A hack in the fullest sense. I’m looking to bring what is normally unaffordable Pilates exercise equipment to a much needed larger audience

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

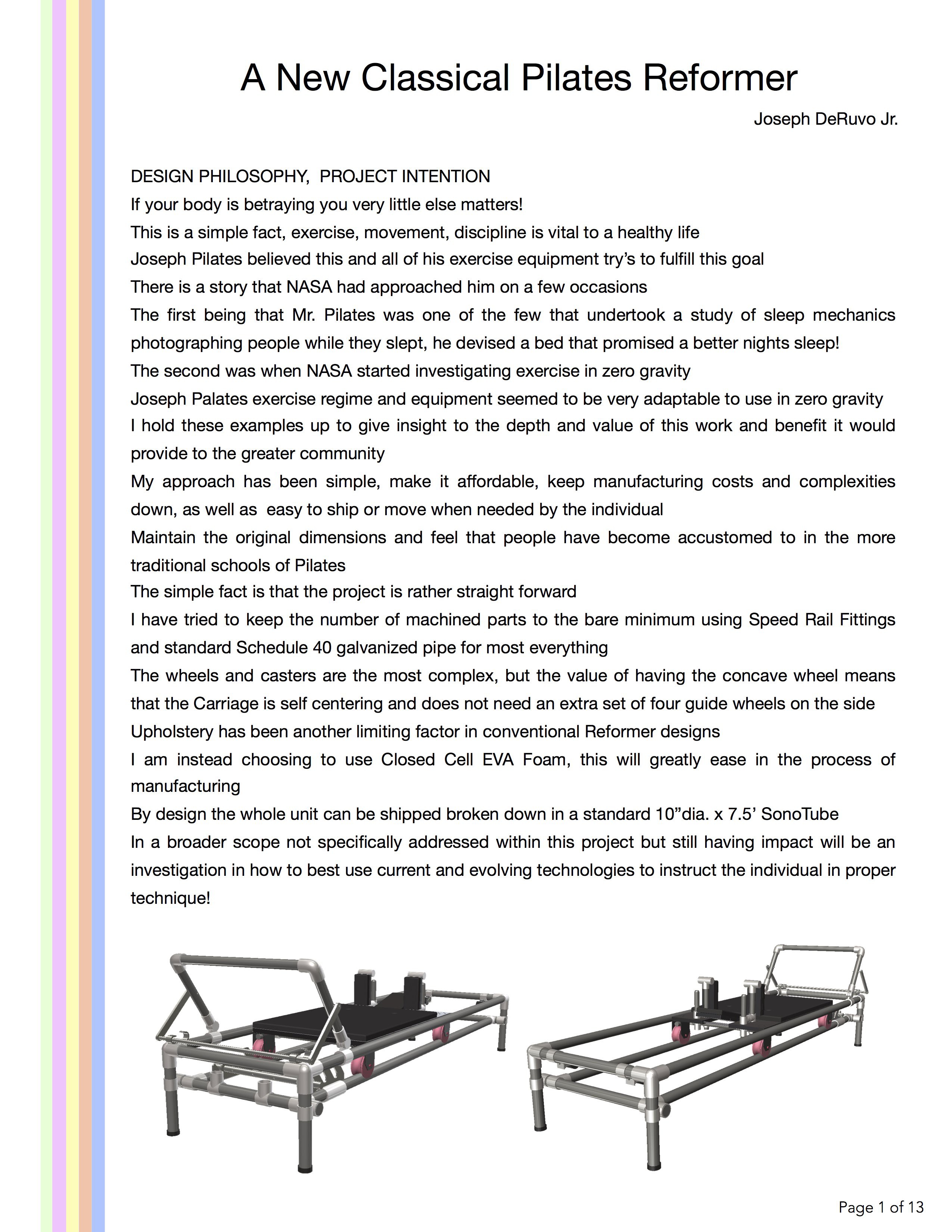

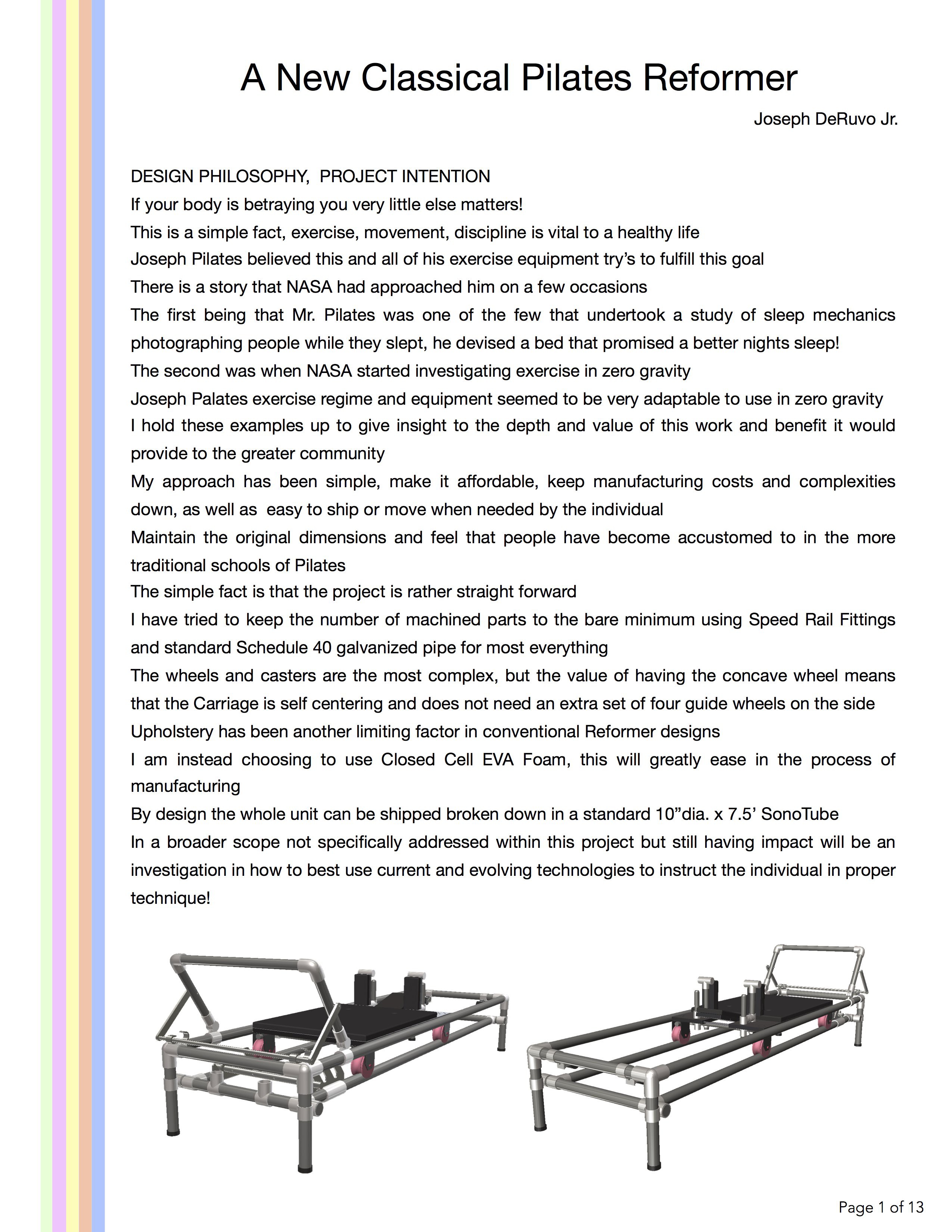

20181130 215923.jpgA conventional Reformer is on the leftJPEG Image - 1.53 MB - 05/23/2019 at 04:37 |

|

|

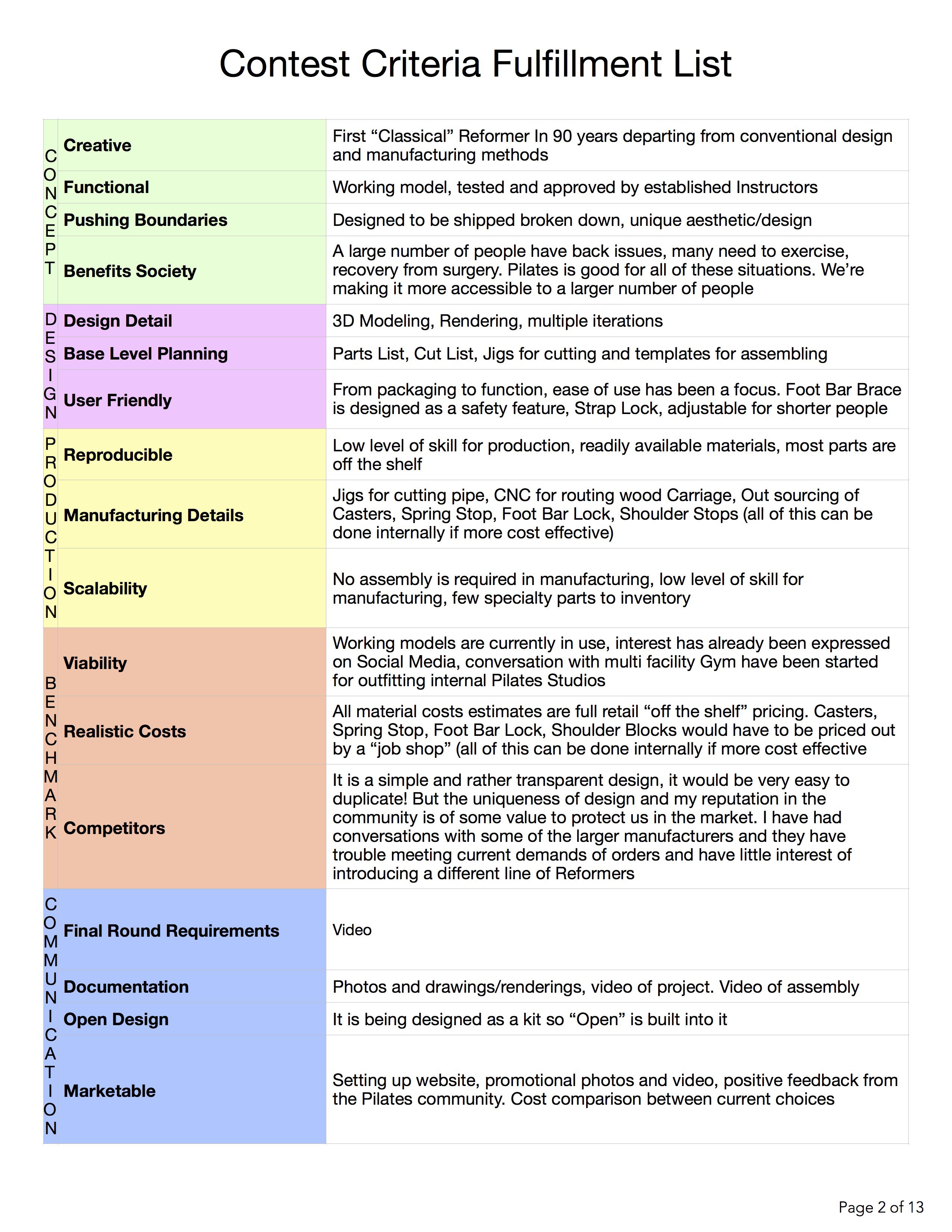

20181221 143053.pngWheel and CasterPortable Network Graphics (PNG) - 3.69 MB - 05/23/2019 at 04:29 |

