-

Picking up and placing on

03/14/2019 at 17:43 • 0 commentsHere is a quick video of the pick and place machine that is making the PCB's for the cube. They are working on it right now. The clock is ticking. If you hire a third party to design your PCB's, it is always a good idea to ask them to optimize it for SMT as much as possible. This is pretty much assumed most of the times, but well, better be safe than sorry.

SMT is the acronym for Surface Mount Technology and in a nutshell, it is the technology behind Pick and Place machines and electronic components optimized for such equipment.

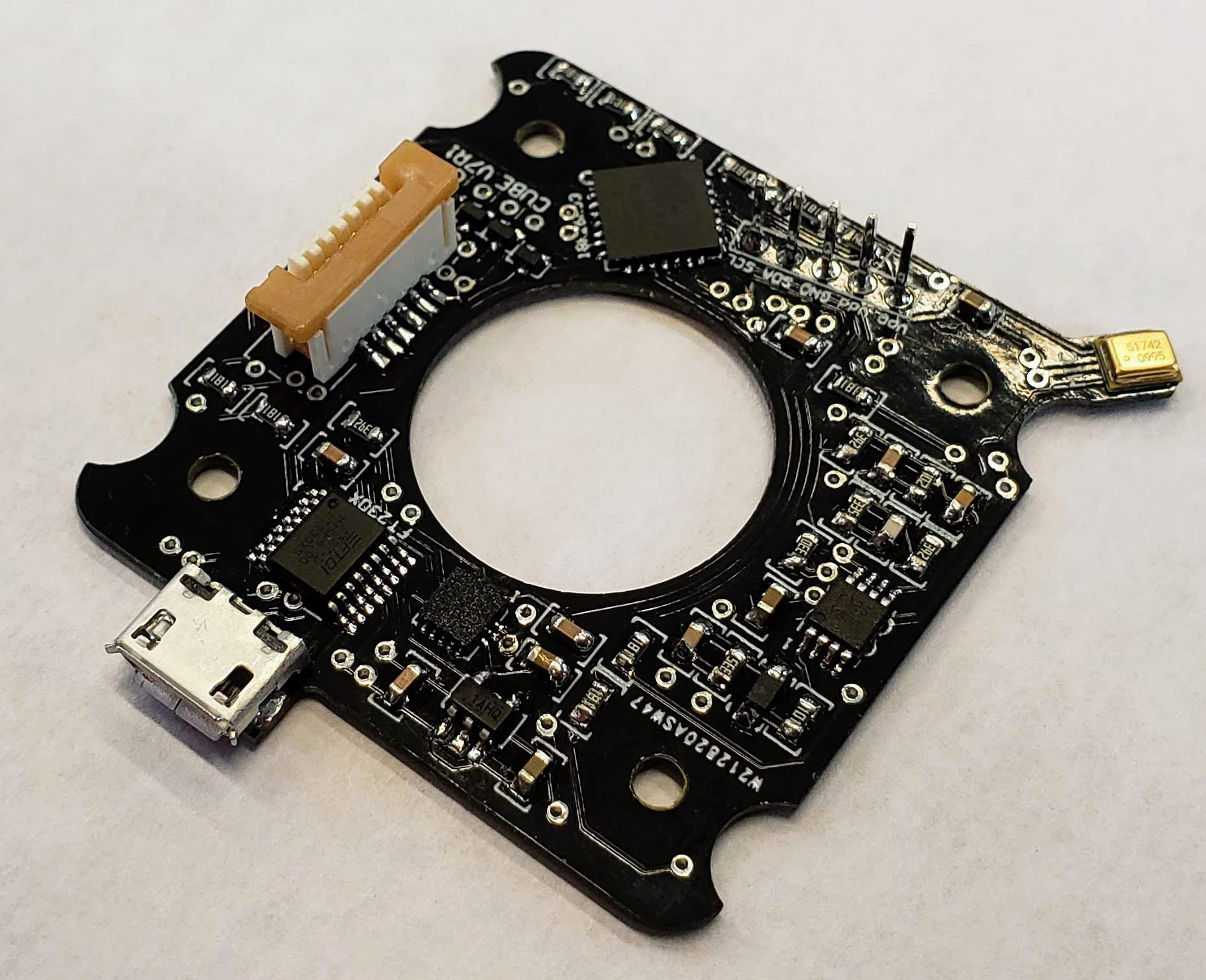

And this is a photo of a prototype of the PCB

![]()

