-

not reinventing the wheel

02/18/2020 at 23:42 • 0 commentsAfter some thought I have gone down the road of seeing if I can't use one of those little bluetooth tile like trackers as the timer. They have built in buzzing, lights, batteries and are found for < $5. They also have the added benefit of being able to connect to a phone to allow easier customization on timers, logging , etc. The ultimate goal would be to allow for phone-free control still but give the option to change some settings if desired. Progress will slow a little other projects have picked up. Just wanted to share the thoughts with others.

-

Crashed into Mars

09/10/2019 at 07:19 • 0 commentsSo I made a nice mistake on rev-00 of the PCB. I used metric 0603 and not (imperial?) 0603. Also the pads for the attiny SOIC were incorrect(narrow). So that has been fixed also. The new files are uploaded. I should not work at NASA.

On a positive note I test fit the rest of the components on the board and it was a perfect fit. Even the buttons worked with the case from Shapeways. I was very surprised I got that right the first try. The SOIC programming claw from sparkfun grips nicely on the Attiny and I'm looking forward to my Rev-01 boards from oshpark.

Next time it is not 1am I will get around to posting a better case.

-

Boaaards here!, get your boards here!

09/04/2019 at 04:19 • 0 commentsAll Aboaaaaard!

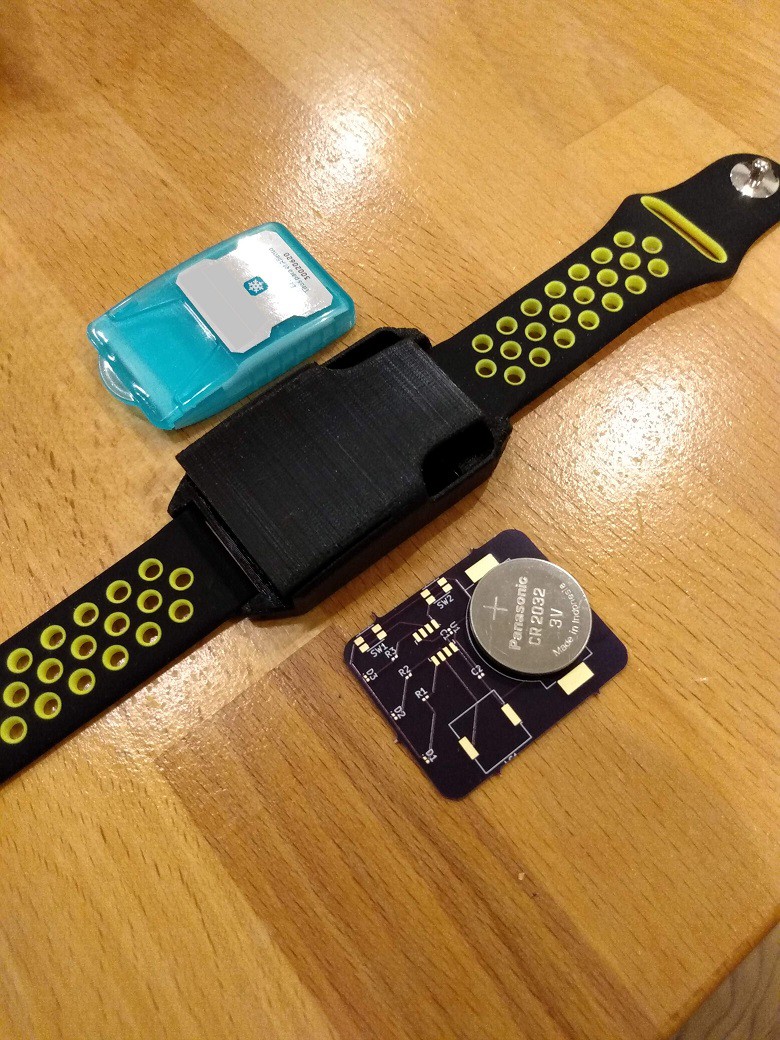

If you didn't notice. My boards came in. :-)

Aren't they pretty. The thinnest boards Osh Park had and one sided to boot. The test fit of board, battery and mint case all fit perfect. Swell.

