-

Need Bigger Wheels

07/30/2019 at 04:16 • 0 comments In continuing tests, I managed to tag the flange on the rear pulley and completely crack it off. Oops! What did I hit? The little bump at the beginning of the driveway ramp through a sidewalk.

In continuing tests, I managed to tag the flange on the rear pulley and completely crack it off. Oops! What did I hit? The little bump at the beginning of the driveway ramp through a sidewalk. This thing.

So no, the wheels are not big enough, for this and several other reasons.

However, in the interest of continued learning, I will keep moving forward with the current design, building out the steering column next so we can all see an e-scooter actually fit in half the space of a normal backpack.

-

First Rides

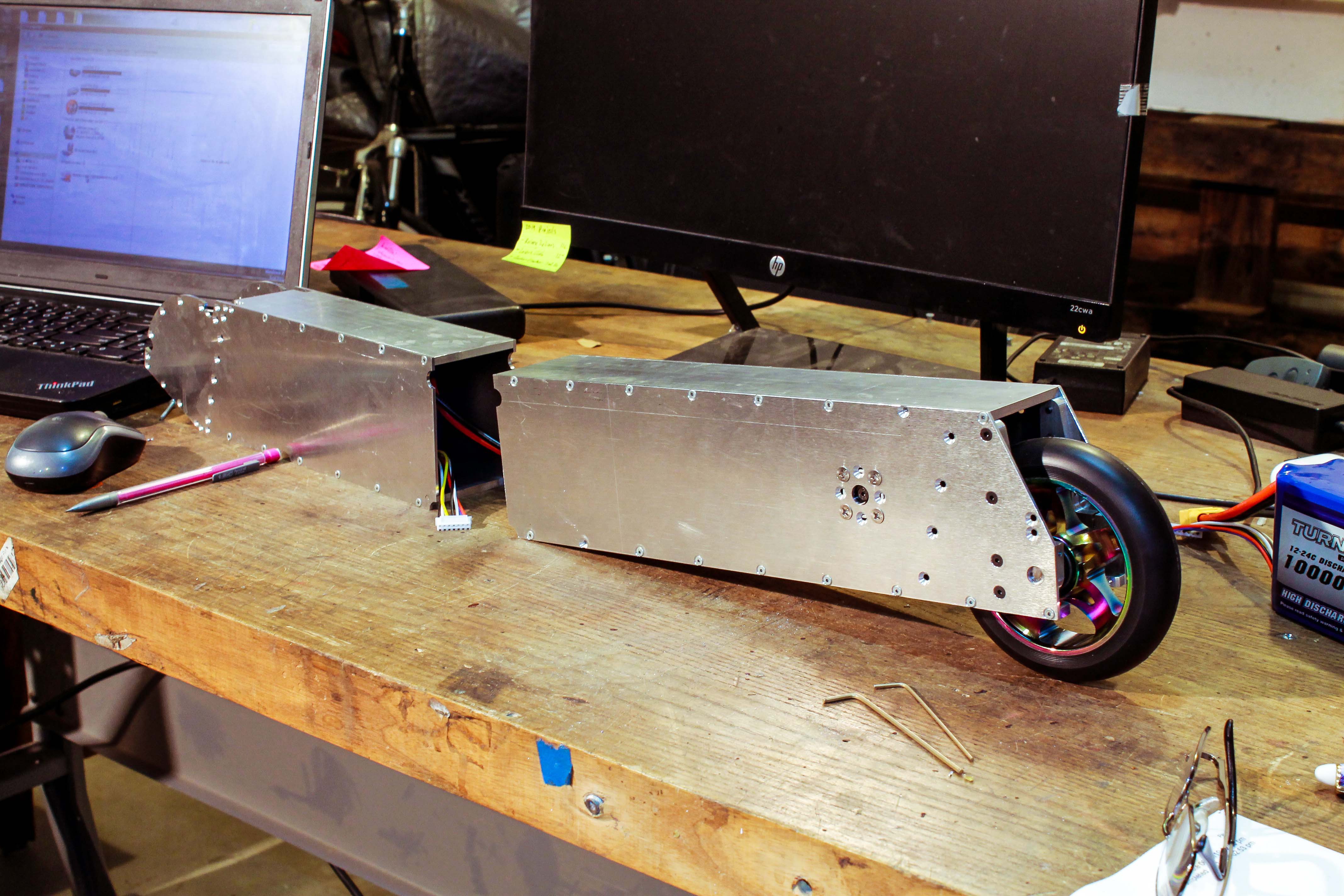

07/19/2019 at 12:50 • 4 commentsI could not wait any longer for a ride, so I chopped the steering off of a Razor scooter and welded it to my neck assembly. The resulting frankenscooter feels very undersized, but it does go!

The new to-do items are as follows:

Increase available thrust

On a steep hill, the scooter does not quite perform as well as I would hope. I did not find a hill that stopped it, but on a ramp to a train platform, I experienced the scooter just barely maintaining speed at the rated motor current of 35A. I know the motor can handle 65A for short durations without de-magnetizing, but I'd prefer 50% more headroom.

Configure ESC for smoother control of braking and acceleration

The available torque, despite being inadequate for steep hills, can still produce a scary amount of acceleration given the present wheelbase. Wheelies are easy to produce. Ultimately, a slower turn-on of the current and a mapping to decrease sensitivity at the low end of the control would be easy improvements.

Either decrease the top speed target, or increase wheel diameter and wheelbase

I have only run with 6S (6 3.7V Li-Ion cells in series) configuration so far, which is half the voltage I was originally planning on. This produces roughly (not accounting for increased drag) half the speed on the flat as the planned 12S configuration would. The max speed is presently 11mph.

22mph would be too fast for this chassis, given how 11mph feels. I can either make it safer at speed or design for a lower speed. For now, I'm goitn to target 15mph, defer on increasing the size of wheels or the base and focus on maintaining 15mph on steep terrain.

