-

1Print the plastic parts

I used the Prusa i3 Mk2.5 to print the parts. Your Mosquito hotend should fit into the hotend with barely noticeable clearance. If it feels loose or too tight, adjust the Extrusion multiplier.

-

2Prepare the PTFE bowden tubing

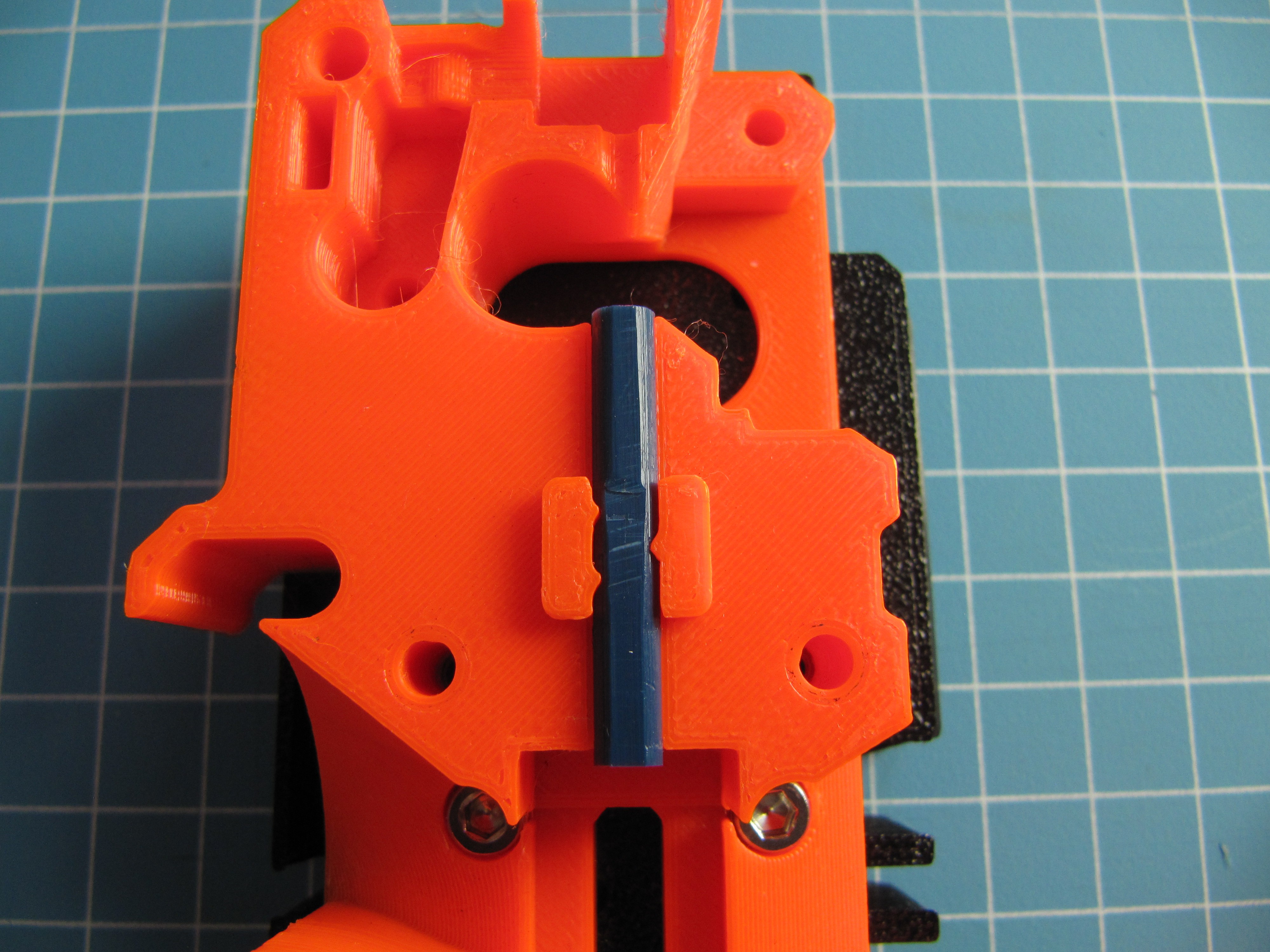

It is necessary to cut some kerfs, corresponding to the teeth on the extruder body. I made a 3D model for a gage to make the cutting easy.

With FDM printing the hole for the tubing inside the extruder body will not be perfectly round. If you put the parts together and see a gap between the extruder body and the motor plate, it will be necessary to flatten the tube with a sharp knife (result is shown in the next picture).