![]()

Time to get some past out and get going. I might try a new method of soldering this time around.

I recently got a UV cure glue pen(search for bondic) and I think it would work super well for tacking parts in place before I solder them. Keep em from moving if I try and hand solder instead of reflow.

-

Self Control for the Common Man

08/30/2019 at 19:09 • 0 commentsI really enjoy beta testing my watch. Always a great conversation piece among friends and co-workers.

"Do you have poor self control? Always eating all the food on your plate. Can't stop munching on the open bowl of chips on the table? No More!"

The latest design looks like so:

![]()

Pretty slick. I think I need to do more to move the electronics on top and hide the mint container more underneath.

Either way the result is the best,

A plate full of left over food and a happy stomach. Look at all the fries I would have otherwise ate.

![]()

I was able to not eat them for a full 20 minutes, when I finally tossed em. What a waste! Next time I will ask for a lot less fries.

-

Comfy on my Wrist

08/28/2019 at 17:33 • 0 commentsI was able to print out Rev 01 of the enclosure on my existing printer. It's a little big, like a gen 1 pebble watch. The settings I used were a 0.4mm nozzle 0.1mm layer height with PLA. I was super impressed The watch band pins fit perfectly in with no drilling! probably only cost 30 cents to print. Already I can see a few changes I need to make to the general shape and use. Primarily I need to add a slot to make it easier to pop the mint case out. Should be easy enough to modify and try out. FYI although I could print it in PLA, PETG might be better as it would be less brittle. The flexible door broke off as my kids started fiddling with it. Another reason why the SLS nylon version will be superior.

![]()

-

Enclosure Economics

08/27/2019 at 08:15 • 0 commentsIf you check the project files you may notice a file for the enclosure. Currently you can order it off shapeways for about $12 in many colors. I ordered Red and Black.

Very economical for small production runs but not very economical for 10k.

But what would the break down be. This design, although great for 3d printing is not good for injection molding.

What if it was 2 piece, or even 3?

let's do a little math. 5k per mold, 0.50 per part.

So Algebra 3*5000+(3*0.5)X = 12X

15000 = 12X-1.5X = 10.5X

15000/10.5 = X = ~1428 Units

So how many units would it take to break even on a 15k investment in molding?

previously I had estimated a total BOM of $23 not including labor, packaging, assembly, soldering etc.

most products are 4x over COG for pricing or 2x if direct sales.

Lets assume the unit could demand a price of $25 and 2k units cost $19.

Ok, a 6$ profit margin. 15k/$6 pays for the mold in 2500 units with terrible margins. Not too bad.

Seems easy right? Except without good marketing good luck selling 2500 units. This is where things like kickstarter shine. They are basically a marketing company and they take their cut for making your project have a substantial set of eyeballs view them.

What would I need raise to not lose my shirt?

15k + 2500*19 = whooooooo 62.5k. So be wary if you see people who say they need only 7k for their kickstarter to fund.

As much as I would love a second mortgage, keeping this case 3d printed from a service house really is economical barring outside investment or internal financial risk. It allows the project to grow and rapidly improve until the market demands it.

Molds are expensive. I will however start designing a 2 or 3 piece 3d moldable/printable case that makes it more weather resistant and easier to change the battery.

-

Submission Time

08/25/2019 at 06:06 • 0 commentsBoards are done and shipping from OshPark, parts are all here waiting. This includes some handy dandy new silicone watch bands off amazon. And an SOIC-08 programming clip. The schematic files have been posted along with rev 01 of the most basic timer code. It does not go into sleep mode and is not settable yet. However all the hardware is there, just waiting for better code to use it.

I Also updated the parts list with exact part numbers I ordered off Digikey.

I am holding off a day on posting the case stl file as I am changing it from apple band design to traditional type. There are far more options for traditional style attachement.

All in all, I should have a half dozen of these shipping out in about a week to beta testers.

