Changes in AEMLOVE R9

- renamed to AEMLBLINK R1 because that better fits its function

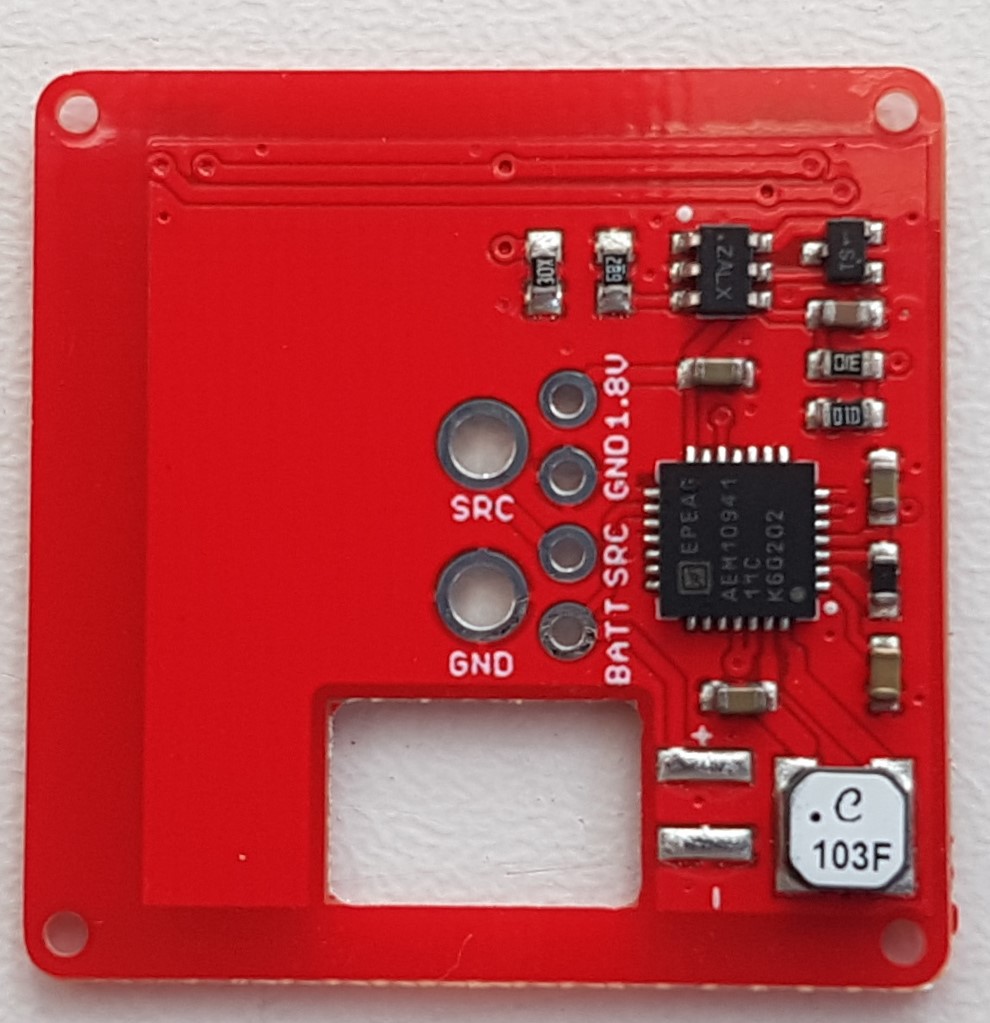

- added 0.1" pitch test pads so the board can be tested after assembly and before super capacitor and solar panel are soldered. Also added one for 1.8V. A user may connect a BLE module or something there.

- removed copper from the left side of the board because BLE module may need copper clearance

