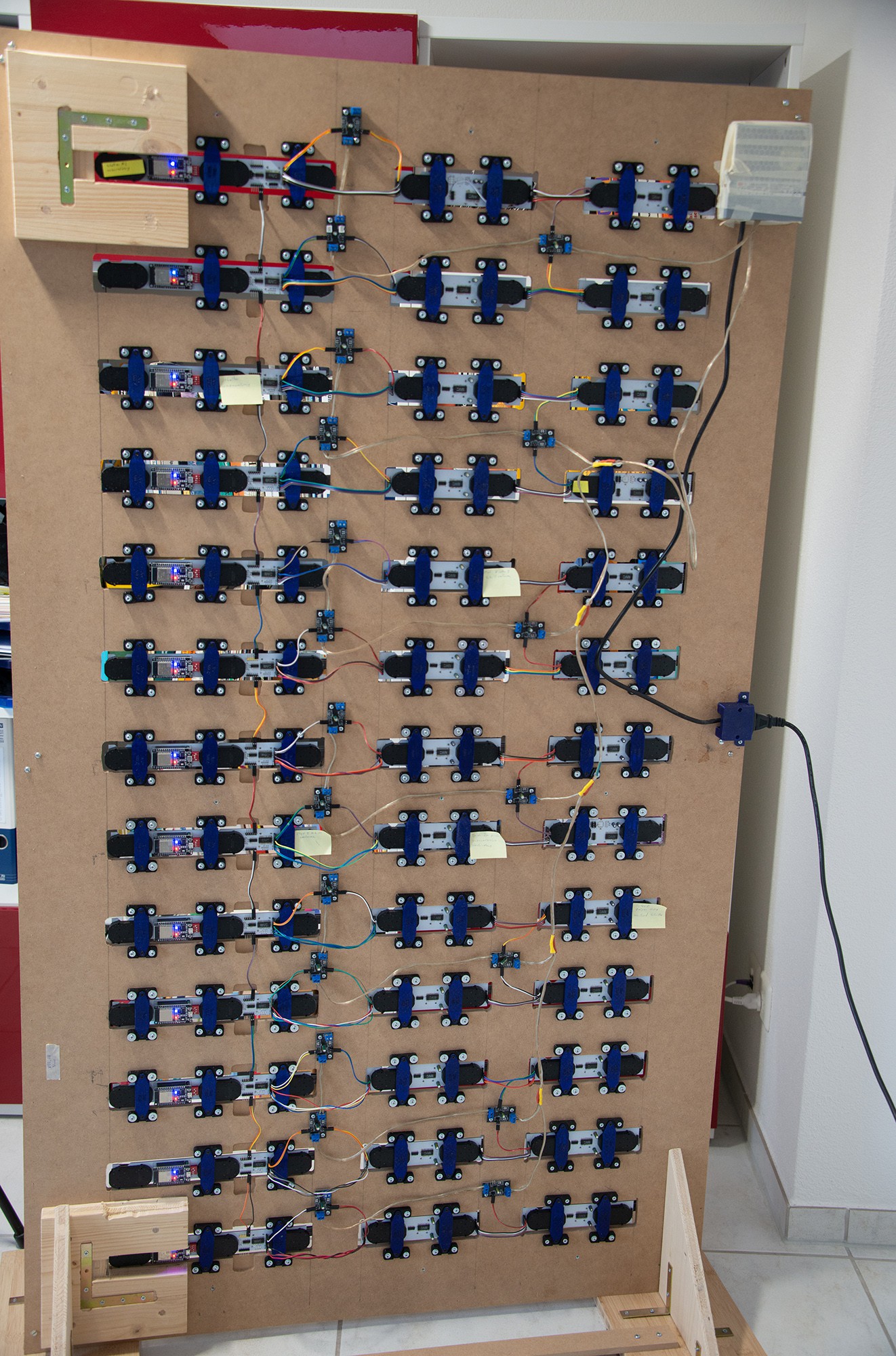

It's a great project to learn many skills. For me, the main learning was that it is a big difference if you design one part or like here for 182 handles. Every small error multiplies up to 182 times and it is really worth the effort to test and work structured! :-)

Have fun and a good time!

-

Time for an update - how to start 2021

01/03/2021 at 17:07 • 6 commentsAfter quite some while, I can present some progress.

