Why

I believe that multi-material 3D printing will be the next big step. Not so much for 3D printing, but the fabrication of highly integrated mechanism. Robots still require a great deal of assembly, which makes them expensive. With multi-material manufacturing, it is possible to fabricate print in place mechanism with several materials which need little to no assembly. There are not many printers out there, which offers a platform robust enough for this task. The most common commercial multi-material printer Ultimaker, Sigmax, and E3D only provide Bowden fed extruder, which are barely capable of processing flexibles.

Soft robot proof of concept

How

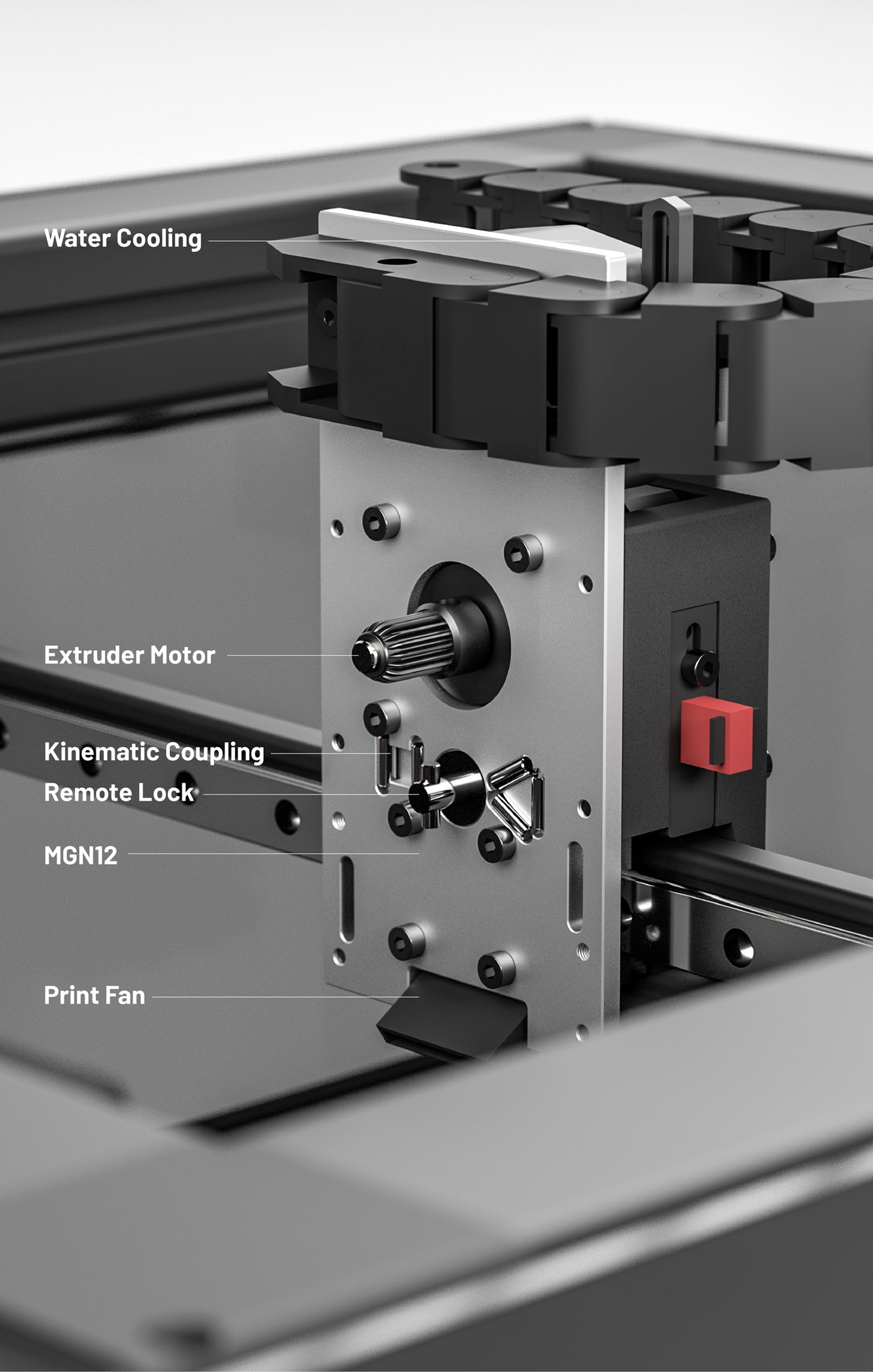

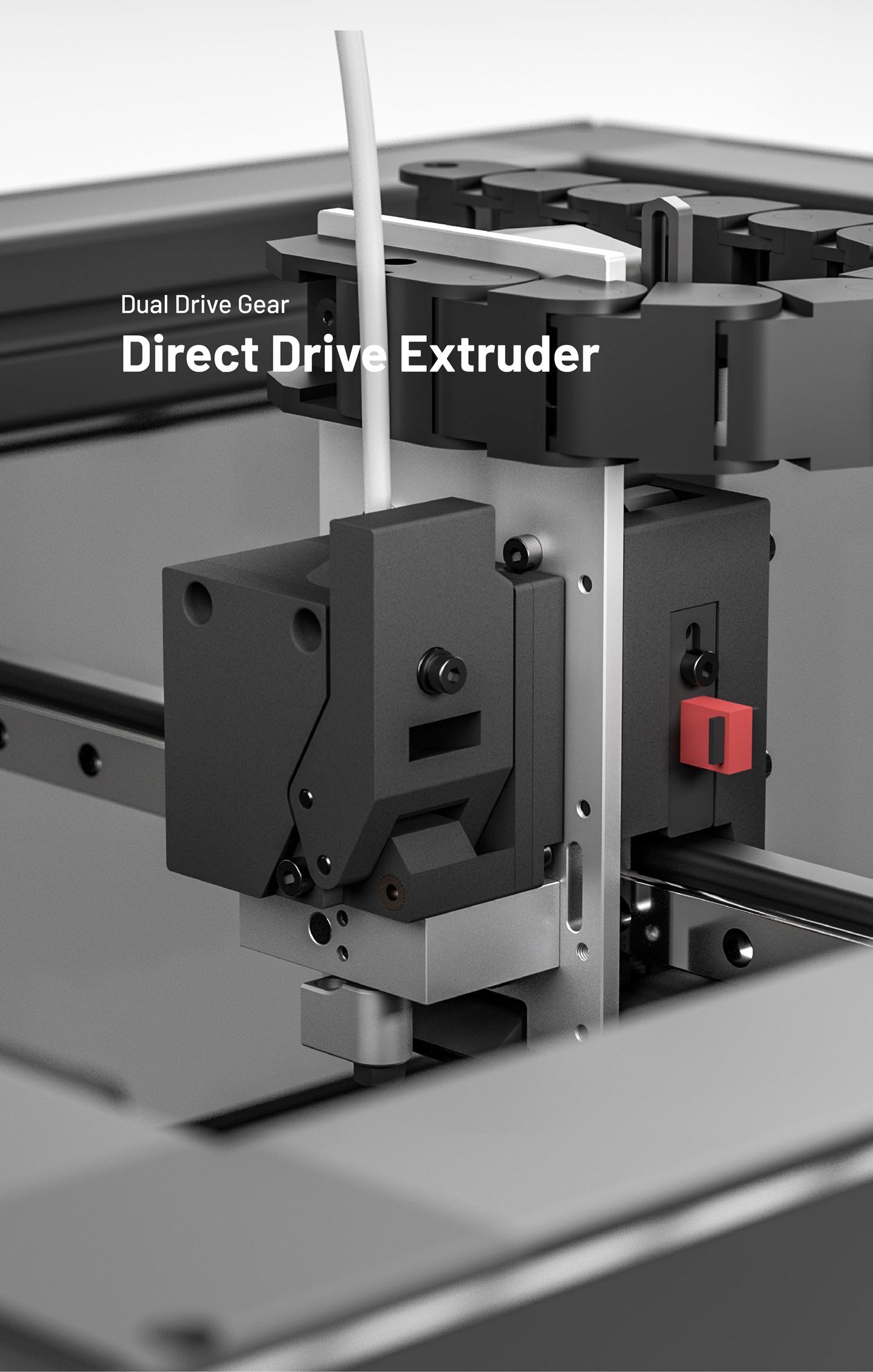

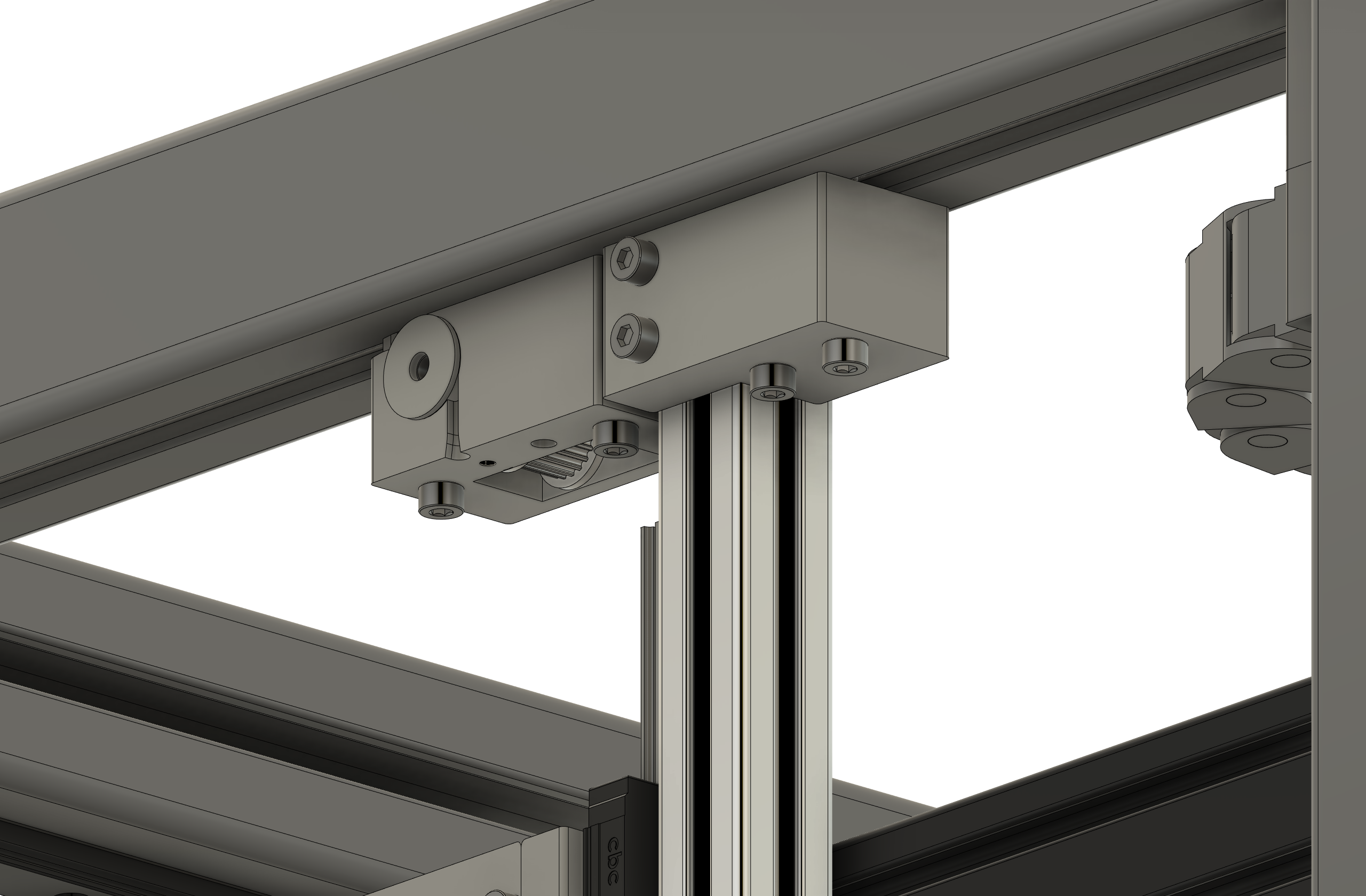

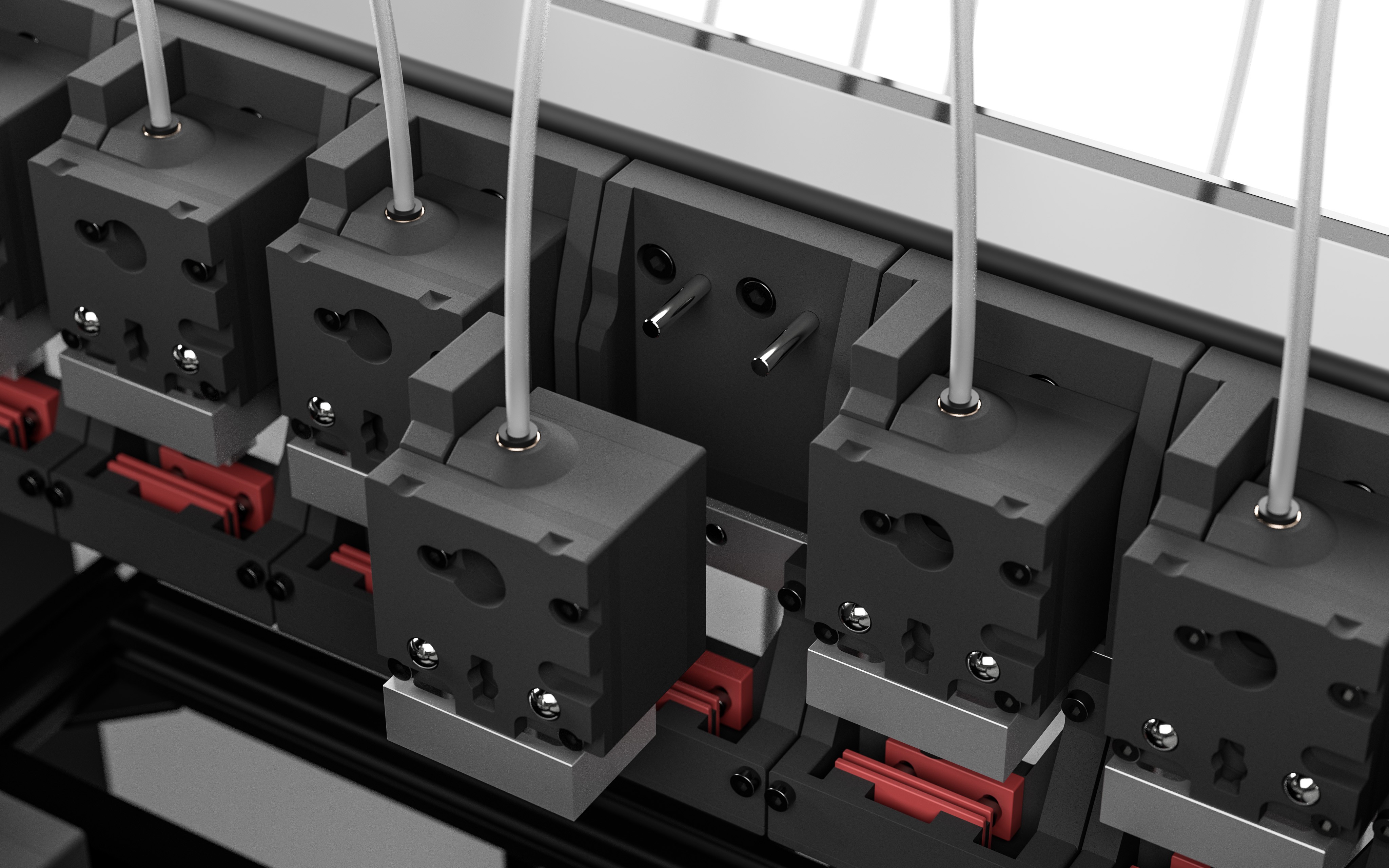

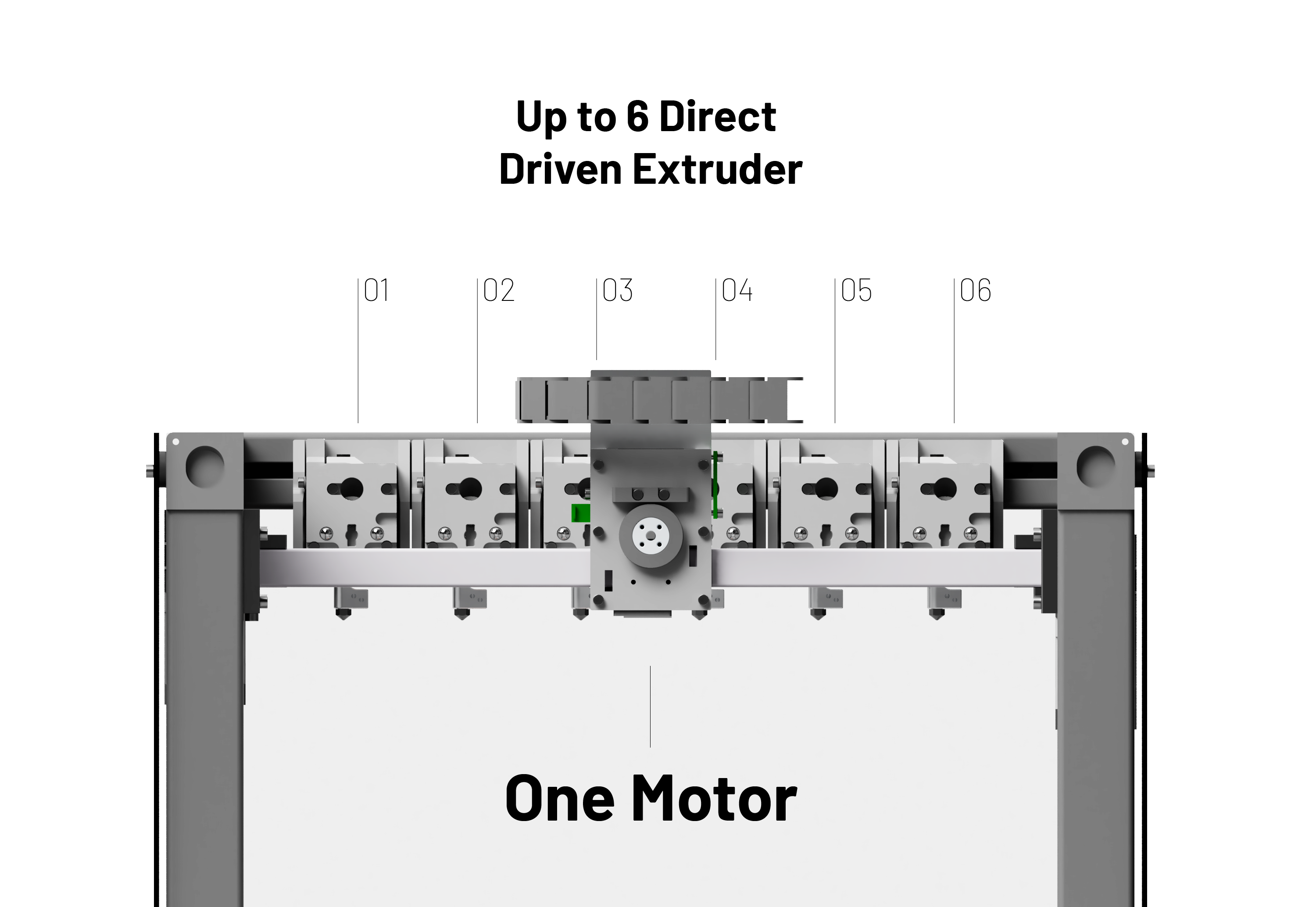

With a tool changing platform trimmed for multi-material printing and material freedom. This is achieved by the unique passive water cooling and coupling system which provides up to six direct driven extruder. The motor is shared among all tools which is why standard electronics can be used. It also offers numerous possibilities to use the extruder motor for different tools with additional axes or various types of toolheads like Paste, Syringe, Fibre or Silicone.