|

|

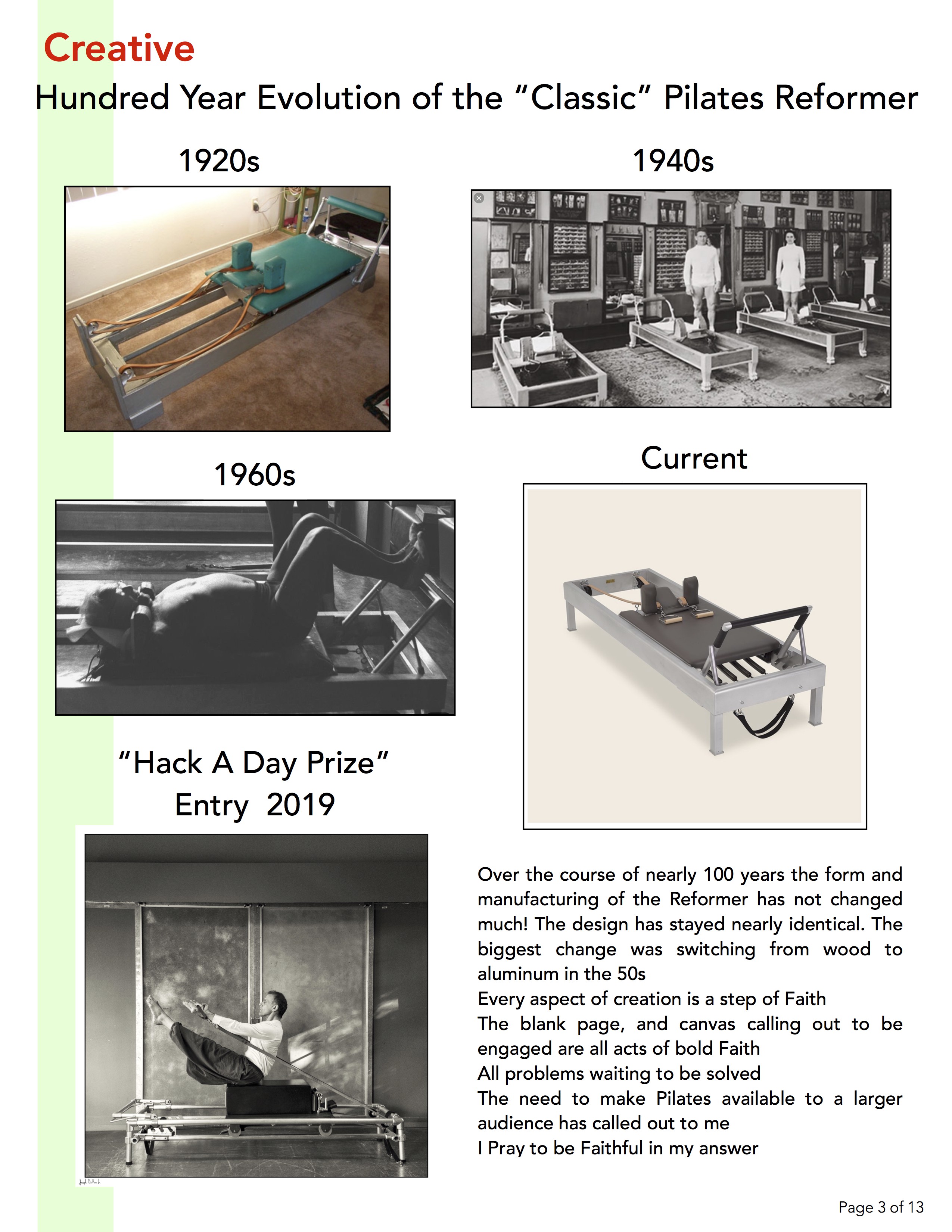

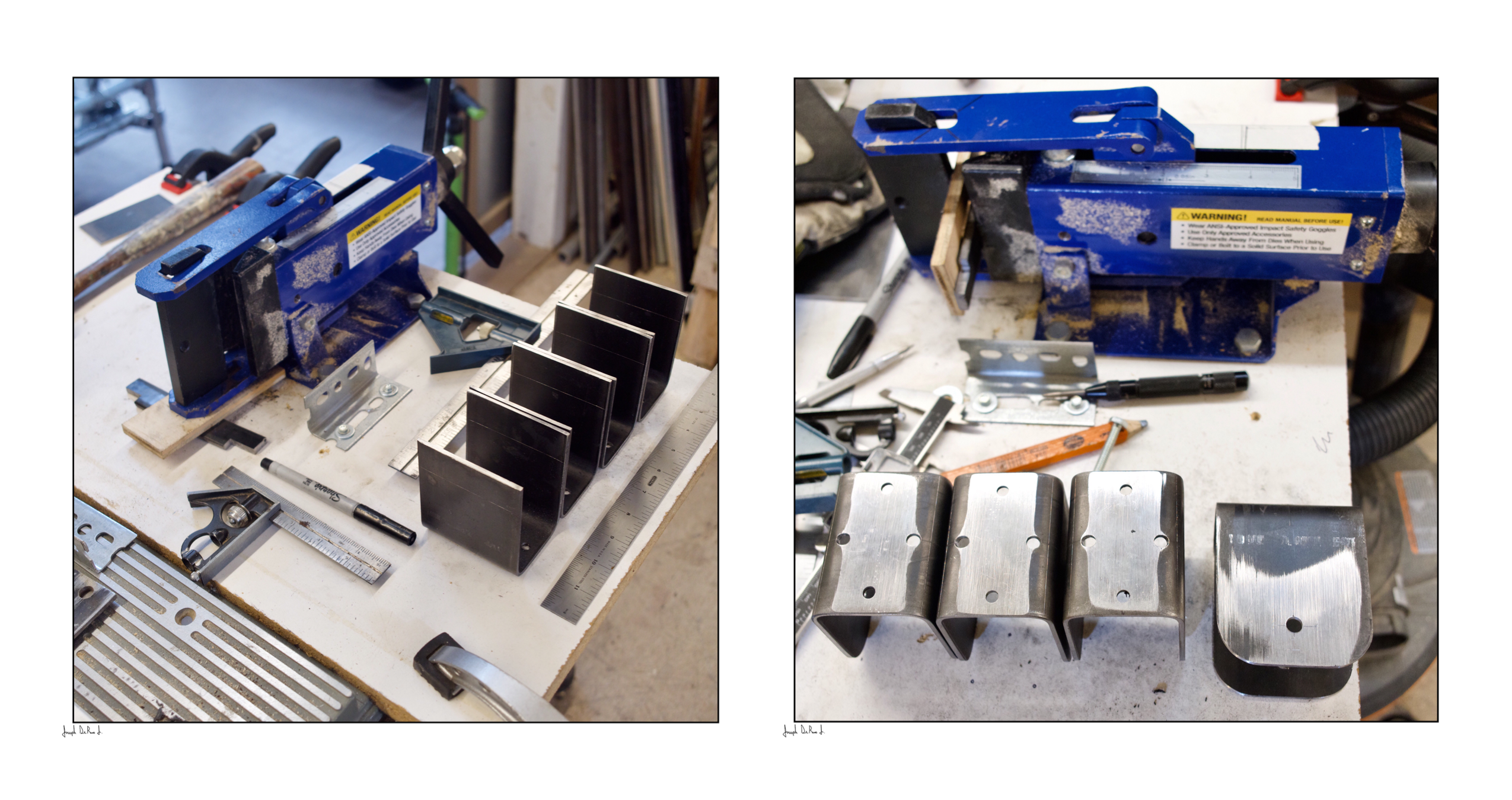

8EA8CCA3-4517-4B69-BD9E-FB23DC830A09.jpegSpring Bar Bracket This holds the bar that the springs are attached toJPEG Image - 1.07 MB - 05/23/2019 at 02:28 |

|

|

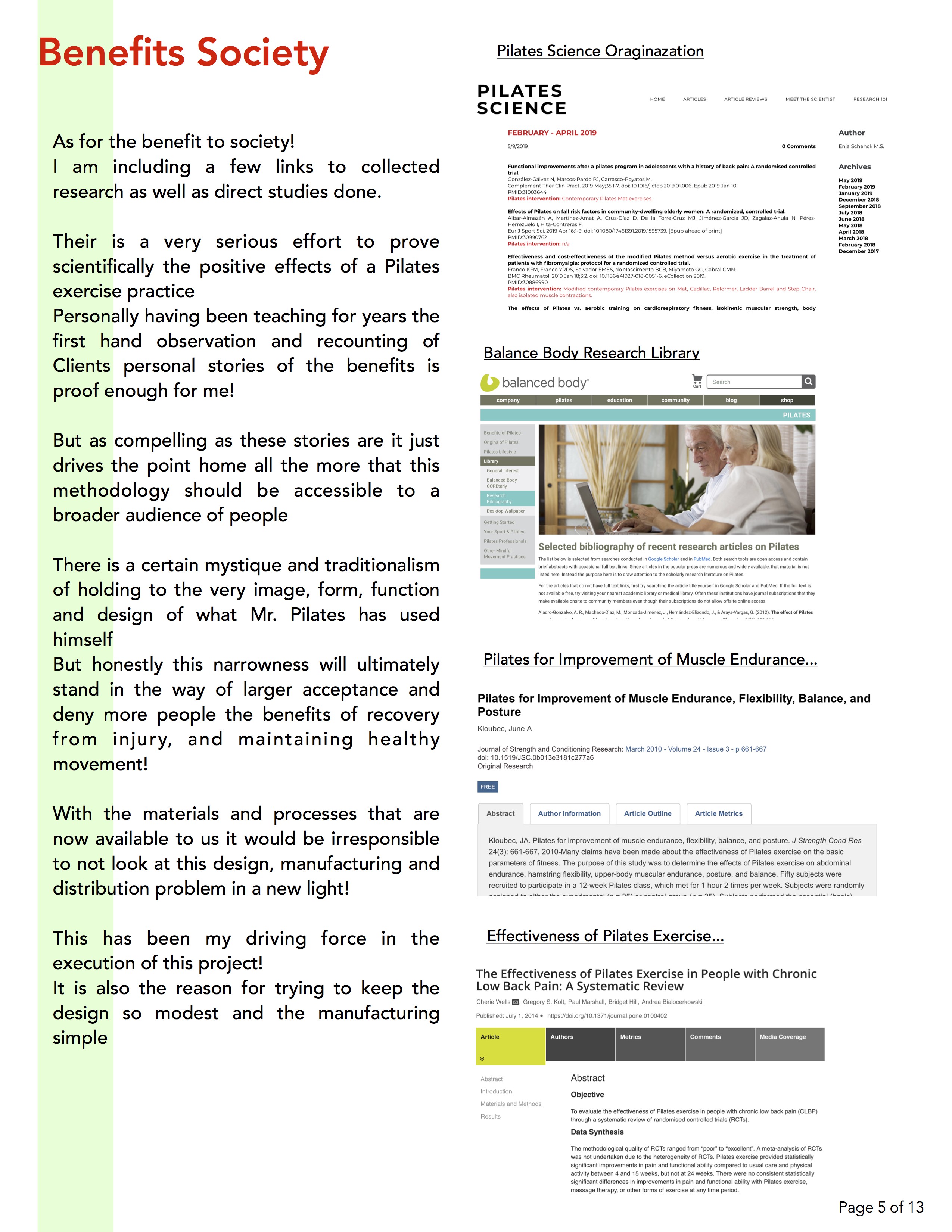

0D7D4C33-3946-4F7A-BE9B-4EAF48251FCB.jpegEnded up designing a purpose built metal bender for the castersJPEG Image - 649.65 kB - 05/23/2019 at 02:28 |