Rough BOM: in QTYs of <10

Watch Band: 4.75

Mouthwash Strips: 0.50

Case: ~10

PCB: 3.05

Components: 5.35

Total: $23.65

Not to shabby. As for the watch band and case the sky is the limit on how expensive you could make them. Shapeways can print out of platinum and there are many fancy watch bands one could get.

At this point I think the project is ready to submit to the HAD Prize. However I'll keep developing and pushing out revisions as I continue towards getting better code and more testing in.

-

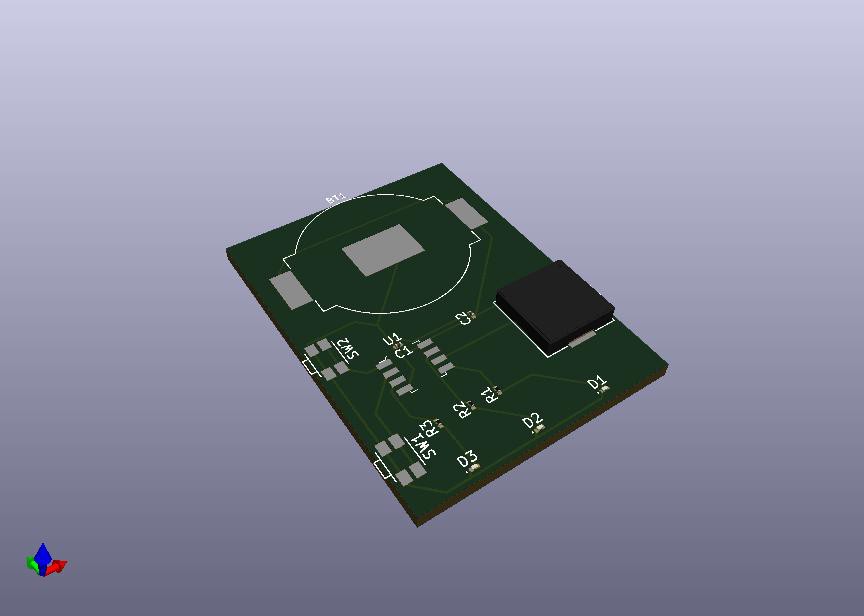

Spinning Boards

08/18/2019 at 08:40 • 0 commentsHad a small adventure learning KiCad from Eagle. I managed to get a nice simple board designed.

I'll order 10x of them for beta testers. While I wait around for the boards to arrive I can continue on the housing design and reducing current consumption with better sleepy code. Expect an update in the Git of the initial code compatible with the new schematic layout. I had to move some IO pins around in order to obtain a single sided PCB. The new Schematic has 3 LEDs, a reset button, 2025 holder, regular button and a buzzer. Some more decoupling capacitors too!

Obscure 2:30am thought...

Someone should make a game of PCB layout. It would be pretty cool. Basically components on a board with color string and each component pin has a color. Connect all the pins and don't cross any string. Add more components to increase the difficulty.

![]()

Good night!