Goal

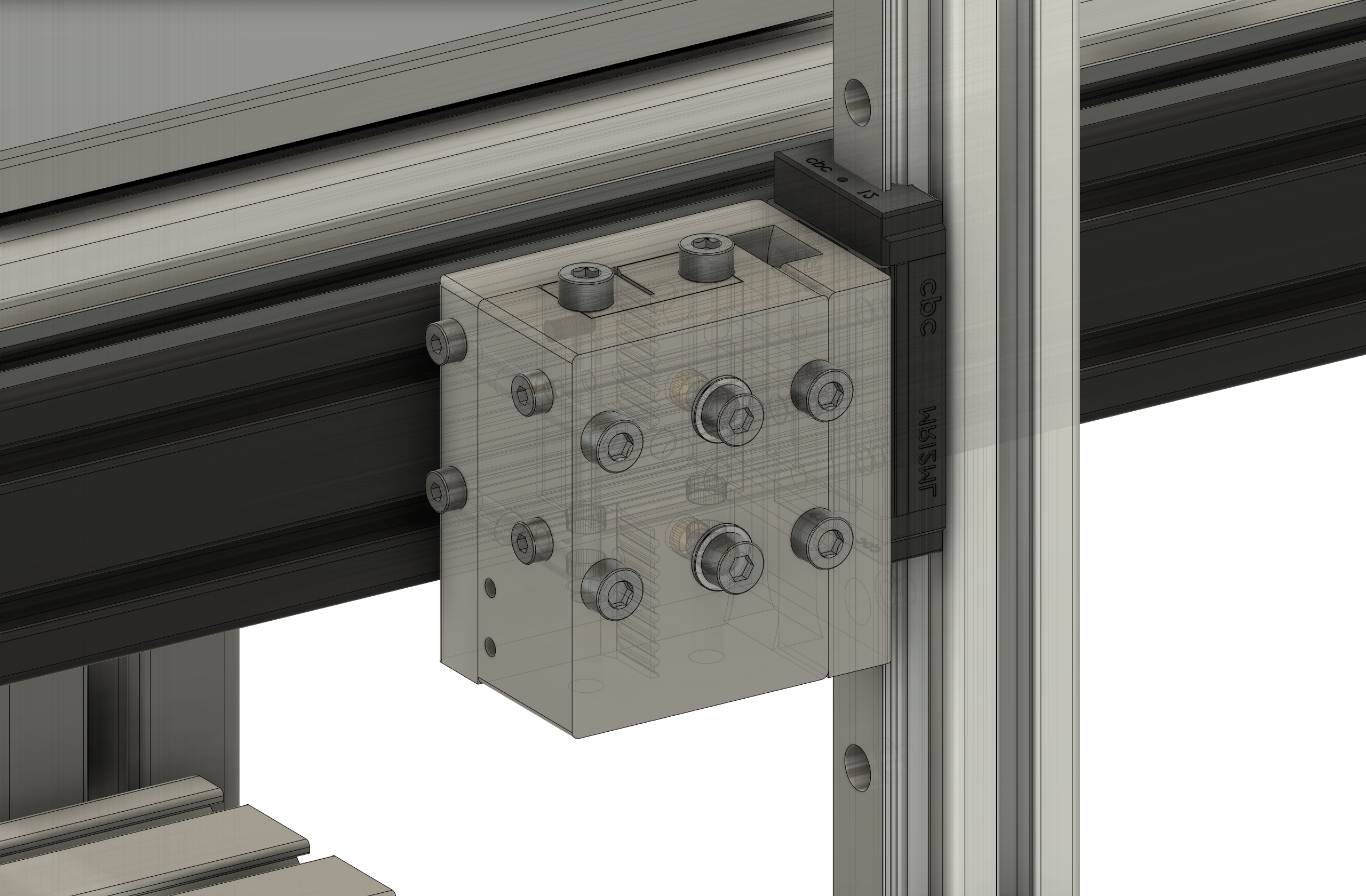

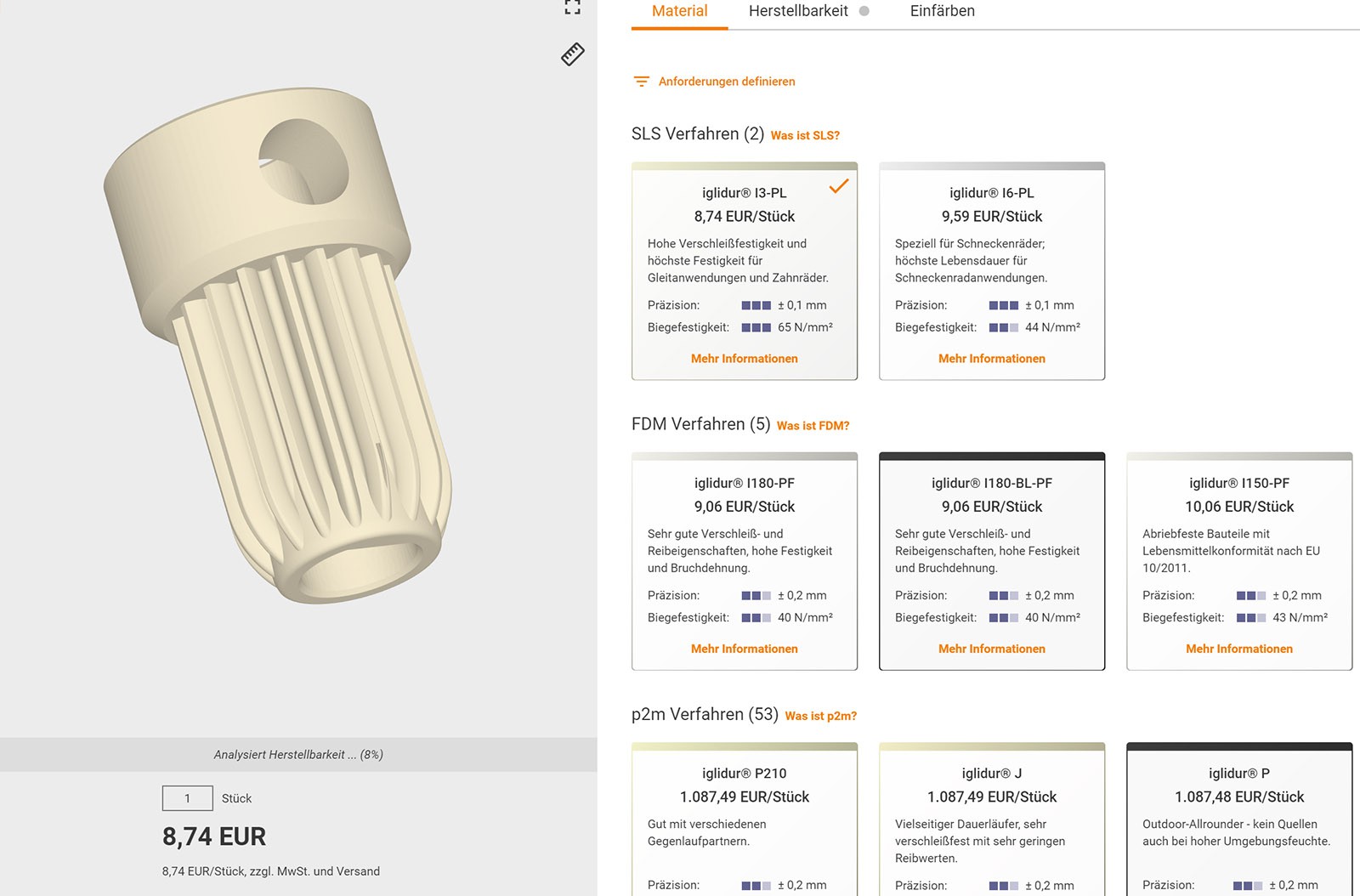

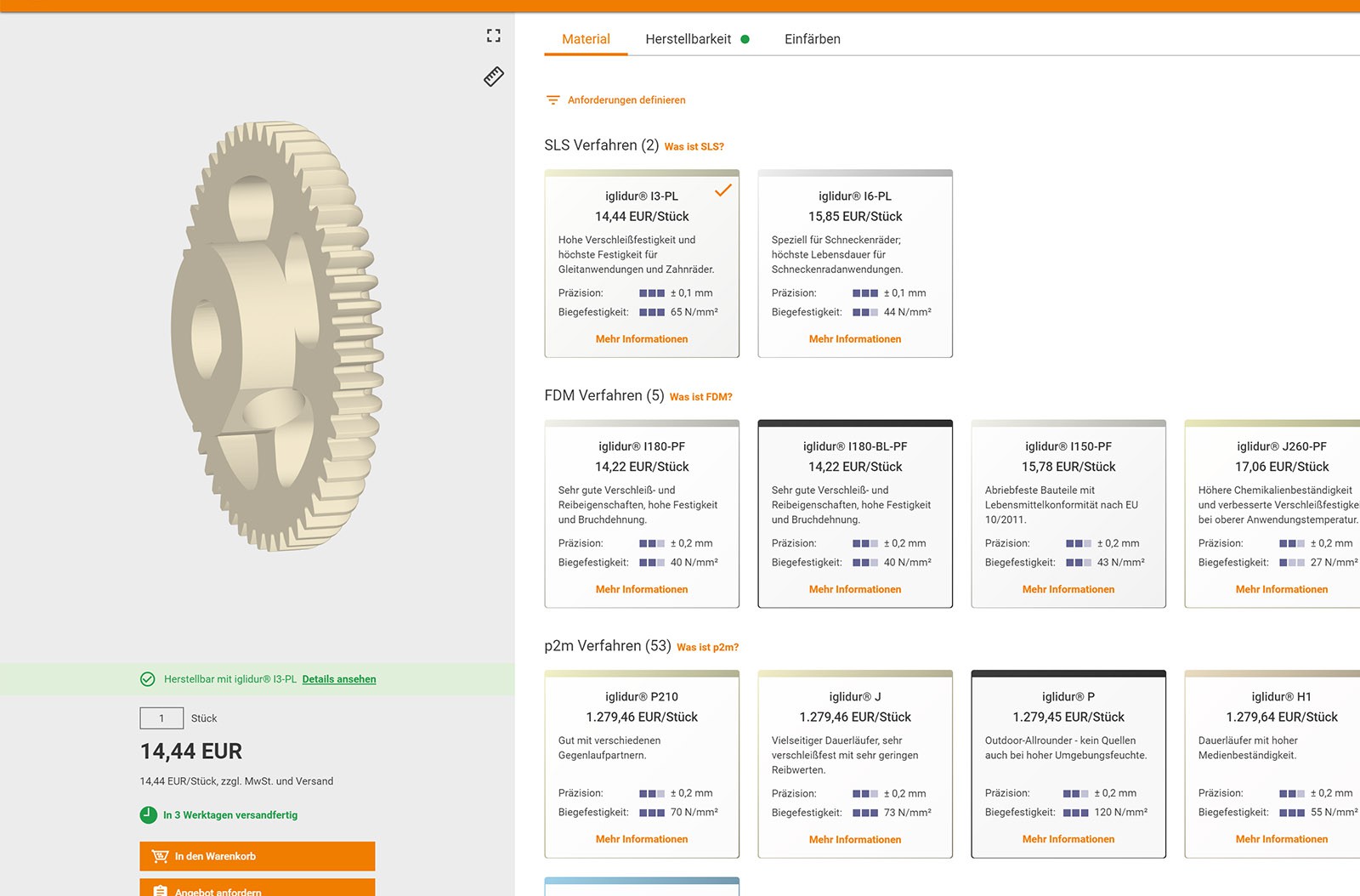

Offering a convenient BOM and producing the custom parts to make this printer replicable. Custom parts are the X-Plate, tool cooler, and coupling lock. We are currently in talks with different supplier to deliver these parts at an attractive price point. From that point, we can add specialized tools and finally experiment and explore what's possible to fabricate with such a multi material beast.