|

|

D2A82BE0-5870-4F14-B3C3-440E922DF6D3.jpegFinal built metal benderJPEG Image - 1.21 MB - 05/23/2019 at 02:28 |

|

|

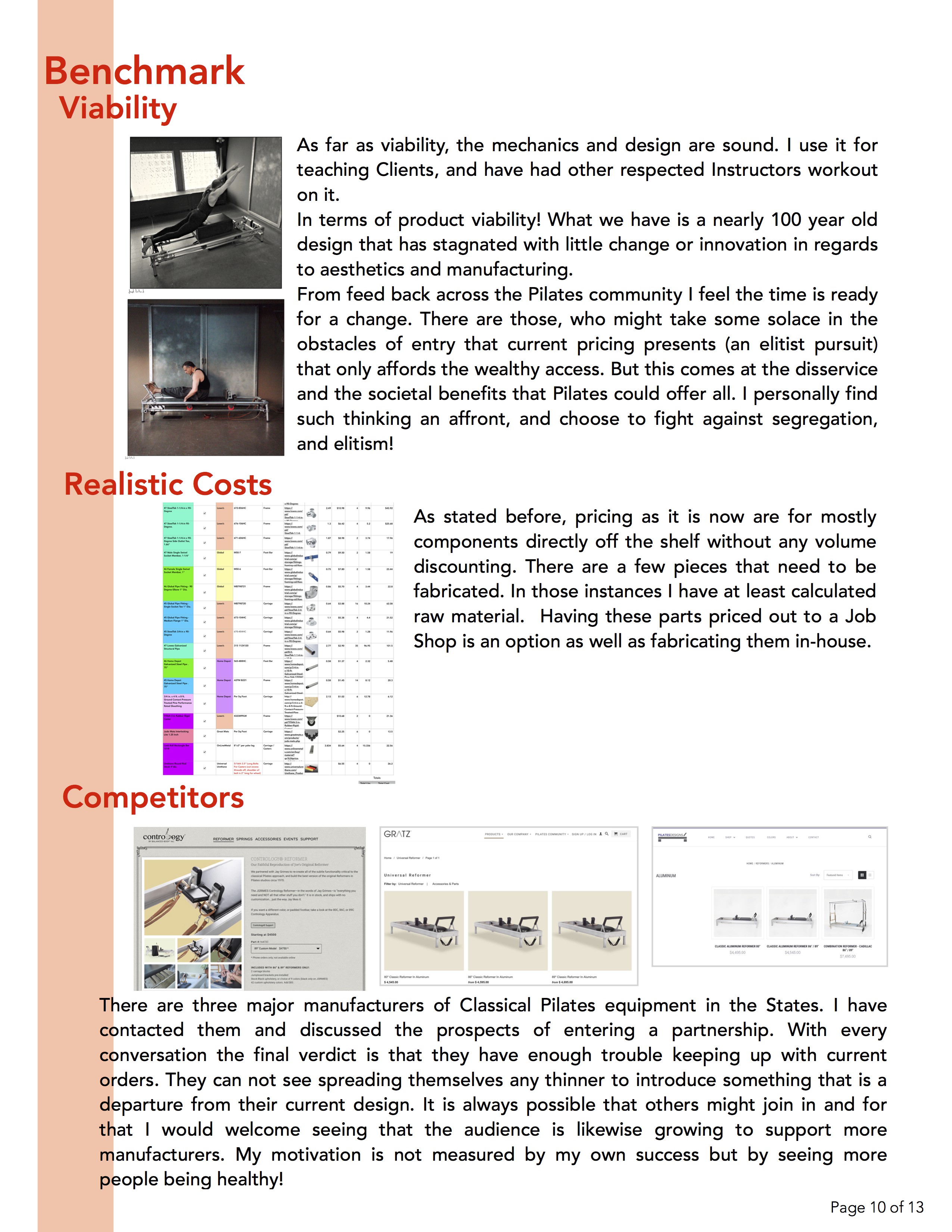

Have the opportunity to showcase the Reformer at a workshop held by a well respected International Pilates Instructor

It is a very nice chance to get feedback from a larger group of established Instructors

But it started us thinking

Being in the middle of building up another Reformer we’re taking the time to give it another once over as far as final build

