-

Update

12/30/2019 at 10:26 • 0 commentsJust a update with what I have done so far.

I dissassembled the original Openbuilds frame that I had completely and used the components for building custom coreXY 3D printer.

Decided to move more for the 3D printed parts.

So I made another all brand new coreXY type frame for the pick and place also. And designed and printed the new head and come strip feeders. Not sure about the about the accuracy of the new frame yet, although I am very pleased with the coreXY concept overall.

So here is the overview of the current system:

Feeders and board holders are held in place with small magnets under them.

Here is the fusion360 link for the head design:https://a360.co/2ZyjDni

-

Wooden part feeders

05/06/2019 at 19:40 • 1 commentI have been making some experimentations with different feeder design ideas.

"Clothes pegs feeders" for example. The aluminium box is nice and the spring for holding the tape flush to the upper surface.

![]()

![]()

Wooden gang drag feeder:

![]()

![]()

Tape peeling roller is yet to come.

Also been thinking about modular 3D printable solution. Even made the following design: https://a360.co/2IXTOri

Sadly do not have acess to 3D printing at the moment so been unable to test it out in practice. It is currently meant to be used with the same metal springs but maybe possible to make the flexible 3D printed leaf spring with usual ball pen spring as extra support under it. The metal springs used are cut from metal cable tie that I found to be suitable stiffness and width.

Teemo

-

Study on using the hobby servo for rotation.

05/05/2019 at 14:14 • 0 commentsSo why to use hobby servo for rotation?

It is light and available. I do not have the hollow shaft Nema9 stepper.

Analysis.

The one and only Arduino hobby servo that I had in my house had a rotation range of about 170 degrees. So not quite enough, need at least 180 degrees.

I studied that some people are able to extend the range of their servos with adding some resistors in series with the feedback potentiometer. Tearing down the thing showed that unfortunately in my case this was not the option, the feedback potentiometer track was physically just 170 degrees and no more. So the stock servo with no modification or with small modification is not doable.

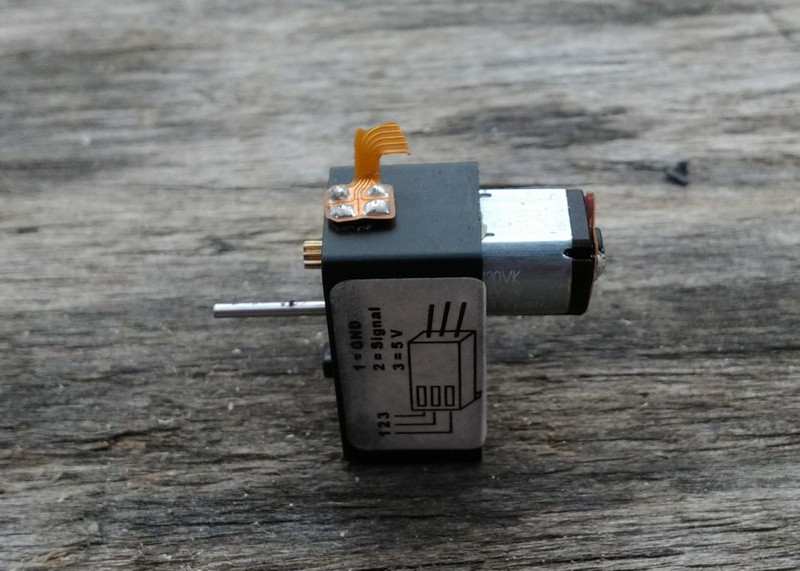

But it still have the nice gearbox. I ripped out the feedback potentiometer and control chip from the servo. Replaced the motor with longer shaft version form the old Canon compact digital camera and had the flapped shutter added to the shaft. Installed the optical counter also from the old camera to count the motor movement. And put together the Arduino Nano and H-bridge to control all this thing.

![]()

![]()

![]()

Arduino simply receives the „step“ and „direction“ commands from the motion controller and drives the motor same amount of steps in the commanded direction. This way I can preserve the stock OpenPnP and Smoohieware operation and only simulate the stepper. Ended up with 5.4 steps per degree resolution. It probably slips a little but hopefully not enough to matter within a single maximum 180 degree rotation. Tricky part is aligning the speeds so that the rotation is actually finished in time. So I is a dirty hack. But works for now, at least until something better comes along.

![]()

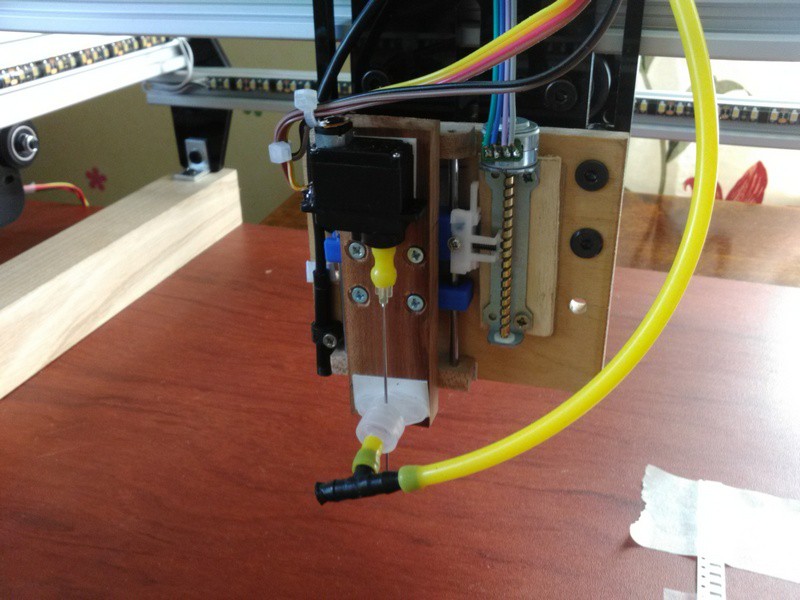

Servo is connected to the needle with just a little piece of silicon tube, same that is used for the vacuum line.

Here is a little video of it in operation.

And yes the board have a scratch on it. This is because while adjusting strip feeder length I accidentally pushed "home" command and it dragged for the X0;Y0 without first raising the nozzle. Still the same needle though, those things are quite tough.

-

Entering Hackaday

05/03/2019 at 09:10 • 0 commentsHello all.

Quite lot of work already done on the project within about two months. This includes ordering the parts assembling the frame multiple times and doing a lot of research on the topic. Currently the machine is already capable of picking 1206 resistors from taped to the base strip feeders and placing them with correct rotation to the board at the right place. However this soluition is not enough for me. The work continues on making the better pick and place head and also on feeder design.

I have a reference PCB board that I am building the machine for. As a summary this board current version needs:

8mm tape feeders 11pcs.

12mm tape feeders 4 pcs.

16mm tape feeders 16 pcs.

+ some loose part box feeders

Regards

Teemo

Details of pick and place machine build.

Just want to share the experience of building pick and place machine.