When building a product, it's important to study the other solutions available on the market, to learn from other's good ideas and mistakes. If you can't significantly improve existing designs, why bother?

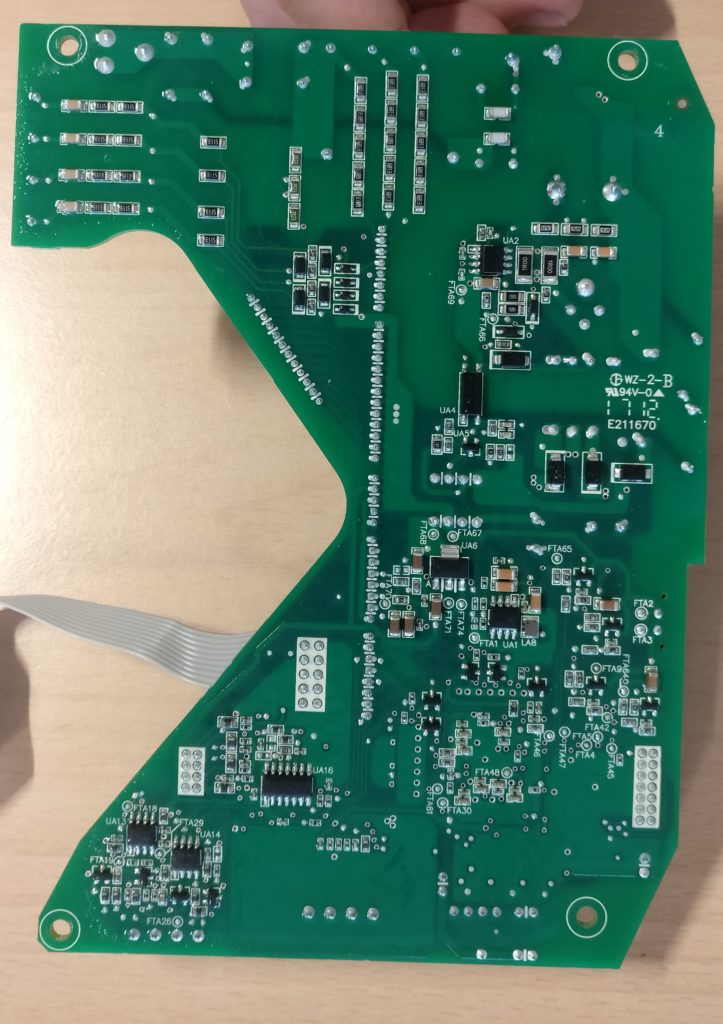

OpenEVSE

![]()

This have been the obvious solution for hobbyist in the past. So of course I built one and was very happy with it! However, there are a few things I dislike about it:

- being designed for the USA market, it's only single-phase; there are a few workarounds to make it 3-phase, but there are many drawbacks

- the standard box they offer has a very plain look, and the 16x2 display is so 90's

- it only connects to WiFi, via an ESP8266 - no ethernet and less easy to program if you're not familiar with the platform.

I liked their pilot signal circuit, so I implemented it in my design. More about that later.

[redacted]

Looking for a nicer (and 3-phase) wallbox to install at the office, I stumbled upon [redacted]. This company makes beautiful products, with some nice features, but I'm now super pissed at them.