-

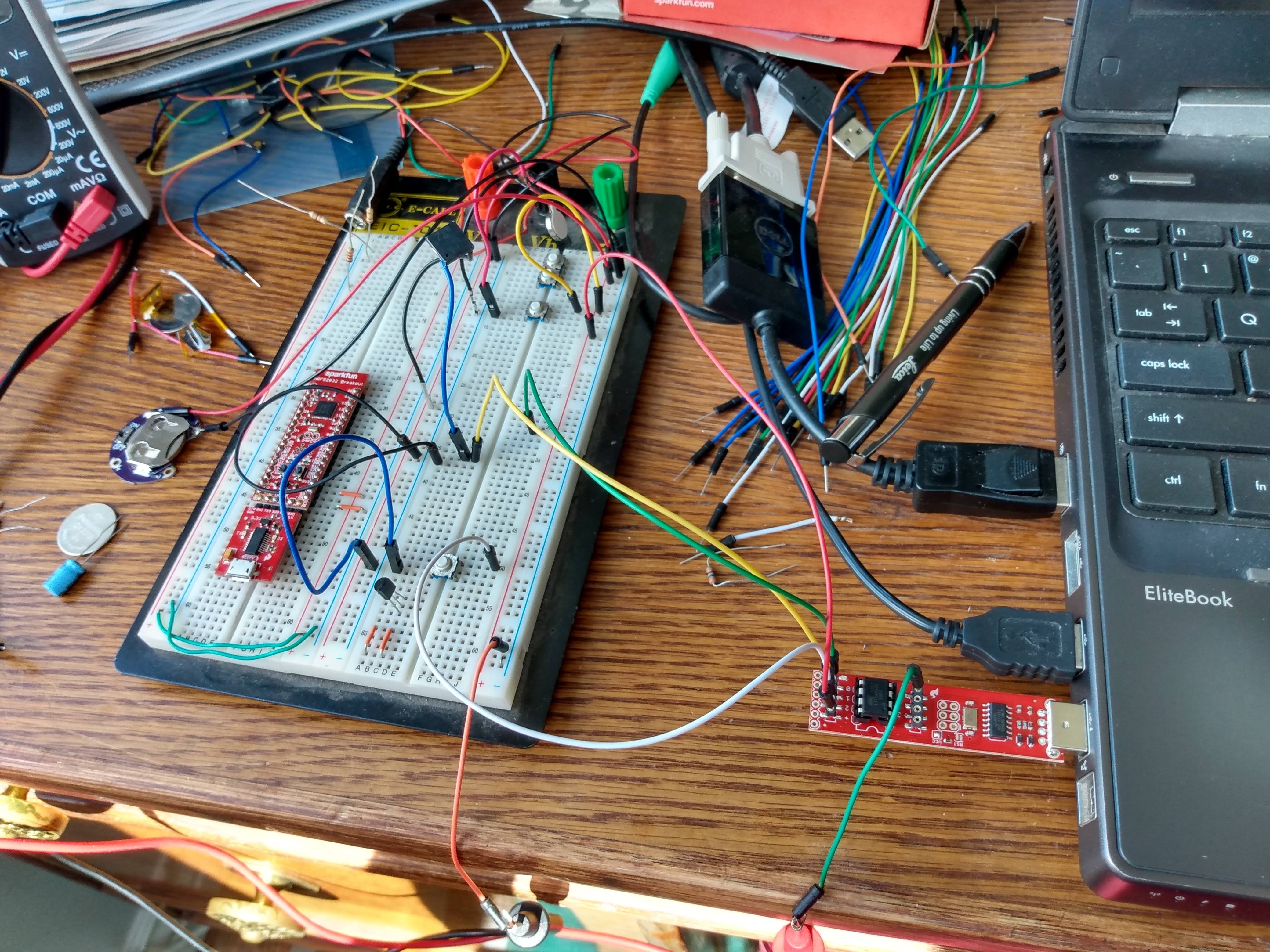

Breadboarding

08/14/2019 at 15:09 • 0 commentsI was having a pain in the rear getting my old atmel MKII programmer to work.

Then I found this tiny AtTiny programmer USB thingy from sparkfun. what a deal!

![]()

It's the one plugged into my computer right now. The cheap multimeter they have also can measure current consumption down to the 1uA level. Pretty Rad.

I hope my family doesn't grow tired of hearing piezo beeps all night long.

-

3D Printing is the bees knees

08/14/2019 at 15:06 • 0 commentsIt really is amazing that with 300$ you can have your own 3D printer and have decent proof of concept prototypes in a matter of hours.

![]()

Here are 3 such. the flexible DLP one didn't work out so well but the others let me test out snap bracelet and apple watch bands. Overall I am learning a ton about what make a watch comfortable.

So far I think I have decided that an independent core housing with normal watchbands will be best.

cheaper to manufacture in small quantities. Especially if people want to 3d print one from shapeways.

It has been hard to get the size down due to the mint container size. But I really haven't found a better solution that works as well.

Once I get my PCB finalized and case finished I'll send it over to shapeways to get out of SLS nylon and Stainless.

Slim Band: Appetite Suppression Wristband

Help fight obesity and food waste through behavioral conditioning

Chaz

Chaz