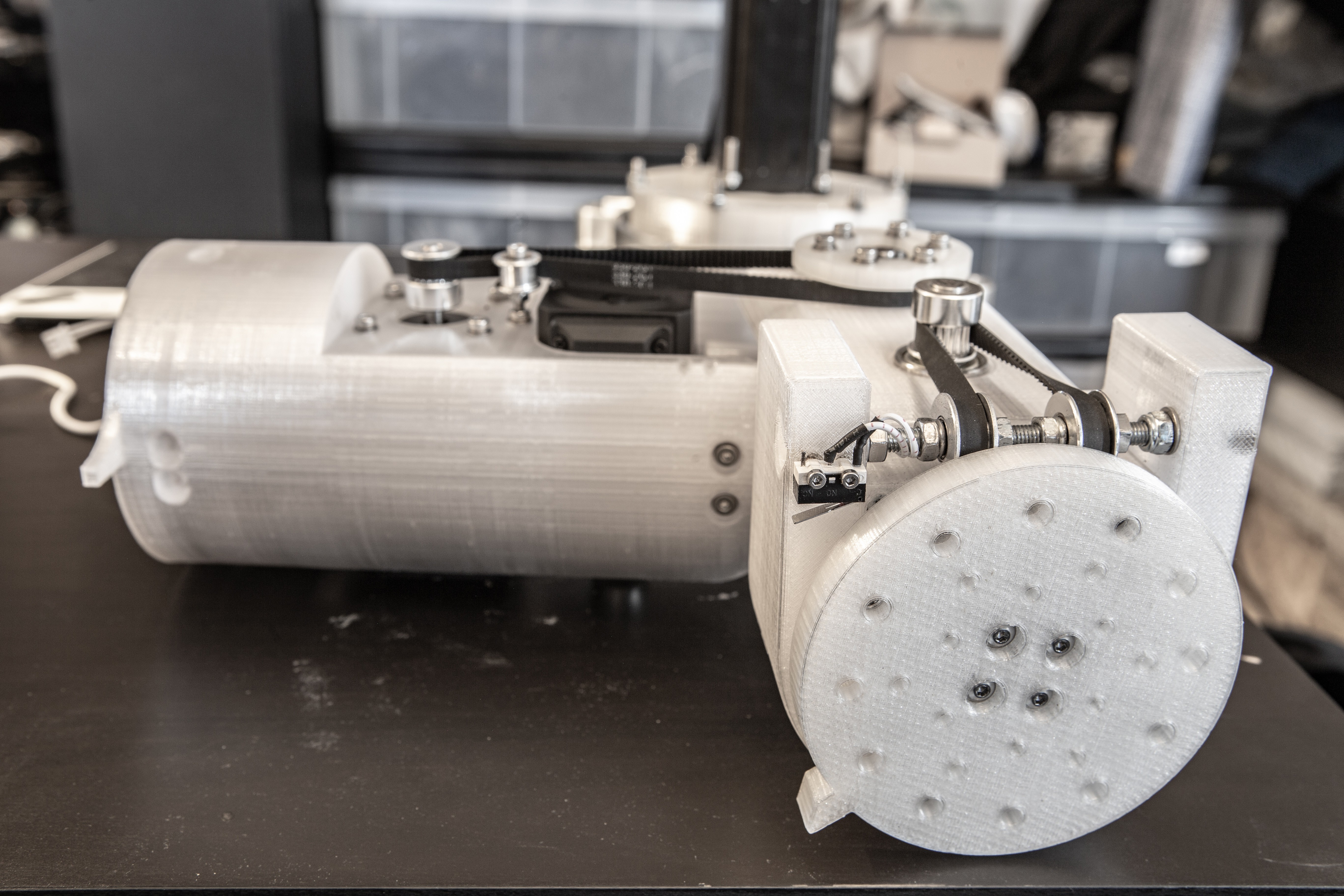

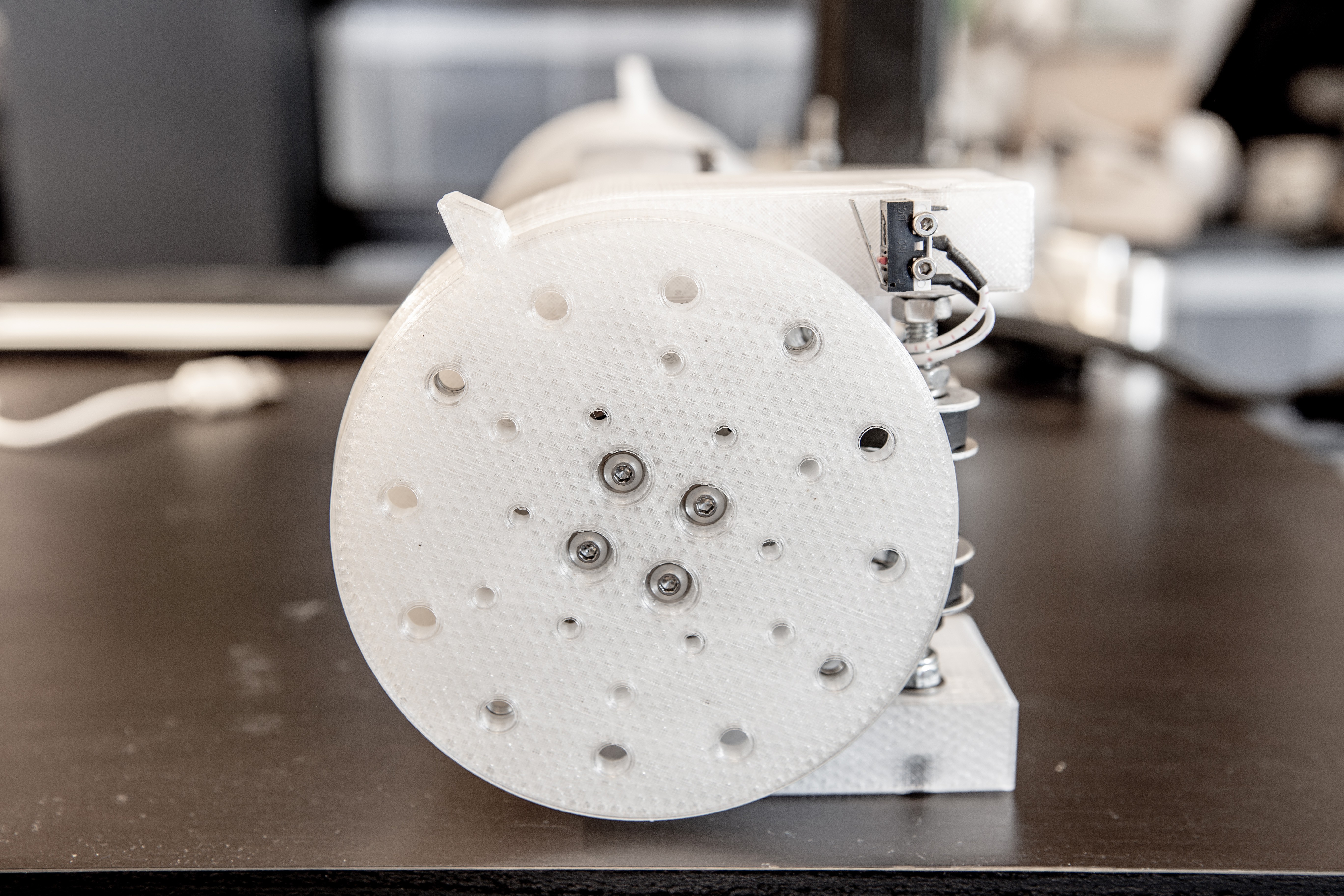

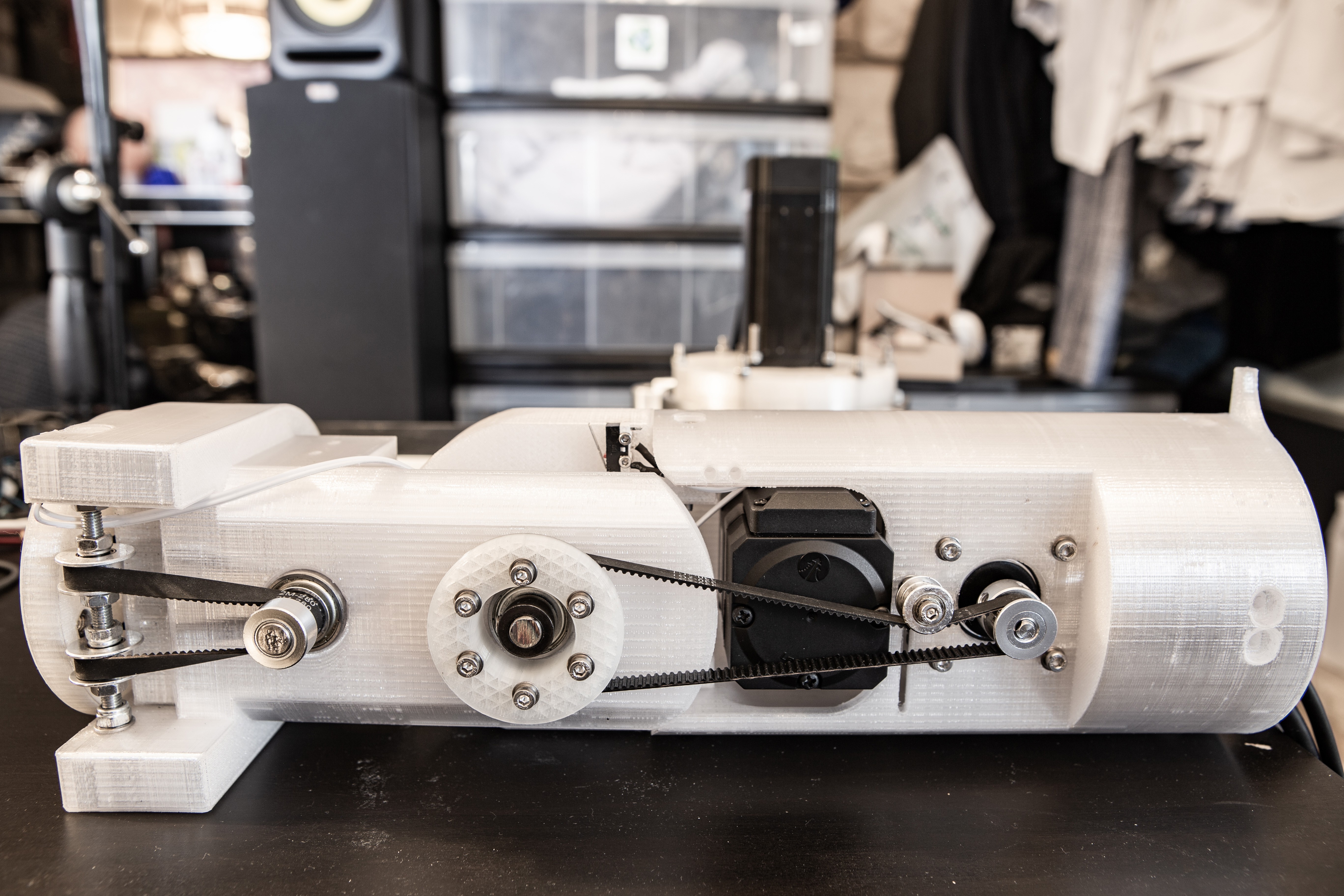