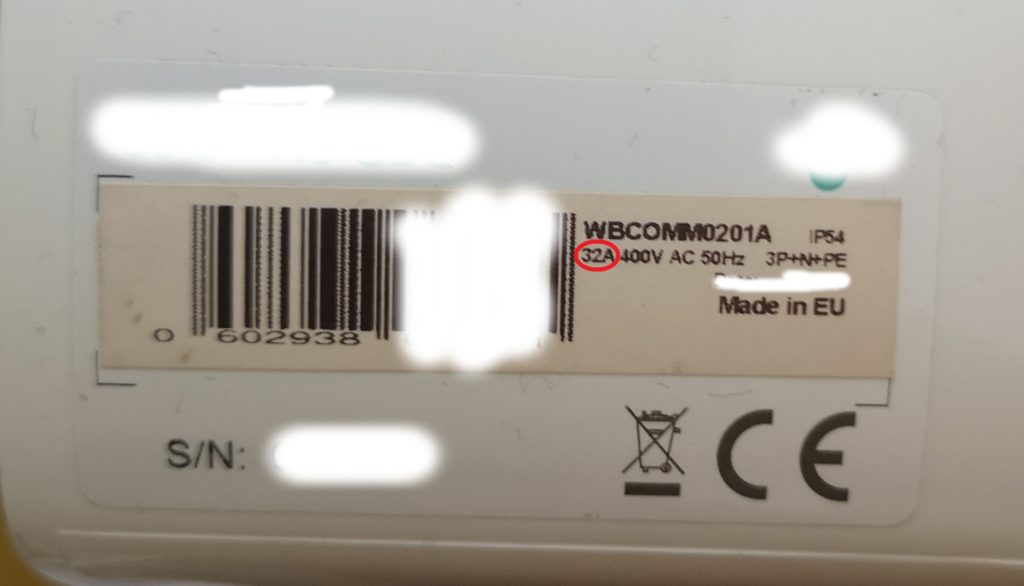

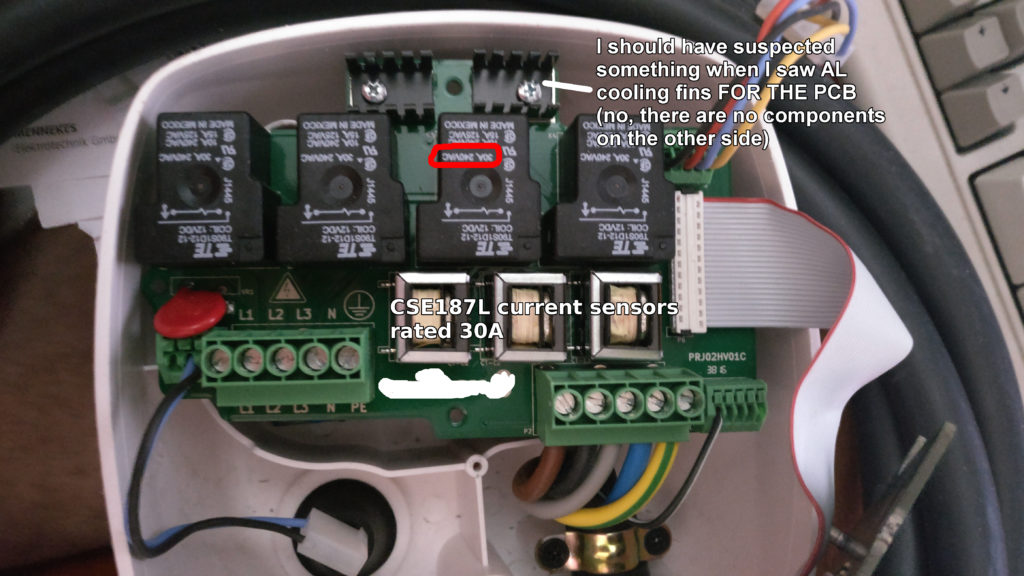

I used this wallbox for a while, until... it exploded. I should have really followed Dave Jones advice here, because if I had tore it apart before turning it on I would have noticed that these f***ers used 30A rated components for their 32A rated product. I have no idea how they passed certification.

So this ticking bomb heated up until THE SOLDER ON A RELAY PIN MELTED and shorted another terminal below. Luckily, this triggered the main breaker, but the charger could have caught fire causing a sh*tload of damages.

