-

VAWT Advantages & Disadvantages

05/02/2019 at 21:29 • 0 commentsVAWT Advantages

These turbines have fewer parts than those that orient the rotary mechanism and blades horizontally. That means fewer components to wear out and break down. Also, the supporting strength of the tower doesn’t need to be as much, because the gearbox and generator are near the ground. Parts for controlling pitch and yaw aren’t needed either.

The turbine doesn’t have to be facing the right wind direction either. In a vertical system, air flowing from any direction or speed can rotate the blades. Therefore, the system can be used to generate power in gusty winds and when they’re blowing steadily.

![]()

VAWTs are:

- Cheaper to produce than horizontal axis turbines.

- More easily installed compared to other wind turbine types.

- Transportable from one location to another.

- Equipped with low-speed blades, lessening the risk to people and birds.

- Function in extreme weather, with variable winds and even mountain conditions.

- Permissible where taller structures are prohibited.

- Quieter to operate, so they don’t disturb people in residential neighborhoods.

Disadvantages of VAWTs

Not all of the blades produce torque at the same time, which limits the efficiency of vertical systems in producing energy. Other blades are simply pushed along. There is also more drag on the blades when they rotate. Although a turbine can work in gusty winds, that is not always the case; the low starting torque and dynamic stability problems can limit functionality in conditions the turbine wasn’t specifically designed for.

Since the wind turbines are lower to the ground, they do not harness the higher wind speeds often found at higher levels. If installers prefer to erect the structure on a tower, these are more difficult to install in such a way. However, it is more practical to install a vertical system on a level base, such as the ground or the top of a building.

Vibration can be an issue at times, and even increase the noise produced by the turbine. Air flow at ground level can increase turbulence, thereby increasing vibration. This can wear out the bearing. At times, this can result in more maintenance and therefore more costs associated with it. In earlier models, blades were prone to bending and cracking, causing the turbine to fail. Small units atop buildings or other structures may be subject to jostling forces, which add lateral stress that warrants ongoing maintenance and the use of stronger, more sturdy materials.

-

Coils and magnets layout

04/12/2019 at 19:15 • 1 comment -

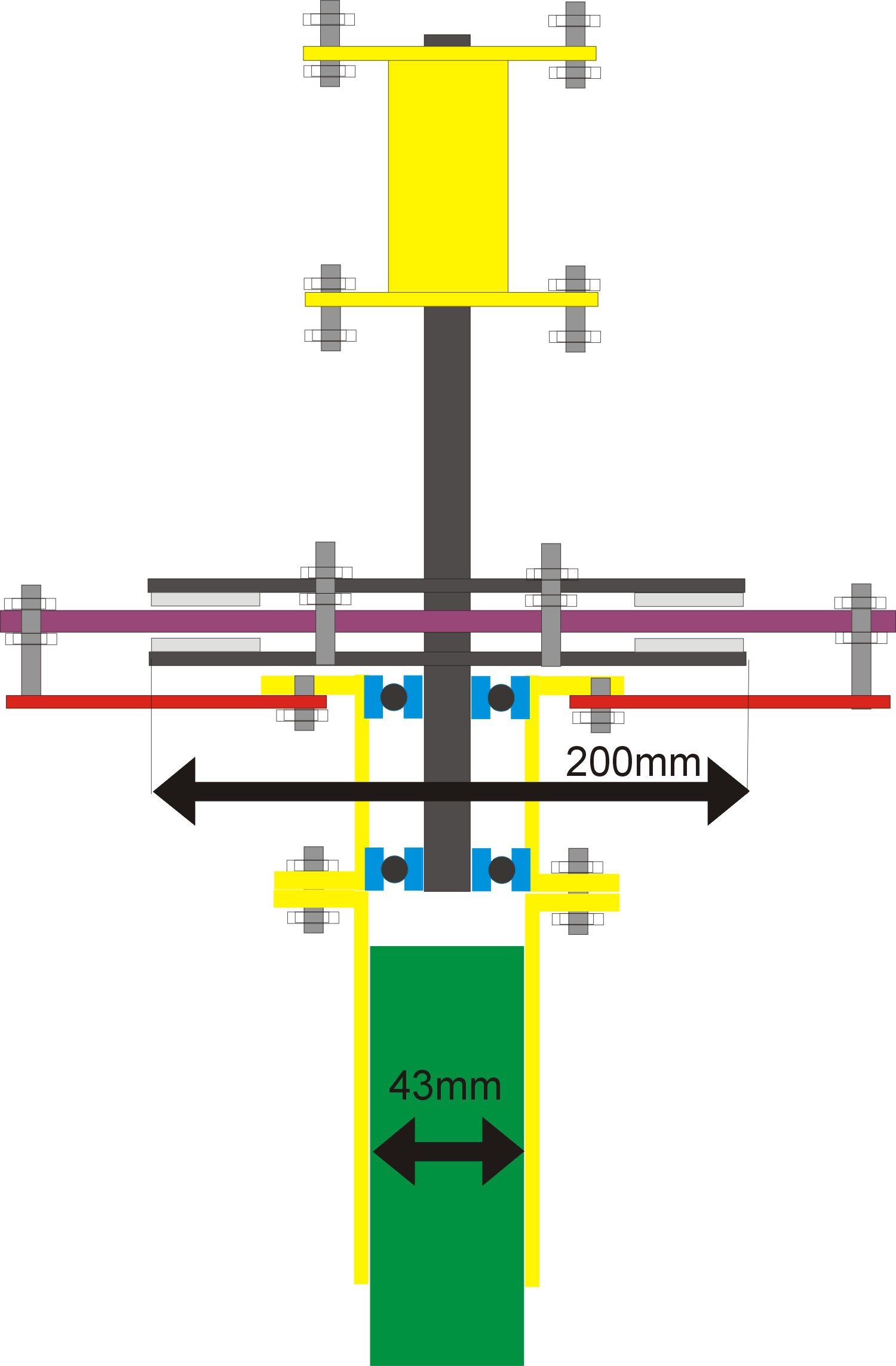

Mechanical drawing

04/12/2019 at 19:11 • 0 comments

BlueFlower

BlueFlower