-

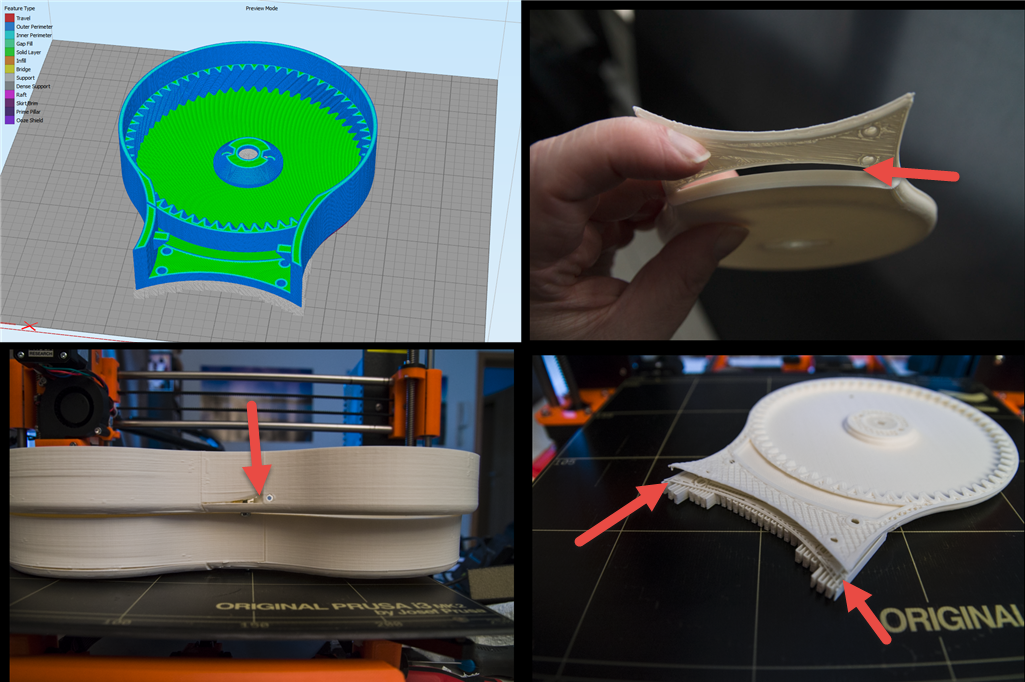

Art3Body and Art2Body printed

11/22/2016 at 20:37 • 1 commentAfter 2 weekends of printing, Art3Body and Art2Body are now complete.

These parts come from the modified version from https://hackaday.io/project/16665-thor-robot-with-addons-and-gui since they are too big for my printer.

To get a sense of time to print. The left part Art3Body is printed into 2 parts then glued together. The printing took about a 16 hours for both halves and the pulley (round thing)

![]()

Art2Body (The 2 objects on the right) is about 22 hours combined. It actually took more hours since I had many "thermal overrun" about 3 hours into the print.

![]()

A detailed view of the cogwheel that is 3D printed.

-

ART2BODYA_1.stl (Update)

11/18/2016 at 09:18 • 0 commentsMany thanks Danny for your model.