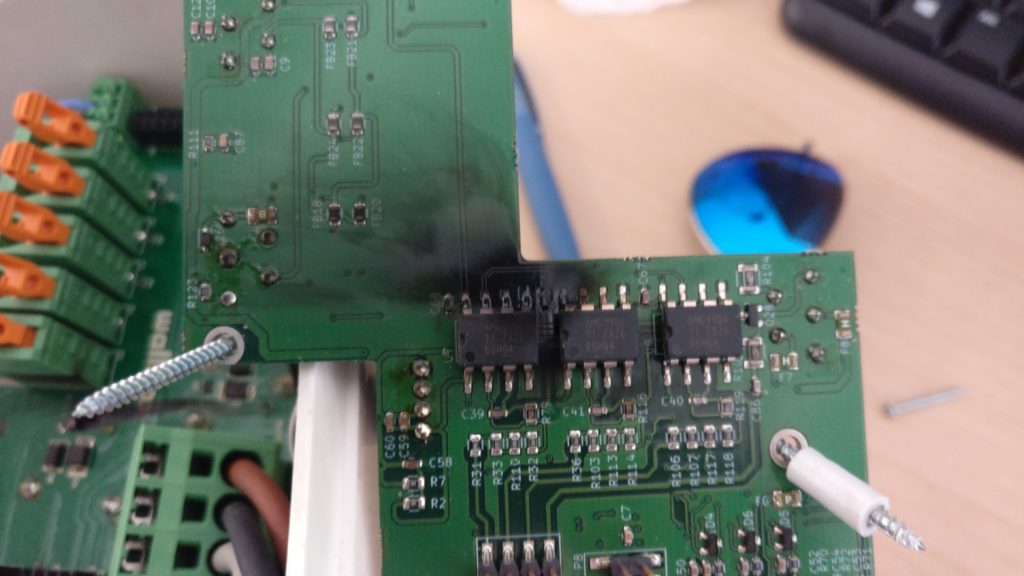

Black Smoke Of Death; this is the upper board that received indirect damage

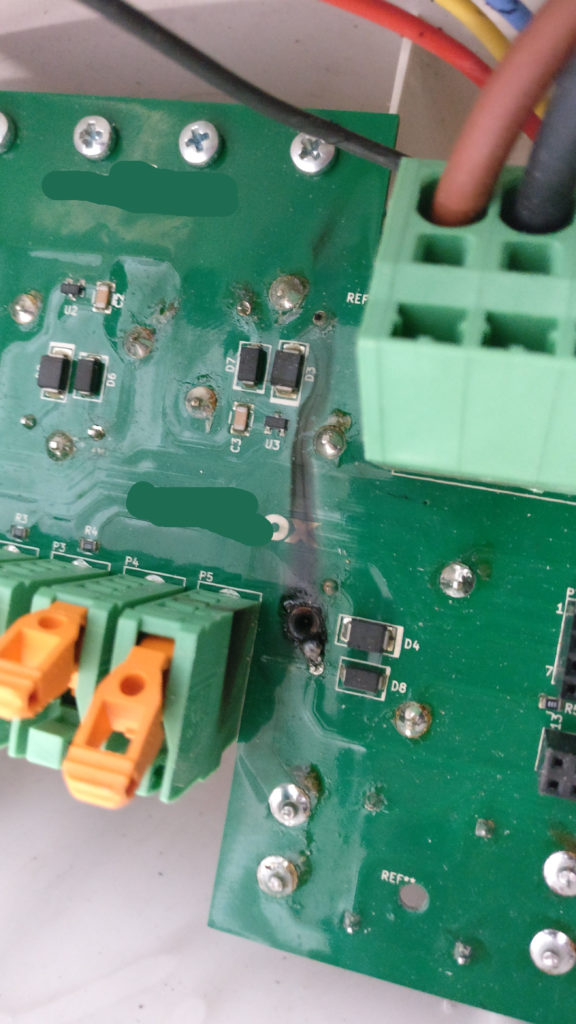

Black Smoke Of Death; this is the upper board that received indirect damage Must have been hot in here

Must have been hot in here Who rated this 32A?

Who rated this 32A? SERIOUSLY??

SERIOUSLY??

Their new product still uses these kind of relays, but to be fair there now is a 40A version in the same format so I guess (hope) they're using those. I didn't have a chance to disassemble one yet. Their current sensors should still be rated at 30A AFAIK, but that is a linearity rating; the copper should be big enough for more, only the measurement linearity would be worse - easily fixed in software.

It IS gorgeous. I love their new design.

It IS gorgeous. I love their new design.