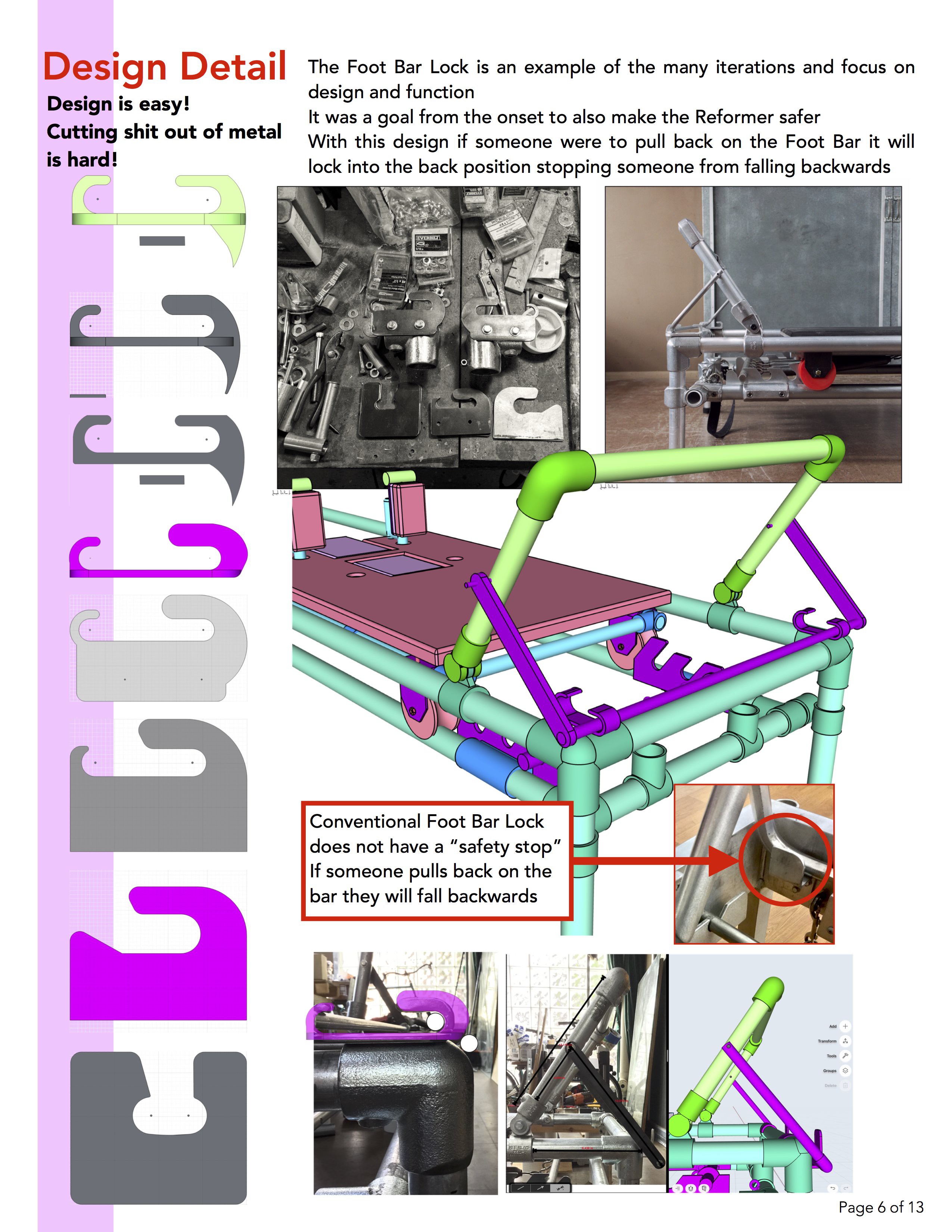

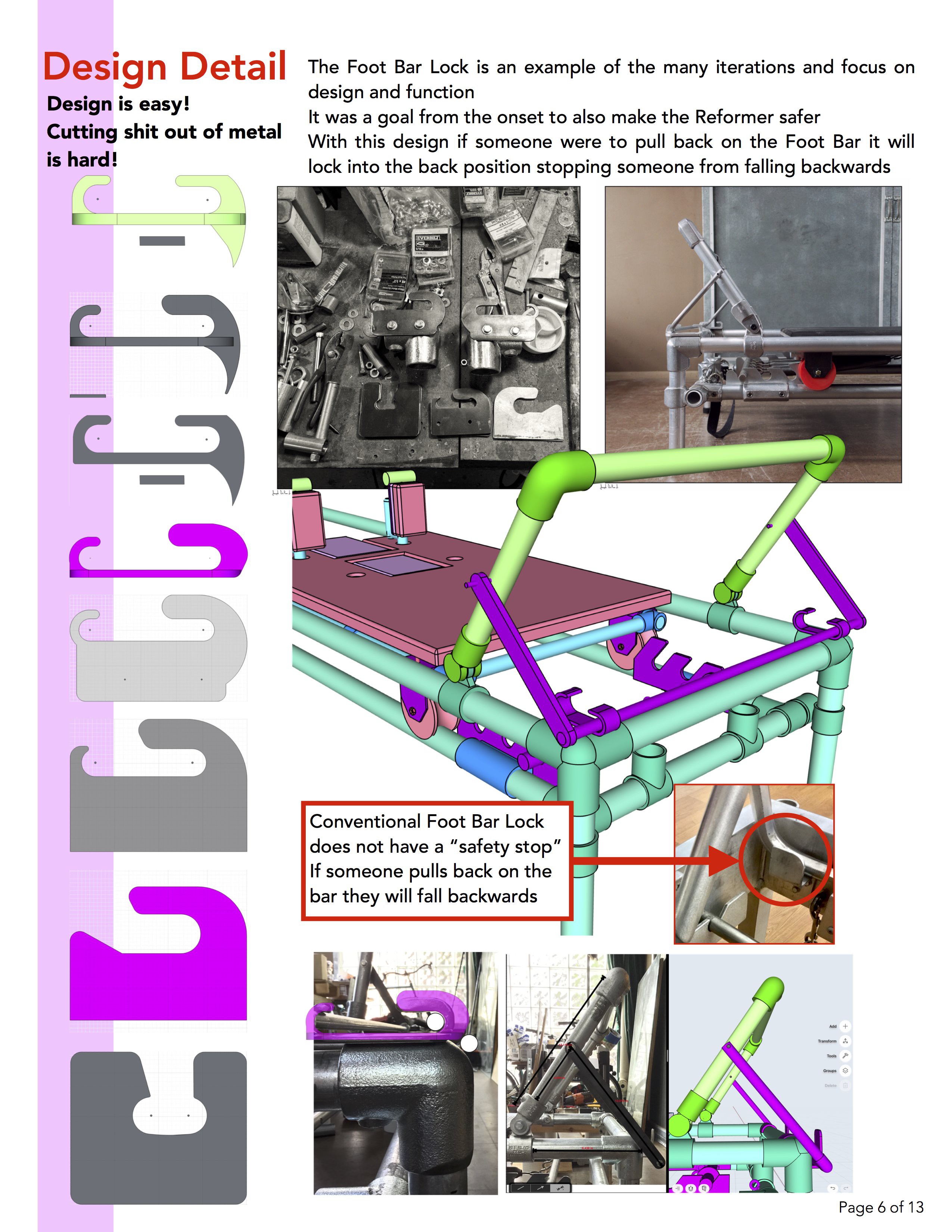

Thinking of disassembling the current Reformer to bring it to the workshop one of the choices we had made in the past was to use a “Tee Joint” in attaching the Track to the cross member

The “Tee” creates a rather clean line, but it does mean that it is a bit harder to get the tracks into parallel (the joint has to much movement in it)

So with that realization we’re switching to a “Crossover”

A “Crossover” will be a more ridged support, and will be easier for keeping the tracks parallel, also faster when it comes to assembling

Making the time to always question, putting aside what your assumptions might have been in the effort to make the process smoother for others (those using the device as well as those manufacturing it) is the fun of all this!

