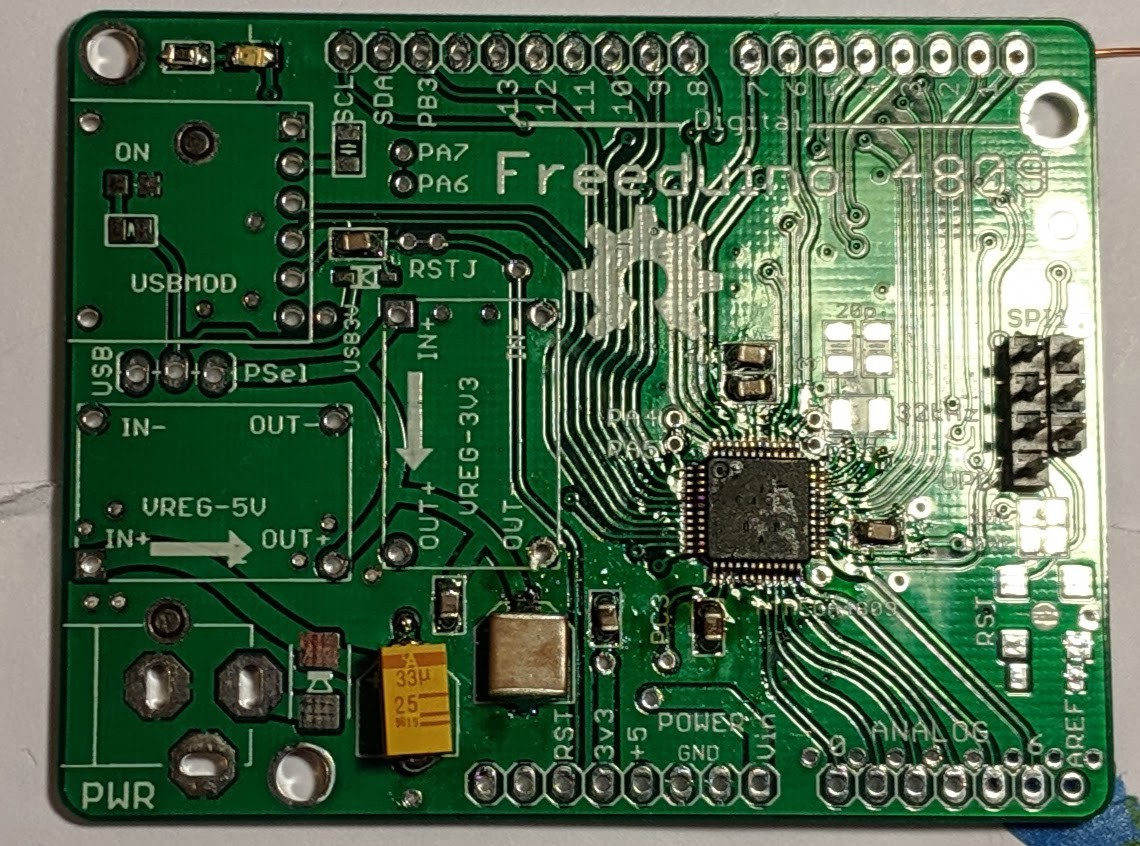

A "Freeduino 4809", the board with the Uno pinout, has now also been assembled, runs a Blinky and Hello World program (on an entirely different pin/USART than the DIP version.)

Pay no attention to the capacitors that don't match the PCB footprints. They fit, mostly, and are what I have in the junk box!

The TX and RX pins on this board are also swapped from how they need to be. :-( I'm going to start putting a set of crossover pads on any PCB where they'll fit!

WestfW

WestfW

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

This was the 2nd board. The first one I did I used paste and a hot-plate, which had worked really well on a QFN SAMC20 board that I'm also working on (busy, busy.) But it didn't work very well at all for the TQFP - I wound up with two edges of pins smack between the pads instead of on them. I guess the "magic surface tension" trick doesn't work as well if there's nothing directly under the chip for it to float on. :-( Anyway, this board I did tack-flood-wick (extra carefully, since I usually suck at that as well.) I went OK, I think. One of the problems with a board like this is that it's a pain to test ALL of the pins...

Are you sure? yes | no

I bet that was not fun to solder. Consider trying some solder paste and a toaster oven from Walmart. There is no need to buy an oven controller, just manually PWM the oven elements to somewhat follow an estimation of the desired temperature profile. Try some practice runs; it is surprisingly simple. Look for an oven with a quarts tube (that seems to do better with IR). This link shows the solder I use.

https://www.digikey.com/products/en?keywords=SMD291AX10-ND

If you find yourself doing enough boards, then it may help to automate the PWM. This link shows the profile, and some other ideas (but the board at my oven is an old version, so the program on Github has sadly not been tested).

https://github.com/epccs/RPUno/tree/master/Reflow

I would not modify the oven, use an SSR to do a slow (e.g., 2 seconds) PWM of the oven elements since there thermal time constant is plenty long.

When you get sick of tweezers, consider a vacuum pick up tool. I wirewrap the metal pickup head through a 1Meg resistor to the metal hand tool, and that should help reduce ESD.

https://duckduckgo.com/?q=Beadsmith+vacume+pick+up

If the project gets huge, my last trick (and this is not for the kids, it is only for the old-timers) is to put the board partly picked and placed in a jar with a dash of kerosene, so the paste does not dry out, and then I can take a break and let my hands rest. That trick has been a game-changer for me.

Are you sure? yes | no