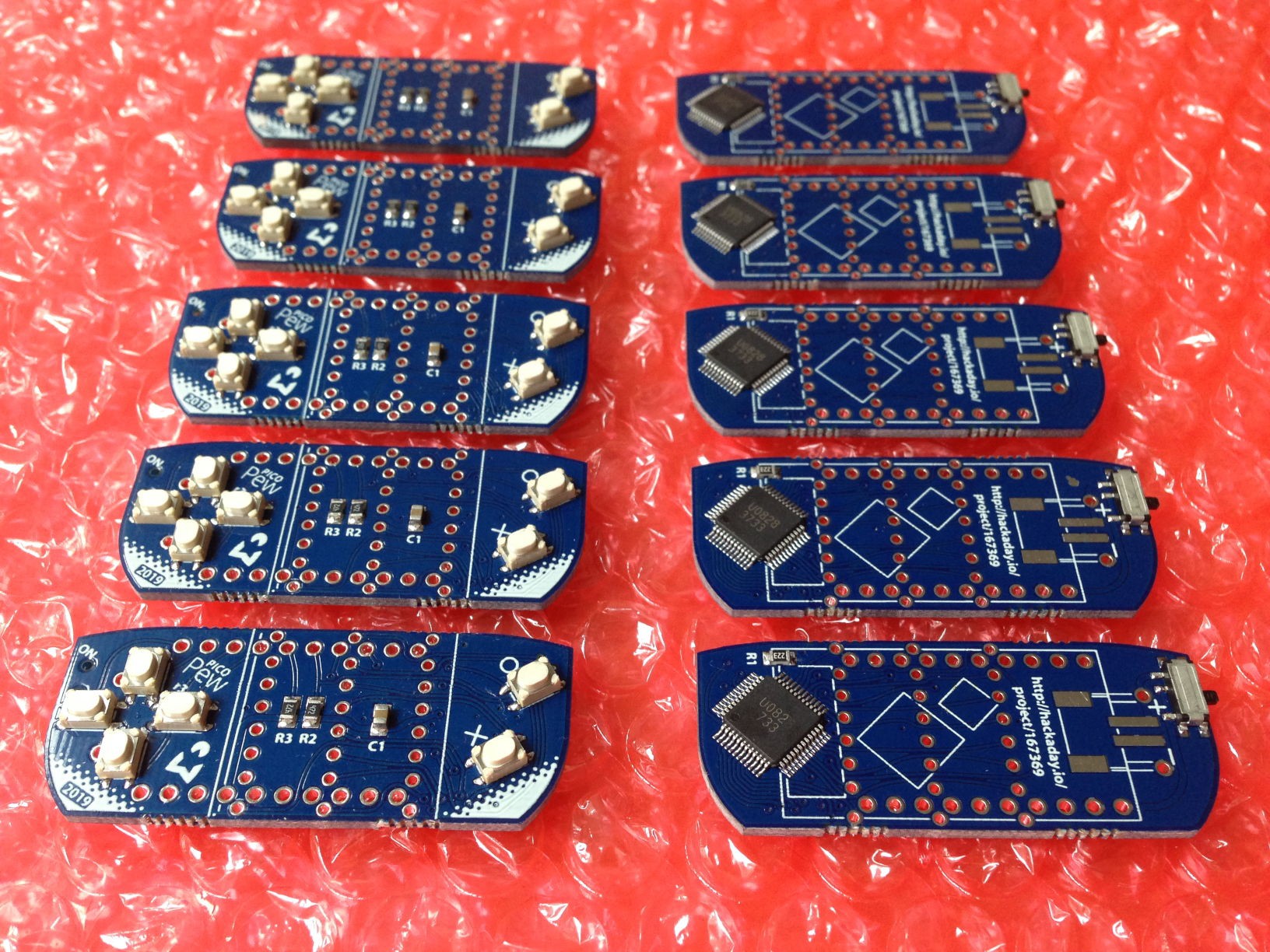

After receiving good PCBs from PCBWay I also wanted to give their PCB assembly service a try and ordered a test run of 10 boards with all the SMD components mounted. They arrived before the holidays and I have now finally gotten around to taking a closer look.

After visual inspection and continuity-testing all the buttons, I am pretty satisfied with them. The soldering is clean, nicer than if I had done it myself, with no bridges between close pads e.g. in the center of the d-pad, and anything relevant to function looks good.

Two boards have cosmetic defects in the solder mask: One, a small speck of exposed and HASL-coated ground plane on the back side. The other, a bit of missing solder mask under an area mostly covered by silkscreen in the bottom left corner on the front, so that the white silkscreen was printed on bare copper, which makes it appear slightly pinkish, surrounded by some silver HASL dots where the silkscreen has holes. Nothing to be overly worried about though.

The single biggest flaw is that, despite my instructions to use capacitors of at most 1.0 mm height (the ones I have are 0.9 mm), they used 1.2 mm high ones (square cross-section), which means that the LED matrix placed over them now does not sit flush on the board, but leaves a gap of about 0.2 mm on one side. Apparently I didn’t insist on that clearly enough, and I couldn’t spot it on the review photo because it was taken from the top, so the thickness of the components was not visible.

I also tried to functionally test one, but it turned out to be very difficult to hold a TinyPICO, the PicoPew board, and an LED matrix together in such a way that all needed pins make reliable contact. All I can say is that it appears to work, but I can’t be certain that all LEDs are connected correctly. Doing this properly will have to wait until the pogo pins I have ordered arrive.

The boards came individually packaged in zip-lock ESD bags, which is great, because it means I will be able to insert the additional components and ship the kits in the same bags. I hadn’t left any instructions on packaging, but will be sure to explicitly request this on follow-up orders.

I had submitted single-board Gerber files and asked them to panelize them in whatever way best fits their process. They chose to make 1×2 panels with breakaway rails at the top and bottom and sent me Gerber files for that for review. I didn’t spot it at that time, but when I saw the assembly review photos, I was a bit worried that the mouse bites on the paneling tabs, which they had placed centered on my original board outline, might have been a little too close to the outermost plated through-holes for the LED matrix that lay in the middle of a tab, and breaking off the tab when depaneling might break through one of these holes rather than through the mouse bites. This turned out unfounded, all the holes were intact – obviously the plating adds some reinforcement, and apparently the engineer who placed the mouse bites knew what they were doing. Still, next time I am going to ask for these mouse bites to be moved a little further out, which also makes for a cleaner board outline.

Christian Walther

Christian Walther

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

How much did you spend per PCB roughly? Does it depend on a number of components placed or PCB area only?

Are you sure? yes | no

USD 16.40 per board, with some promotional offers. (PCBs 20, components 64, assembly 30 (promotion), DHL shipping 13 (promotion), bank fee 7, VAT & customs 30.)

The PCB price depends on area, the assembly price only on the number of components. You can get an automated rough quote at https://www.pcbway.com/quotesmt.aspx (without components, those are only added in the final quote made by a human).

Are you sure? yes | no

thanks for all of the details :) I'll try them I guess

Are you sure? yes | no

This is great news, you got it before the Spring Festival. I suspect they understood your instructions about the capacitors, but simply didn't have any like that in stock — they are probably more expensive when small, too? You could always specify a model number for a part, and demand exactly that, but that would probably increase the lead time and price. I always have problems testing the matrices, especially after manual soldering — the ISS chip is very easy to solder wrong for some reason. It's one reason why I moved to TFT screens instead.

Are you sure? yes | no