-

Manufacturing

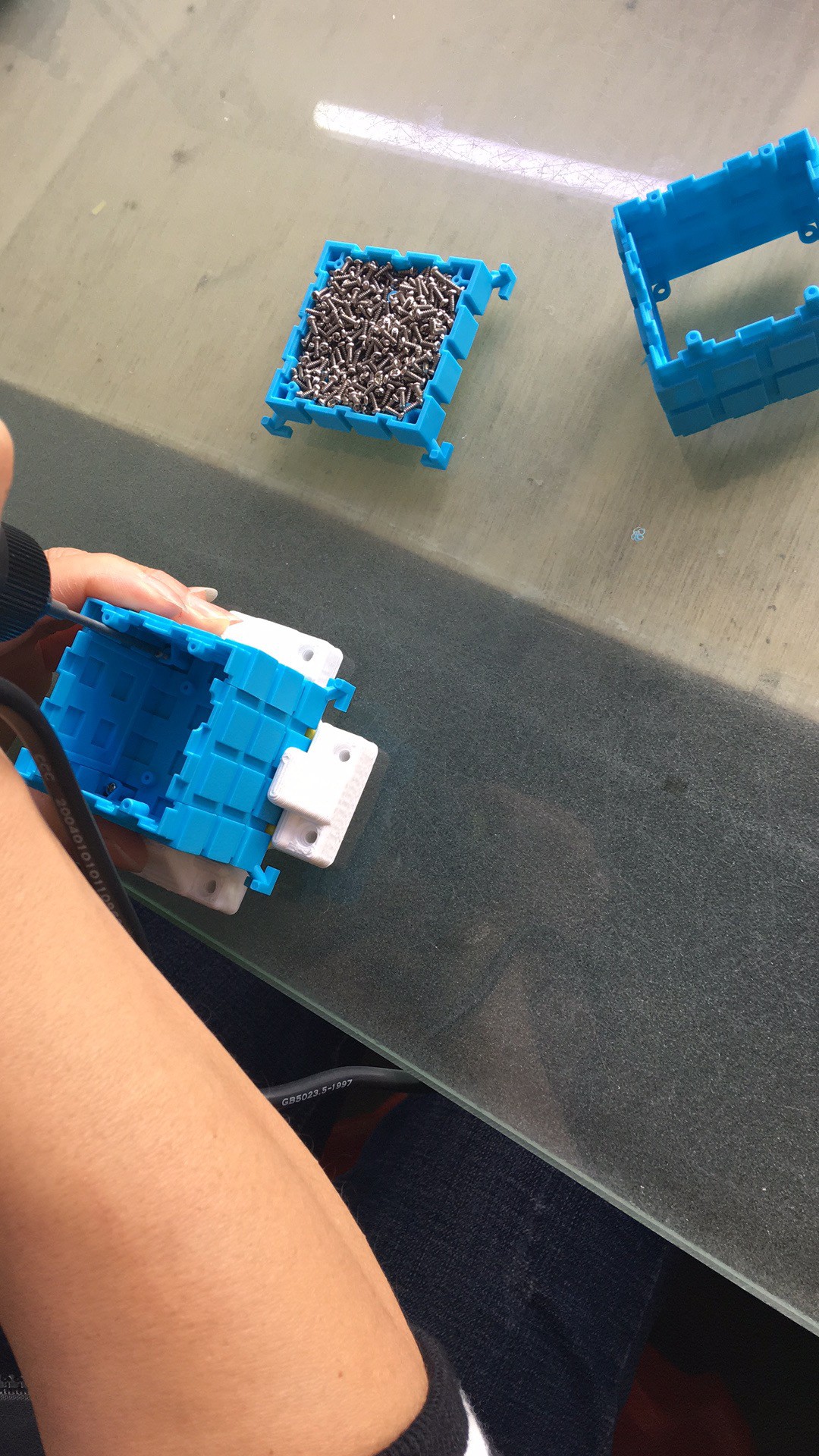

03/11/2019 at 23:07 • 0 commentsWe only have a few days before electronica and seeing WeChat notifications in the middle of the night has now become a ritual. Long after this project is done I am pretty sure I will keep waking up at ungodly hours. Here are some photos of the assembly process.

Designing a cantilever snap fit was trickier than I anticipated and even with a few minor adjustments, snapping the light pipe onto the base required extra strength.

![]()

I am very happy the jigs I made at the DesignLab are being used in China assisting the manufacturing team. I designed them in a way that would keep the cube in a fixed space while protecting the brackets during assembly.

![]()

![]()

-

The thing within the other thing works!

