-

Log #6 development update

12/22/2019 at 16:38 • 0 comments![]()

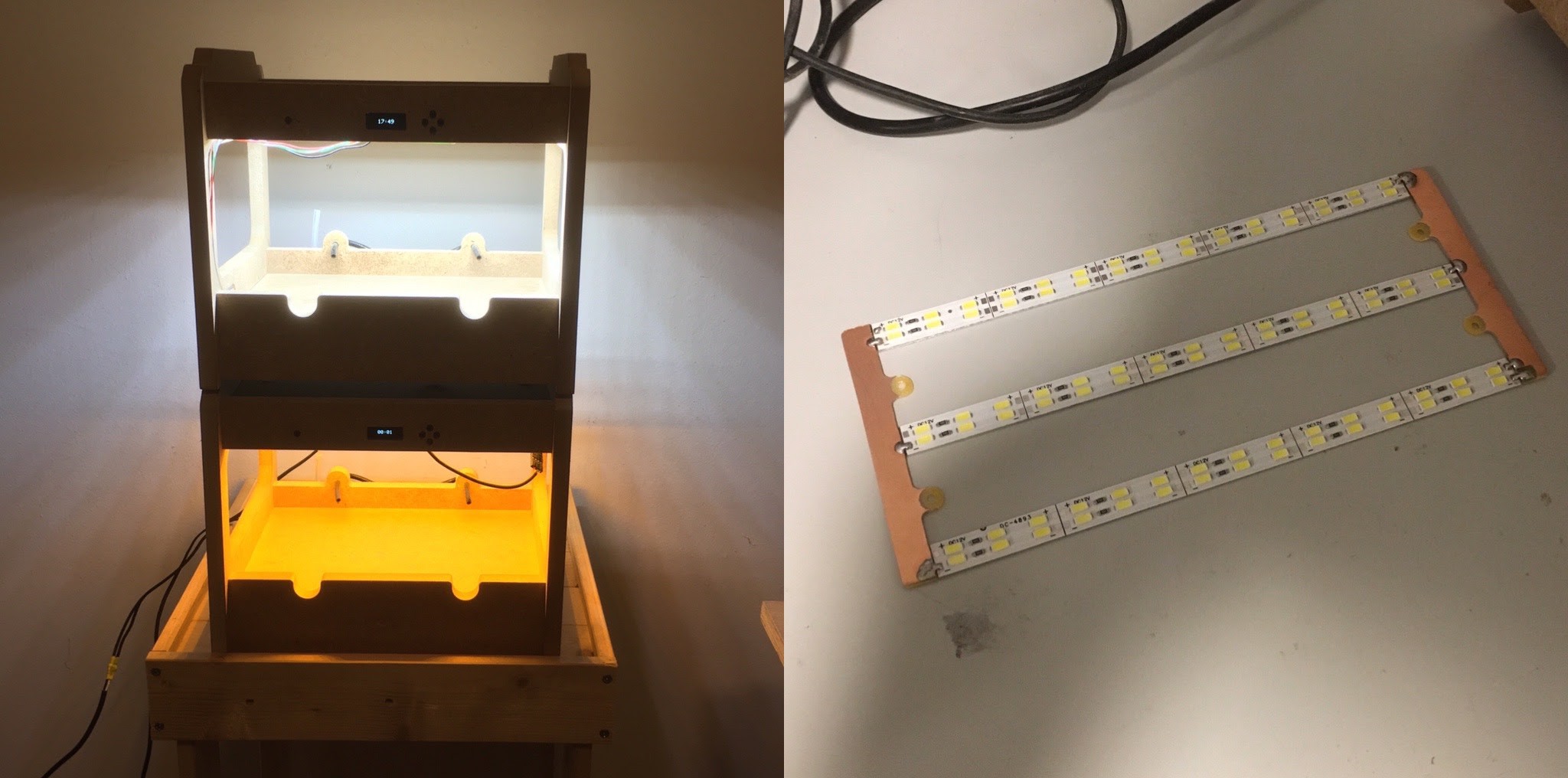

I received another pair of lights recently and installed them in one of the test devices, I will be testing it with some microgreens after I've installed a camera to track the growth. Another thing I am currently working on is a vacuum former to make custom trays for different plants, I would like to make some Microwth's with different heights to grow leafy greens and herbs.

The first results from the vacuum forming look promising, but I still need to settle on a design to vacuum form. I wanted to create a tray design with a flat lid to make it easier to create new ones for different growing mediums/techniques. However it seems like this won't be the easiest to vacuum form, I will be updating the design to see if the results will improve.

![]()

-

Log #5 First grow

12/08/2019 at 12:26 • 0 commentsGrow results (cress) This week I grew some microgreens in the Microwth without intervention, there were a few glitches that seems to be fixed by adding an adequate power supply and shielding/filtering to the pump. The results of after a week are really nice as can be seen above.

Github

I've uploaded all the hardware and software files to Github, set up proper version control and added some issues to work on. The current master branch aren't production ready files but I will continue getting the files ready in the dev branch.

Construction

I received the tee barbs and designed a bracket to nicely mount the tubing. The next feature to add to the design is a water reservoir, I've been looking for something but I am not quite sure where to mount it.

The 3D files can be found on the Github page and are available in step and ipt format. An assembly instruction will be made but I will focus on new functionality first.