-

3Assemble the motor, gears and filament sensor

Just follow the printer handbook.

-

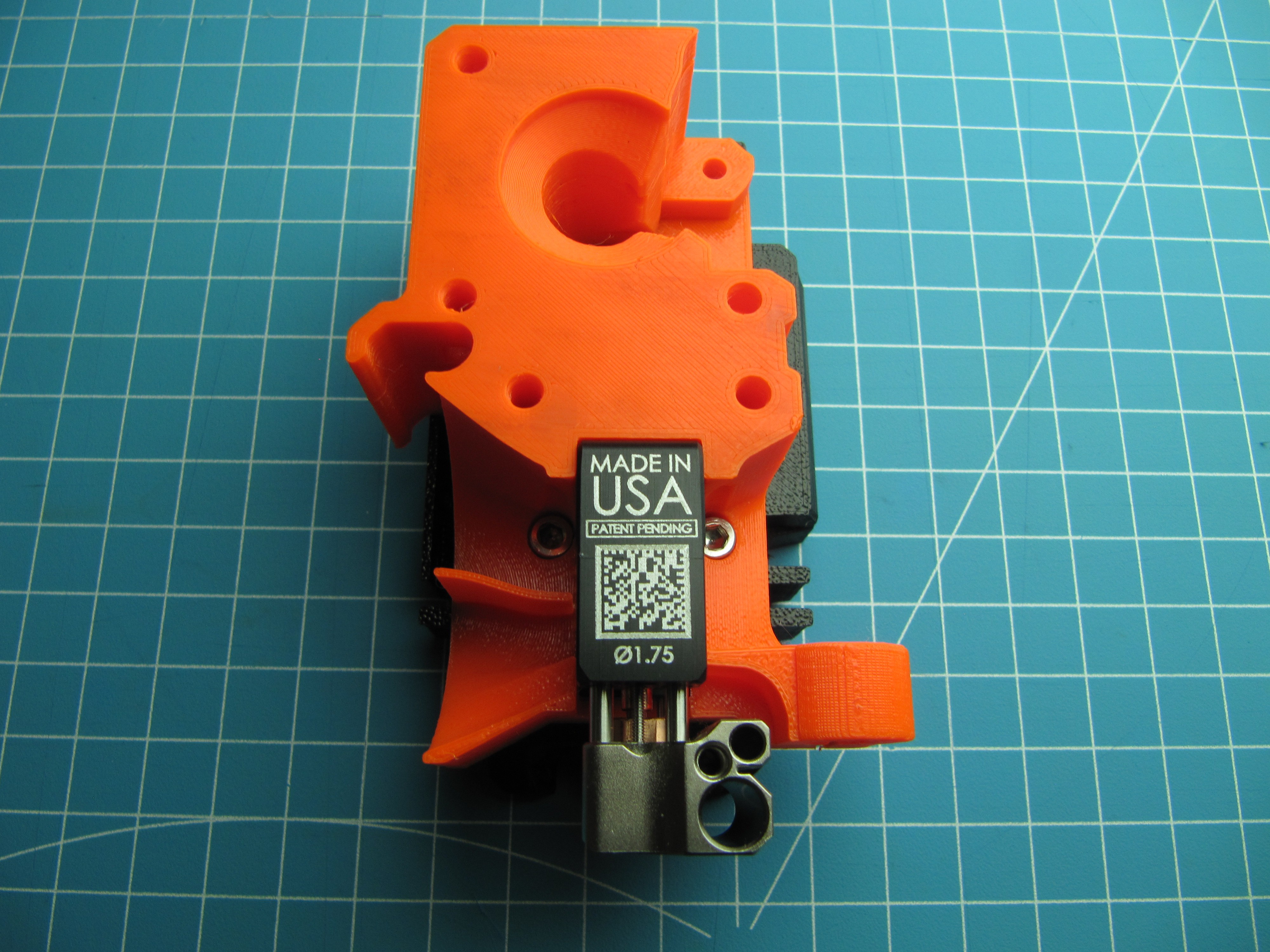

4Remove one bolt from the hotend

There are two bolts in the heater block to prevent the heater cartridge and the thermistor from sliding out. In order to assemble the extruder cover, you have to remove one of the bolts:

-

5Finishing it

Insert the heater and thermistor. Mount the extruder, do the wiring and have fun.

Extruder for Prusa i3 MK3S

Extruder with Mosquito hotend for the original Prusa i3 MK3S

Cadmium

Cadmium

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.