There are 2 major pusher approaches - with rotating rod and rotating tube. Let's leave aside rotating tube, as it's more complicated for DIY. So, we need cylinder with M3 inside. Here are 2 choices again:

- 3d printed cylinder, with brass insert reinforcer.

- Full metal (tube with M3 thread inside).

All appropriate drawing for 3d print are available on github. But for 1cc syringe detail will be too thin - metal pusher needed. Can we do it good enough without lathe? Yes. We need suitable tube and make thread inside.

After experimenting with lot of available materials, it seems optimal use SS tube ID 4mm OD 2mm (description says ID 2.5 mm but it's 2mm). This material is a bit not convenient for drilling, but nothing impossible. So, we need:

- Good M3 tap (2-passes preferred). Cheap aliexpress 1$ taps were not tested.

- 3.2 mm & 2.7 mm HSS Co drill bits (on aliexpress - search "M35" drill bits).

- Vise and electric screwdriver.

To make holes straight, put tube into screwdriver and push with static drill bit (use separate chuck to hold it). After some training, that's not difficult:

- Cut 45mm tube peace.

- Drill through 2.7mm. Use max RPM to reduce screwdriver chuck axial vibrations.

- Drill with 3.2mm about 35-38mm to leave about 7mm for the thread.

- Make thread.

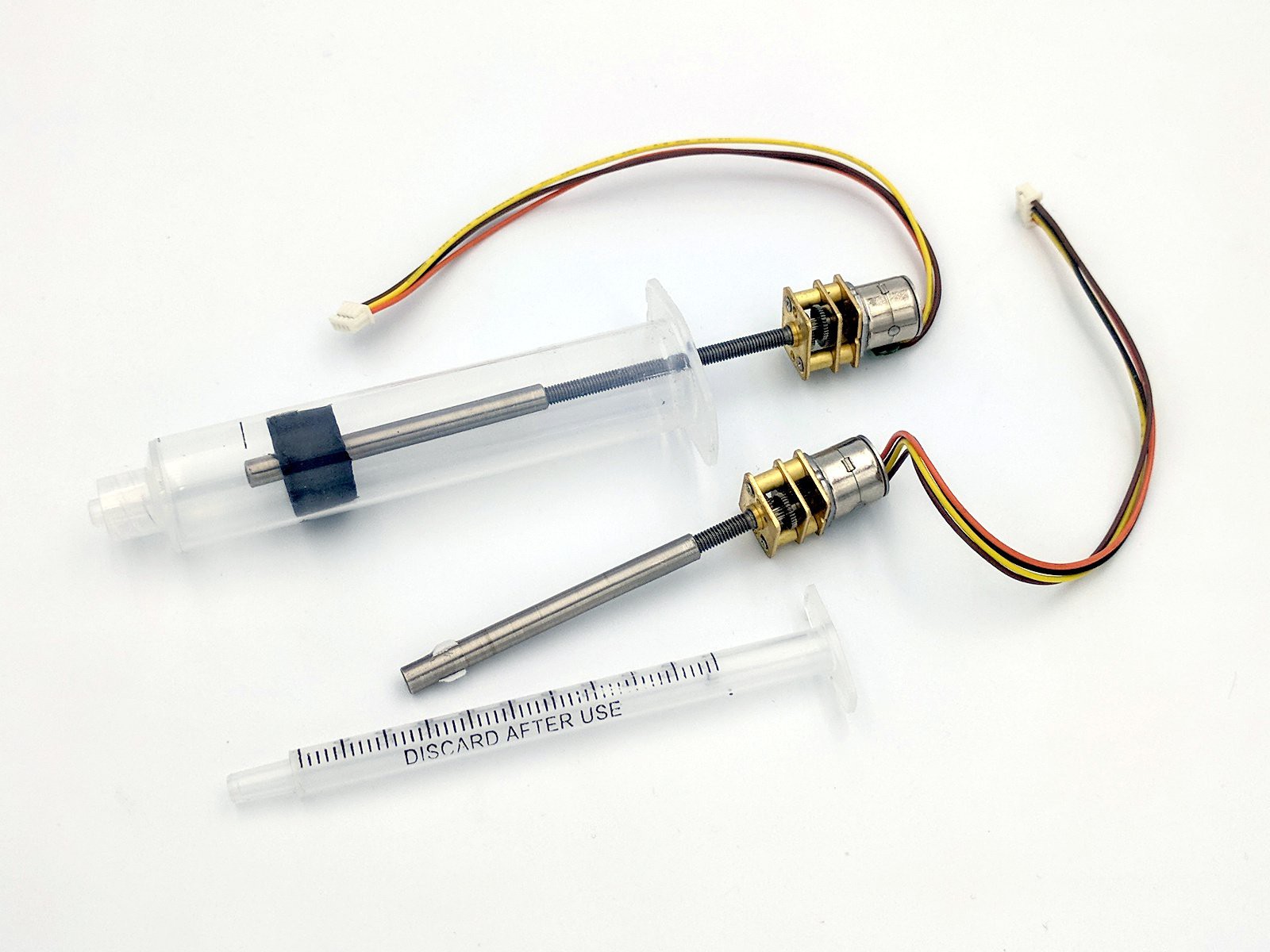

Here is a result:

Small pieces of soft adhesive tape add friction with syringe body and exclude rotation on install.

So, even for 1cc syringe, everything can be done at home, without advanced and expensive tools.

Next step is prototype assembly & testing to it fits in hand.

Vitaly

Vitaly

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.