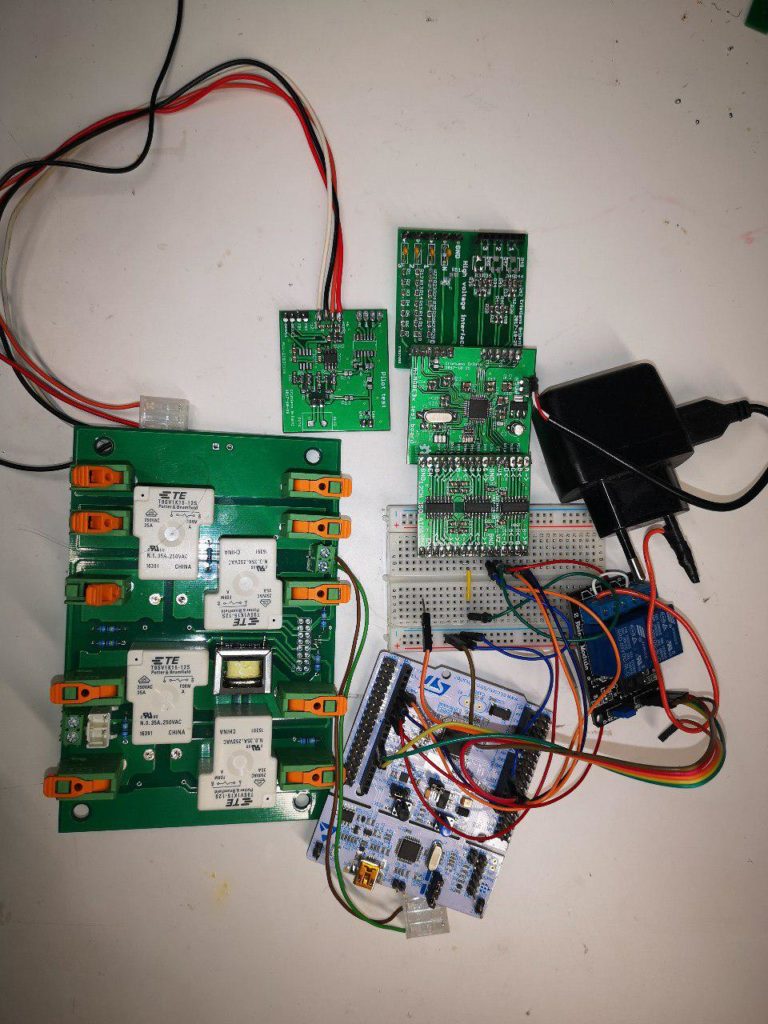

At around the same time I was experimenting with a first prototype of my own design, with the 35A version of the same relays.

This made me reconsider my choices and look around for better solutions, so I disassembled...

...The Tesla HPWC

This wallbox is what I'd consider state of the art. It is so over-engineered that I'm sure the guys responsible for it are sleeping like koalas. That's the feeling I desire; I want to sleep well knowing that I didn't cut any corner and that if I get a call from a customer with a burned-down garage I would know it wasn't my product's fault.

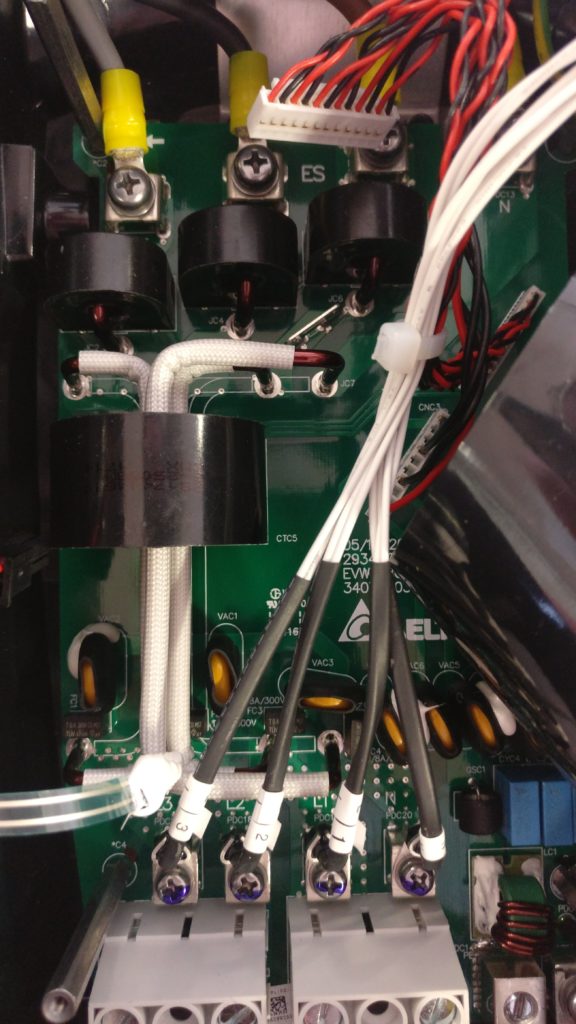

Here, enjoy some pornography:

Look at that HUUUGE contactor!

Look at that HUUUGE contactor! It's all run by a TI DSP

It's all run by a TI DSP Look at those nice voltage dividers with a bunch of resistors in series to increase isolation!

Look at those nice voltage dividers with a bunch of resistors in series to increase isolation! What are these? Temperature sensors on each line? Am I dreaming?

What are these? Temperature sensors on each line? Am I dreaming?

To be fair, the temperature sensors are probably needed because the final installer will have to tighten these screw terminals, and they don't always do the best job. Spring terminals would work way better here. More on that later.

Those copper wires certainly look THICCCCCC

Those copper wires certainly look THICCCCCC

To be fair, Tesla's HPWC (High Power Wall Charger) isn't perfect either; you can buy it only if you own a Tesla, and it's not "IoT". It has RS485 though and the protocol has been reverse engineered, a guy even fitted a Raspberry Pi Zero inside it, so if you're crafty and curious you can mod it.