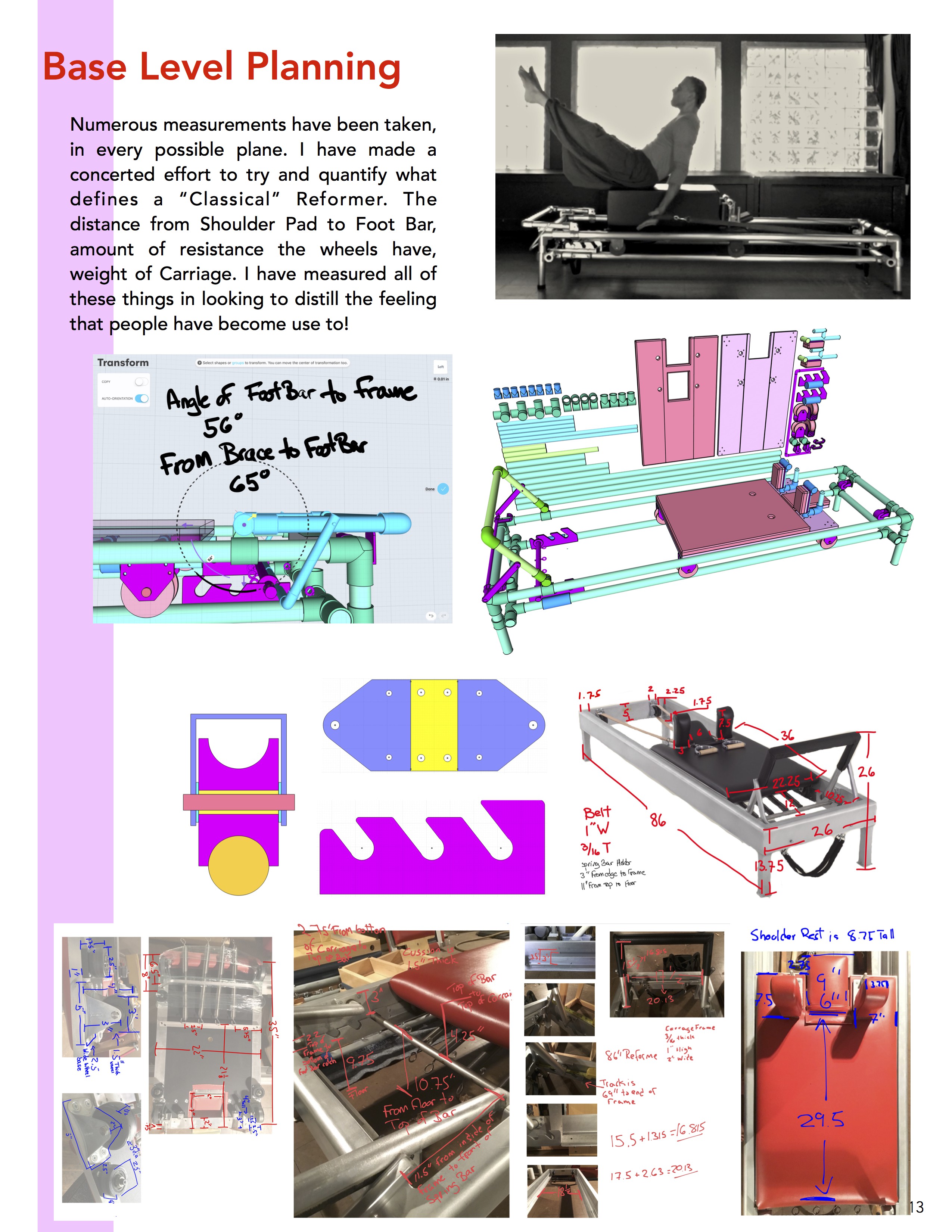

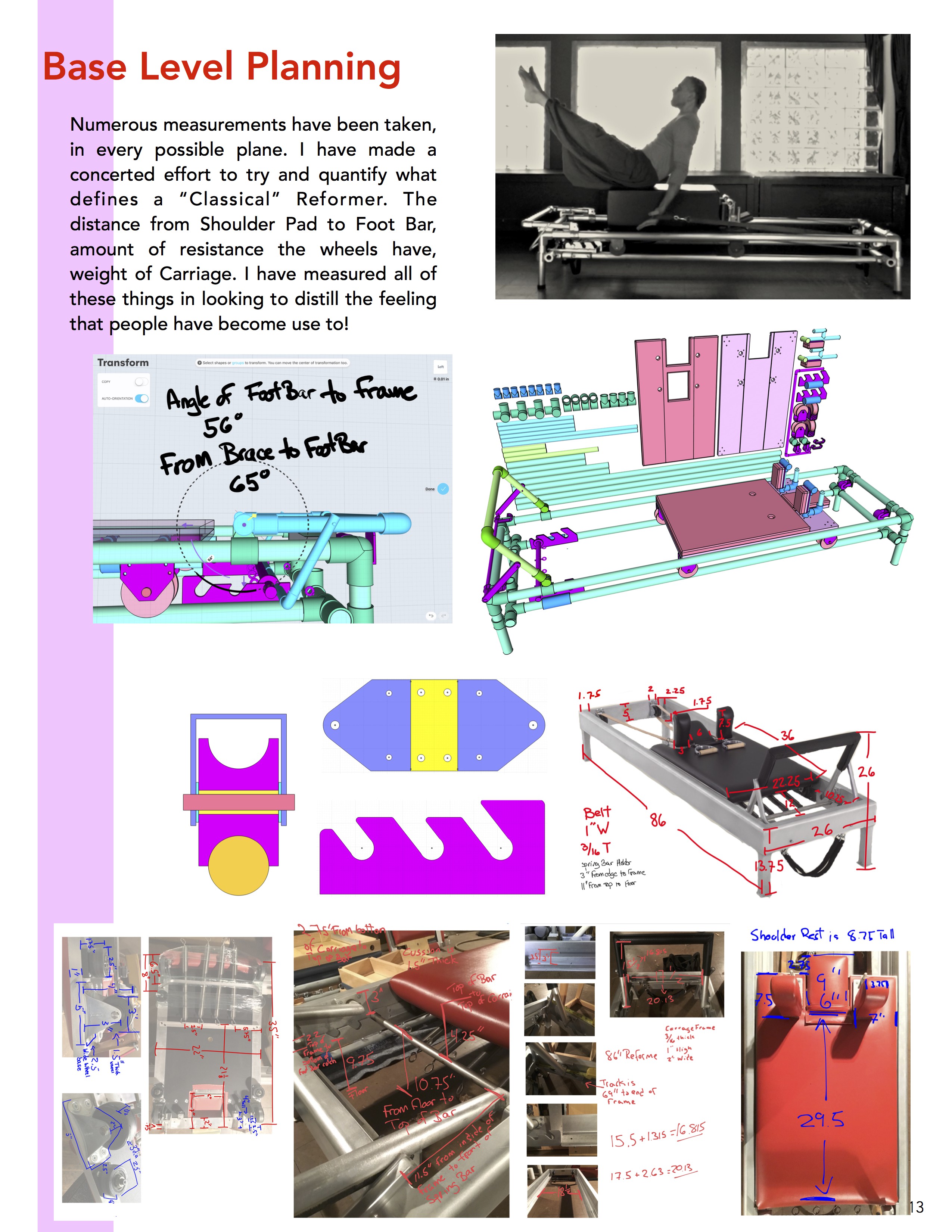

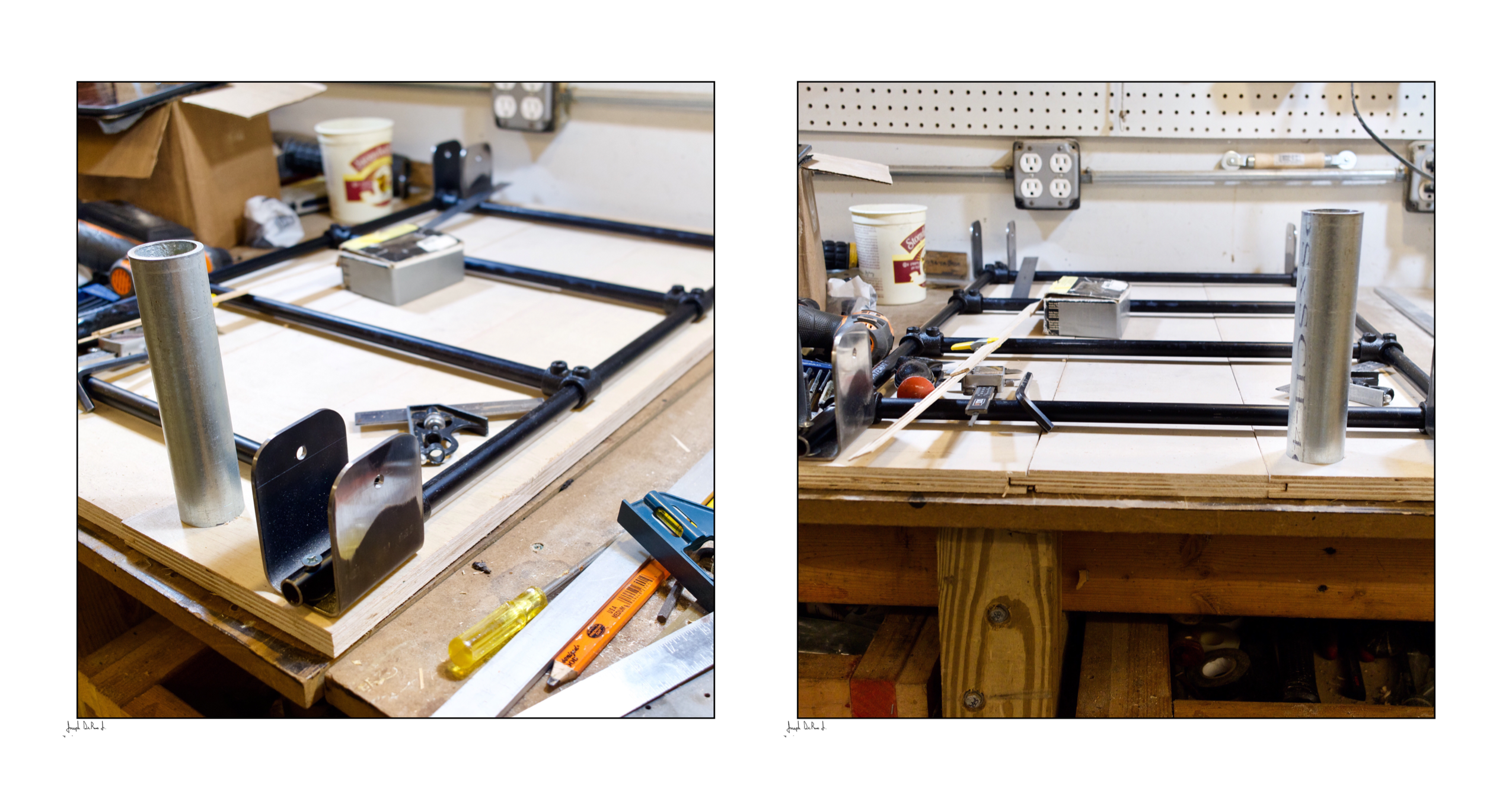

There were two primary reasons for making a new Carriage

First was using smaller diameter pipe, and second was seeing if using three panels of wood that are tongue and grooved would work for the Carriage platform

In an attempt to keep the weight down and make things more manageable for shipping the thought was to try dropping down to a smaller diameter pipe for the Carriage frame

We had some concerns as far as the strength and if flexing would be a problem!

Happy to have discovered that it looks pretty rigid and should work fine!

As far as the wood platform one of the issues with using panels (panels was necessary if it were to fit in the shipping tube) rather than a solid piece of wood was getting it to hold together

We didn’t want the user to have to glue it, and using screws or brackets seemed cumbersome

The thought of a simple tongue and groove was considered to be the simplest of solutions

The panels needed to be bolted to the frame for the casters already so that meant they would have a bolt to fasten them to the pipe frame

Jigging up to cut the groove and tongue was a bit finicky but definitely in the long run seems to be worth the effort!

So things move along and sometimes take an unexpected turn!

A conversation was started with the folks over at Steel Tek

If you don’t know them it’s worth going into most any Lowe’s

They have a full selection of speed fittings that make any DIY project much easier

The convenience of being able to run down to the nearest Lowe’s and pick an odd fitting up makes things much more fluid!

They were excited to see the Hack A Day entry and offered to send some fittings our way in support of the competition

With a box full of fittings (a friend coming into the dining room seeing the box with fittings exclaimed “looks like Christmas came early) we got to work on a new frame!

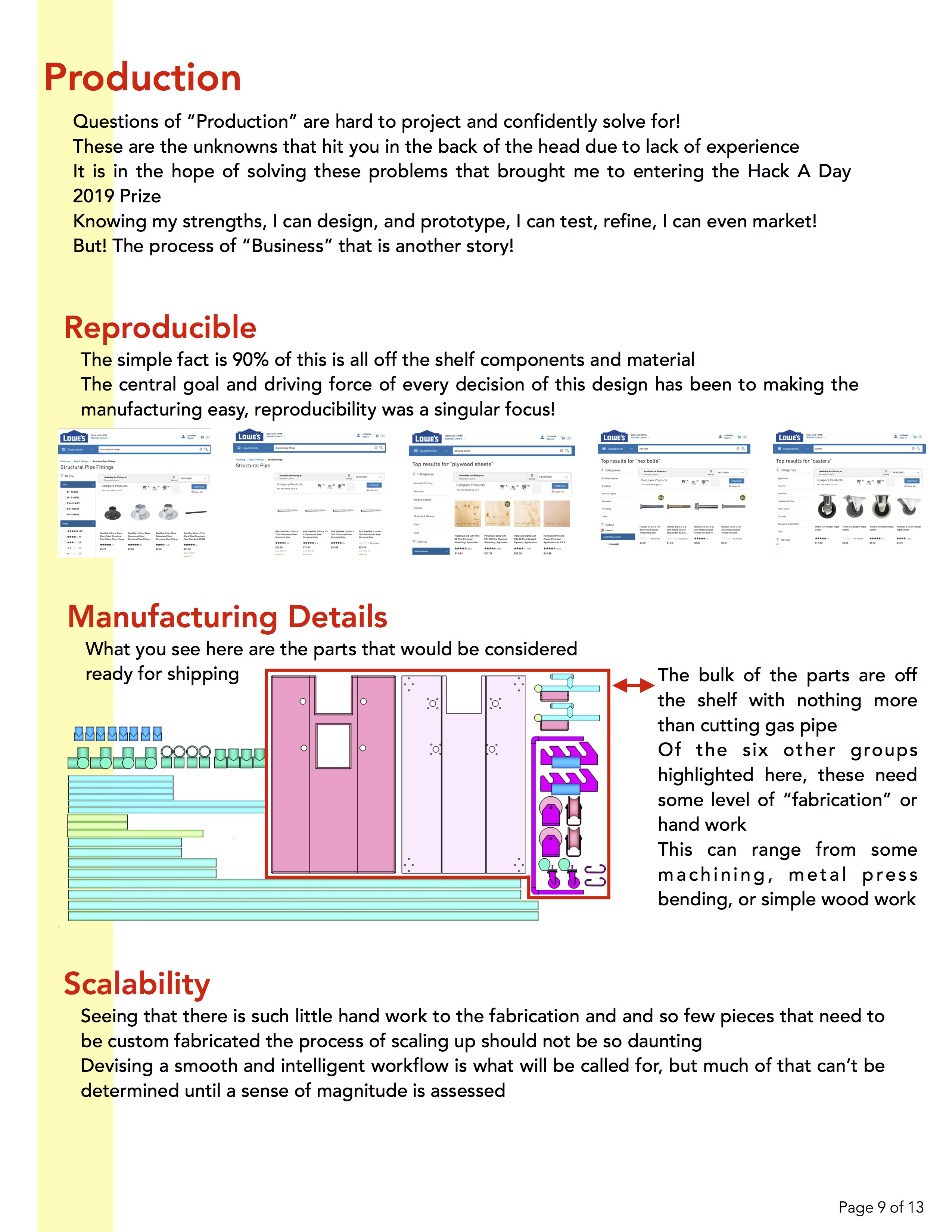

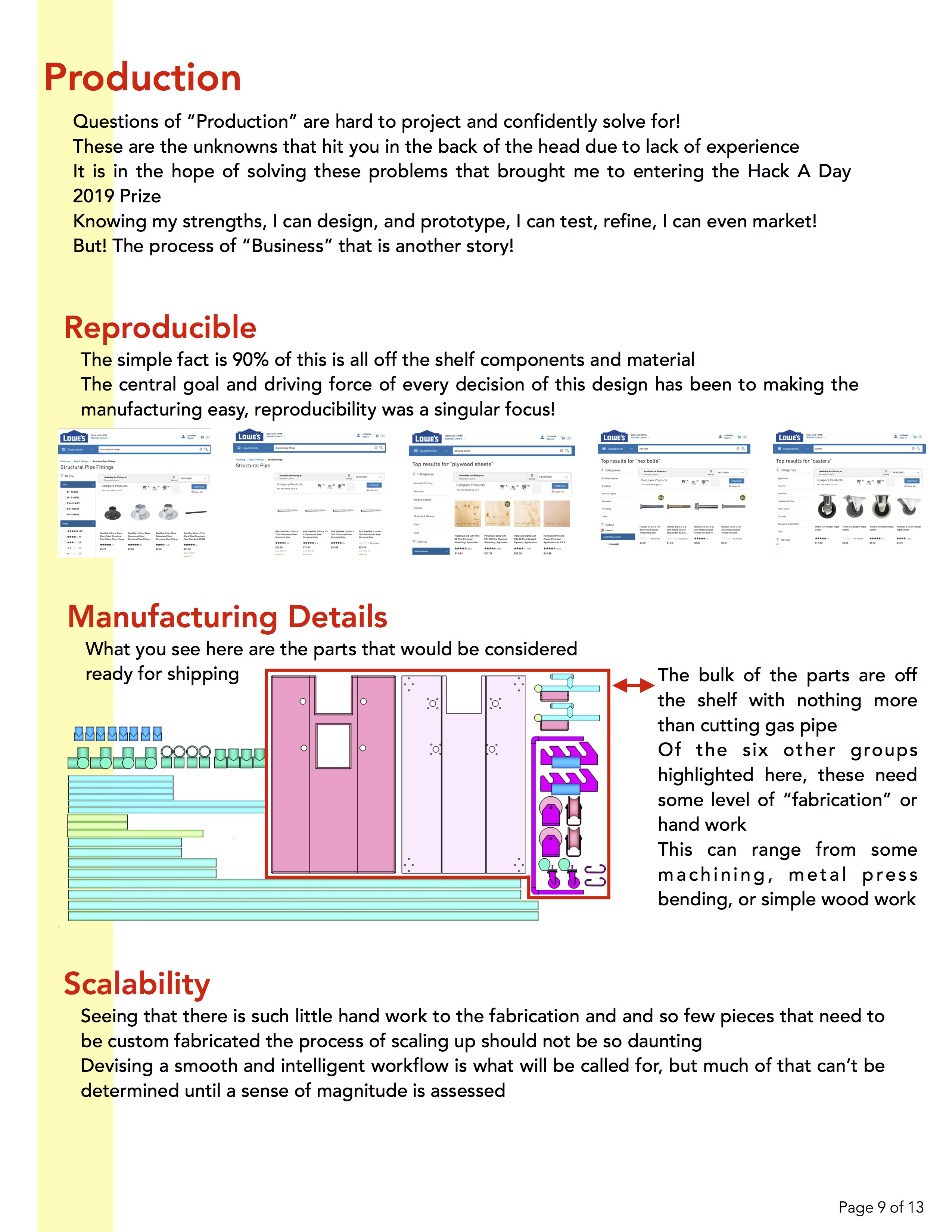

This iteration is being used to nail down the final cutting dimensions

Often the process of “hacking something together” is closer to sculpture then that of engineering

You chip away at this problem and the next, having things evolve and take shape as you progress

But, designing something for production is a very different story

Once you recognize that 100, 1000 units might be built it is no longer a piece of sculpture but becomes an act of engineering!

