$1 PCB Christmas Tree

A Christmas tree made on printed circuit board with embedded 0805 SMD flashing LEDs

A Christmas tree made on printed circuit board with embedded 0805 SMD flashing LEDs

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Eagle_PCB_Christmas_Tree.rarRAR Archive - 49.19 kB - 01/03/2019 at 13:46 |

|

Instructions and Eagle files have been uploaded. Gerber files will follow soon.

You will need:

Necessary tools:

Optional (but handy) tools:

Skills:

Bill of materials:

| Components | Supplier | Wholesale price ($) | Price per PCB ($) |

|---|---|---|---|

| 11x 0805 SMD blinking leds | Aliexpress | 15,79 | 0,29 |

| 1x CR1220 battery | 0,75 | 0,15 | |

| 1x battery holder | 6,58 | 0,07 | |

| 1x toggle switch | 2,62 | 0,03 | |

| 2x 2 pins header | 0,51 | 0,01 | |

| 1x PCB | 4,90 | 0,12 |

I've chosen cheap components to keep the BOM below the symbolic price of $1 per Christmas tree PCB. The total price for one PCB Christmas tree with all the electronic components soldered is estimated to $0,67.

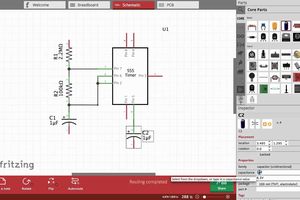

I designed my PCB Christmas tree using Autodesk EAGLE. EAGLE is an electronic design automation (EDA) software enabling schematic diagrams design, component placement and PCB routing.

I started the design by creating the schematic of the electronic circuit. It consists in 11 flashing LEDs in parallel, powered by a 3 V button cell battery. A switch can open or close the circuit. Finally, an optional filtering capacitor of 10 µF is placed between the battery voltage and the ground.

I made the choice to not include a resistor in series with the LEDs as 3 V is very close to the forward voltage of many LEDs colors:

The schematic and the PCB are divided in three parts:

I decided to opt for a reduced size of 48 * 48 mm per fir by drawing the outline of the board with the 20th layer "Dimension".

I drew the shape of the fir tree using the 46th layer "Milling" with a width of 3 mm: this line is interpreted as a milling area for the manufacturer, and separate the fir from its fins.

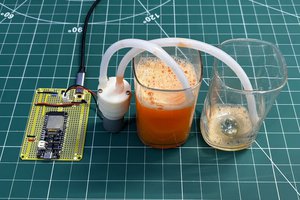

Once the outline of the circuit clearly defined, I placed the largest components such as the battery holder and the switch, then the LEDs so that their distribution is pleasant.

I added another milling area on one fin so the battery holder can fits and a hole on the top the tree to be able to hang it anywhere (in a real Christmas tree for exemple).

Then, I routed all the components using Top and Bottom layers : the battery voltage is distributed to the LEDs with 0,5 mm width traces and an overall ground plane.

Finally, I designed two breakaway tabs and placed them between the main fir and its fins on the 3 mm milling trace in order to keep my board as a single design and allow PCB panelization (see next step for more details).

All Eagle files can be found on my github

Most PCB manufacturers now offer a single price of $5 for 10 PCBs up to 100*100 mm in size. The price remains the same whether the circuit is 50*50 mm or 100*100 mm. Cost optimization is then possible by maximizing the number of circuits on this maximum area. PCB panelization consists of creating a single PCB from several small ones in order to reduce cost and waste.

Most PCB manufacturers do not charge extra cost for identical design panelization. It means you can manage to fit several small PCBs into one for free, but it must remains the same design for all. More informations can be found on the PCB manufacturer Seeedstudio's website.

PCB panelization can comes in 2 ways:

More informations about PCB panelization design can be found in the very well documented article written by Jack Lucas for www.ElectronicDesign.com.

In order to reduce the cost of my project, I've decided to panelize four of my PCB Christmas trees into one single board. First, I had to link the two fins of the PCB Christmas tree to the main board. I designed two breakaway tabs with a 3-holes perforation pattern which link each fin to the main Christmas tree board. The breakaway tabs are made of 2*3 holes with a diameter of 0,9 mm.

Once the design of one PCB Christmas tree finished, I duplicated it four times and dispatched each of them side by side to fill the 100*100 mm area imposed by the manufacturer. All designs are spaced by 3mm and connected with breakaway tabs with a 3-holes perforation pattern.

The final PCB has a size of 100*100 mm and contains 4 Christmas tree PCBs. The cost of a PCB unit is so divided by 4 !

Create an account to leave a comment. Already have an account? Log In.

Wow! That panelization is brilliant. I was looking at it for like 40 seconds wondering why you have circuits in the waste part of the panel and then realized the two halves are the perpendicular boards that make the tree 3-dimensional. So clever.

Thank you ! I reused the panelization method I found in an Instructable when I was looking for inspiration : https://www.instructables.com/id/PCB-Christms-Tree/

Become a member to follow this project and never miss any updates

Arnov Sharma

Arnov Sharma

Elecrow

Elecrow

Lithium ION

Lithium ION

Tree stand falls can lead to good sized accidents like damaged bones, concussions and inner stand to make best hunting tent. Occasionally, a fall can result in a head injury or spine harm that consequences in paralysis.