- set solder mask oversize to 0.05mm, previously it was 0.00mm

- added clear LED polarity indicators on silkscreen

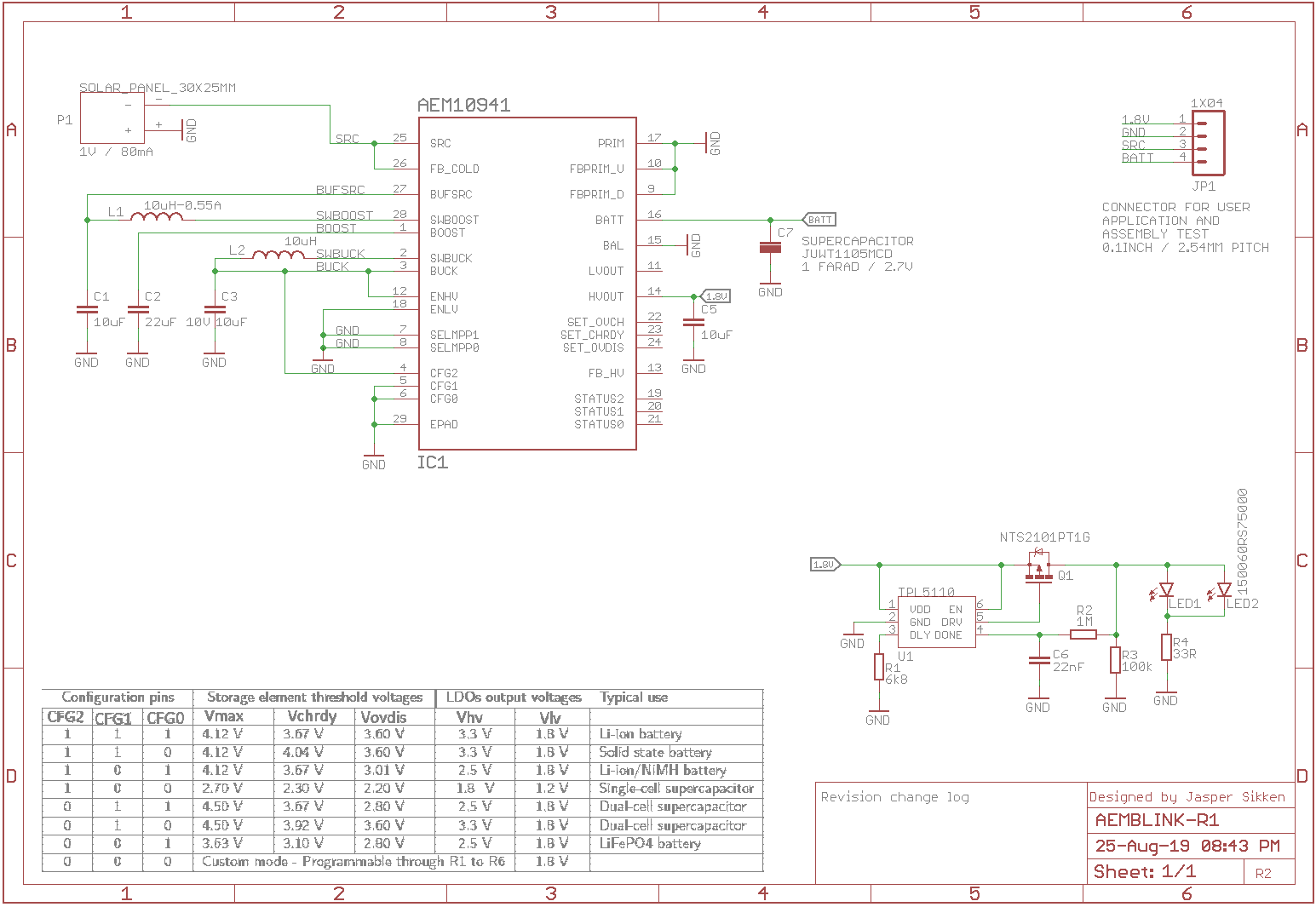

Below is the schematic design

I had 10 boards assembled at Elecrow

I have created a simple pen shaped PCBA test tool. It is to test the PCBA after assembly and before the solar panel and supercapacitors are soldered. It's just a small perf board with four 0.1" pitch male headers, a 1.5V alkaline battery to simulate a solar panel and a 220uF capacitor to simulate the supercapacitor. When the LEDs on the AEMBLINK board start to blink I know that the AEM10941 and the TPL5110 circuits work correctly. It also has a LED on the 1.8V output from the board. I

The super capacitor is full in 5 minutes in full sun.

Blinking duration is at least 8 hours on a full super capacitor.

I have tested blink duration with with 20, 27, 33 and 43 ohm LED series resistance. All 10 assembled boards blinked for at least 8 hours with a 33R series resistance.

So far what I've learned

- yeah I like the PCB design

- I need to change LED series resistor to 33R on all boards

- next step is selling on Tindie. Some boards I will coat and sell as earrings or necklace, some I will pot with epoxy in a heart shape and sell as necklace, and some I will pot into a silicone piramid shape and sell as desktop gadget

Jasper Sikken

Jasper Sikken

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.