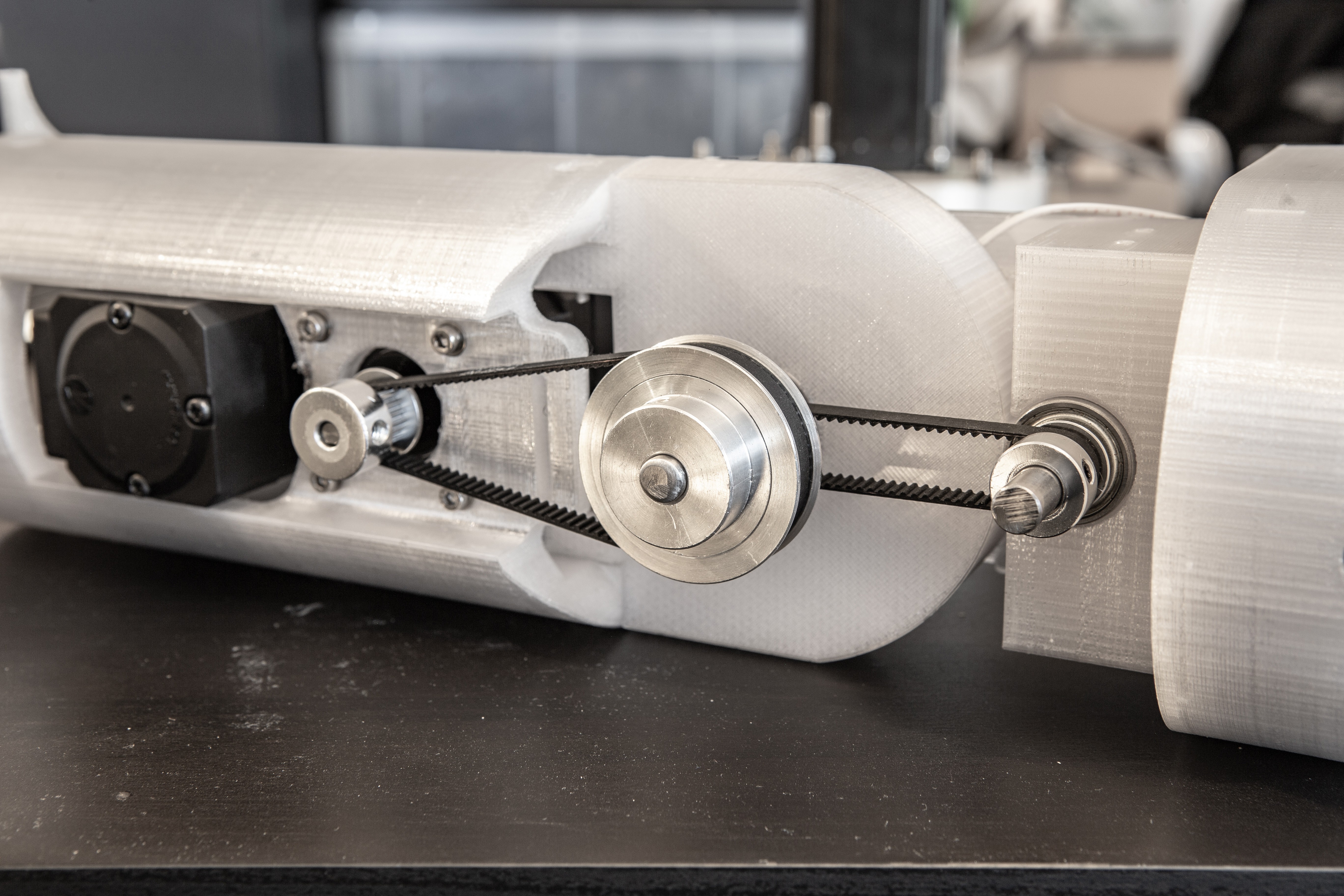

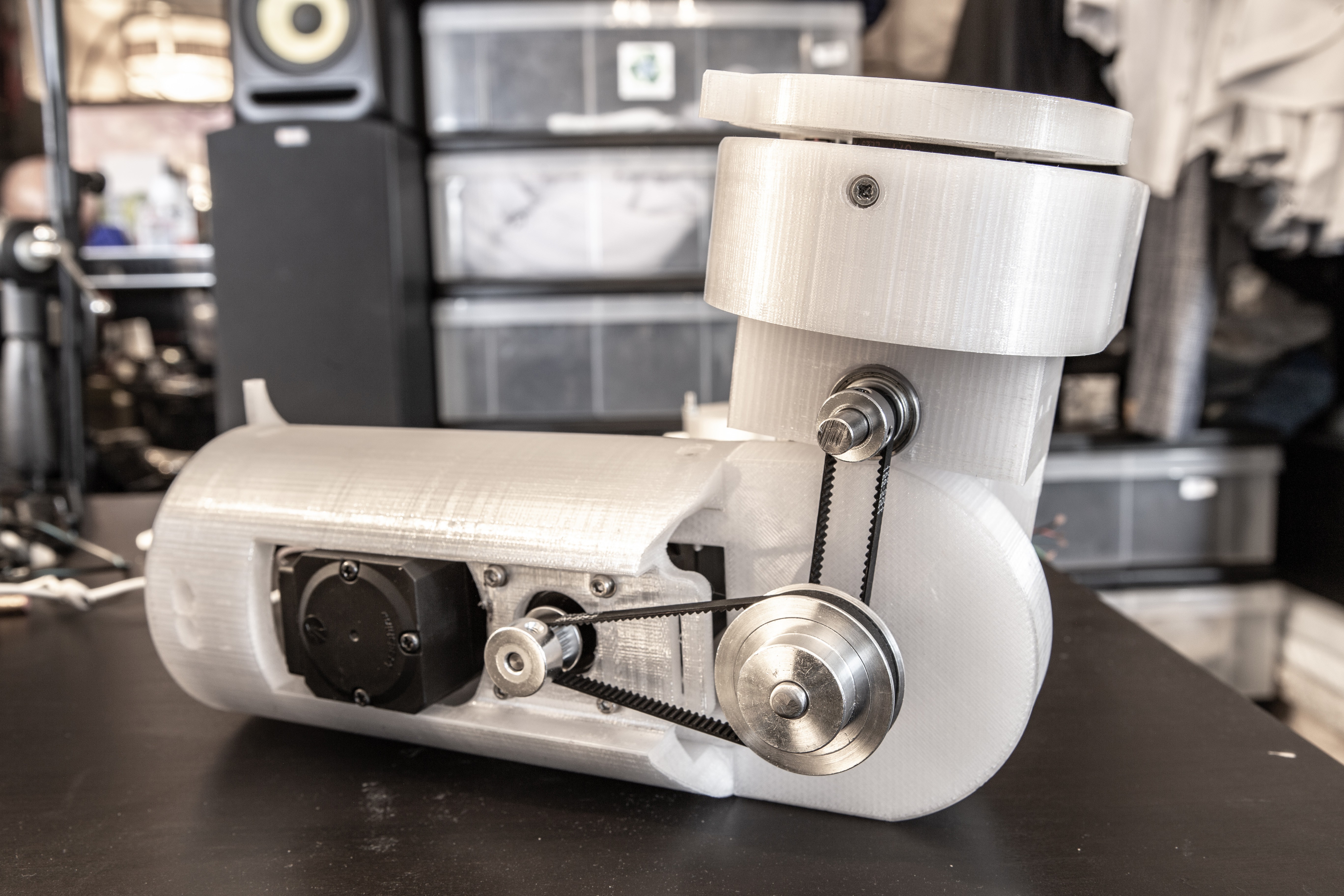

I have worked for 3 weeks on these 2 joints hardware, most of the time doing tests on the endstops positioning as well as the length of the closed loop 2GT belts.

Joint 6's motor is decoupling through a series of 4 2GT timing pulleys which should reduce the inertia of the whole assembly. While this setup increases the complexity of the programming, I find that the mechanical advantages far outweighs its drawbacks.

Leo Vu

Leo Vu

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.