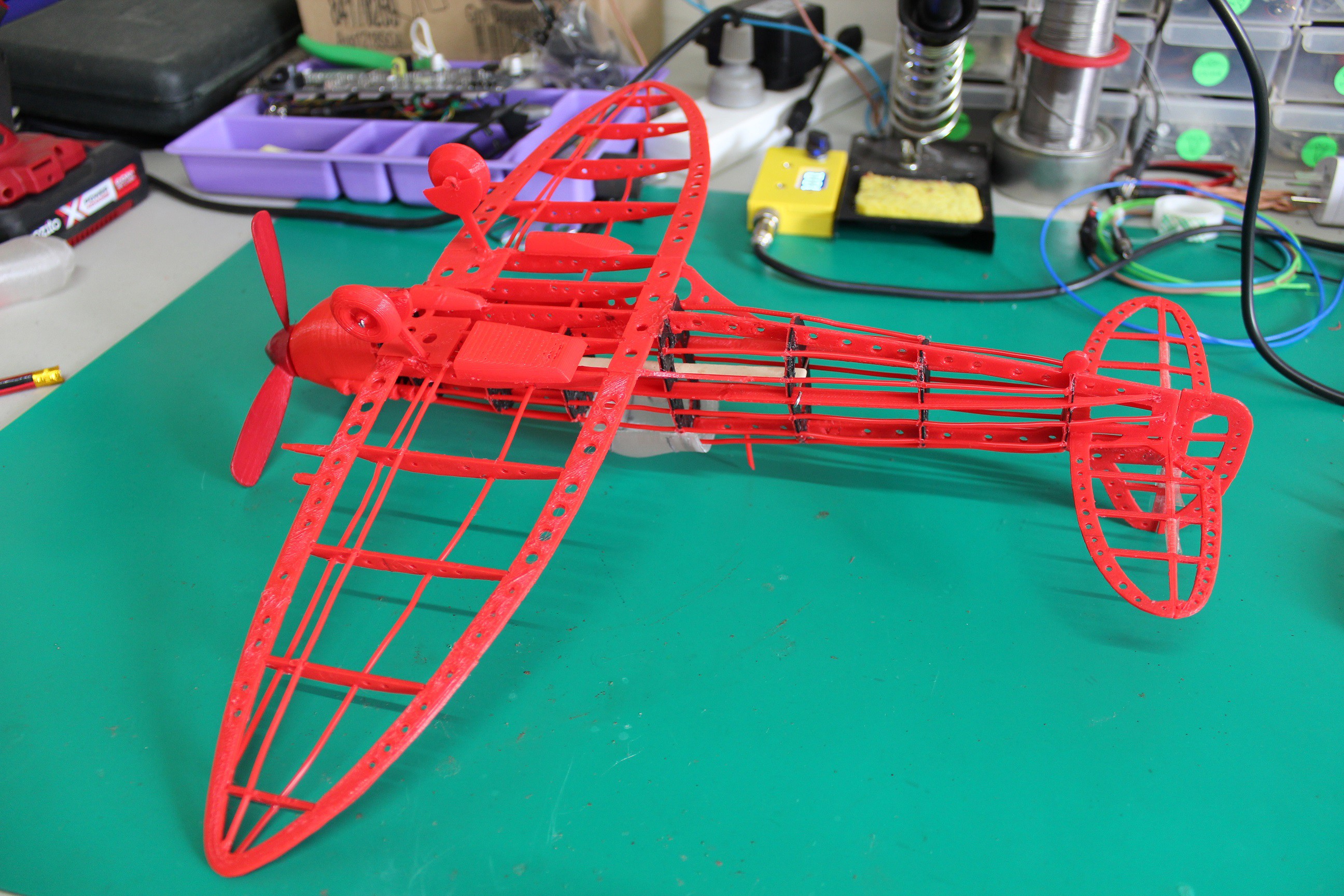

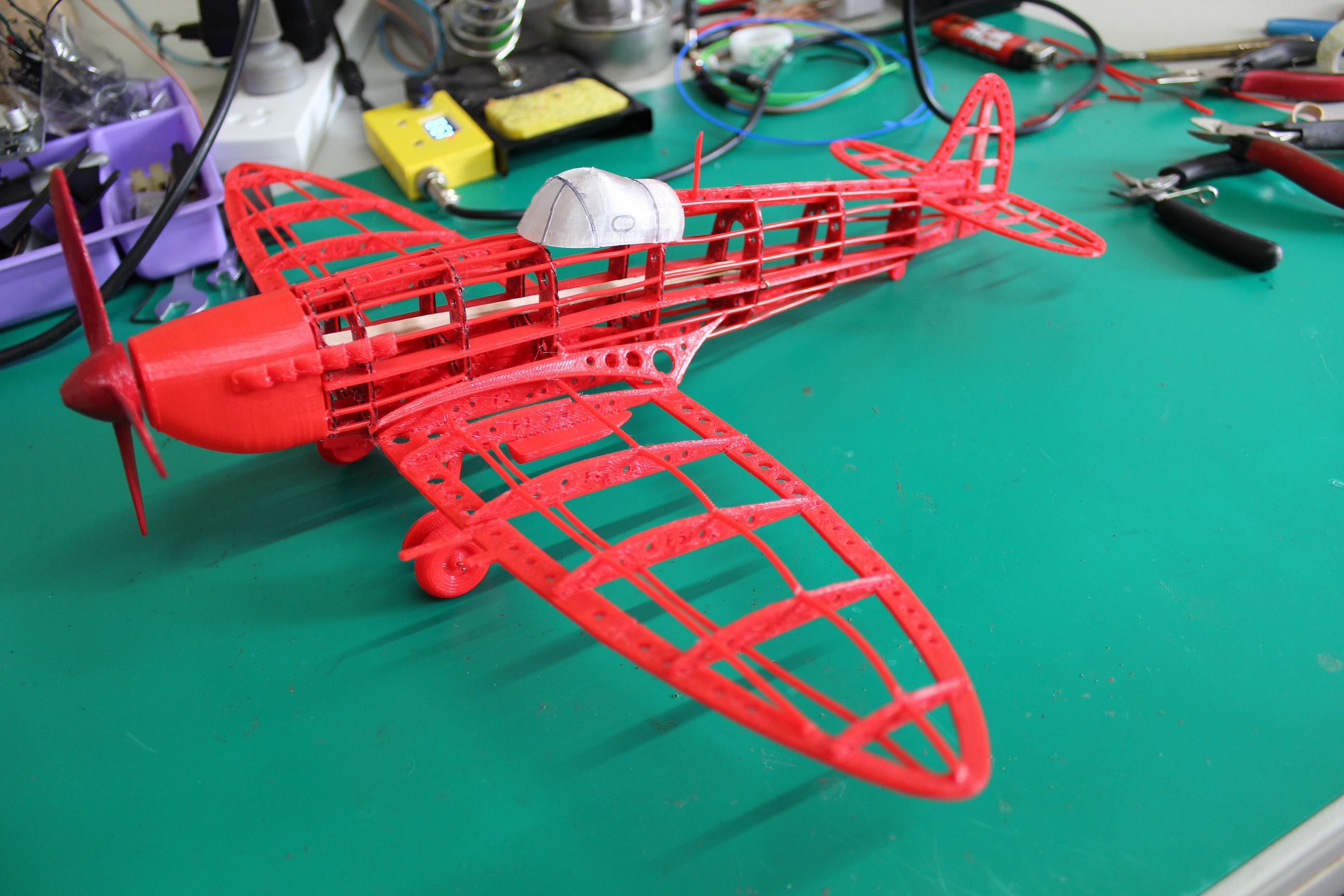