The decisions you make are no longer about how will I make this particular piece to solve problem “X” but how will 100 of these be made, and is there a smarter solution that doesn’t need that particular piece at all!

So where some might look at the process and think “how do you have the patience” or “how boring it must be to keep having to redo this”

No! The simple fact of the matter is that this is the process, this is how things get built, this is how meaningful change comes, how you make an impact on people’s lives

It is a discipline, it is work!

But the truth of the matter is that it brings us such pleasure, every part of it, it is what we have always done and trust by God’s Mercy what we were made to be!

Decided to build up a new Carriage

This is now the third one

One by one we’ve been dropping down the pipe size each time

There are a number of other refinements

Cutting the base in thirds, adding a tongue and grooves to the edges so that it can be broken down and assembled more easily

Repositioning the wheels for greater stability

Reworking the shoulder Blocks

One of the casualties of switching to a narrower pipe dimension is that the strap lock will no longer work

So we’re left revisiting alternatives

All of this is a process and as things change we take the opportunity to make things better, if not better at least being able to resolve questions of what is scenarios is always of value! 😊

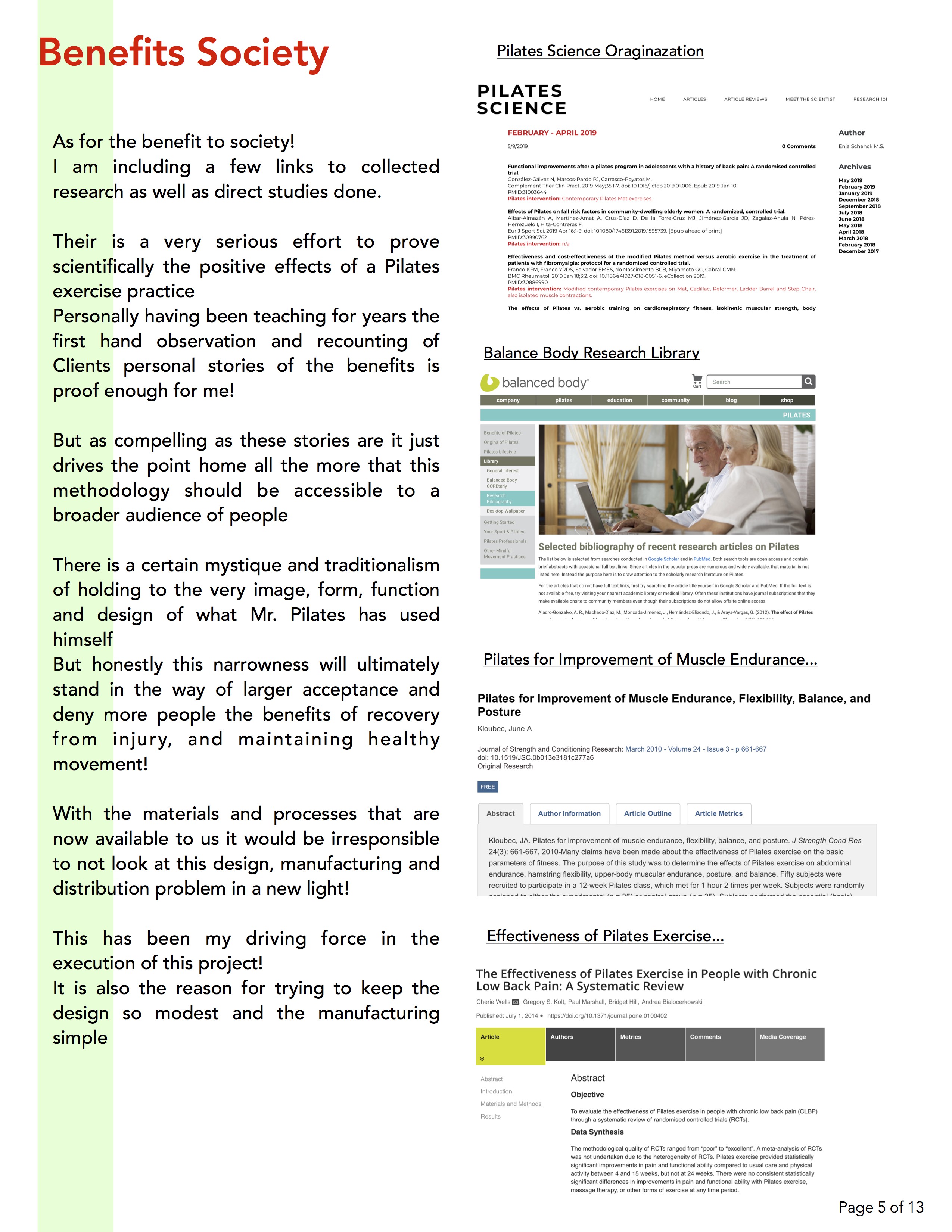

To another point was the idea of jobbing out the metal bending of the casters

At this point it is easy enough to do them by hand, figuring saving a few dollars is worth it!

