-

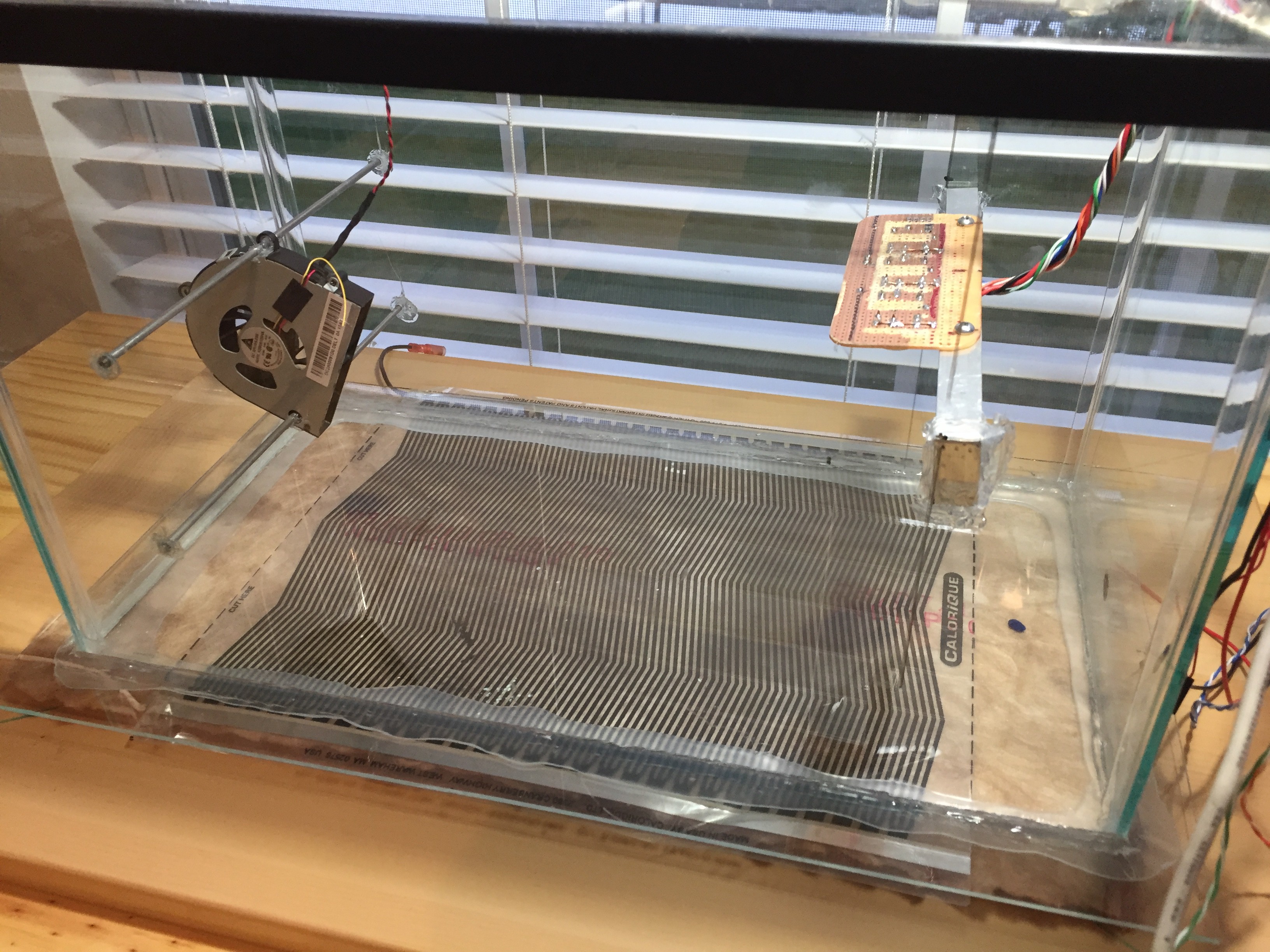

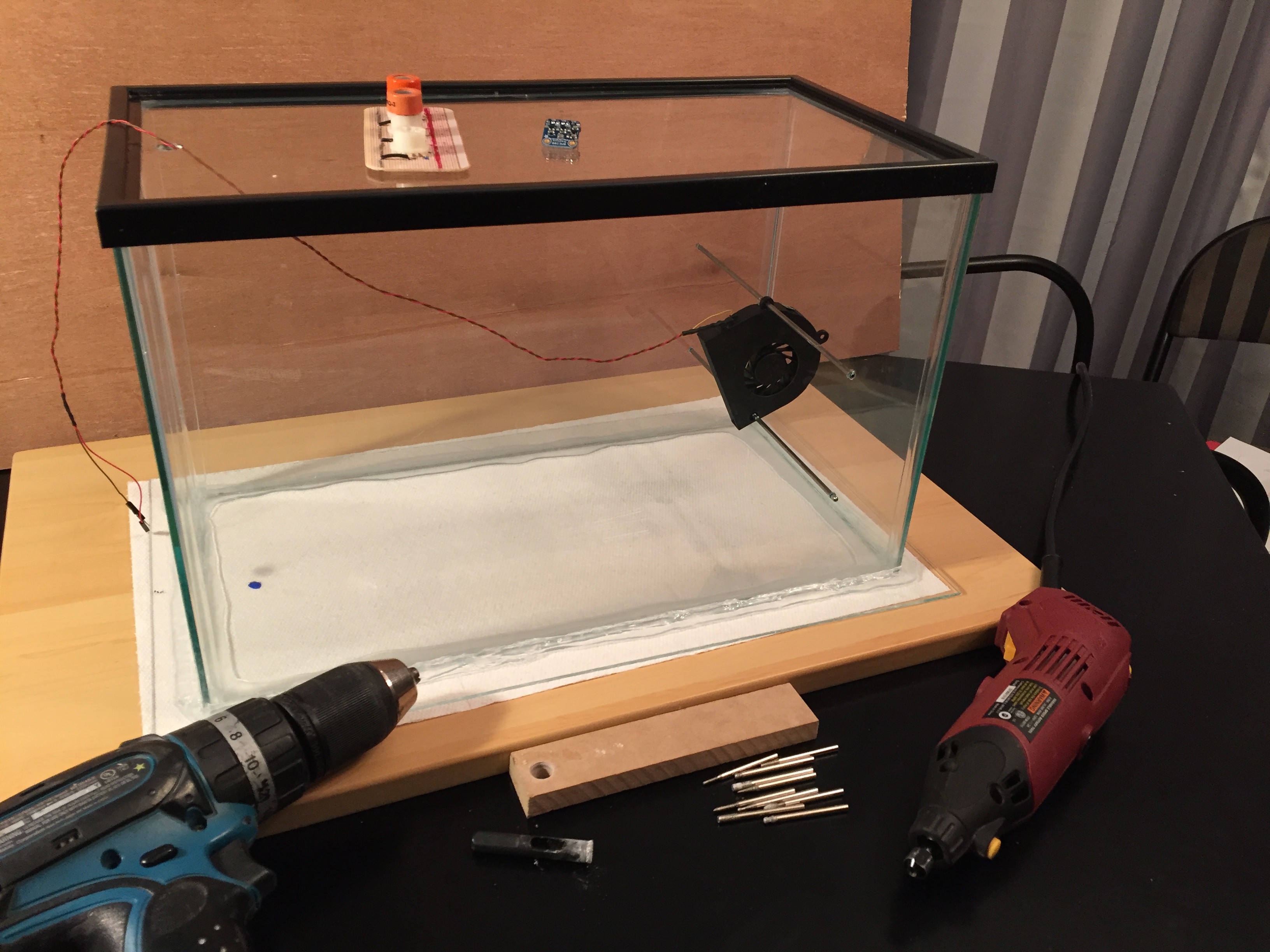

Test Chamber Build part 2

09/22/2019 at 23:22 • 0 commentsMy test chamber is nearly done. The main portion that I'm adding is a port to introduce precisely measured volumes of acetone (I can't drill the hole for it until I've re-checked my calculations).