https://hackaday.io/project/16665-thor-robot-with-addons-and-gui

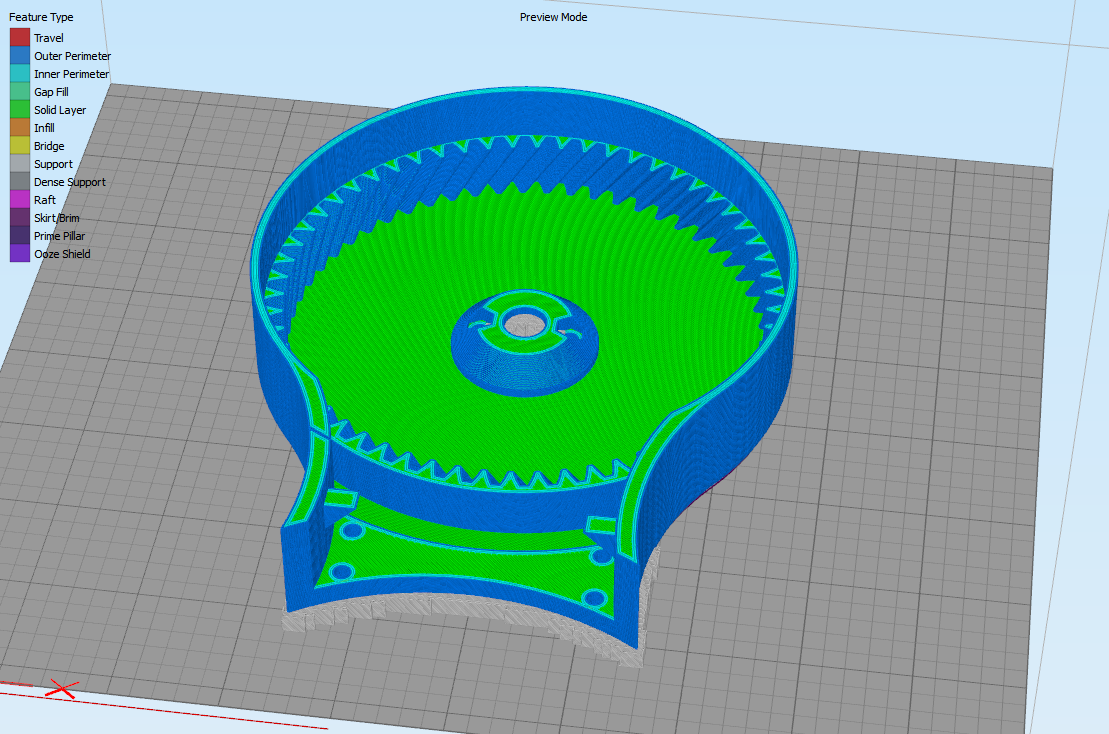

I finally 3D printed ART2BODYA_1.stl completely and managed to montage it using glue. The model is completely functional so no complaining here.

During the printing, I have a persistent issue with one of the corners. The flat surface is above the bed so it needs support structures. But every time I printed it, the first real model layer somehow curled up and pulled the support structures up when it cooled making it disconnect from the bed and even from the model.

Bottom right is the first model that came lose and I had to abort. (Note: The model was not printed like that. I just took it back out of the garbage can to take this image)

Bottom up shows a gap, but once glued it became a none-issue.

Bottom left is the glued together prints The upper print I continued printing, so it self rectified it. The lower one I aborted the print, took the model off and started the print from the first layer. Then glued both layers together.

![]()

I think it is the pointy parts that is the issue. If we cut the model differently so that these pointing structures are printed directly on the bed instead, it might not curl up.

-

ART2BODYA_1.stl

11/10/2016 at 23:02 • 0 comments![]()

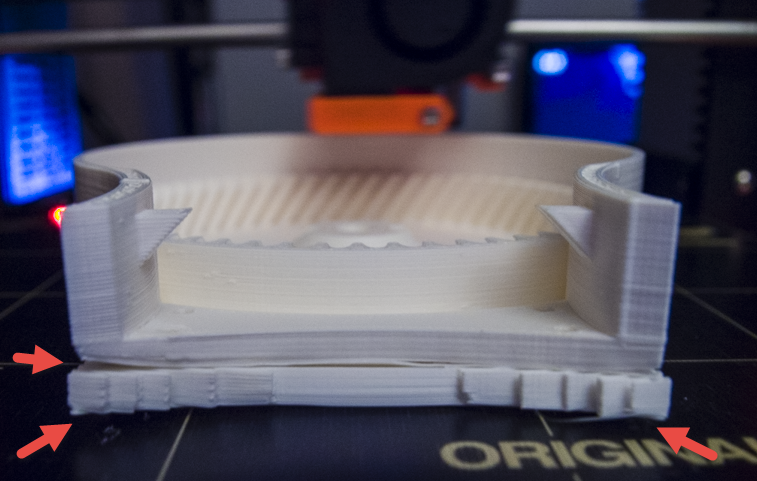

My printer is not big enough to print all parts of the Thor project but dannyvandenheuvel has an interesting variation where 2 parts can be glued together. This is the first part I am trying to print. ART2BODYA_1.stl.

See his project here

https://hackaday.io/project/16665-thor-robot-with-addons-and-gui

This part is expected to be an 5h30 job using ABS.