Bonus Trivia: as you may already know, Teslas are "computers on wheels", always connected and receiving constant updates. This philosophy seem to be missing from the HPWC, as it looks like there's no way to upgrade its firmware. But Tesla is also famous for thinking outside the box: turns out, every Tesla car hosts a copy of the latest HPWC firmware and updates them when you plug in to charge. They do so by starting a non-standard single wire CAN communication on the Pilot pin, the same way they talk with Superchargers, via a NCV7356.

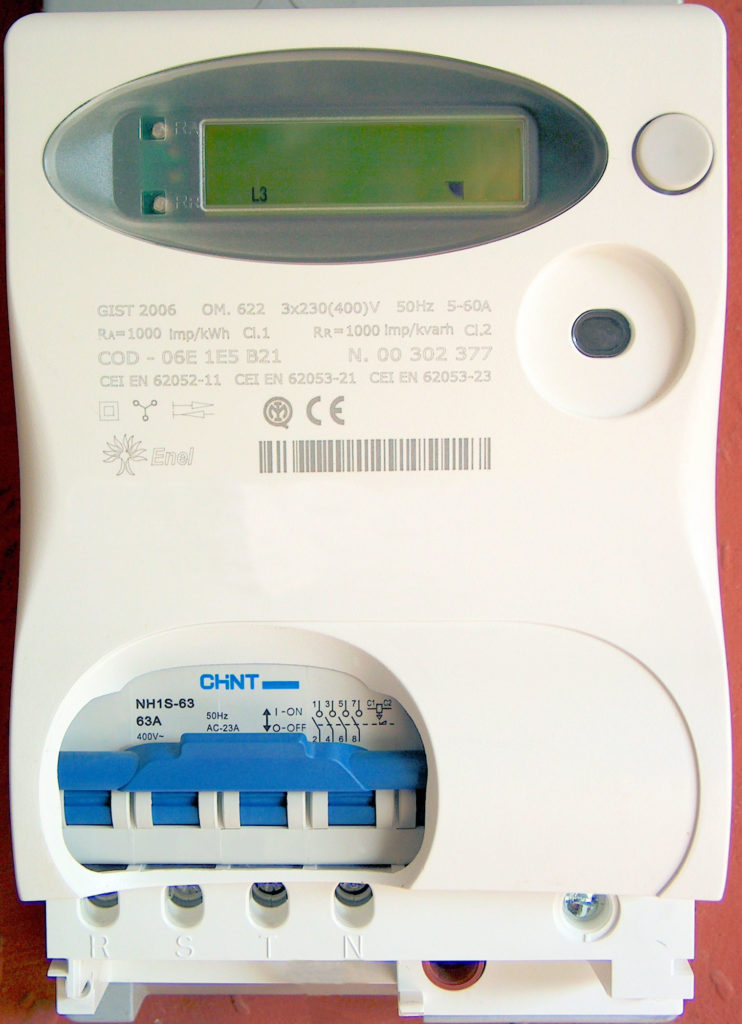

But the greatest tip I got from this teardown is that, really, the best way to switch a 32A constant load is to use a proper industrial contactor. Unfortunately, the ABB model Tesla's using is really expensive, way out of our startup quantity price range. But there are many companies making industrial components, and one day, when power went out at my home, I found the answer:

ENEL, the Italian energy distributor, uses CHINT components in their million meters installed all around the country! This means that they're cheap, and they work well! And presto, I contacted the local distributor and found the perfect device:

ENEL, the Italian energy distributor, uses CHINT components in their million meters installed all around the country! This means that they're cheap, and they work well! And presto, I contacted the local distributor and found the perfect device:

Certified in Europe and guaranteed for 63A, almost double what it will ever see, with a sturdy industrial case and a price point that makes it worth it, despite costing about four times more than the relay solution.

Certified in Europe and guaranteed for 63A, almost double what it will ever see, with a sturdy industrial case and a price point that makes it worth it, despite costing about four times more than the relay solution.

But I'm getting ahead of the story here; there's still a lot of history to tell that happened before I found this contactor! Stay tuned!

Mastro Gippo

Mastro Gippo

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Hello Mastro!

Please could you tell me the reference of UA2. It's the PWM for the power supply under the main board EVWTS80HT-1. Mine has burned and a spark has destroy the power supply!!! Needs more insulation.

Please please :)

Are you sure? yes | no

I haven't seen your circuit, but be mindful of current surges when the contactor closes.

Filter caps can lead to huge surges when you connect in the mains.

You may need to soft-start with a second relay to get the contactor life you expect.

Are you sure? yes | no

Thanks! I checked with the manufacturer and ran some tests on the vehicle, the surge doesn't seem to be that big. No competitor adds the precharge relay, so I guess that's enough :)

Are you sure? yes | no