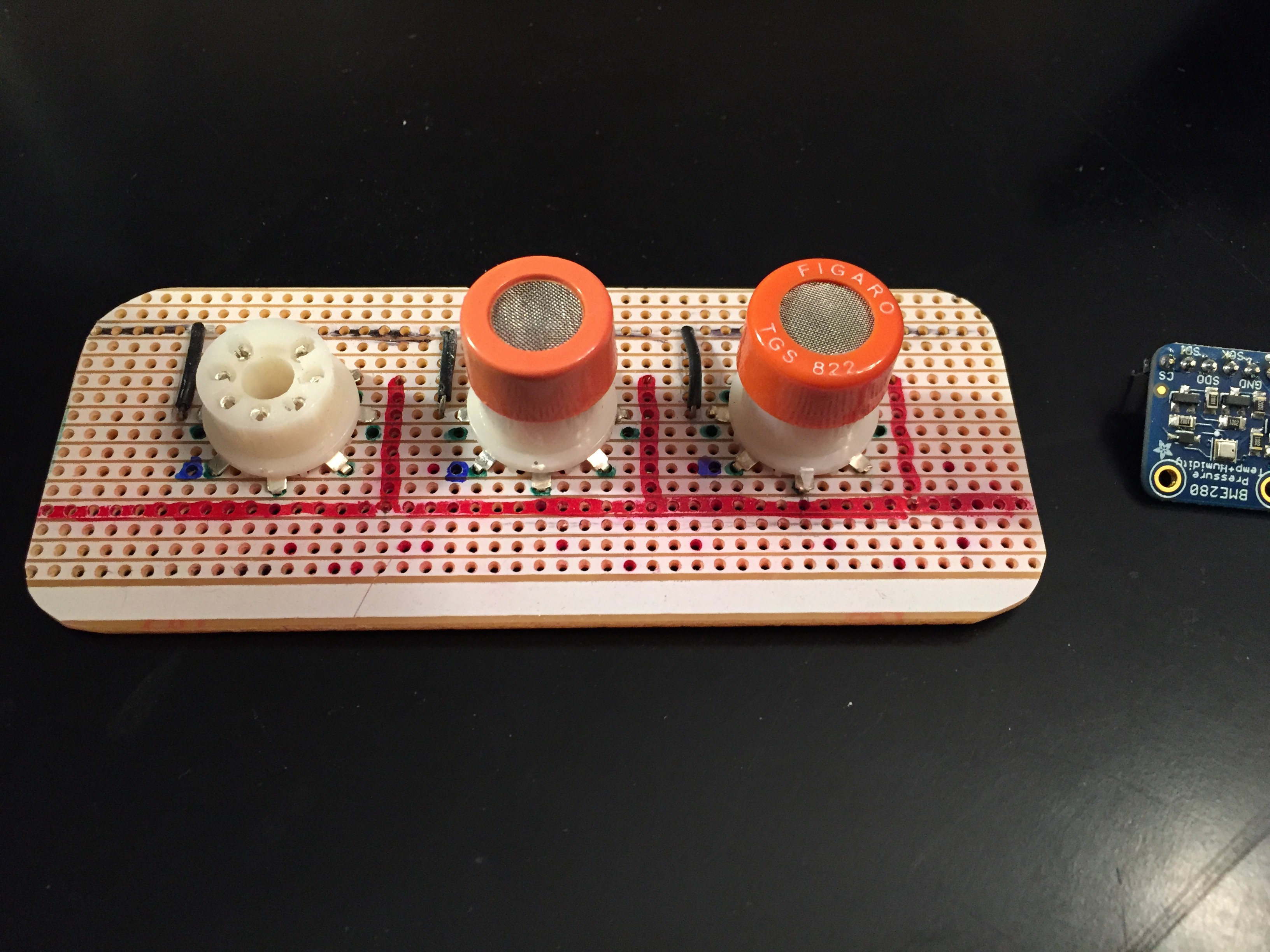

I finally received my MQ138 sensor, it took a little longer than expected due to few suppliers actually carrying it (Digikey, Mouser and Newark do not). In addition, it cost's considerably more than other commonly available gas sensors (instead of $5-10 it more like $40-50).

For my test chamber, I've completed the surround for insulation, heater pad on the bottom and finished all the wiring for the sensors, fan and heater. All wiring ports are sealed with silicone.

