What is the aim?

This log is all about: How can we make the whole board cheaper while keeping all the features and not killing its safety functions. This all refers to the early v0.2 version which is by no means optimized yet!

Ways to cut costs

I try to think of mass production here (Disclaimer: I AM NO PROFESSIONAL, it's just what I would do to keep it cheap).

Let's say we want to make a thousand of those boards to sell them. A few thoughts come to my mind then:

- less parts = cheaper

- substituting expensive parts with widely available "china brands" = saving costs

- using jellybean parts and same footprints

- smaller boards = cheaper

- boards need to come fully assembled

- [...]

Let's get into more details here

The above points will be anatomized in greater detail here.

1 – using less parts

This is a no-brainer, right? It's not as easy as it sounds. Most parts are there for a reason, so we need to look at every part and ask ourselves: do we really need it?

Here are a few parts which can be substituted by other brands but can not be left out altogether:

- Microcontroller: needs to be there for all the main functions and hackability

- MOSFET: our main-switch

- input and output connectors

- a voltage regulator: we need at least a low-Iq 5V rail for our logic-level MOSFET

- a few caps at the various inputs of the chips for stability

So, if all those parts are needed, which parts could we possibly cut from the list? A decision in this category usually has some effects on other parts of the circuit.

1.1 - choosing another voltage regulator

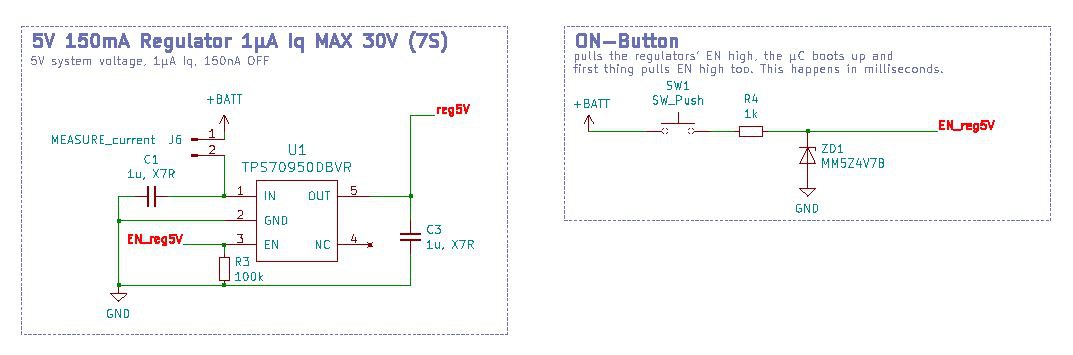

The TPS70950 is a nice LDO voltage regulator with an EN-pin and <0.1µA quiescent current in shutdown mode. Neat! But this comes at a cost: €0.3395 per piece buying 1000.

No we need to ask: what OFF-current draw can we accept? From other circuits I know we can get ATMEGAs and ATTINYs down to around 2µA total using a system load switch. Say, we would accept 10µA total OFF-current. This doesn't drain an already "empty" cell too much. So we have 8µA for other parts. A hint from @Simon Merrett was using an HT7550-1 from Holtek. These draw max. 3µA idling (with no load), having no EN-pin though.

Fits our bill perfectly! Costs €0.075/pc buying 1000. Here's what I mean with changes down the line when substituting components:

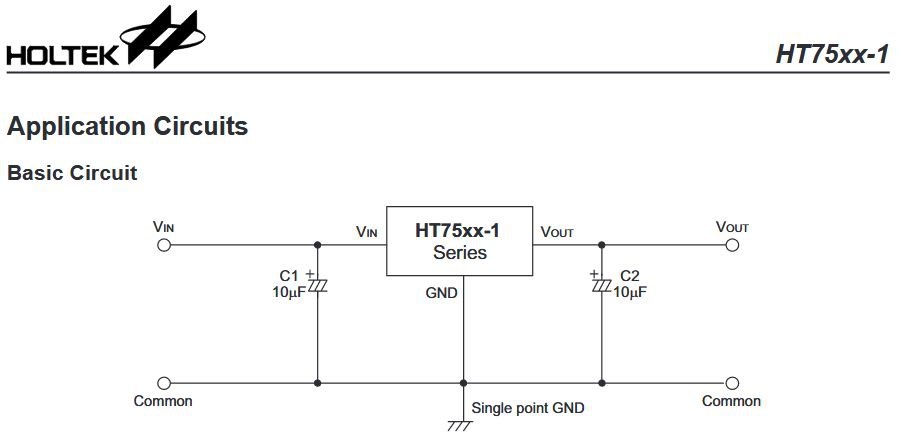

Looking at the circuit above we can use the HT7550-1 instead:

The 1µF caps can stay in place, no need for 10µF in our circuit, cause it uses only little current.

Changes to the circuit are:

- the EN-button needs to be tied to one of the µC's interrupt pins

- ZD1 can be left out as the 5V rail will be always on. While not exactly expensive it's another saving!

- R3 can be omitted as well

Total savings: Around 87%. or 265€ per 1000 boards.

1.2 - choosing another MOSFET

With MOSFETs it's a bit more like "pay less get less". Considerations are:

- Switchable current 8A (10A) max.

- max. input voltage 30V

- no mounted heatsink

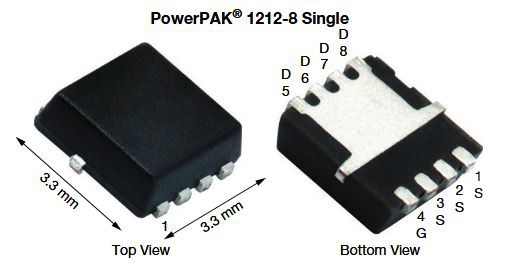

- small PCB area

So, we need a type with a maximum drain to source voltage of > 30V to keep the MOSFET from destruction, that's why I chose 40V (the v0.1 one has 30V max.).

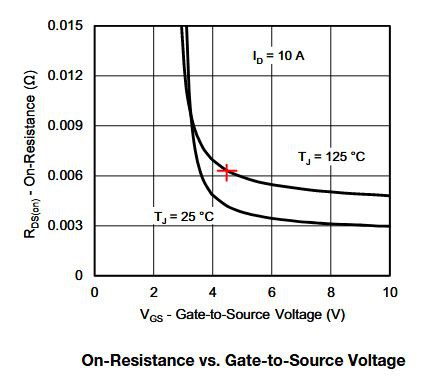

Next consideration is the resistance RDSon at a gate voltage of 4.5V. Datasheet values are mostly for a MOSFET silicon temperature of 25°C. So we need to de-rate it with the given value of the datasheet to be sure it is proper low resistance even when hot.

With little board-space we need to take the heat-up into account which is around 50°C per W of "wasted" current.

A quick look at Digikey presented me the SiSA72DN.

On-resistance is around 0.007 ohm at a die-temperature of 125°C and 4.5V gate-voltage.

Fits our needs perfectly and has a very small footprint too:

Power dissipation at 10A will be 10² x 0.007R = 0.7 Watt. This would heat the MOSFET to around 25°C (given a surface mount on 1x1" copper on FR4). Let's see if we can give it that much space. This will be worth another complete log.

The Toshiba is 0,86516€/pc @ qty1000, while the Vishay SISA72DN is 0,18778€. Saves 677.38€ per 1000 boards.

1.3 - choosing another microcontroller

This one is a real cost-driver! I chose the Atmega328P because I use it for most of my stuff and have many of them in my drawers.

For a mass-produced board this micro is too expensive, because I don't need that much FLASH, nor do I need all those in and outputs. To keep the board programmable and hackable by a huge community I want to have a chip which is easily programmed by the Arduino IDE.

The Attiny-Series have some very interesting options here. After a bit of looking around I selected the Attiny261A in a VQFN30 case.

It has enough IO's and is cheap enough. Atmega328P-MU is 1,52640€/pc @ qty1000, the Attiny261A is only 0,31950€. Saves 1206,9€ per 1000 boards.

To be continued...

Jan

Jan

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I love it. I don't know if the other hackaday prize entrants are exposing their value engineering process like this but you should definitely get points for it!

Are you sure? yes | no