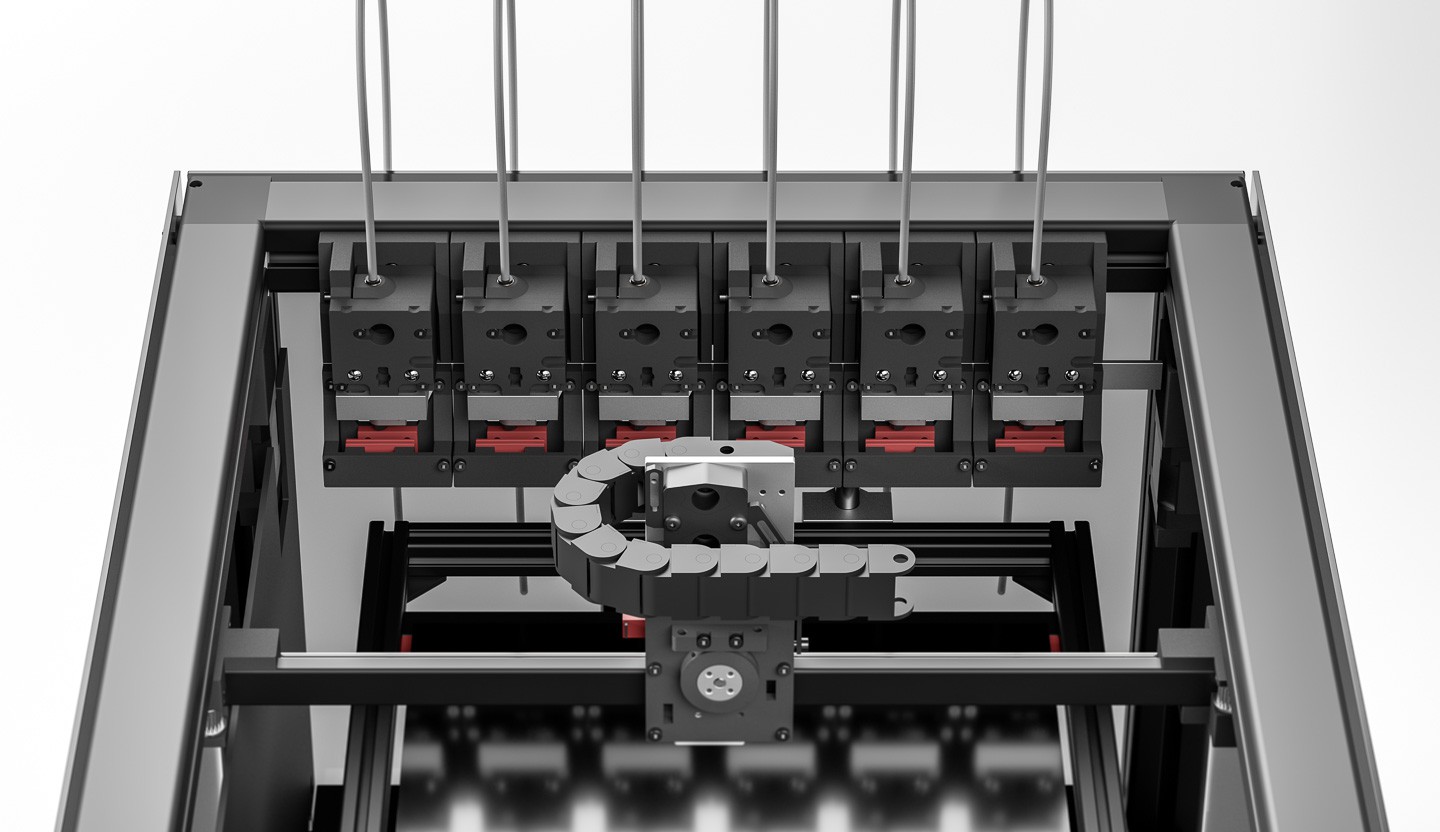

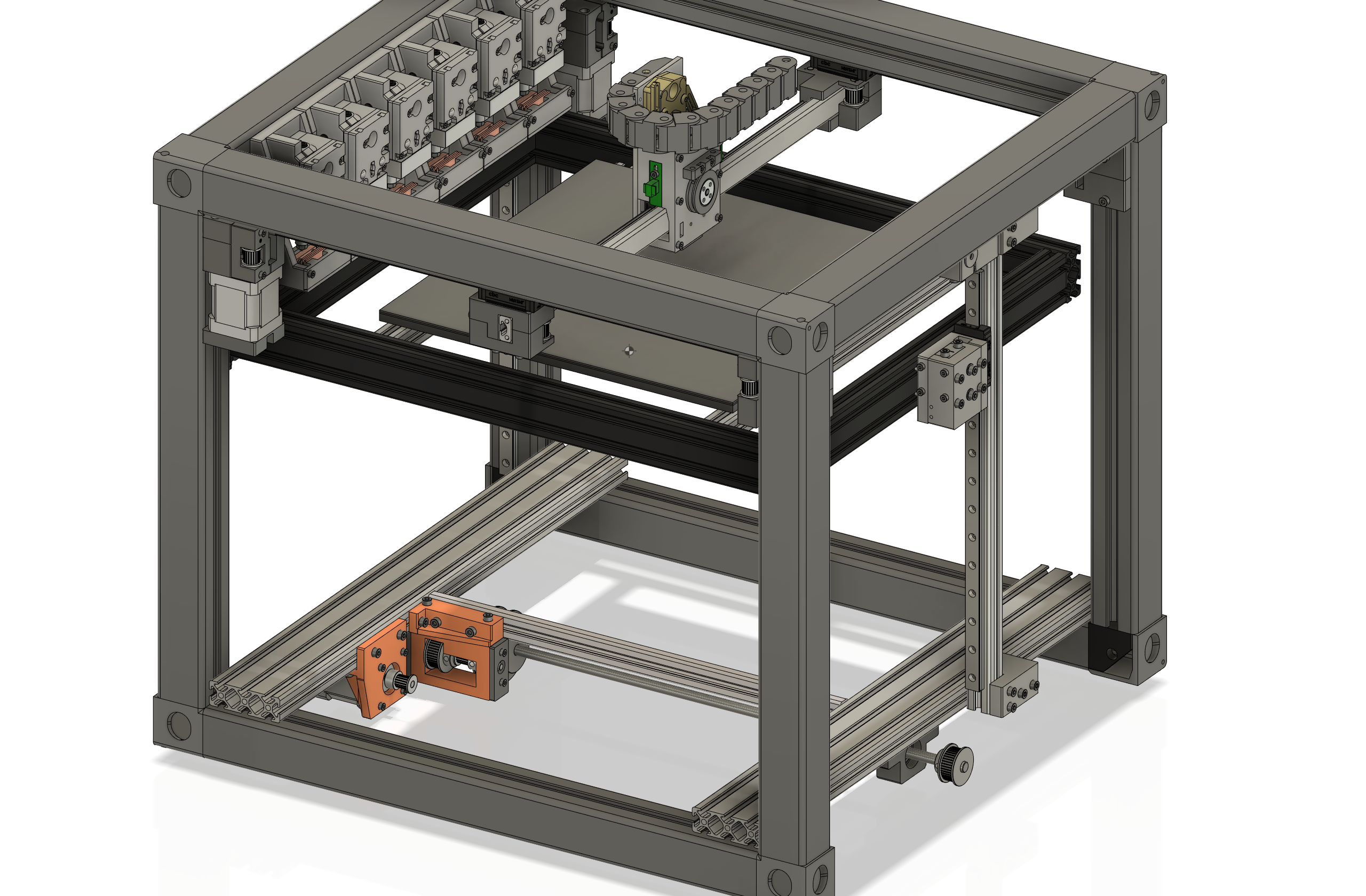

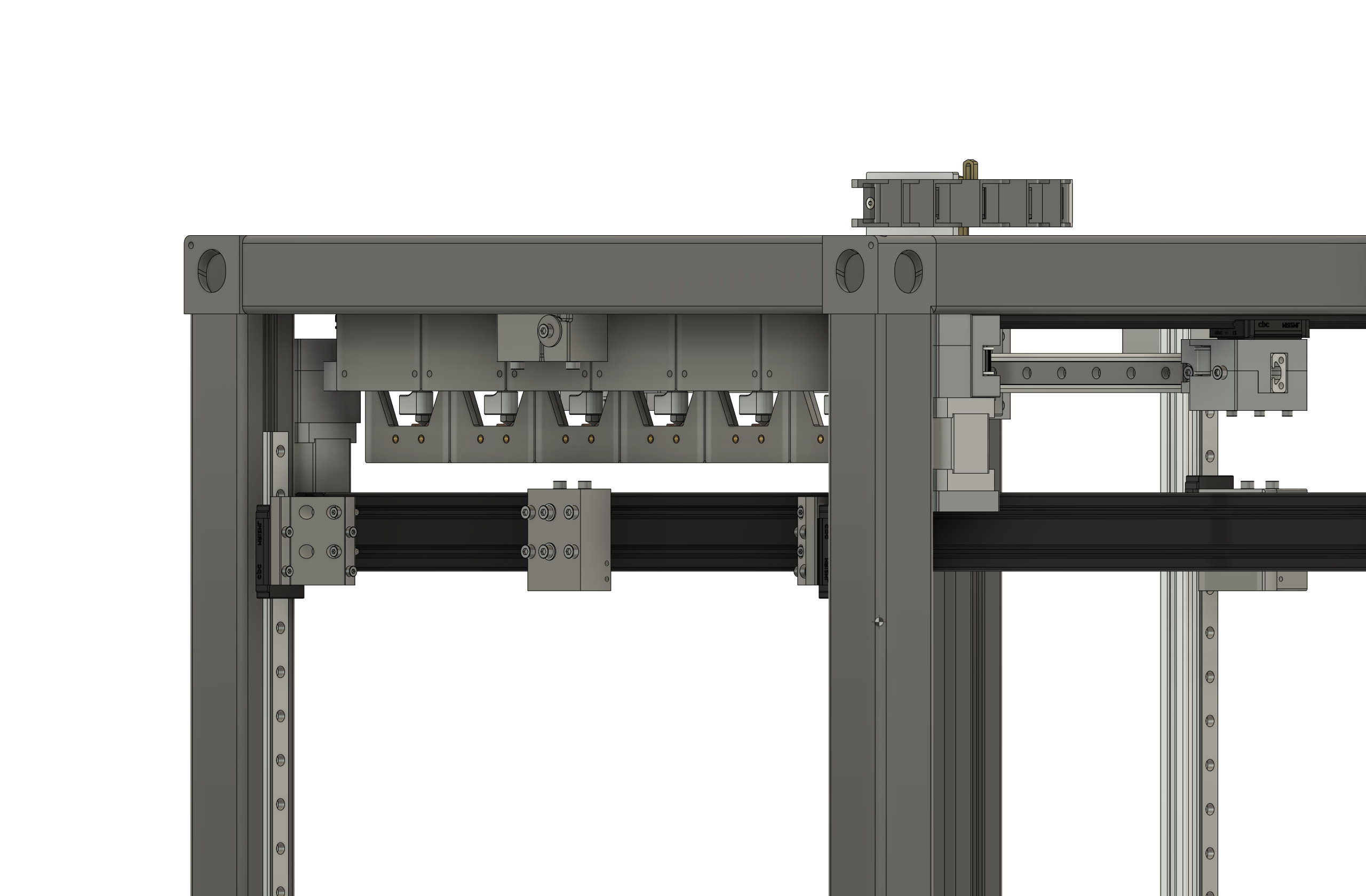

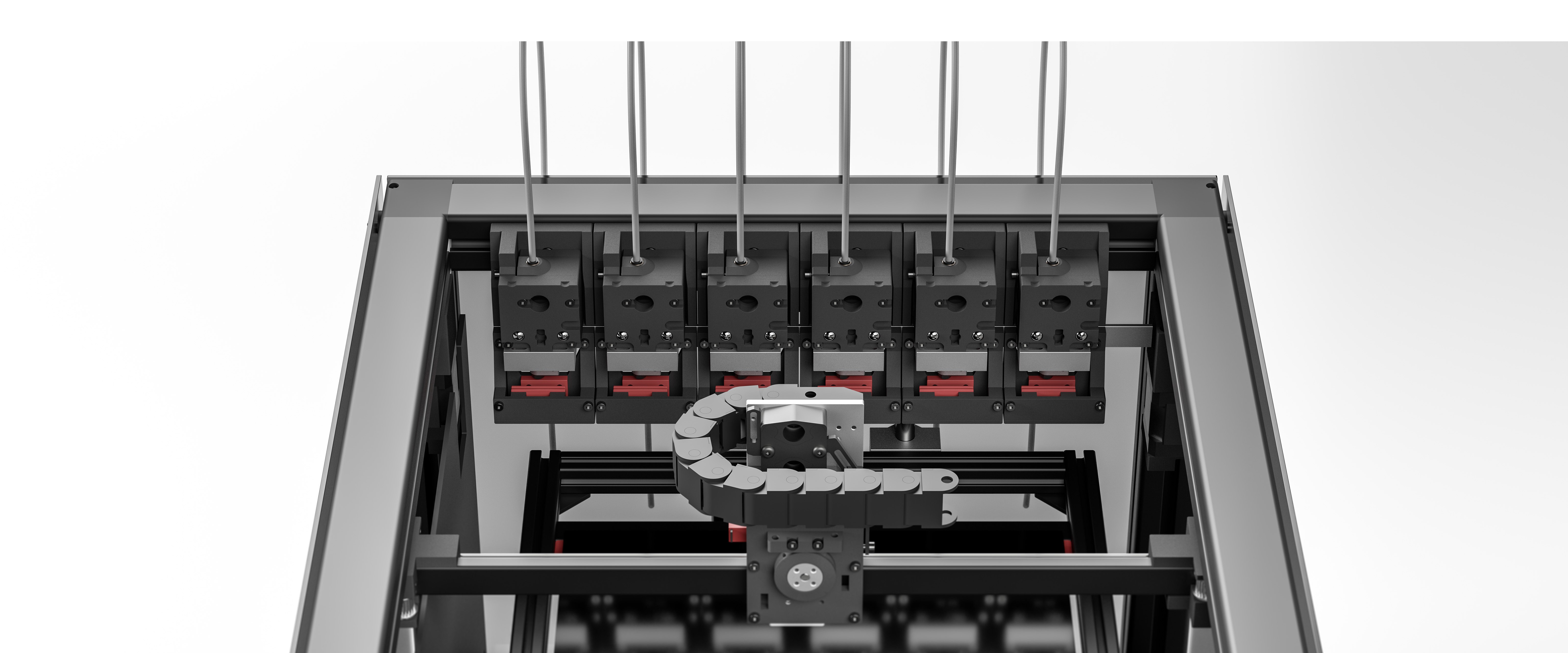