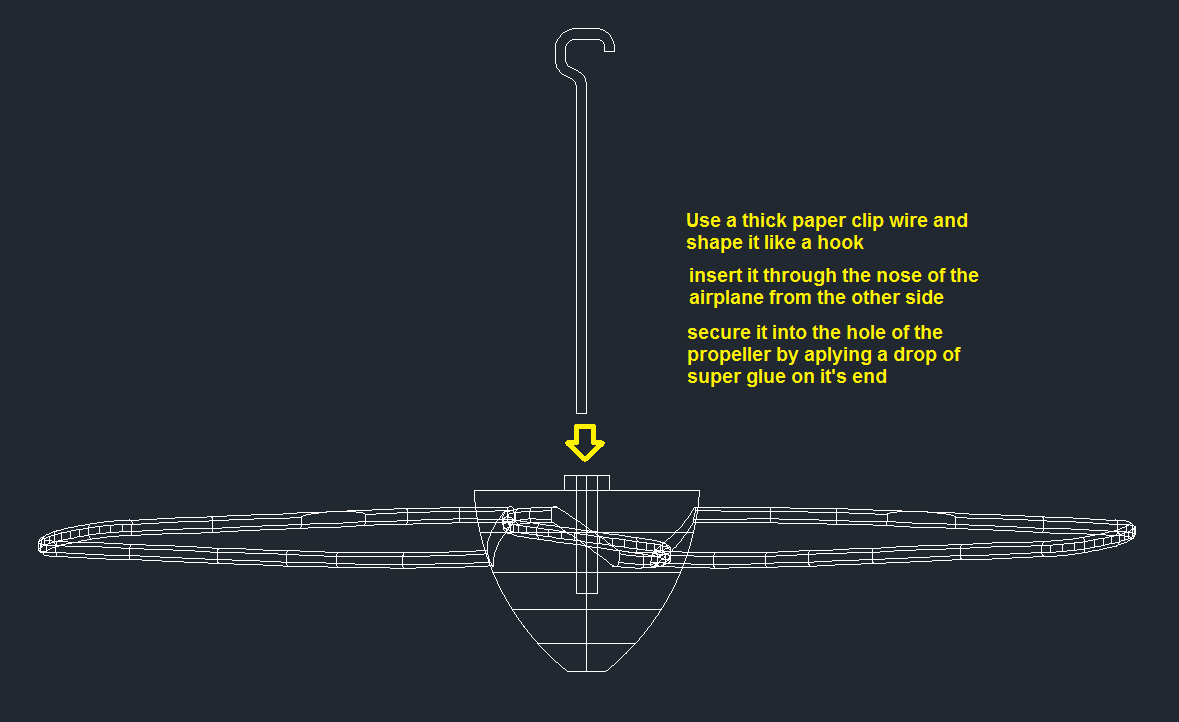

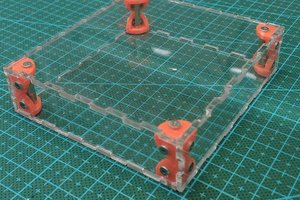

- Print or laser cut all of the parts

- Watch the video assembly below:

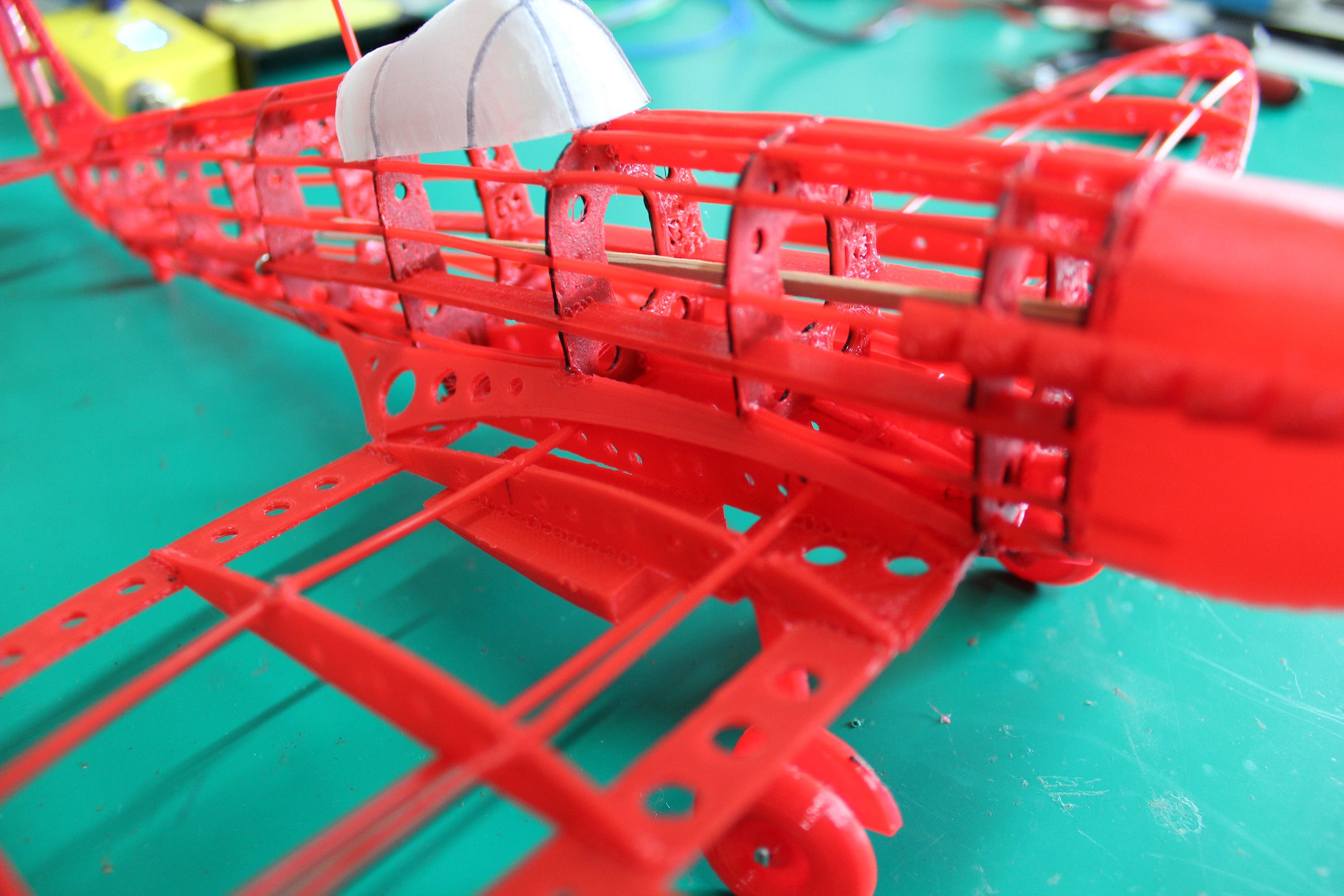

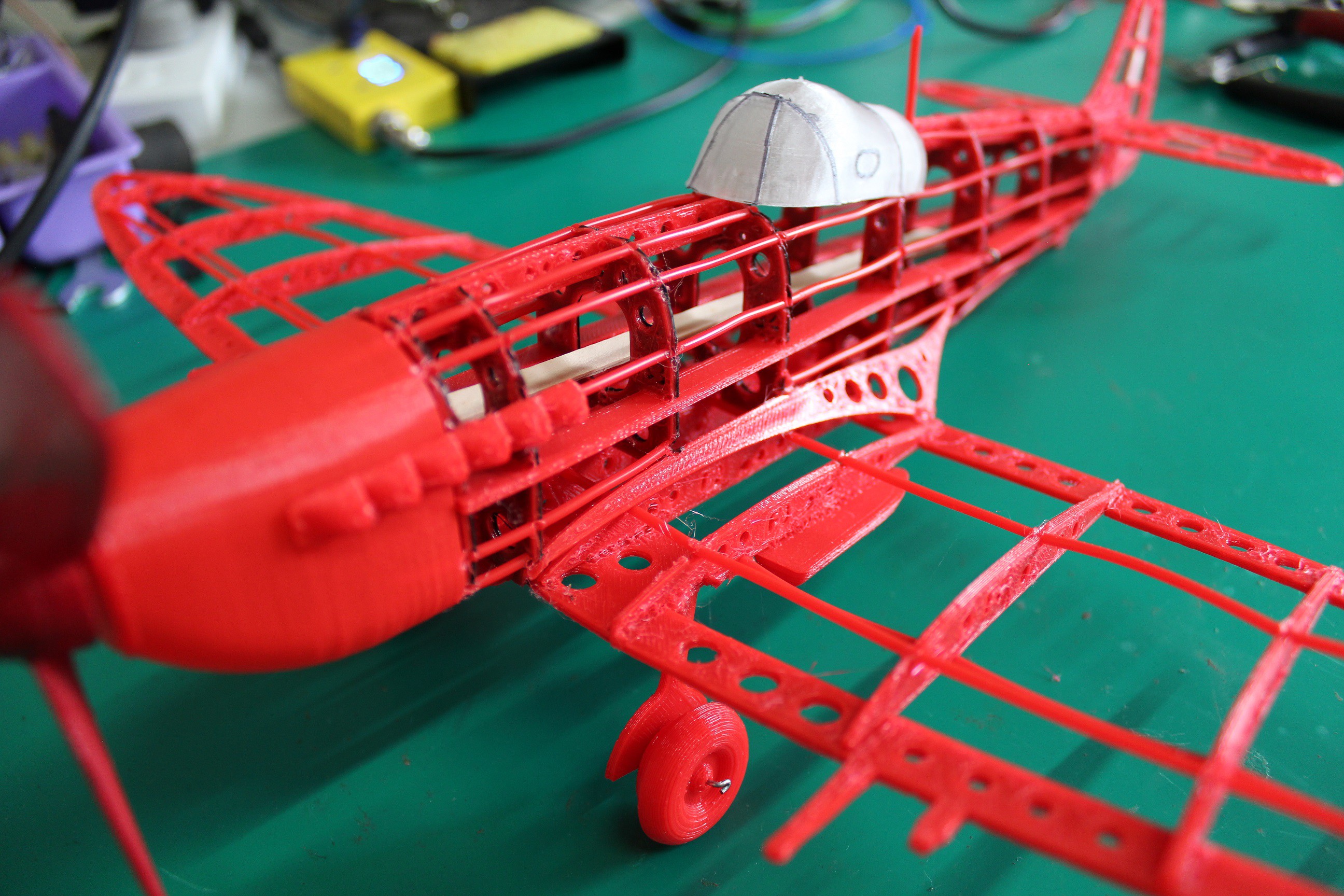

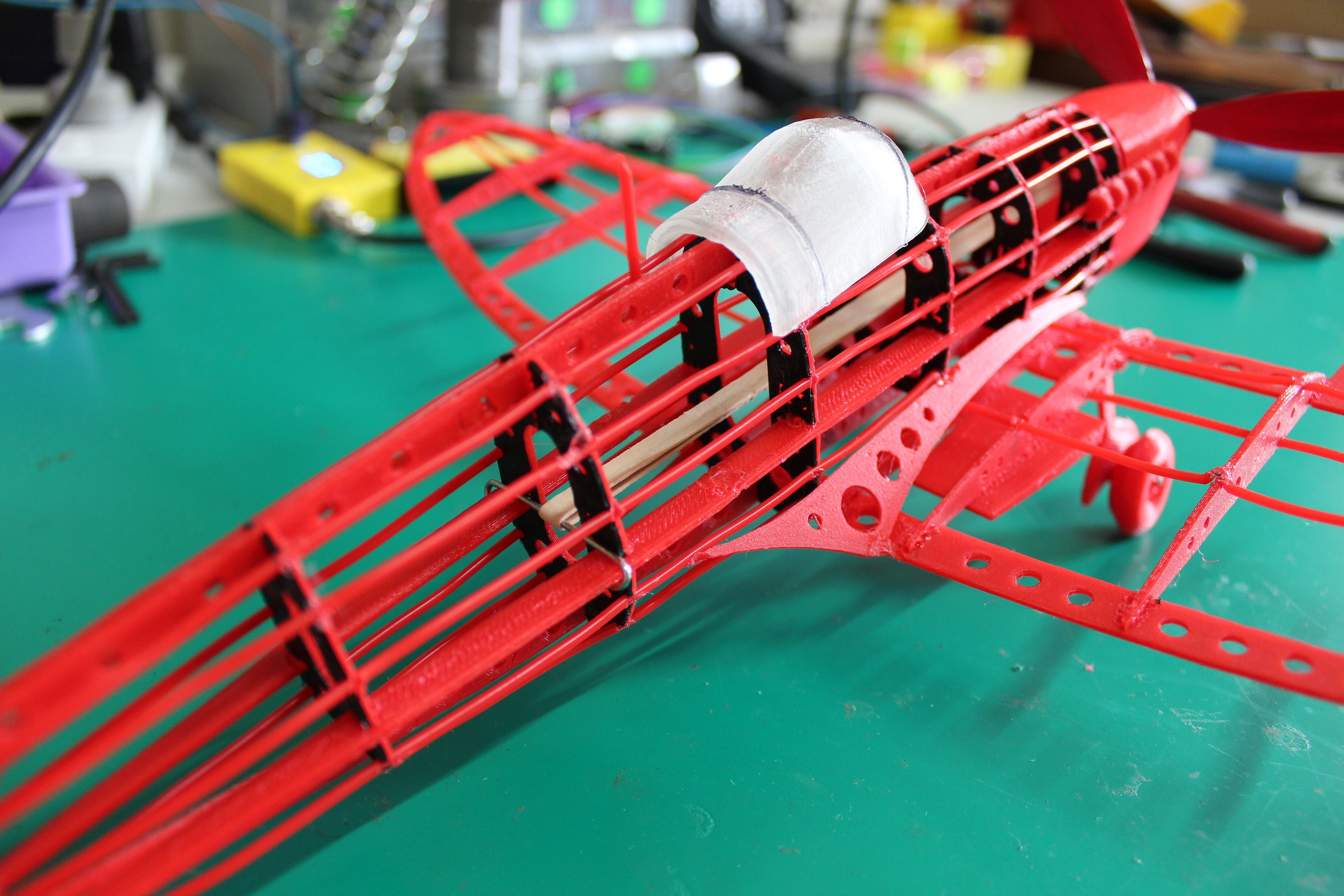

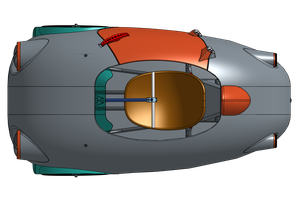

- Some of the parts as the cockpit and the nose of the airplane are being optimized for spiral vase printing.

- Check the files section. Also visit the cults page for full build details, printing instructions and more:

These planes can be downloaded from:

https://cults3d.com/en/3d-model/game/spitfire-model-plane-for-laser-cutting-or-3d-printing

and

https://cults3d.com/en/3d-model/game/hawker-hurricane-mkiia-model-plane

Somebody asked me this question and I’m posting it here since I think is good information other people might be interested in.

DM: They were beautiful planes, weren't they? I kind of miss the balsa and paper days, but I like the idea of printing the parts.

Question: why heat weld the parts rather than gluing them?