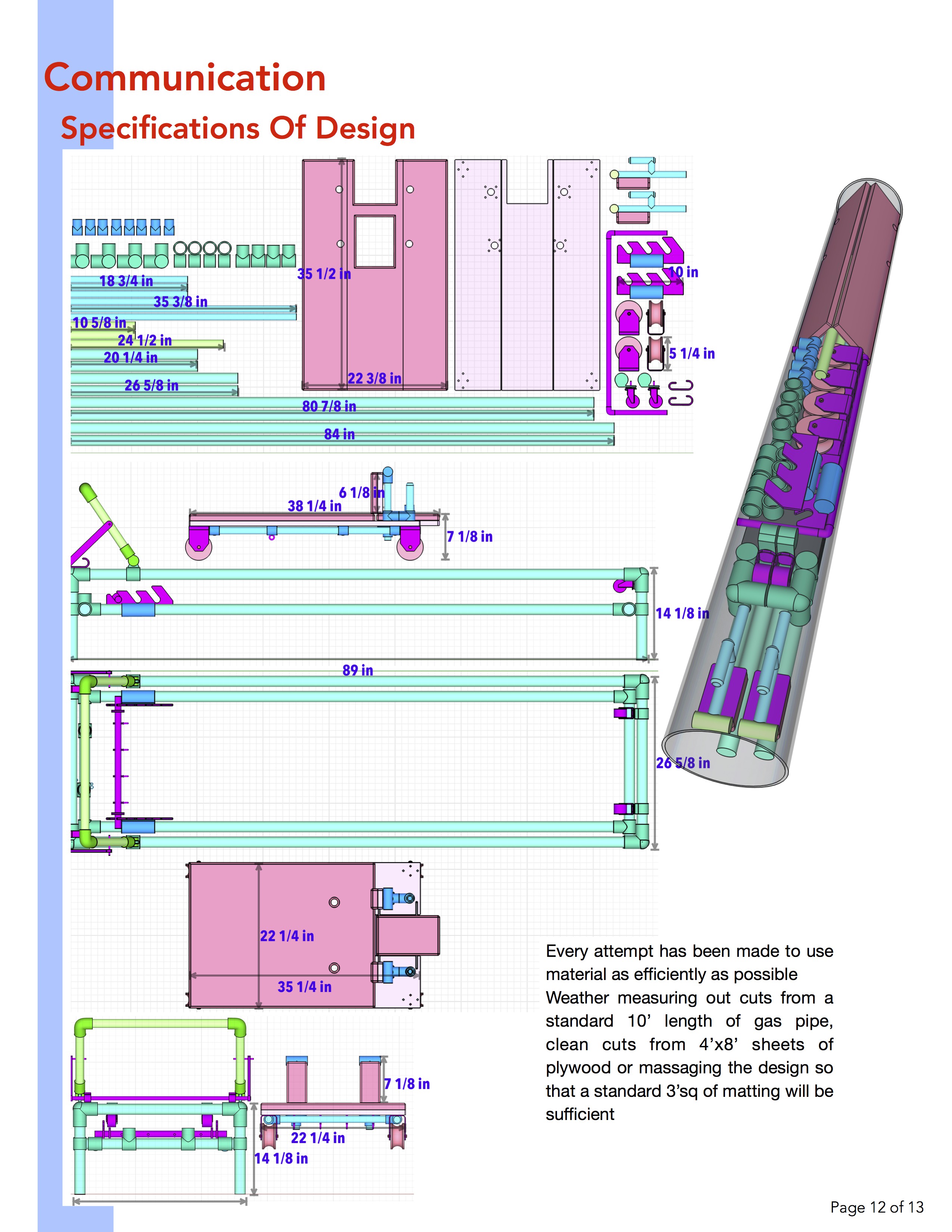

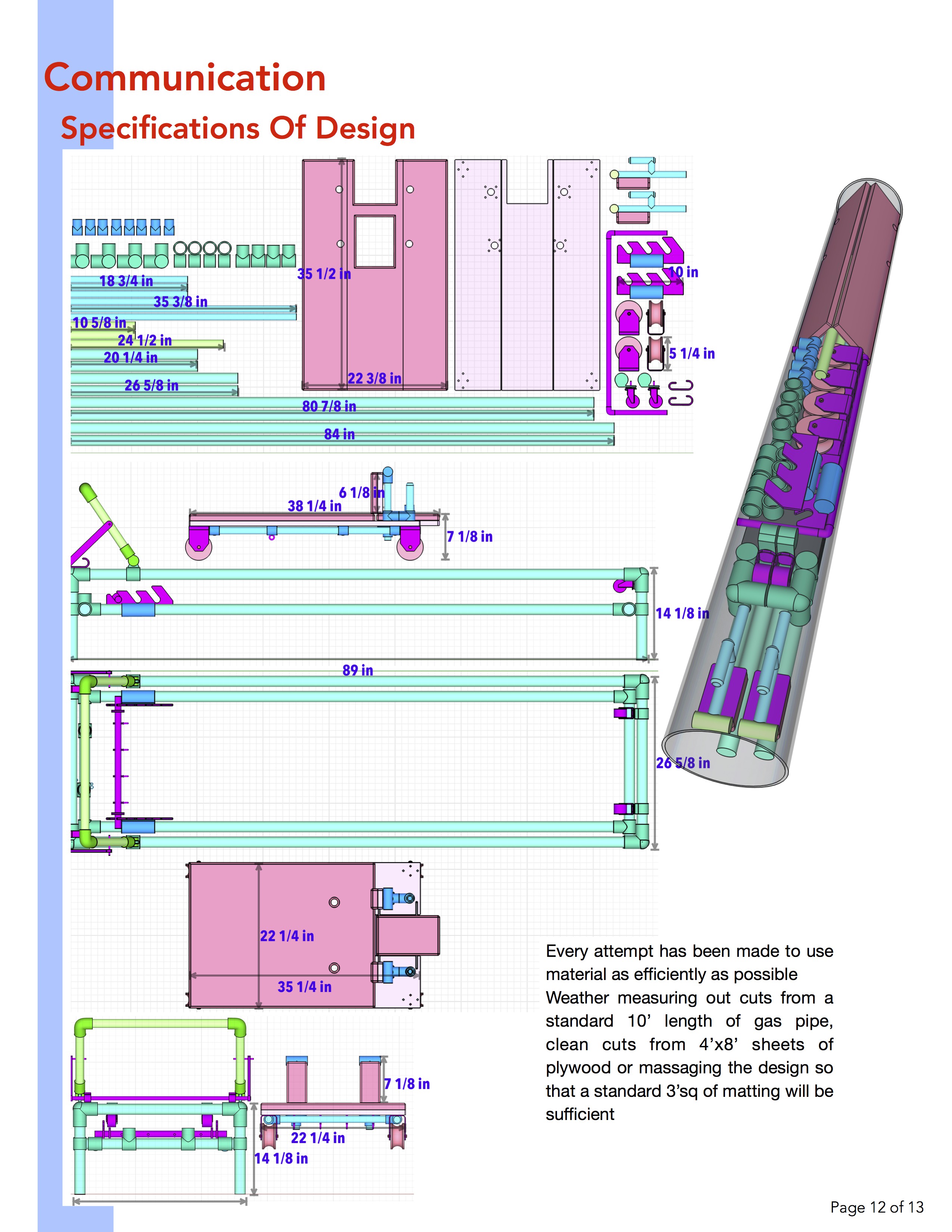

What you see here are the renderings for all the major pieces of equipment in a Pilates Studio

When a problem arises the first instinct is to attack that problem, and find a solution for it

That is how it was regarding this project

The Reformer is what presented it’s self as the problem, and that is where we focused

We had worked through a number of designs and was getting to a place where things were feeling good

But it was at this point that the realization set in, and the larger picture presented it’s self

The problem wasn’t just the Reformer, but it was all the Pilates equipment used!

With that we had to take a step back and look at the problem from a completely different perspective

What followed was scrapping our original design, and start from scratch

This time, not just looking singularly at the Reformer, but making sure that all of the solutions and elements would ripple down through every piece of Apparatus

This was done by working through all of the individual pieces concurrently

Design elements and solutions to problems, were tried out up and down the line, to see if they not only worked in one instance, but across the board

It meant that there were far more balls in the air being juggled, but it was the only way we could see not to be blind sided, and then have to go back for something and start from scratch

It also allowed a much more holistic approach to the process, a unifying design aesthetic

This would have been near impossible if it weren’t for having an iPad Pro and running Shapr3D on it!

The combination of the two created such a powerful tool that it allowed us to keep all the balls in the air! 😊

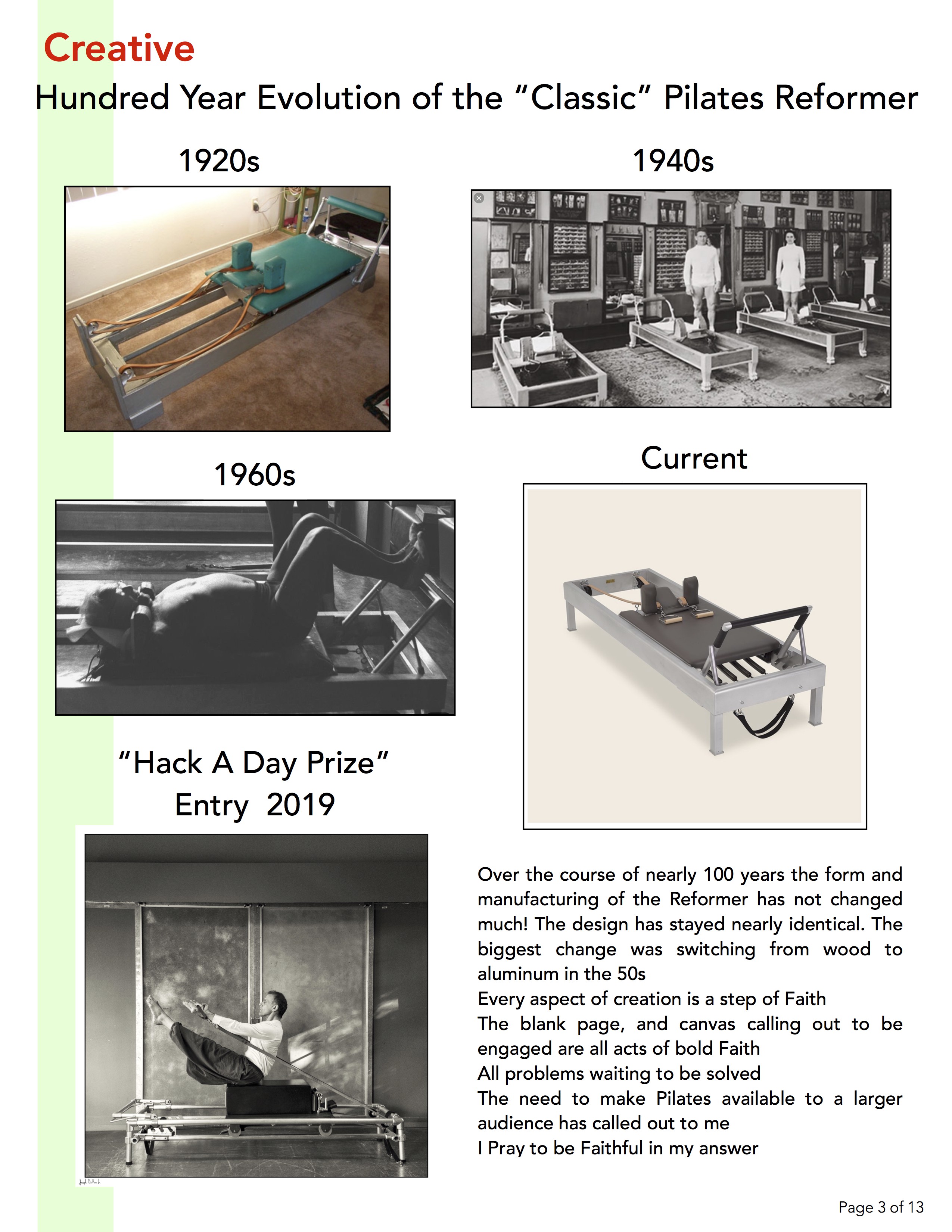

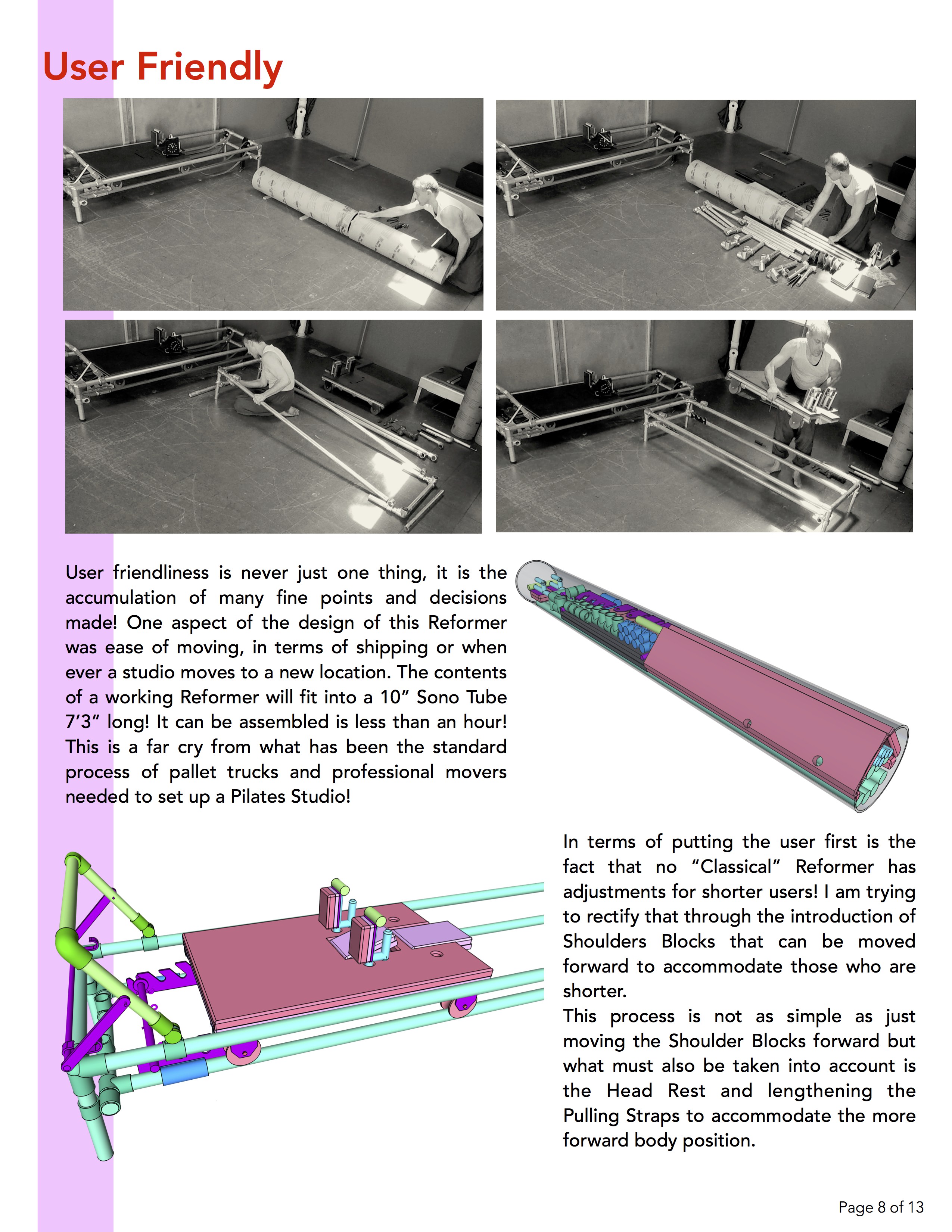

The Reformer Carriage has a leather strap attached to the bottom of it, the strap is threaded through an anchored caster wheel and on the other end is a pulling handle. On the bottom of most every “Classical” Reformer there is an “L” bracket. The bracket has a hole through it that the leather strap with a permanent D-Ring and I-Bolt attached to it is placed through the hole with locking nuts on both sides.

