-

Refocus

06/26/2019 at 01:46 • 0 commentsSo you might notice a lack of updates here...

A month or so ago we decided to pivot our entry for the Hackaday Prize. OMEB's core value is its extensibility, but for it to really function in the maker community it requires a healthy ecosystem surrounding it. We had plans for several modules to give it a running start, but ultimately those dilute the goal of creating a framework and are liable to even overtake it in terms of customer value, at least initially. So we decided to shelf the plans for OMEB and reduce our scope to a single tool which would be similarly impactful with a much lower outward complexity. Indeed, the focus became simplicity, and we are glad to announce that the Probe-Scope is coming along swimmingly.

The Probe-Scope is a completely self-contained 50MHz oscilloscope, with a USB port on one end and a probe on the other. We've just sent out our subsystem test boards for manufacturing, and will be working of software these next couple weeks before packing everything in a box small enough to fit on a cable. You can follow our progress on the new project page: https://hackaday.io/project/165964-50mhz-250msps-probe-scope

We still are fond of the OMEB concept and believe it has value, and hope to return to it someday. Perhaps for the Hackaday Prize 2020! Thanks for your interest - we hope you'll be equally interested in the Probe-Scope.

-

Open Modular Electronics Bench Architecture

04/04/2019 at 06:21 • 0 commentsThe goal of the Open Modular Electronics Bench is to provide a modular and easily extensible benchtop instrumentation system, in order to facilitate a community-driven ecosystem of instrument modules. Haphazard design choices will kill adoption of any framework before it begins, so a solid foundation is required to achieve this goal: the system architecture.

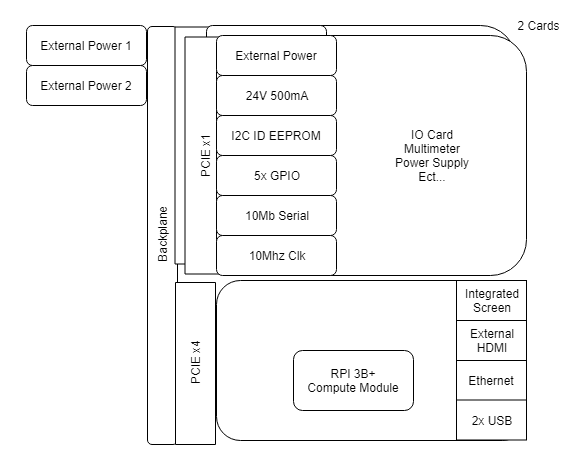

The system is designed around modules that can be swapped and provide the functionality of various instruments (such as a multimeter, oscilloscope, or even a power supply), and a controller which is the brains of the operation, collecting, coordinating and displaying data from all of the instrument modules. The modules connect to a single backplane board, which can accommodate scaling from one to four modules with a single controller. The module interface is a PCIe x1 slot, and the controller interface is a PCIe x4 slot, both chosen for their high pin count and common availability.

The controller will be designed around a Raspberry Pi compute module, because it is easy to use and program, avoids the unnecessary complexity of a from-scratch single-board computer, and has guaranteed availability until January 2026. It connects to a 5-inch touchscreen on the front panel as the primary means of interacting with the system, but also supports an external HDMI display, or remote access over a network. The controller also integrates an AC-DC converter, providing the 24V power used by the instrument modules.

The system provides a wide array of I/O to the modules, including five 3.3V GPIOs, a serial port capable of up to 12Mbaud, a 10MHz reference clock, and an inter-module sync line. This array of control options allows modules to be as simple or complex as they need to be. For example, an oscilloscope module might have a powerful processor onboard, streaming pre-processed back data to the host. On the other hand, a scanner card could be designed which is nothing but a bunch of relays just connected to the card’s GPIO. Instrument modules by default have 24V 500mA power available for use, which is plenty for most applications. Modules that require higher power can utilize a set of pins on the card connector which are directly passed through to external power inputs on the back of the system. These pins allow for up to 100V at 8.8A: 880W! With this much power even a beefy power supply is possible. We

shamelessly stoletook inspiration from the Raspberry Pi Hat ID EEPROM format, so the system can identify and automatically load the software for the card inserted, presenting a seamless experience to the user.By establishing this architecture up front, we hope to go from hardware development all the way to wrapping up the software without designing ourselves into a hole. We’re working on the electronics design for the controller, backplane, and a dummy instrument now, hopefully getting a working hardware setup by the beginning of May. From there, we will start on the controller software and a reference implementation of instrument serial control firmware.

Open Modular Electronics Bench

The Open Modular Electronics Bench is the first Open Source Low-Cost Modular Data Acquisition System

Mark Omo

Mark Omo