Prioritize mounting the electronics

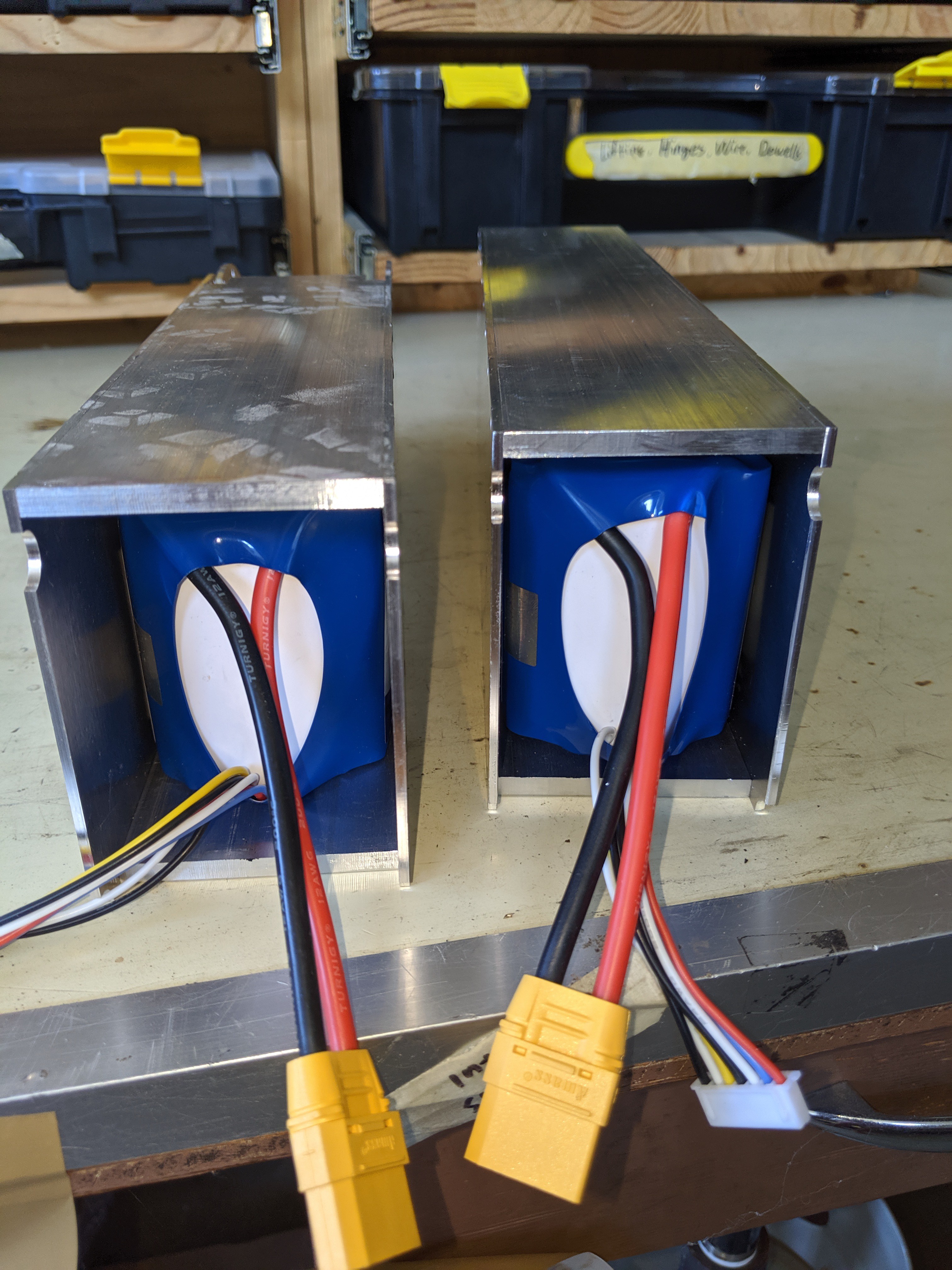

It is very cramped inside the frames with the batteries. I can't actually close the case as presently designed with both batteries and all the cables and connectors. I hope I can get away with just shortening leads up and re-arranging.

Here is what the front end adaptation looked like. My finest for sure.

-

Deck Frames Milled

07/06/2019 at 09:10 • 0 commentsProgress Report:

The machining is underway and the decks are beginning to take shape.

Here the rear axle supports are being milled. These parts clamp either side of the rear axle and distribute the load while also allowing the belt tension to be adjusted then locked in.

Why start with Milling?

I chose to emphasize milling in the prototype stage for the following reasons:

- Milling itself works as both a low-volume and mid-volume process.

- I can use strong materials.

- Milling generally produces good results on the first parts.

- Milling lends itself to threaded fasteners, which is like giving myself an "undo" button as I navigate assembly!

- Milling has many relatives in NC-controlled cutting family. By starting with milling, I can more readily bring part designs to contract manufacturers with other cutting capabilities. For example, I would really like to see the deck frames become laser-cut tubes. Maybe someday!

-

Battery Selection

07/06/2019 at 05:00 • 0 commentsIn selecting the battery, I was looking for something that was compact enough to fit in the narrow deck frame, but high-powered enough to make it up hills and last for miles. Lithium ion batteries are somewhat expensive, but have a high enough energy density to satisfy my target specs for speed and power. Here are the ones that I opted for:

https://hobbyking.com/en_us/turnigy-high-capacity-10000mah-6s-12c-multi-rotor-lipo-pack-w-xt90.html

There are two of these batteries included in the deck assembly for a single scooter.

If this scooter were to be produced on a larger scale, I would purchase Lithium Ion 18650 cells and attempt to produce a custom pack. This form factor is cheaper than the rectangular batteries, and because of its popularity, provides more options for customization and replacement.

-

Target Specs

07/05/2019 at 19:46 • 0 commentsWhile I'm still developing the first prototype, here are some target specs that I'm aiming for:

weight < 30 lbs packed dimensions 12" x 3" x 16" power 15 mph at 15% grade capacity 220 lbs speed 24 mph on a flat surface max grade 20%

Packable Electric Kick Scooter

A folding electric scooter that takes up only half the space in your backpack

Mike Thielvoldt

Mike Thielvoldt