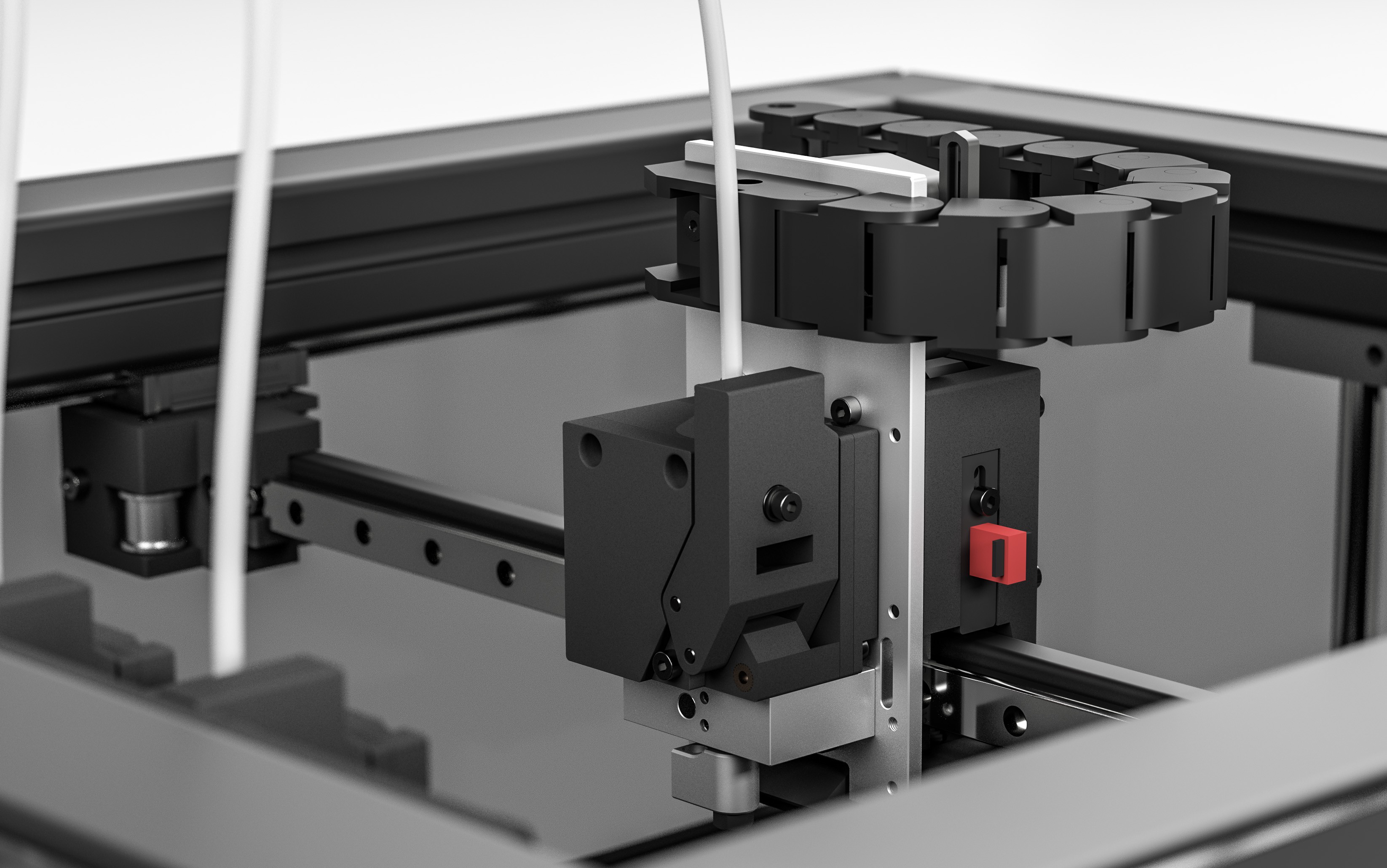

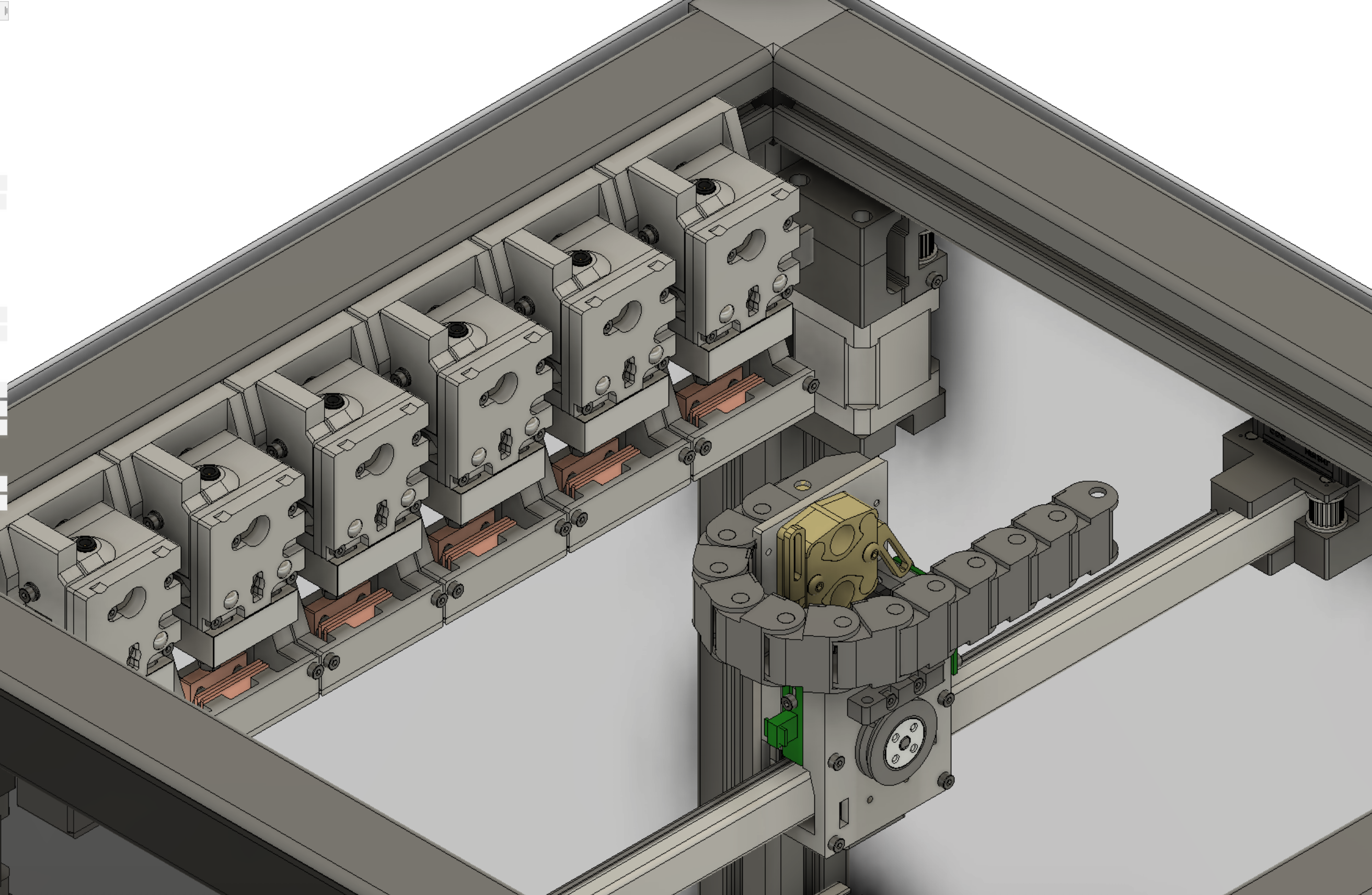

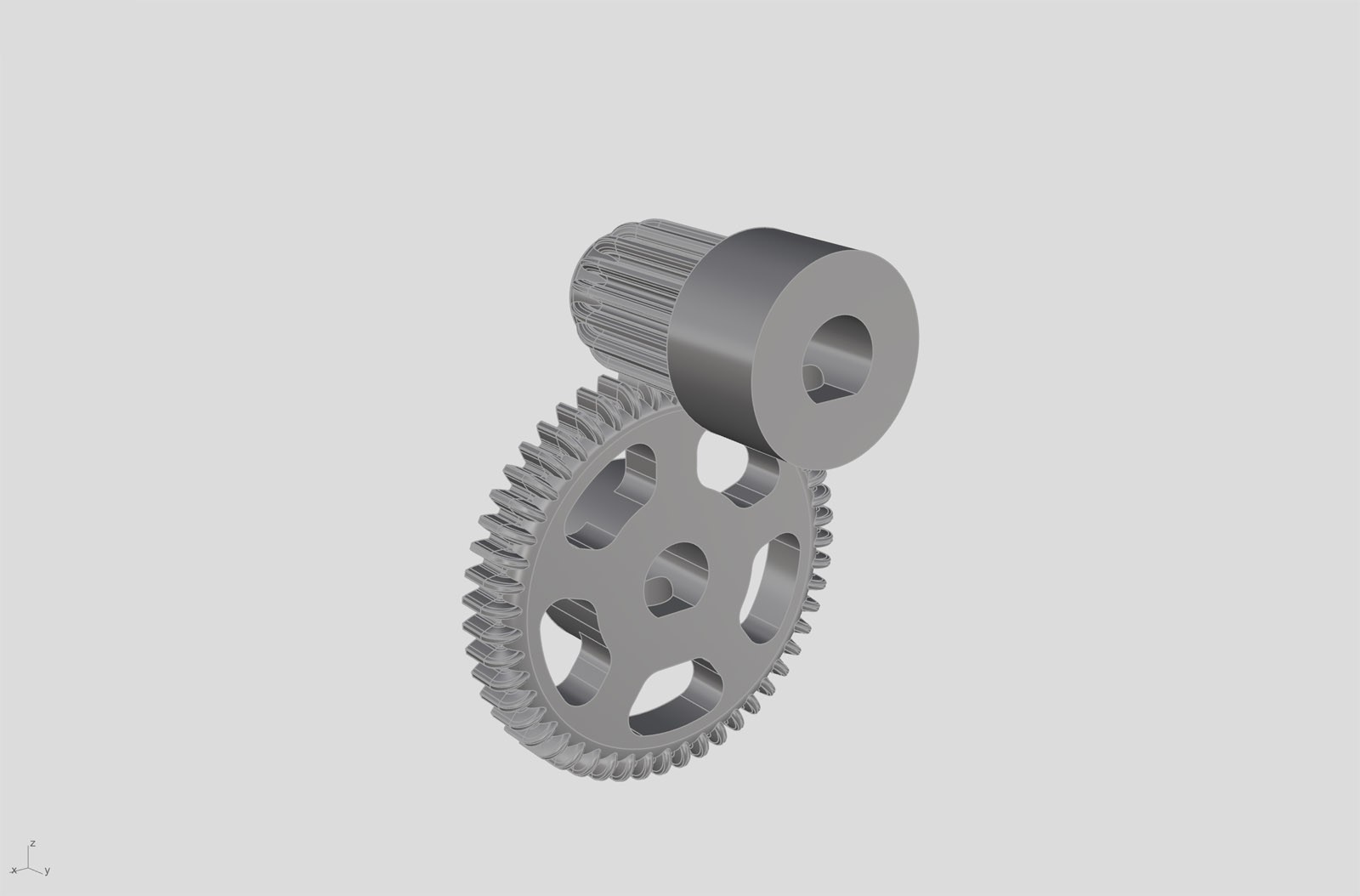

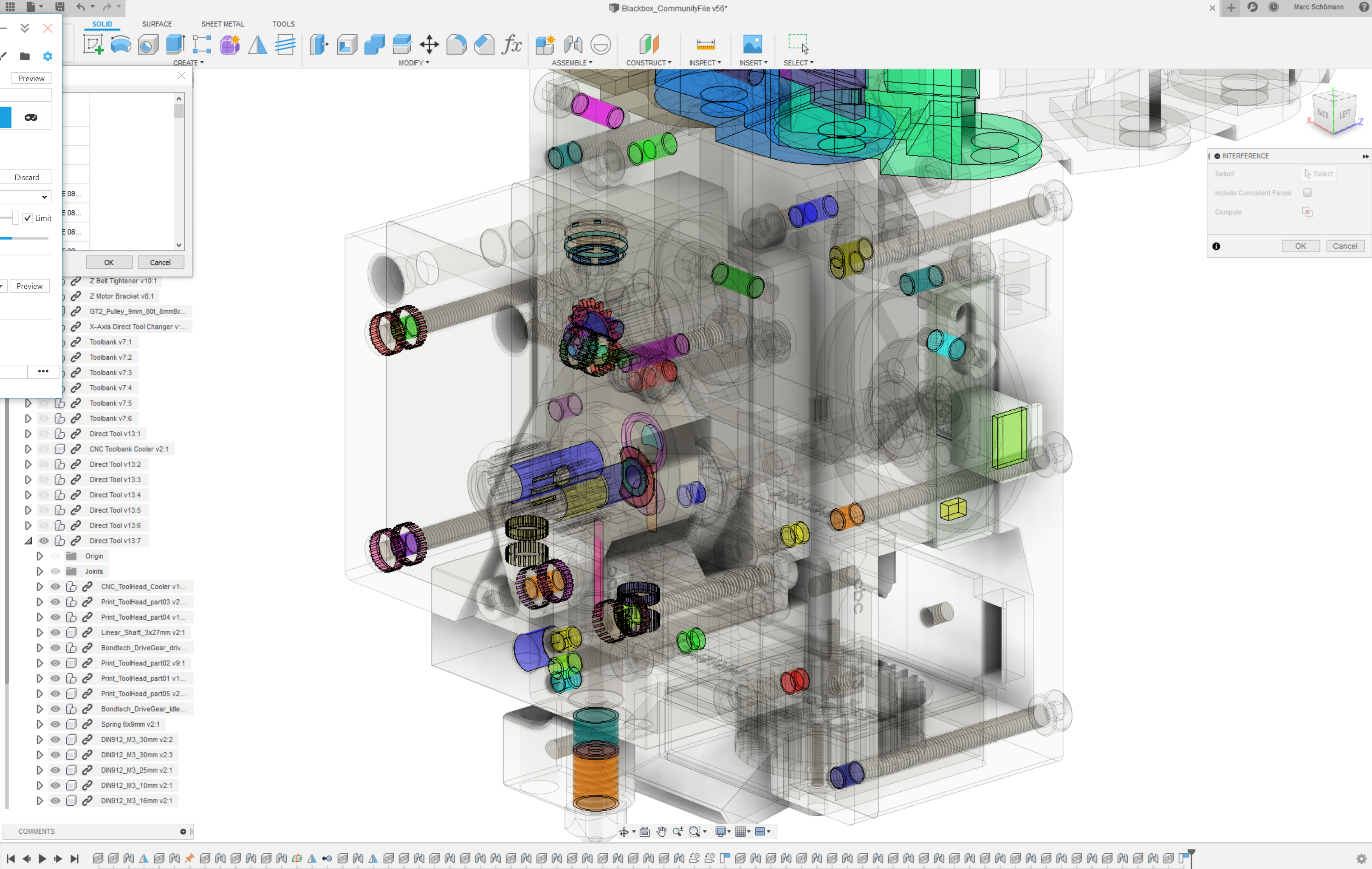