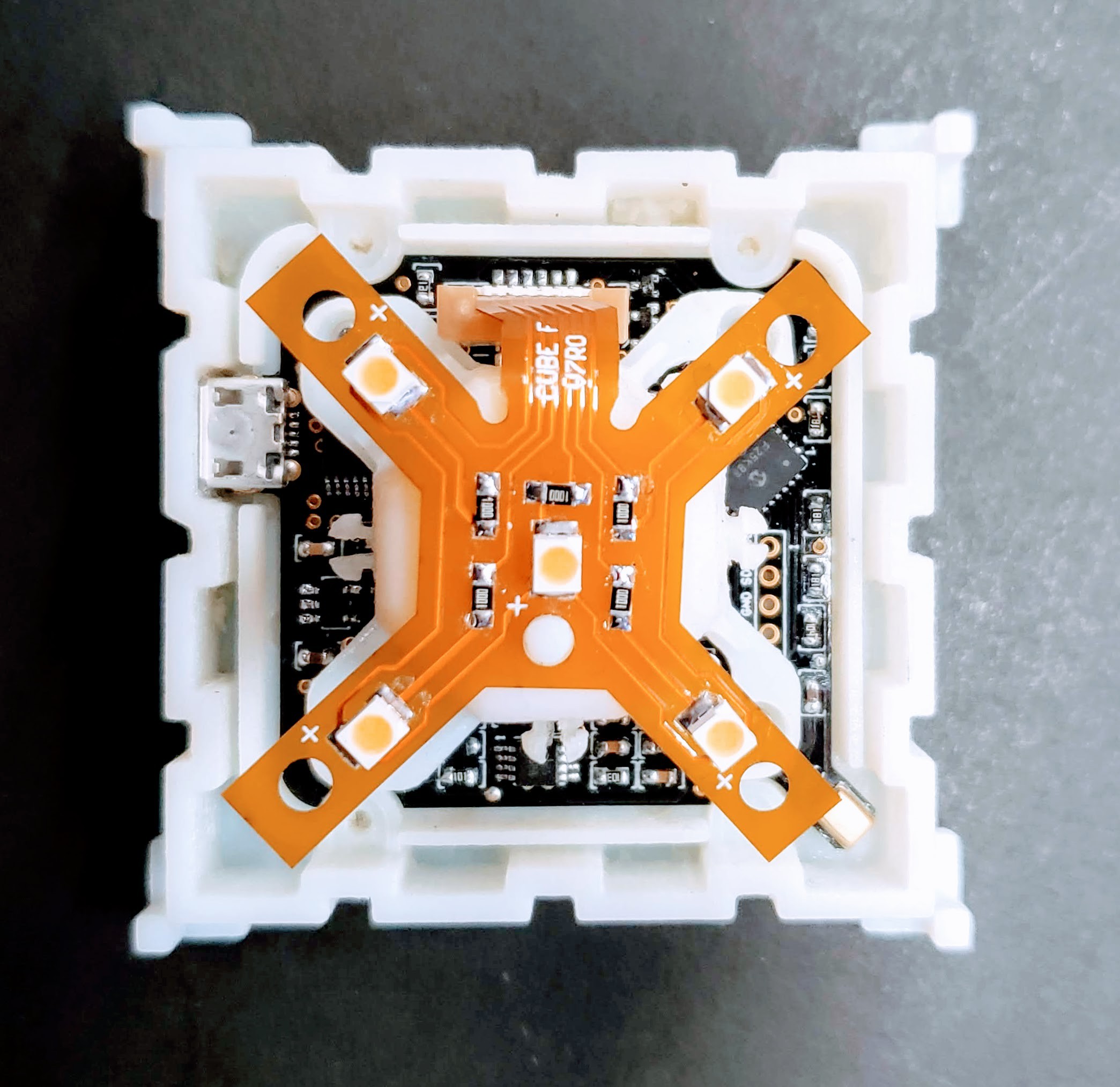

03/07/2019 at 19:47 • 0 commentsThe thing works! Voja and I developed this LED-populated, X-shaped, flexible PCB that orients light at different directions without the need of separate PCB's.

![]()

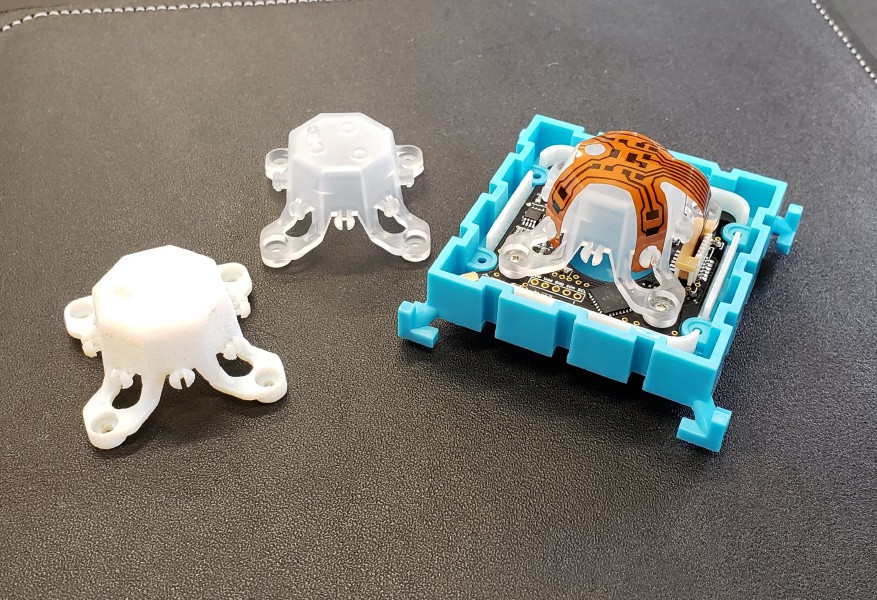

A huge challenge was to design a plastic fixture that would, well, fix the PCB at all those planes securely, that would be easy to mount at the assembly line, and that would be made with an injection mold with no sliders. The first samples are here and they work like a charm!

To the left there is a prototype we printed at the DesignLab, an actual production part, and the whole assembly to the right.

![]()

Giovanni

Giovanni