This setup takes two wrenches to attach and adjust the strap as it stretches with use (it is near unanimous amongst Classical Pilates teachers that leather straps are the only ones that have the correct feel)

An extra problem for our Reformer Design is that the shoulder blocks are adjustable, accommodating clients of average height and shorter. With the movement of the shoulder blocks there is a corresponding adjustment that needs to be made for the straps

Maintaining the original attachment mechanism would make this on the fly adjustment impossible

What is needed is a quick release lock for the strap

Cut two slots into the pipe for the strap to go through

Drill and Tap a screw hole into the pipe centered to the slot

Cut a circular retaining notch into a thumbscrew

Using a piece of copper pipe half the internal diameter of the frame pipe drill a hole the diameter of the reduced thumb screw notch

Cut a slit lengthwise in the copper pipe, round off edges so the sleeve can be slid over the thumbscrew once it is threaded into the larger Carriage Frame pipe

This creates a guillotine clamp that distributes the pressure while providing a very secure hold, all while needing no more tools or much turning pressure on the thumbscrew to provide a positive lock

The process is a whole other story! The process was many many thoughts in all sorts of directions. Drawing and modeling at least five different relatively good solutions. Building two rough working proof of concepts. The first proof of concept had a rounded nose bolt, threaded into the pipe that just pressed into the leather strap. This was a simple solution, and easy to execute. Unfortunately it created an indent in the leather that over time would weaken the leather. All of this is speaking to the very mechanical and linear aspect of designing and building something. The truth of the matter is that the process is one of deep thinking, tangent connections while pouring over the most abstract details of others solutions to other problems not your own. But you go through all of this process and thinking in hopes of solving your problem! And truth be told it is not just you! It is a spouse and children who look at you and repeat simple questions multiple times waiting for you to come out of that place where you dwell most of the time to produce an answer such as “coffee sounds good!” Now we’re not saying that every designer/hacker is this way, but in our house this is the way it goes. It is also because of a loving and understanding, an appreciative family that we have that unstructured time to just think and ponder these sorts of problems.

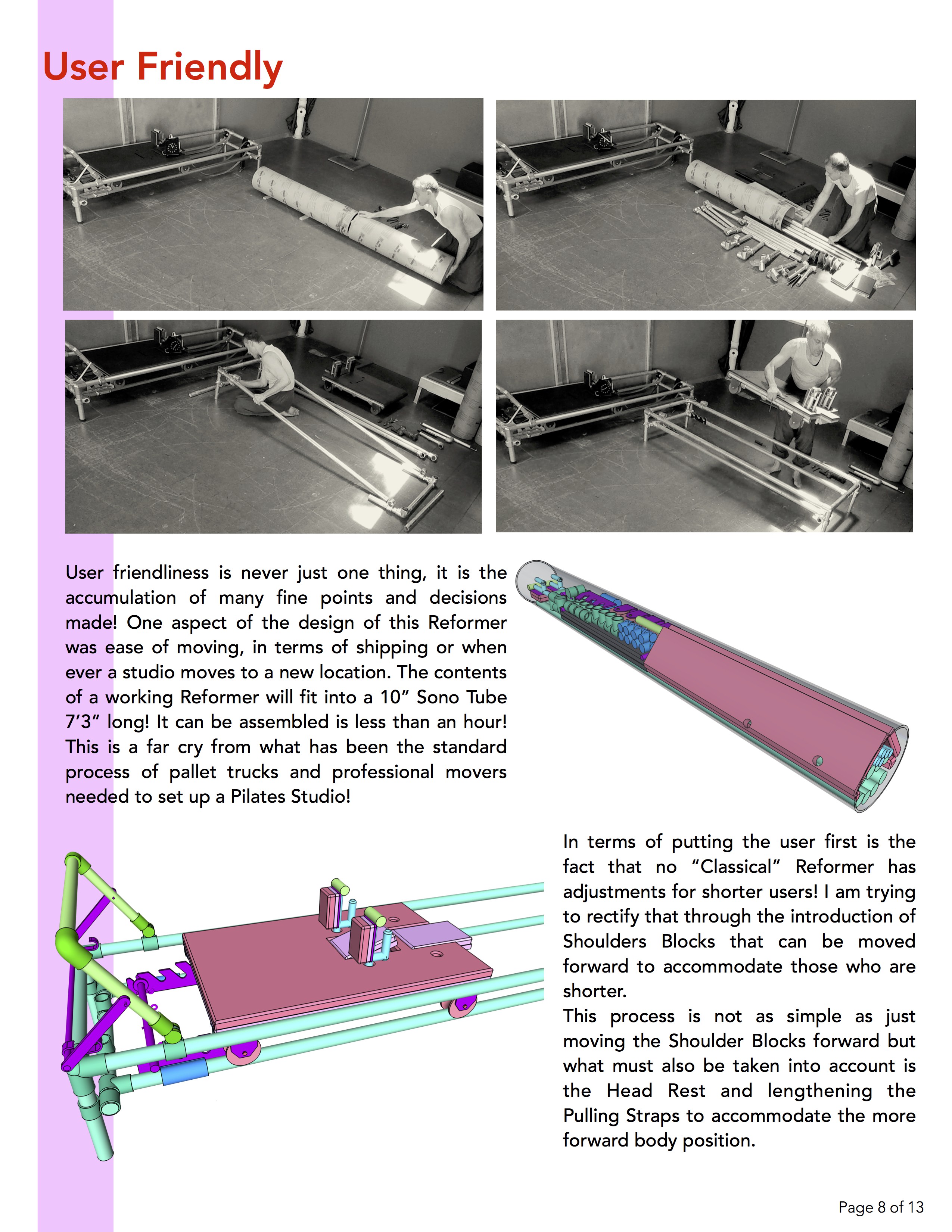

This was the first time of packing it and then reassembling!

Putting it together took just 45min start to finish!

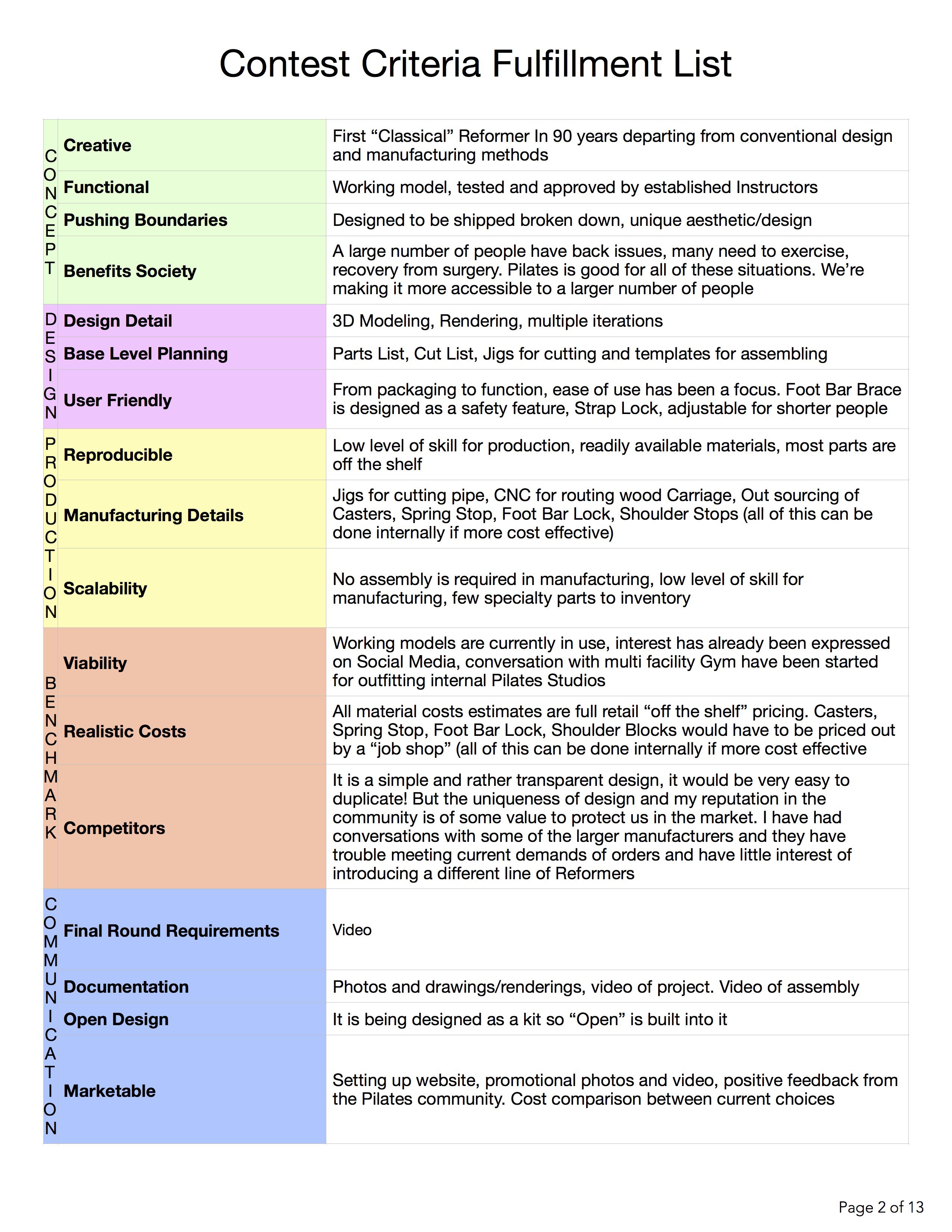

Wheels have been tricky

All of the designing for the wheels as well as the whole project has been done using an iPad app called Shapr 3D (it has been a life saver)

At 4" dia. they are a bit hard to cut square

This is of course without any real machining tools!

Built a new jig for cutting the groove

Create an account to leave a comment. Already have an account? Log In.

If you could make the project about the parts that are not easily attainable (wheel, springs??) and instructions so that shipping is cheaper (ie wood for carriage). Give the people the opportunity to purchase the entire set, or the downgraded set, so the buyer can have some sweat equity in their project.

Become a member to follow this project and never miss any updates

Hello, i was wondering whether this was still going? I'd be interested in getting involved. I'd love to make one up and see if I can improve. I'm an engineer and huge pilates fan, as is my brother and his wife is a teacher so we'd love to play around with the designs.