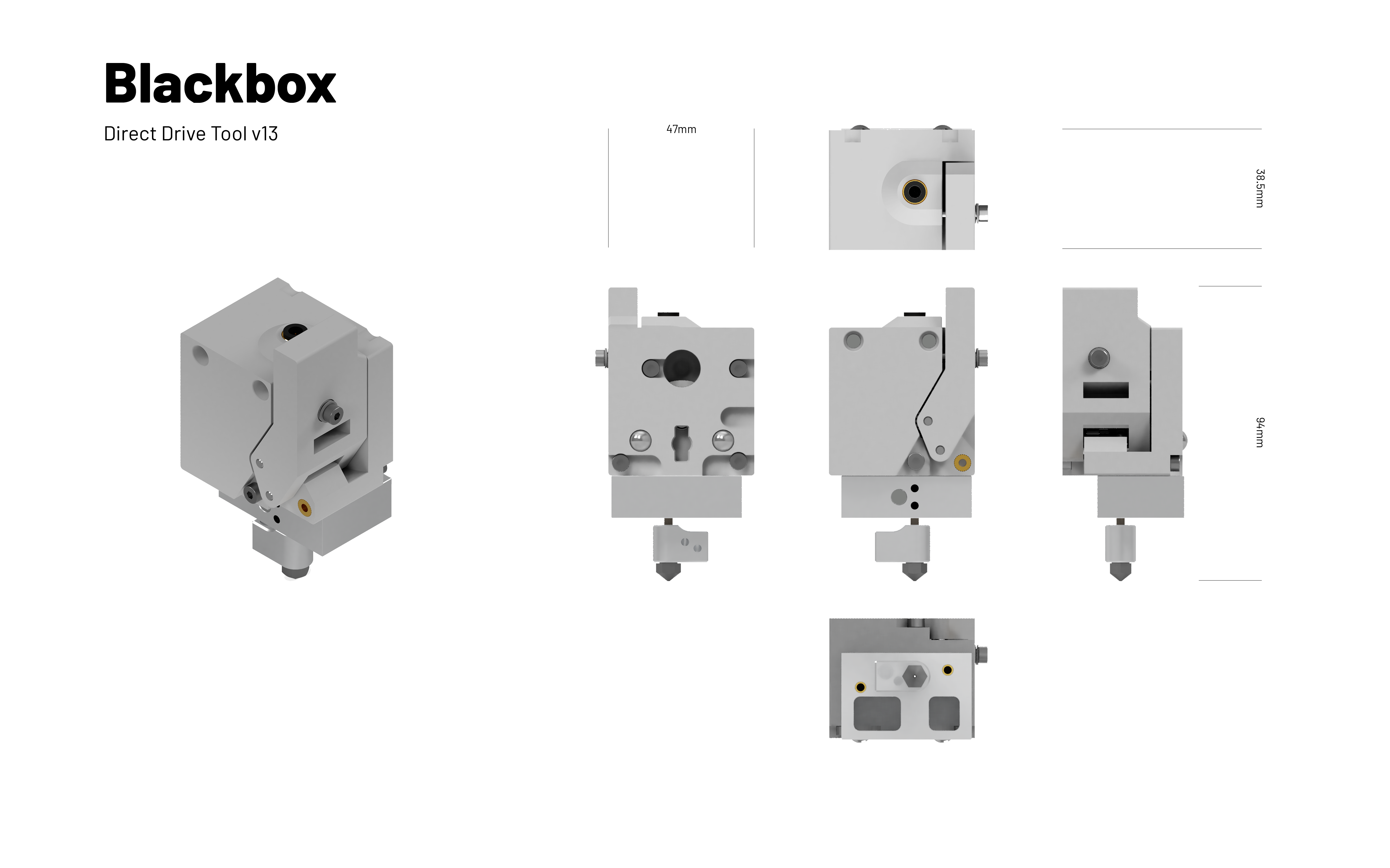

Blackbox complete with 6 direct drive tools

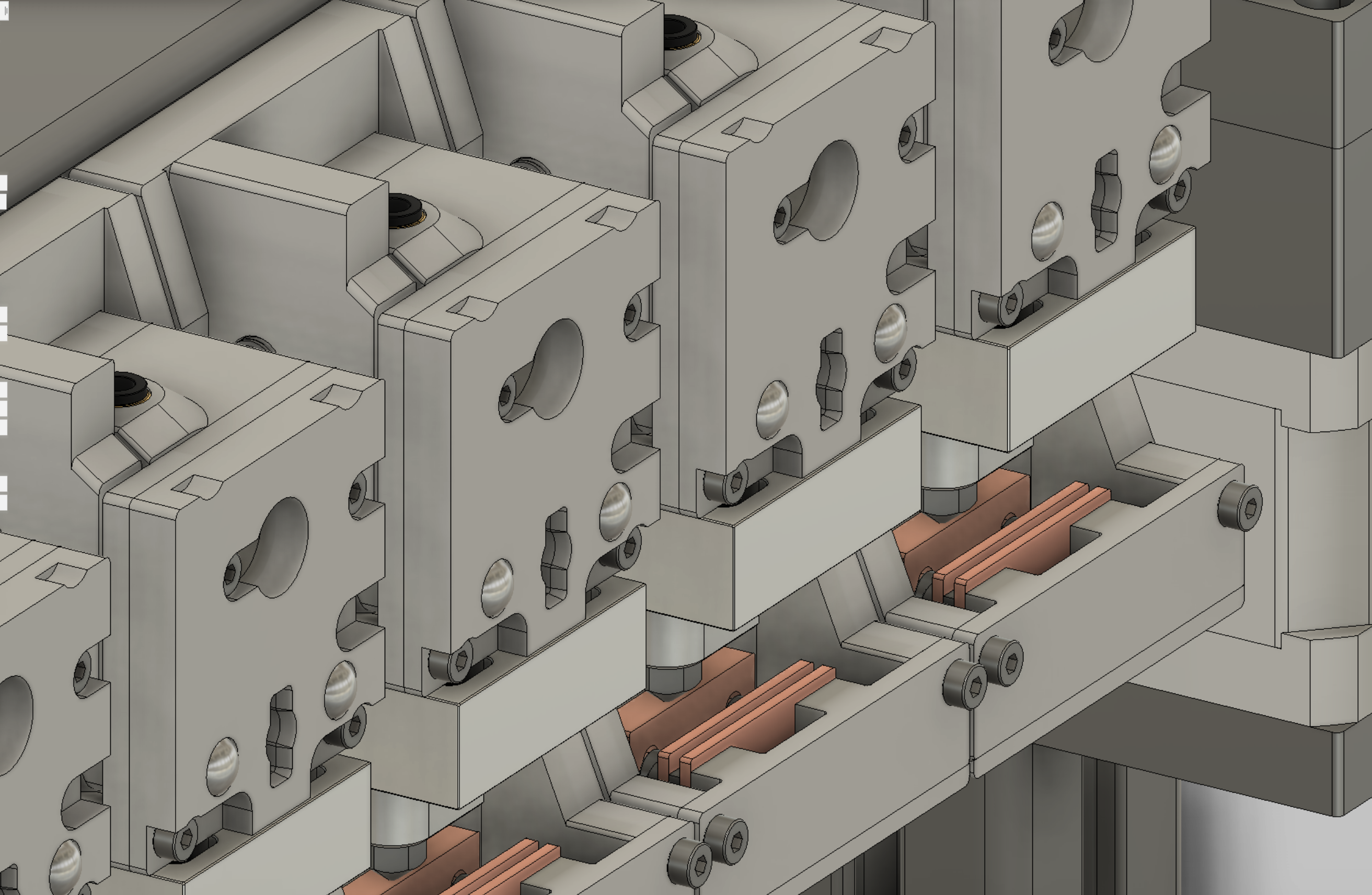

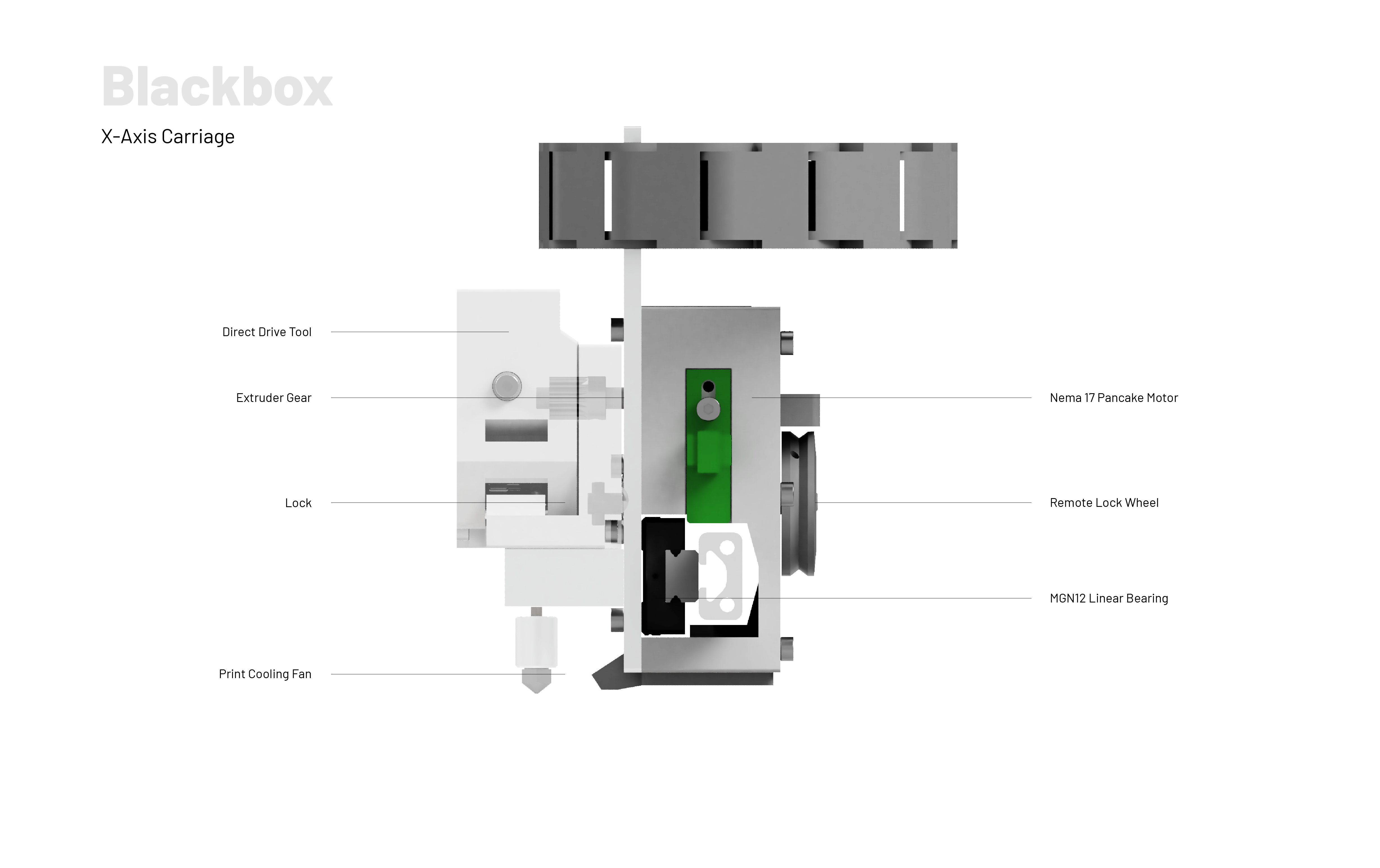