Update: 3 hours into the print the support structures came lose from the bed

![]()

I tried to clean the heat-bed and tried again but the support structures again came lose from the bed at 3 hours into the print.

I believe that the moment I start to print a solid layer on top of these support structures, it pulls the support structures up.

This time I continued the print, and the print ended up being usable.

-

Art56GearPlate to Art56MotorCoverRing

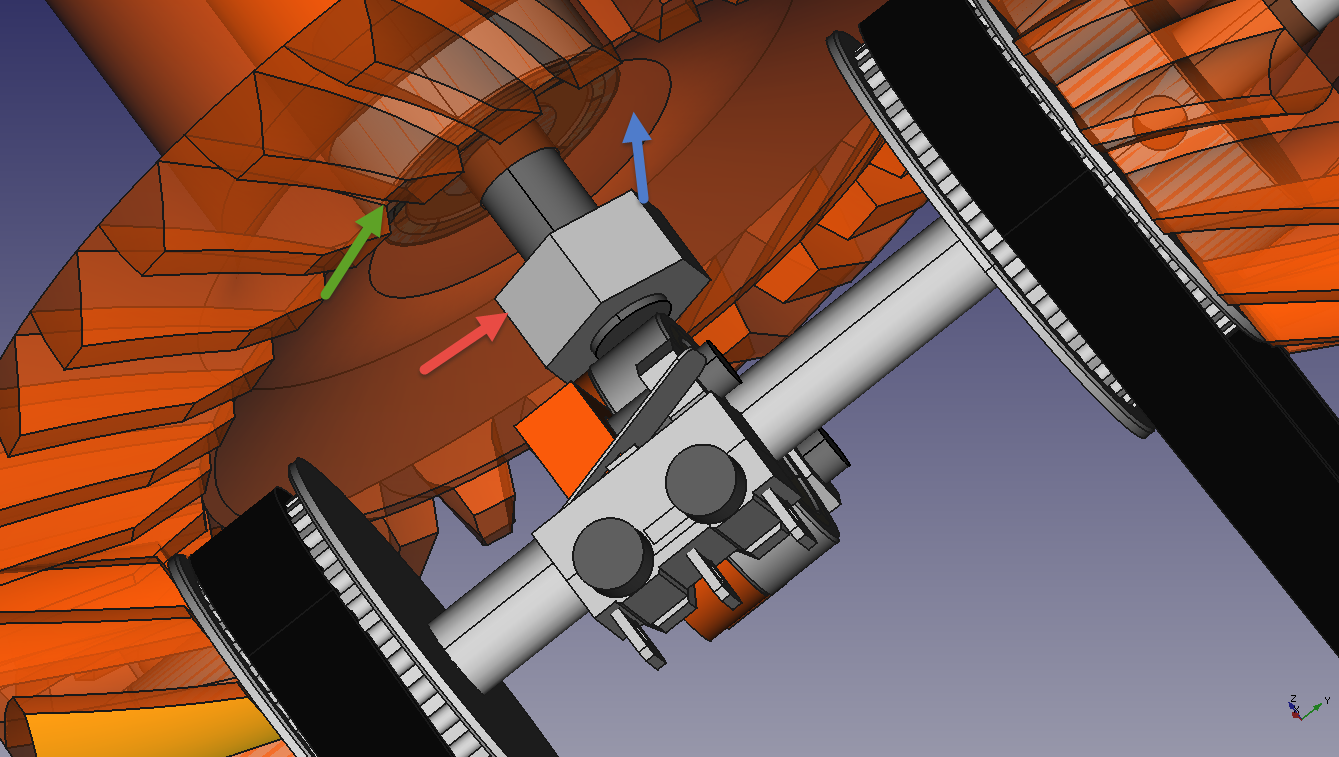

11/05/2016 at 20:04 • 0 comments![]()

I have a hard time to understand how Art56GearPlate_01 is supposed to operate. It appears to be connected using one ball bearing, and one nut and bolt that is anchored in Art56MotorCoverRing_01 (hidden in this view).

I understand that the ball bearing is fixed to Art56GearPlate_01 but I expect that I need a second ball bearing otherwise it will rest on Art56MotorCoverRing_01 and plastic on plastic does not make a good gliding surface.

Building the Thor robot

Building a 6-axis robot based on the Thor robot. When size DOES matter!