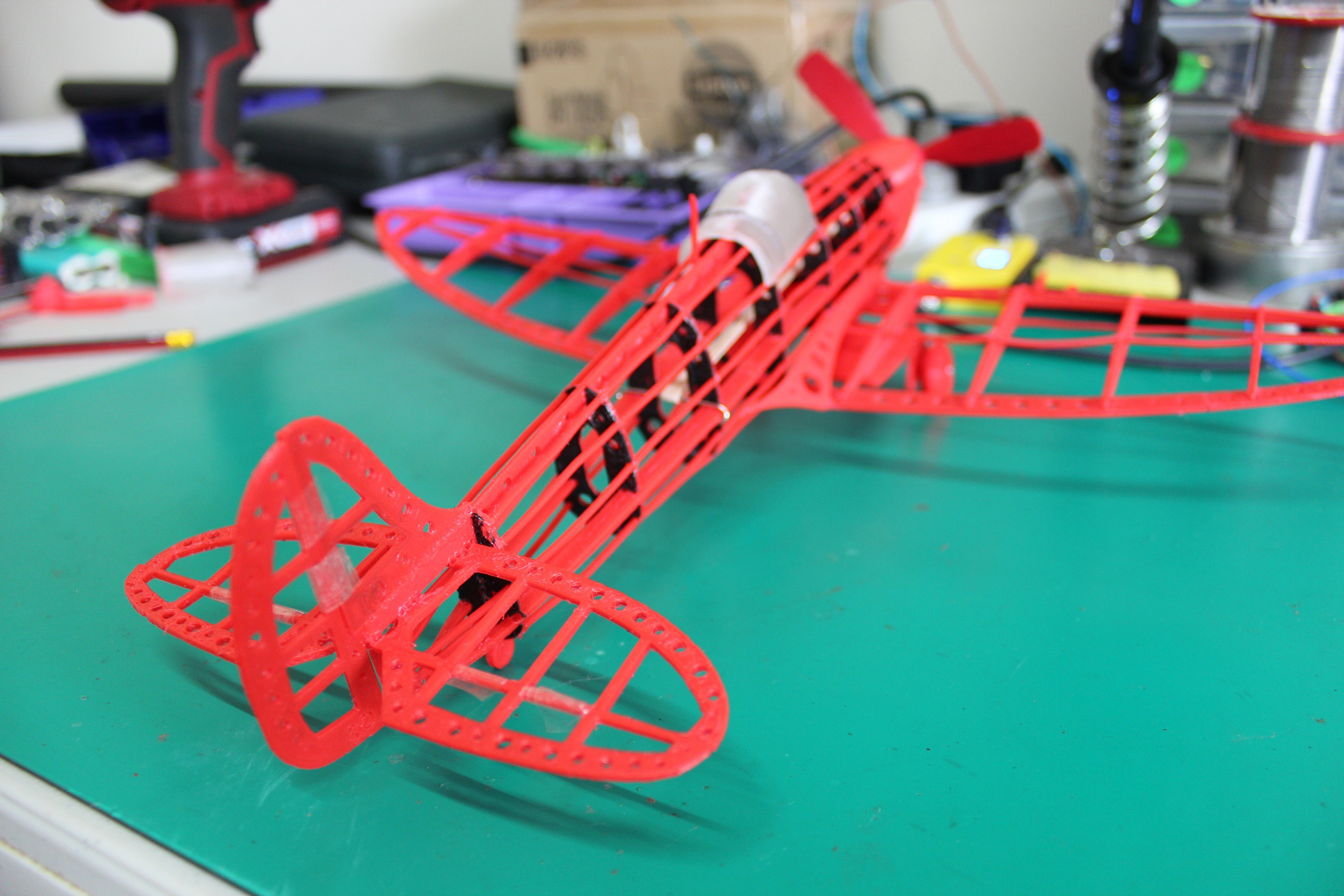

MT: Of course one could glue the parts, especially if they choose to laser cut some wooden or cardboard sheets. I choose to weld them for the simple reason of having a fast build I could share with my son and record in a short video. I created these parts being inspired by an older balsa wood plane design from the '80s. I realized there are not so many of these models being uploaded on Thingiverse nor any other sites. People have plotters for cutting cardboard and laser cutting cnc machines nowadays and they could easily involve in creative weekend activities with their kids like I did with my son, but the models are nowhere to be found. I checked the ebay and online markets to see if I could find some old school balsa wood models for sale and they are either too expensive, preassembled or inexistent. You rather find lego kits or dismantled drones, but is not the same thing. If you check the hobby stores you are most likely to find balsa wood plane kits, but most of the parts are semi-assembled. Like the wing is made out of 2 or 3 parts one has to glue together, and the fuselage is made of 5-6 U-shaped segments. They simplified the build to make it faster. Maybe the kids nowadays don't have the patience to spend 2 or 3 days to build it and they would rather have it finished in one afternoon. But on the other hand, my kid would probably never understand the shape of a wing rib and why it needs to be like that if the wing comes preassembled in the package.

Marius Taciuc

Marius Taciuc

Tina Belmont

Tina Belmont

Robin Hartley

Robin Hartley

Gonzalo P. Chomon

Gonzalo P. Chomon

Twisted Pair in my Hair

Twisted Pair in my Hair

Somebody asked me the following question on youtube so I’m posting it and the answer here for anyone interested.

JW: Does it fly?

TM: Good question. It is a little bit heavy for flying with the rubber band propulsion, but it should definitely fly with an electric motor. It is symmetrical and the roll balance is already perfect. The current weight of this rubber band model skeleton is about 98 grams. So if somebody chooses to print all of the parts at 200% scale, they would end up having an 840mm wingspan model frame weighing about 400g. With the heatshrink film, the RX receiver, battery, ESC, 3x 9g servos and the motor it should rise up to slightly below 1Kg. If they choose a 1000kV 2026 brushless motor of about 500g of thrust with a 9047 propeller, this configuration should be more than enough to make it fly really good and perform well. If I will have some time I would definitely give it a try. If I will modify this model to fit all of the electronics inside, I will definitely post the files so anyone interested should subscribe to my channel or follow me on Thingiverse. This plastic skeleton should be more resistant to crashes than the classical balsa wood frame. And it has the advantage of being able to be welded instantly with the soldering iron and have it fixed and ready to fly in seconds. This is what I'm flying right now and I can tell you that I'm kind of getting tired of patching and gluing it: https://www.youtube.com/watch?v=Hcwf_bLUbgk