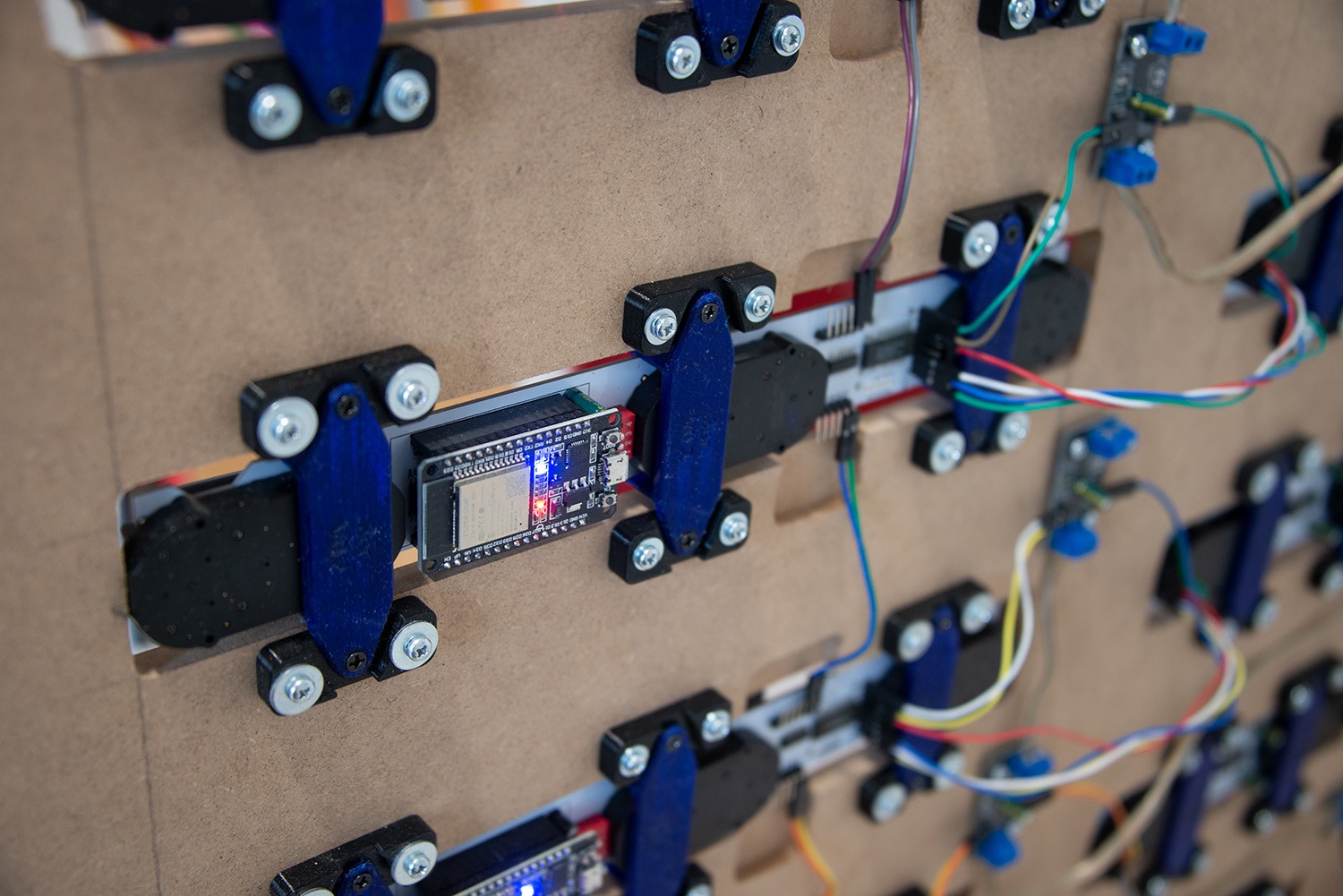

All 182 handles are working fine. I controll them over 13 ESP32 MCU. Between the "master" and the "slaves" (I know, this does not exist with ESP-NOW) I communicate with ESP-NOW. In future, an ANDROID app will controll the master.

The communication between the slave ESP32 and the stepper drivers, is via I2C and - don't follow this!! - Dupont wires.

I learned the hard way, what seems to be obvious to all experienced makers...

Dupont = prototyping

Dupont = NOT for large scale and/or permanent installations!They are simply not reliable. So I need to change to JST-XH... All of them... outch :-(

The PCBs with the motors are hold by a bracket which is screwed to a support on the wooden frame. With this, I can exchange easily individual PCBs later. Also they are interchangeable. I think, this almost 100h of 3D printing was worth the effort.