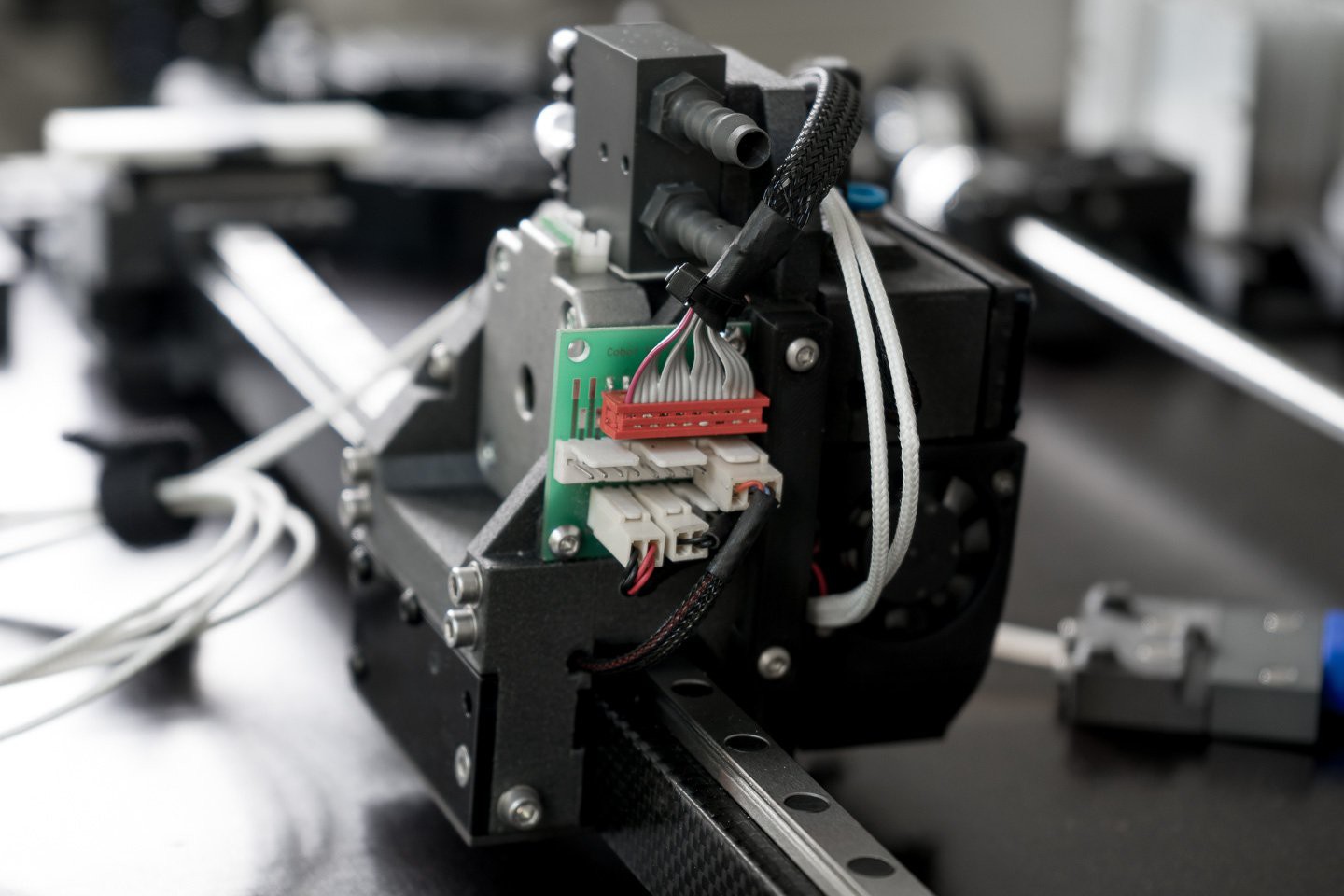

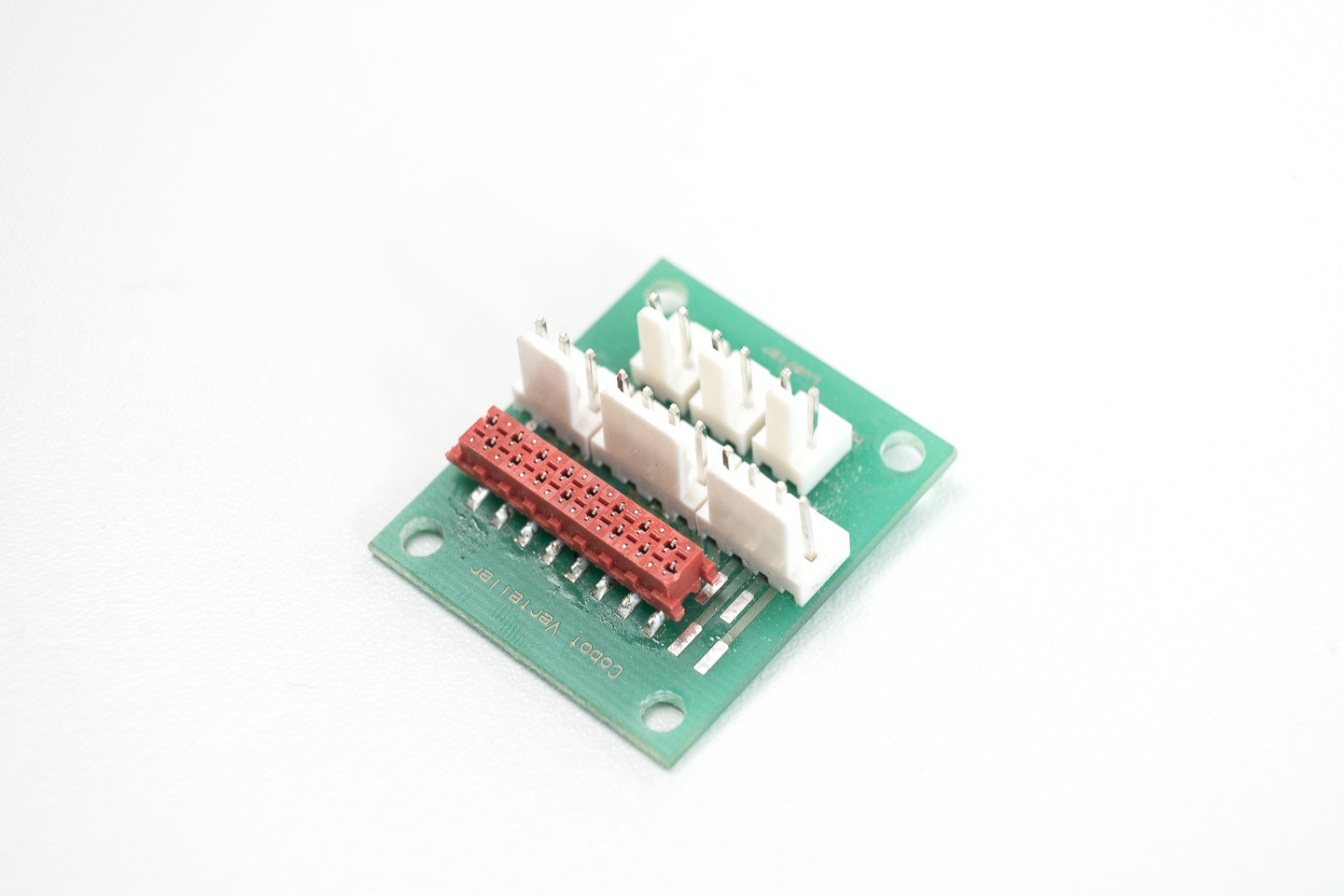

Blackbox Multi Tool X-Axis, highly integrated and completely watercooled.