-

Semiconductor Gas Sensors for Acetone

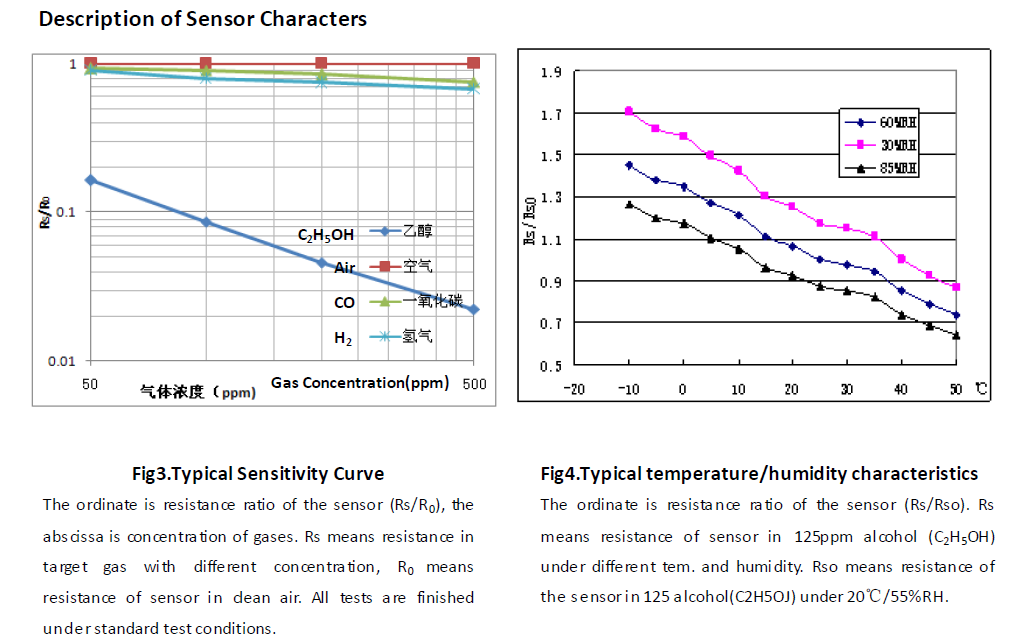

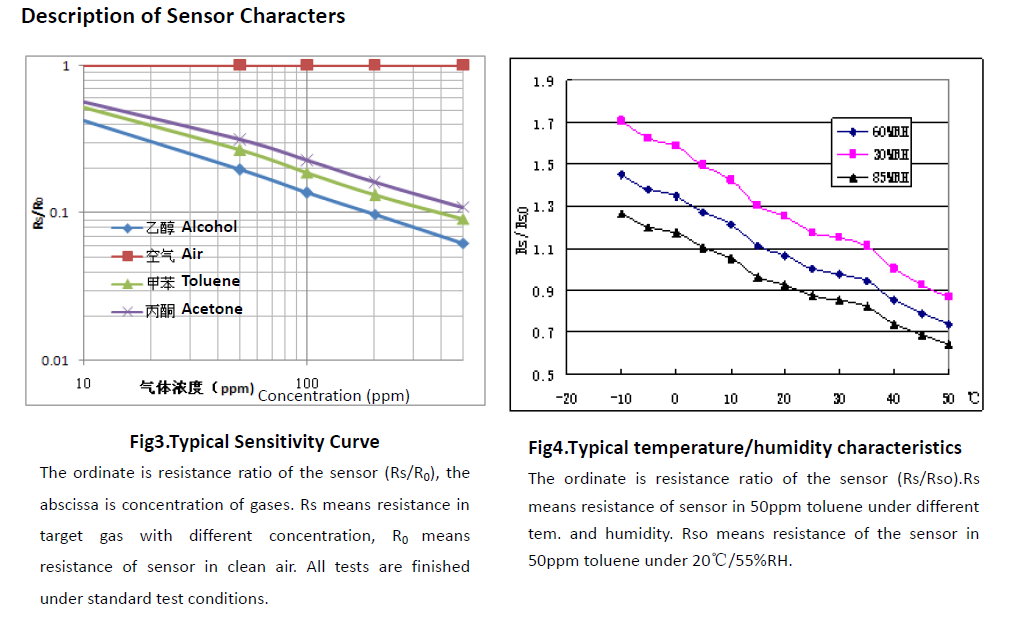

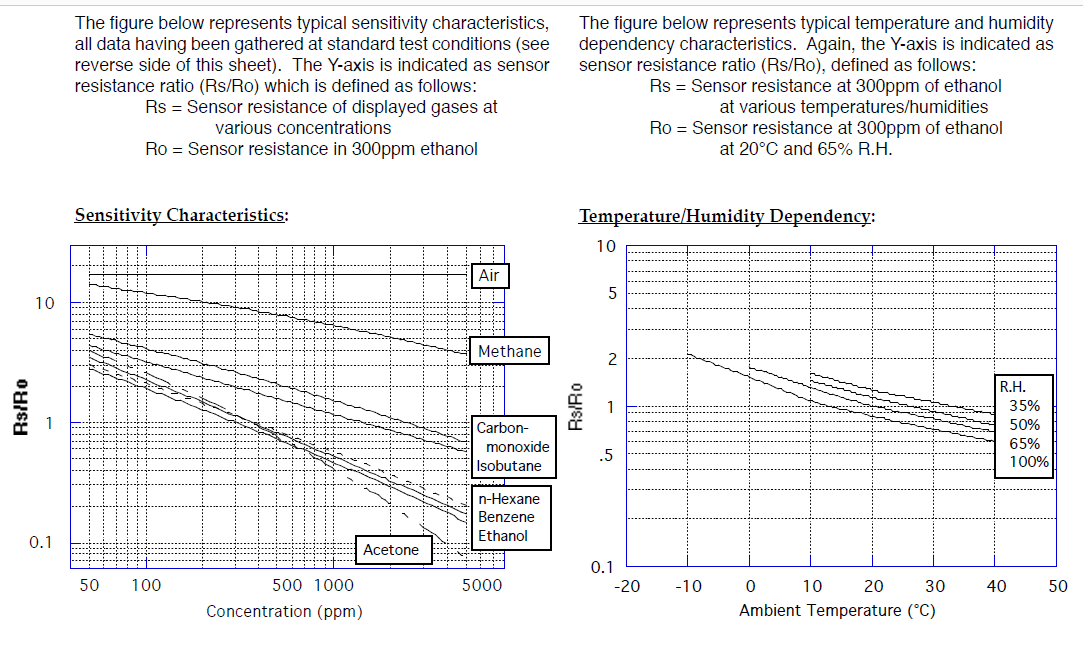

09/04/2019 at 01:12 • 0 commentsPresently, I am testing the following gas sensors. I'm including the sensitivity graphs from the data sheets:

MQ3

![]()

MQ138

![]()

TGS822

![]()

-

Test Chamber for Validating Sensors

09/04/2019 at 01:06 • 0 commentsSemiconductor gas sensors are relatively inexpensive but they come with one caveat - you have to calibrate them with known concentrations of the gas(es) you are using the sensor to detect. It is one thing to detect if a gas is present but if determining its actual concentration is the objective (which it certainly is, in this instance) then we need to test each sensor against different known concentrations to determine their sensitivity to to our target gas (acetone) as well as the relationship between sensor values and gas concentration.

For this chamber, I have a number of design considerations:

- Needs to be air tight

- Temperature controlled

- Made from materials that are non-reactive (and minimally absorbent) to acetone.

- Reasonable size - big enough so that it is convenient to measure out acetone to place in chamber, but not so big that controlling temperature, etc., becomes a burden.

- Include desiccant to maintain low humidity (non-reactive to acetone and ethanol)

- Environmental sensors to determine temperature humidity and atmospheric pressure