![]()

![]()

![]()

![]()

-

Version end of the year - not End of the project ;-)

12/29/2019 at 17:37 • 0 commentsSo, the year is ending and I have a little progress to show. It's like 10 step forward, 9 backward… Anyhow:

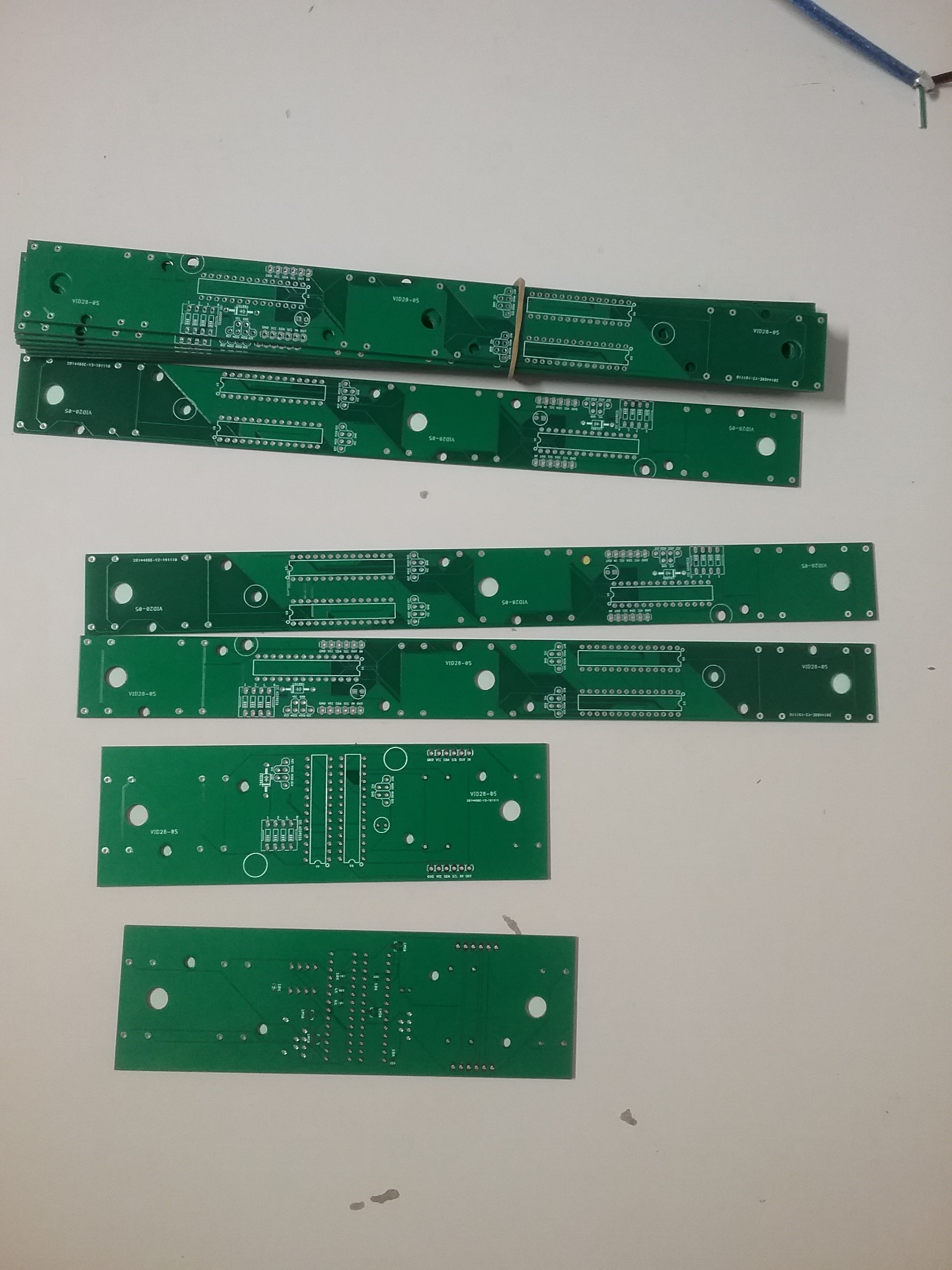

The new PCB's arrived, I figured out all errors I did and the motors are running. I have also got the first set of 3D printed handles (PLA) which fits more or less on the motor.

I have two different PCB because this is the maximum size I can get with the Autodesk Eagle free version. Otherwise I need to pay (and the project is expensive enough…). So I have one PCB with 3 motors and one with 2 motors. At the end, the installation will have 5 motors vertically and 11 (or 13) horizontally.

What does it do now?

First the lower handle rotate until it passes a hall sensor. Every handle has a hall sensor and a different offset to know where is zero position (12 o'clock). After this, the handle goes to 3 o'clock to avoid an interference with the upper handle. As the upper handle is quite far away from the hall sensor, the magnetic field change is very little and therefore the other magnet shall not be too close.