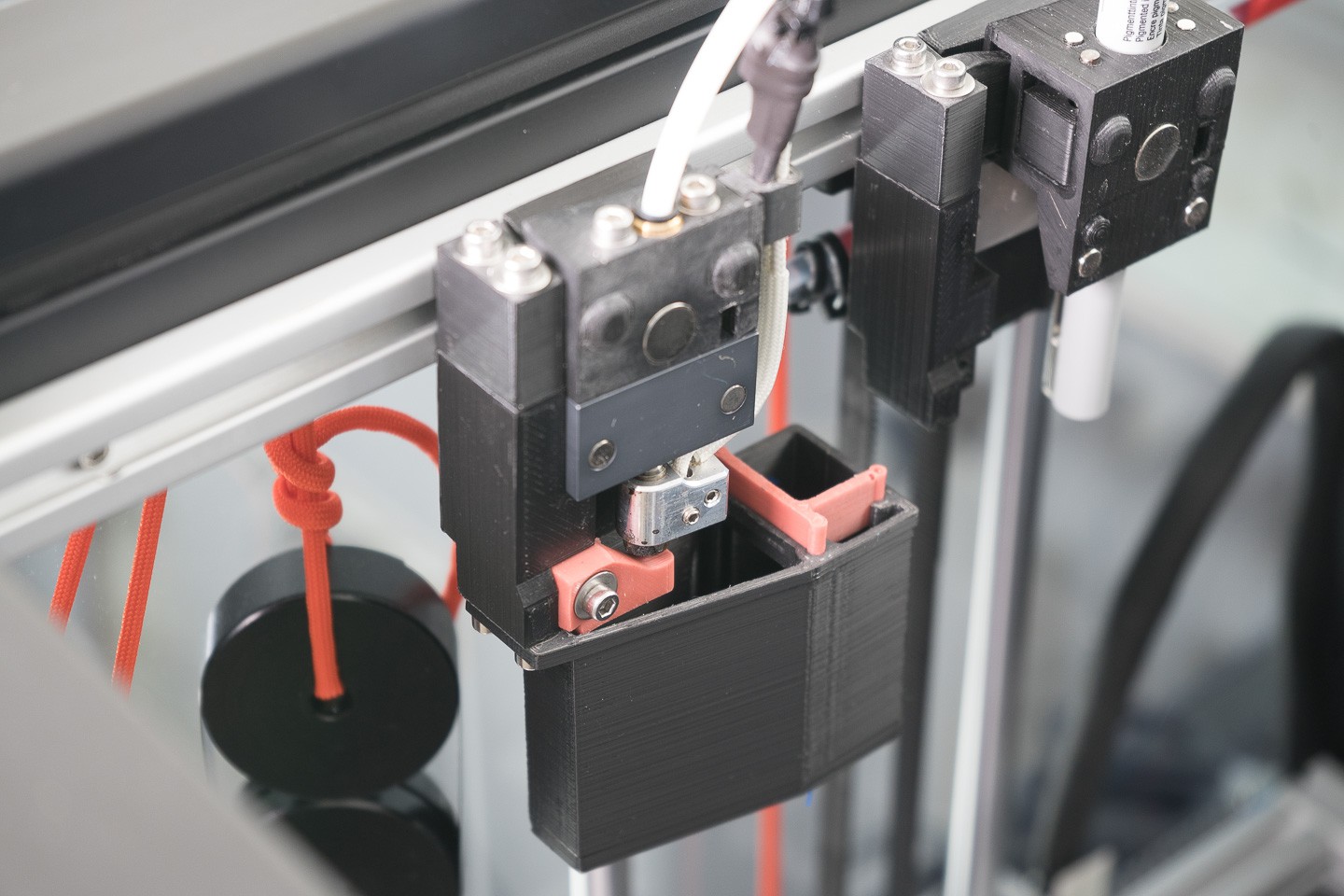

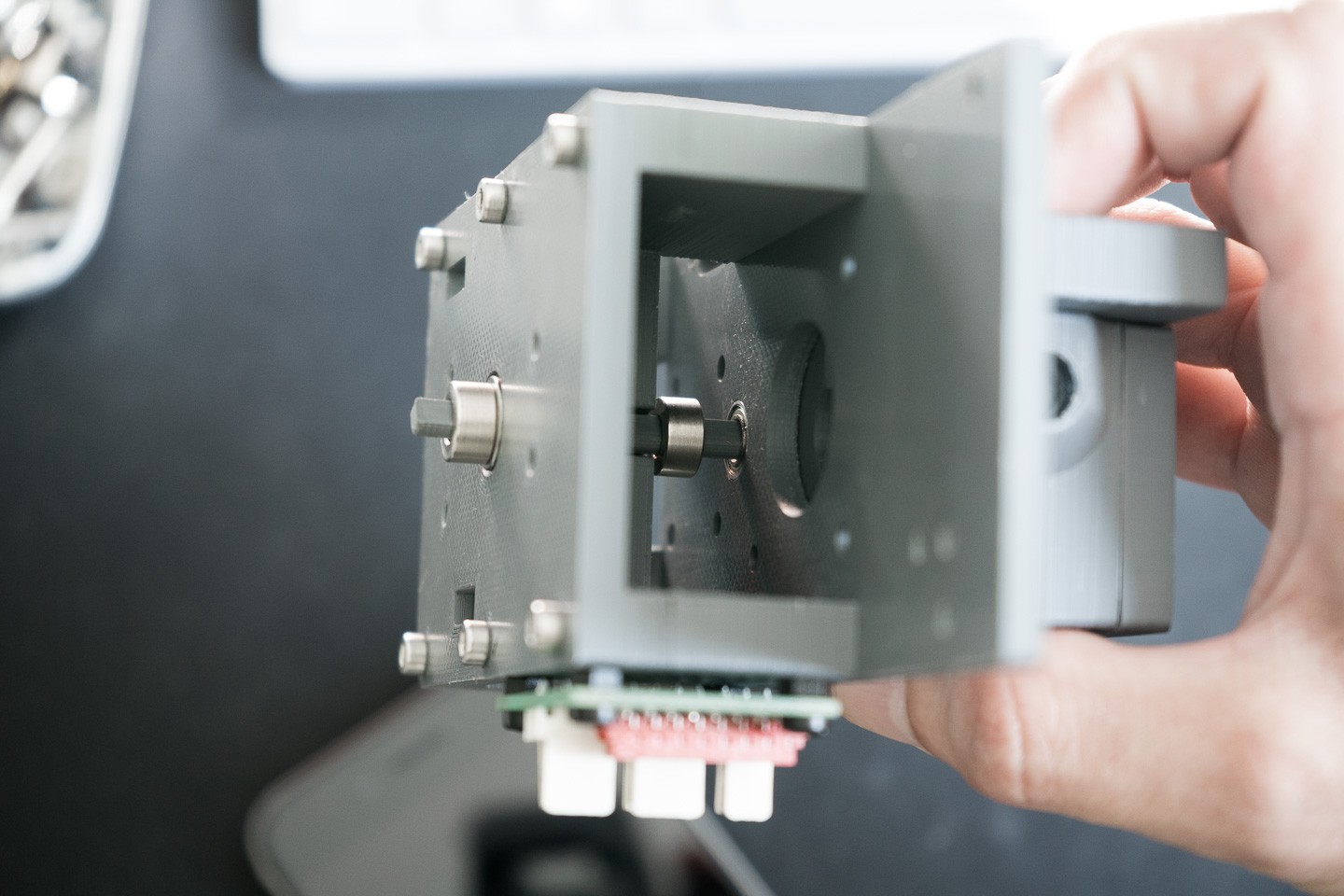

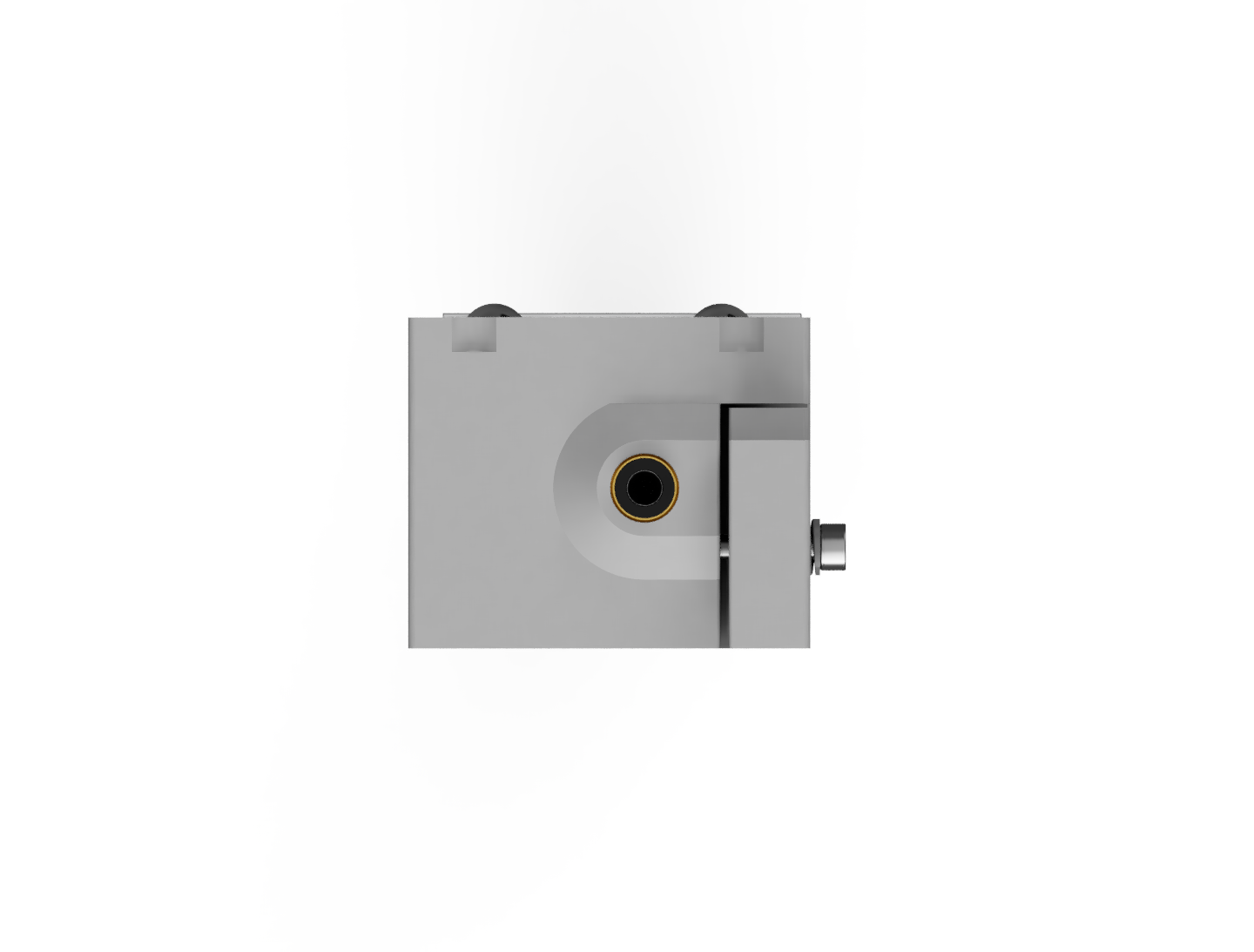

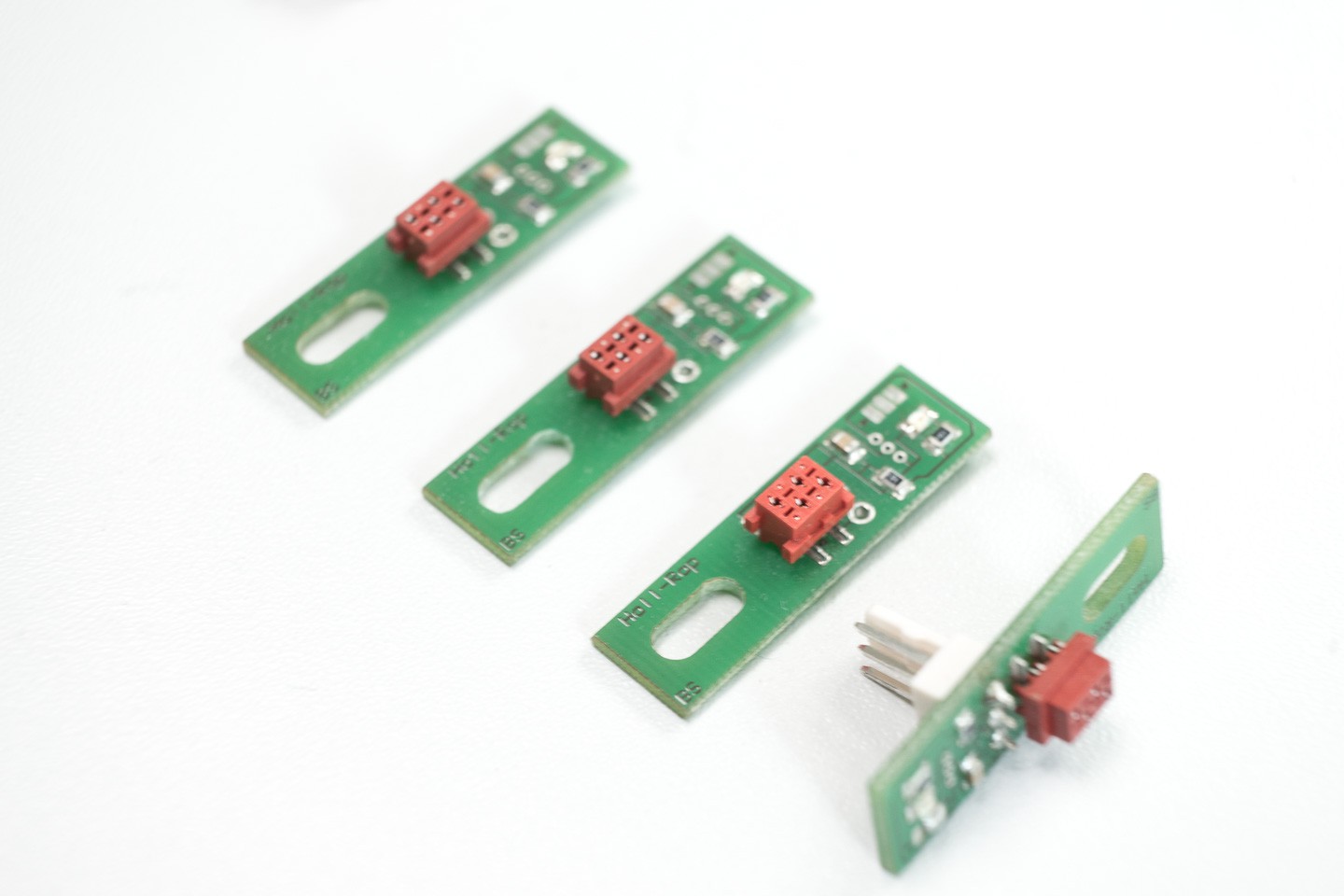

Direct drive tool coupled to the X-Axis

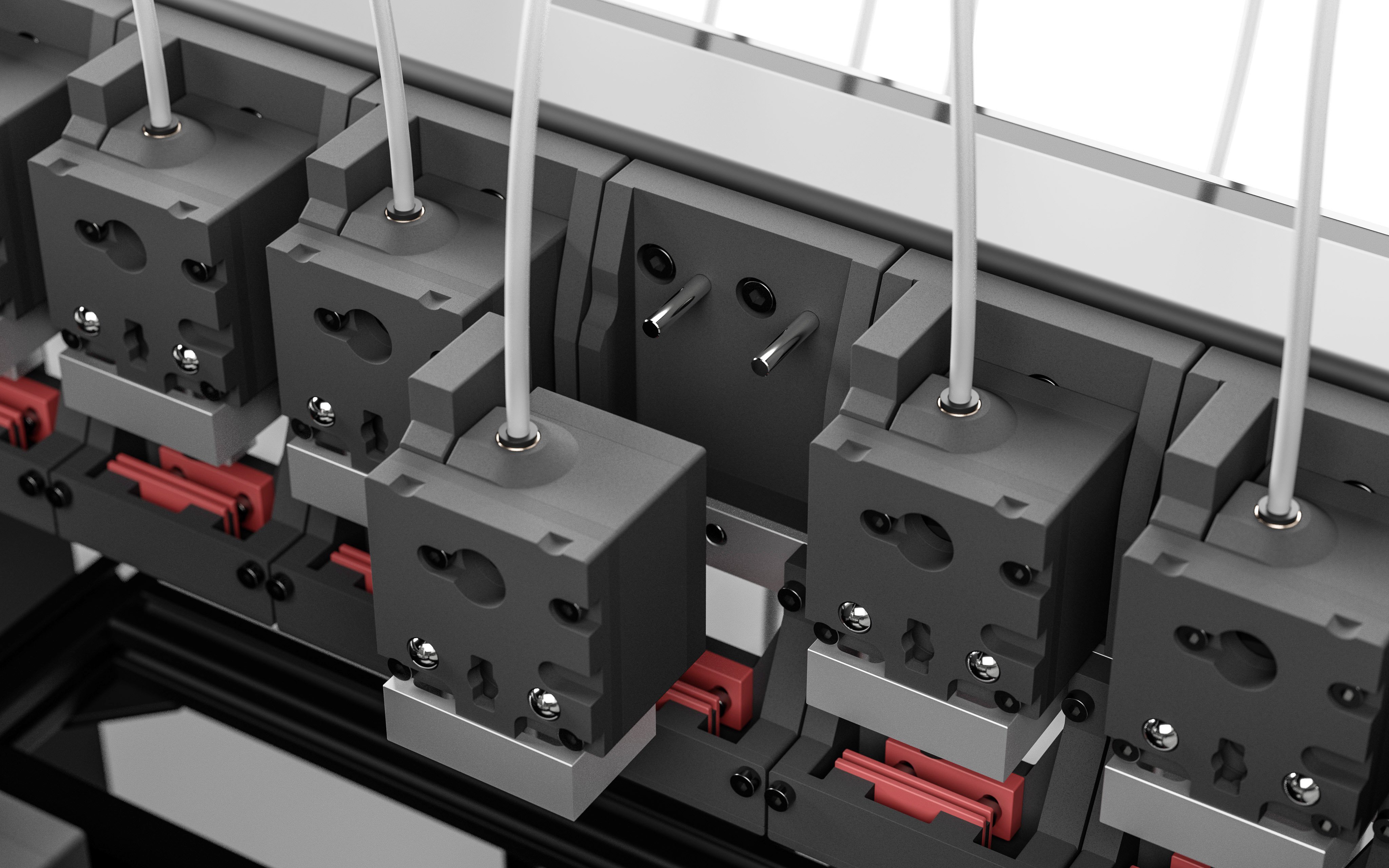

Toolbank with parking tools

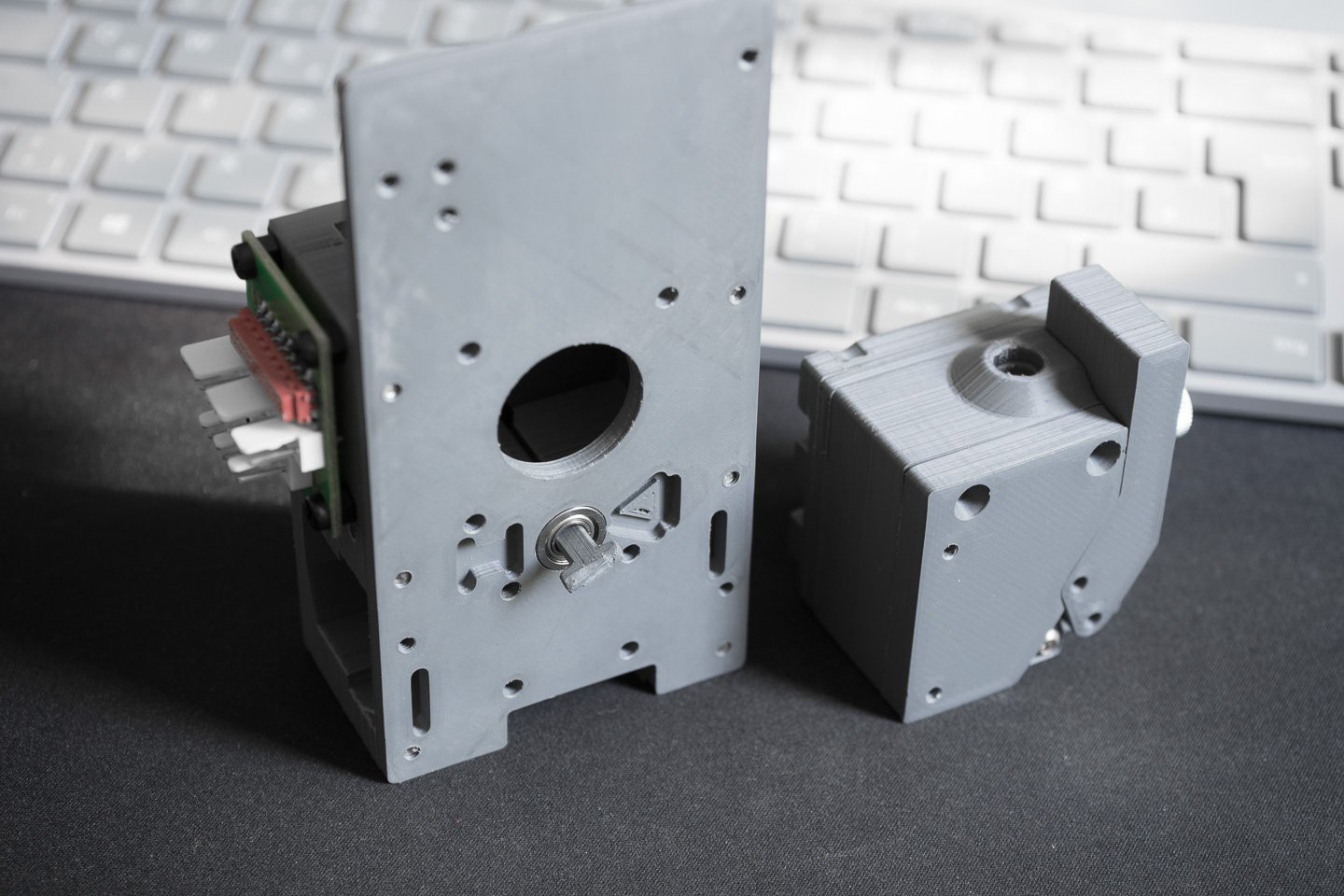

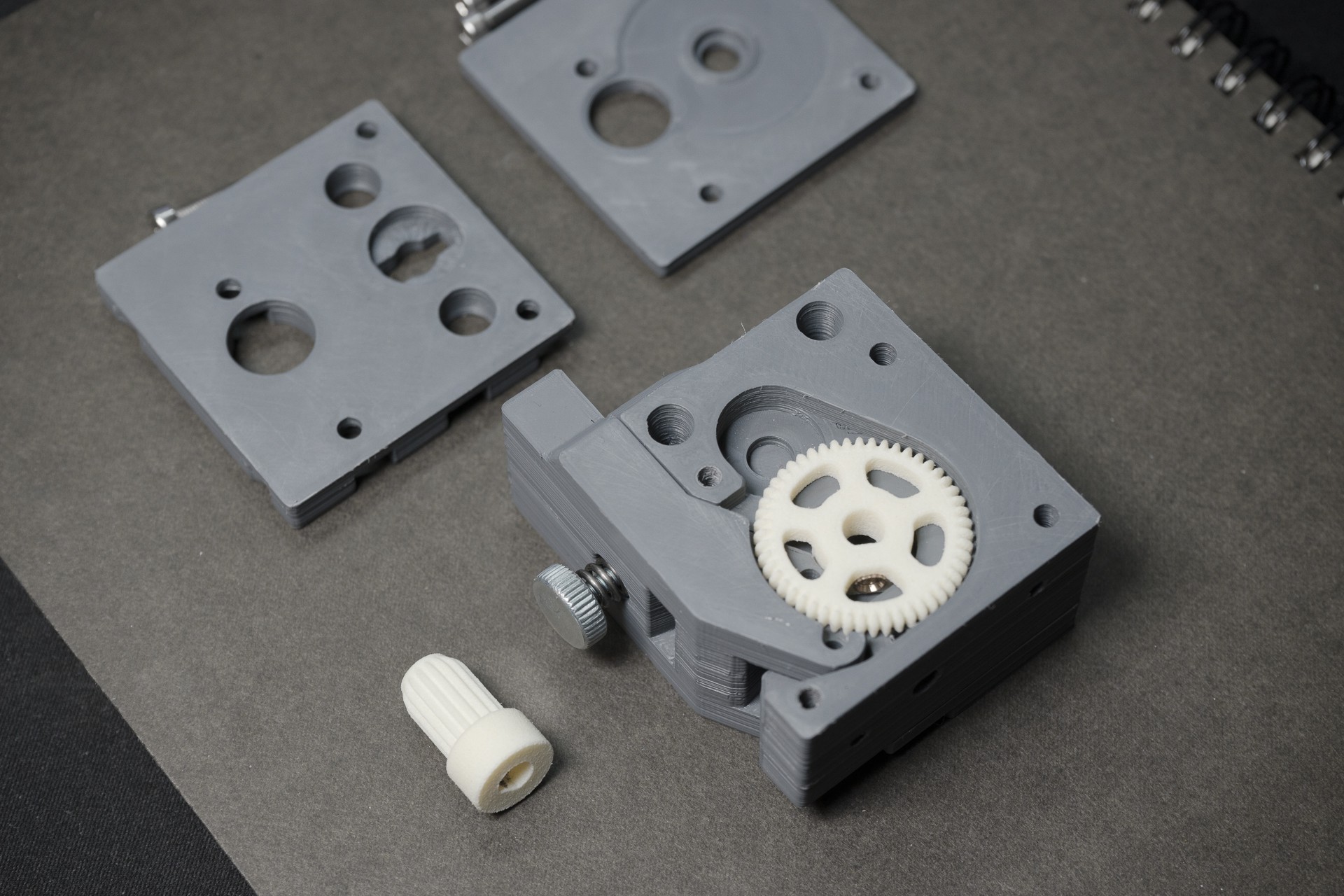

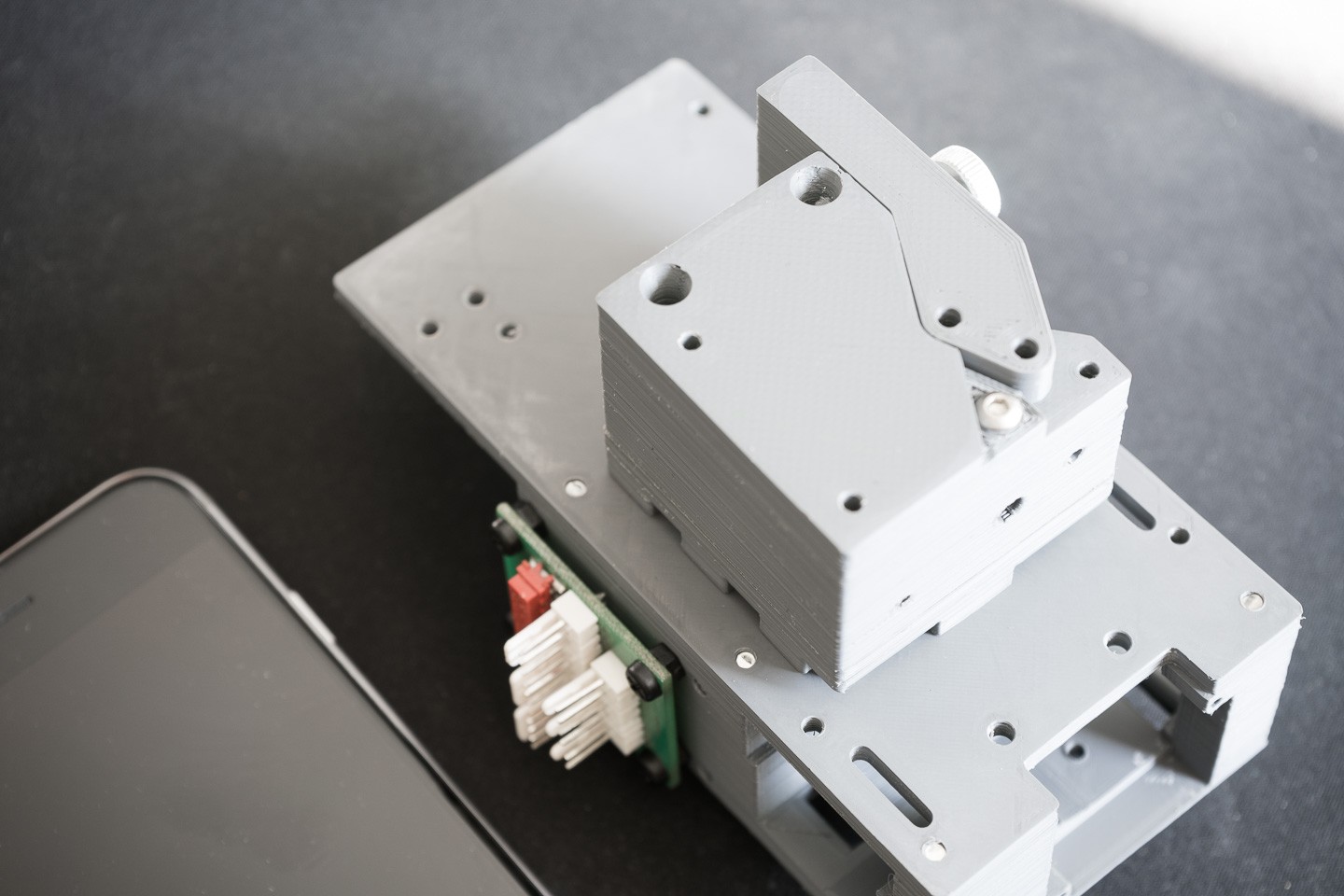

X-Carriage and direct tool prototype

Soft robot gripper printed out of TPU and PLA in one process

Soft robot gripper printed out of TPU and PLA in one processFeatures

- Up to 6 direct driven tools

- Passive Water cooling

- High-Speed Z-Axis for 3D movement

- True RepRap, most custom parts are printed

- Built with Off-the-shelf Parts

- Readily accessible

- Adaptable for specialization (especially medical applications)

- Air cooling is possible as an affordable alternative

Technical Data

- Prinsize: 300x300x275, fully usable with any tool

- CoreXY Kinematics

- T-Slot Frame

- MGN 12 Linear Rails

- Belted Z-Axis

- 9mm GT2 Belts

- Tailored for Duet3D Board

Marc Schömann

Marc Schömann

Hello,

First, congratulations on your project: a maker dream is being born from your work.

I have several practical questions:

1) do you plan to open source your work, and for "less technical" people go for commercial distribution?

2) with you already avenues for additional alternative tools; all will not be able to go, a priori, with your head, or am I wrong?

3) How can we help you? If you are looking for beta testers / makers, do not hesitate!

Yves-Louis

==============================================================================

Bonjour,

Tout d'abord félicitations pour votre projet : un rêve de maker est en train de naître de votre travail.

J'ai plusieurs questions pratiques :

1) comptez vous mettre en open source votre travail, et pour des personnes "moins techniques" allez vers une distribution commerciale ?

2) avec vous déjà des pistes pour des outils alternatifs complémentaires ; tous ne pourront aller, à priori, avec votre tête, ou je me trompe ?

3) comment pouvons nous vous aider ? Si vous recherchez des béta testeurs / makers, n'hésitez pas !

Yves-Louis