- Continuous air circulation within chamber

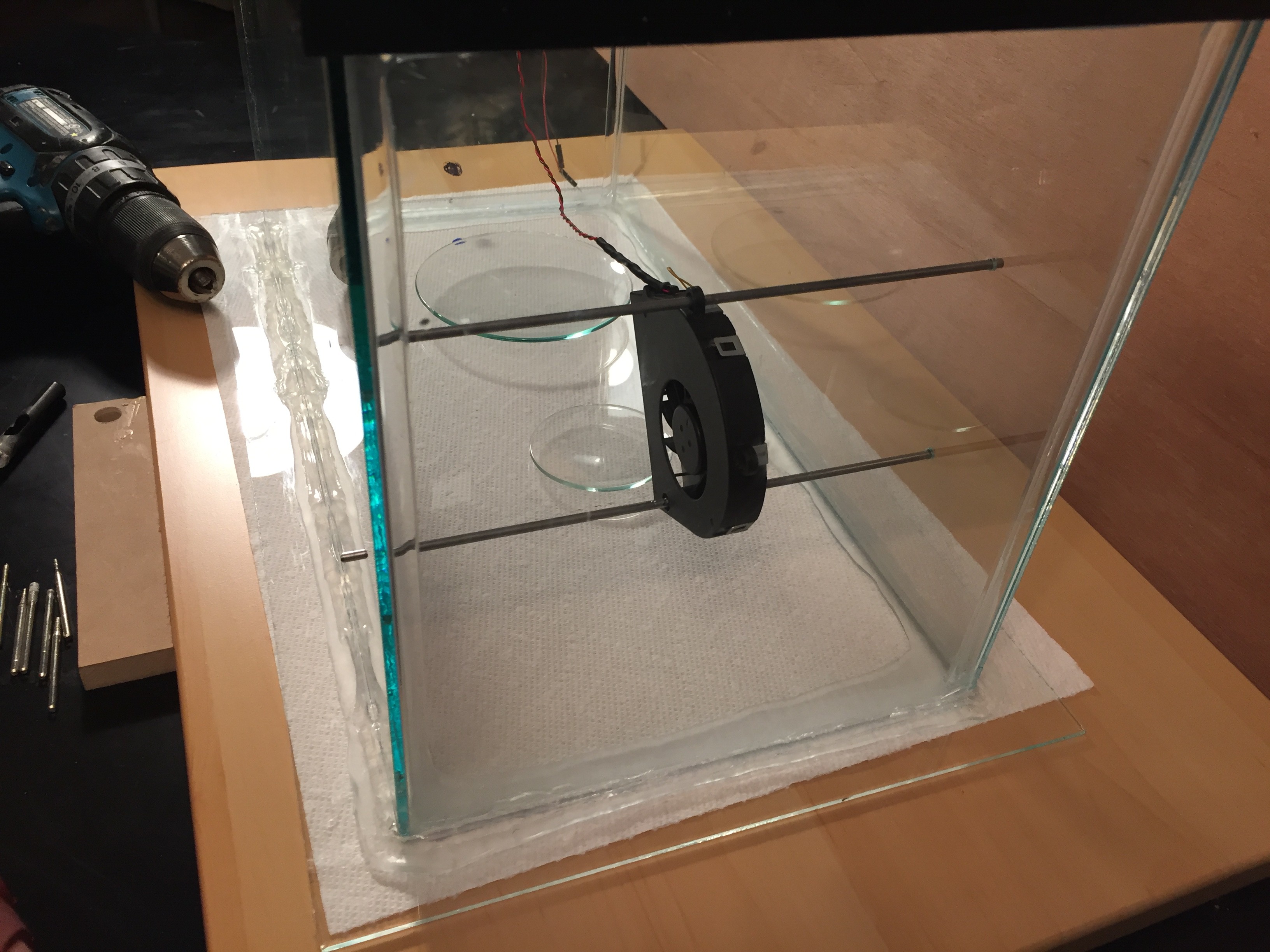

Presently, I am finishing a chamber design and build that uses an inexpensive glass aquarium (I did remove the upper plastic rim since I believe it is made from ABS - very absorbent to acetone) and mounting sensors and fan inside, along with a watch glass for the evaporation of acetone. In addition, a Calorique heating element external to the tank and insulation surrounding the whole structure.

The sensors that I am currently including are: BME280 (for temperature, humidity and barometric pressure), MQ 3 gas sensor, MQ138 gas sensor and TGS822 gas sensor.

The chamber has a silicone gasket (fabricated) to seal it. Wiring is routed into the tank via holes drilled in the glass and sealed with silicone.

Below are a few pictures of my progress so far:

Keep tuned, I'll have additional updates tomorrow!

Breathalyzer for Blood Glucose

Portable, simple and inexpensive test to provide Type I diabetics an indirect measure of blood glucose via breath analysis.

Tom Meehan

Tom Meehan