After this, the handles go to 12 o'clock. As soon as they are there they give the signal that they are ready. When all are ready, the master gives a new position via I2C for all MCU (every motor has a MCU with a different I2C Address). The new positions have the informations:

- delay prior to run

- new position

- speed

- accellerationIssues:

- Some bugs on the PCB :-(

- The magnets are too close. One handle can push the other slightly

- One broken motor was replaced, two other seems to have problems with the gear too. I am not sure if it's because I treated them bad or if they wear so fast? I hope not!

You see the damages on the handle of the motor "2" with the sticker on it. The gear is sometimes jumping a little bit when the handle should turn upwards.Changes for the next version:

- Hall sensors further away

- upper handle closer to the PCB (for the signal of the hall sensor)

- Test with other motors (X40)

The video to show how it works is here:

All files are in the document section "V08".

![]()

So I am always open for ideas, inputs and questions :-)

Wish you a happy new year!

-

Next attempt with new library

09/15/2019 at 14:42 • 0 commentsSo, after the last attempt (without acceleration) worked, I realized that the accelerations are hard to compute for two handles in parallel for an ATMEGA328 with the accelstepper library. The square root calculation takes a lot of time. So I have two solutions:

A) one MCU per handle (this will be expensive and a pure Overkill, but it has proven to work well)

B) change the way to calculate the acceleration

So obviously I have chosen B...

The approach for the following discussion is always, to have a certain frequency at which the programm is run (at the moment at 0.6ms) and it checks every time if there is a move to be run. Means, a speed of "2" makes a step every seccond tick. A speed of "4" makes a step every 4th tick...

As first, I calculated with a simple formula the acceleration and deceleration. Formula for deceleration:

amountOfTicksToAccelerate)*accelerationSpeed/(targetTick-actualTick).

This Formula works very well for acceleration, but at deceleration it is highly risky that the computed values will not match exactly and it ends up in non-matching position vs. timing.

So I made it the "easy" - and for programmers horrible - way. I saved an array for the acceleration. After how many ticks, shall the next step be made. The array is 50 items long:

accelArray[50] = { 12,11,10,10,9,9,8,7,7,6,6,6,5,5,4,4,4,3,3,3,3,3,2,2,2,2,2,2,2,1,1,1,1,1,1,1,1,1,1,0,1,1,0,0,1,1,0,0,0,1 }

The first move is after 12 ticks. Tick timing is 0.6ms, so after 7.2ms the first move is done. The seccond step is after 11 ticks (6.6ms) etc. To decelerate I run the array backward. The main curve was calculated and then tested with different speed/acceleration combinations until it looked smooth.

So the acceleration phase with acceleration value of "1" ist always 50 steps. If you choose acceleration of "3", then it runs the array 3 times. Means, 3 times after 12 ticks, then 3 times after 11 ticks…

It's not nice, I know, but at least I was able to make it work smooth and reliable.

Here is the video: https://youtu.be/93-9P3XuW-w

The code and library is uploaded in the document section.

Any input/suggestion is highly welcome! :-)

-

New PCB arrived

08/26/2019 at 19:25 • 2 commentsSo, summer is ending and the new PCB arrived after the vacation. The Hall sensor works pretty well. However, the speed is an issue at the moment. Not that I want to run the handles very fast, but the max speed (if both are running at the same time) is roughly 9s/turn. And in addition, when one handle is running at constant speed, it changes speed when the other is accelerating. Seeing all the other attempts on the internet, I doubt that the ATMEGA328p is at his limits. But what is then the reason???

Video can be seen here:

And yes, I did an error on the PCB, therefore I had to handsolder a little bit ;-) Looking for half a hour on the PCB prior to manufacturing is obviously not enough...

Have a good start of the week!

-

Home function with hall sensor tested

04/27/2019 at 22:10 • 0 commentsFinally, I managed to work again on the prototype. The zeroing of the handle seems to be a Problem. I did not find much Details on all the other Projects which attempted this. My Approach was now with a Hall sensor and a small magnet. I was surprised how precise it can work on a distance of 5mm. It works also quite good on a larger distance.

Now I have to make new PCB and replace all my handles with the new PCB. Let's see how this will work...

You find the Video of the test here:

-

First prototype working

11/30/2018 at 15:59 • 0 commentsAfter many attempts, many PCB scraped... here is my first working prototype. However, there seems to be many issues with it.

As motors I have used the cheap VID28-05, but trying now also the X40 motors.

My own "a million times clock-clock"

cheap rip off from the art installation of Humans Since 1982