Cloud software ideas

The standalone software is fully working and only a few enhancements should be made, that's why I will start looking into ways to connect the systems to the internet for more precise control and data logging.

I would like to create something to help with the planning, send reminder and warnings. For this I would need a web application with an API to connect the Microwth to.

-

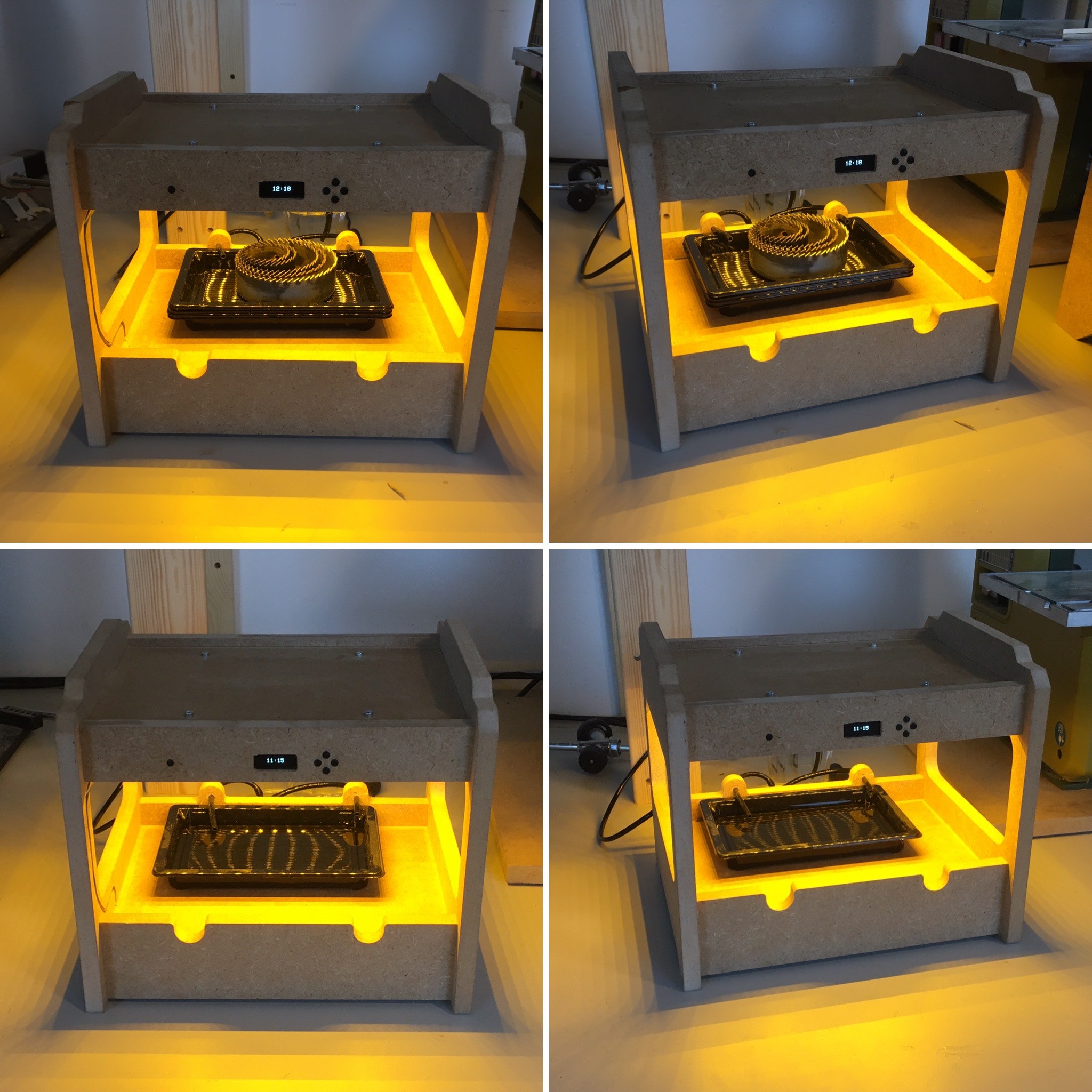

Log #4 Let's start growing

11/30/2019 at 11:41 • 0 commentsLast week I installed the first motor controller and wanted to start growing, but when I was testing the device I ran into some issues. I wasn't able to upload any program to the ESP it did still run (unlike the other time when I broke the ESP ;)) but it started spitting out garbage over serial after a few seconds. When I took it apart and installed a new controller the issues for this unit were resolved. So I started testing the "broken" controller and to my surprise, I was able to upload code again. I hypothesize that the power source is a bit unstable while the motor is connected and that this caused some issue when I uploaded some software, however when I disconnected only the motor I couldn't get it working either. When I was disconnecting it further I did found a power connection that might have been the culprit, but I don't know for sure. One thing is for sure and that is that there's some noisy power when the pump is running because the OLED starts glitching.

At least the first version is working I added a pull-down resistor to the mosfet to keep the pump off when the system is powered up, and I ran the first successful watering test. I've just sown some microgreens to grow the coming week.

![]()

Top:

Sown trays stacked and weighted to germinate in the dark and establish a good rooting inside the growing medium.

Bottom:

First watering test. -

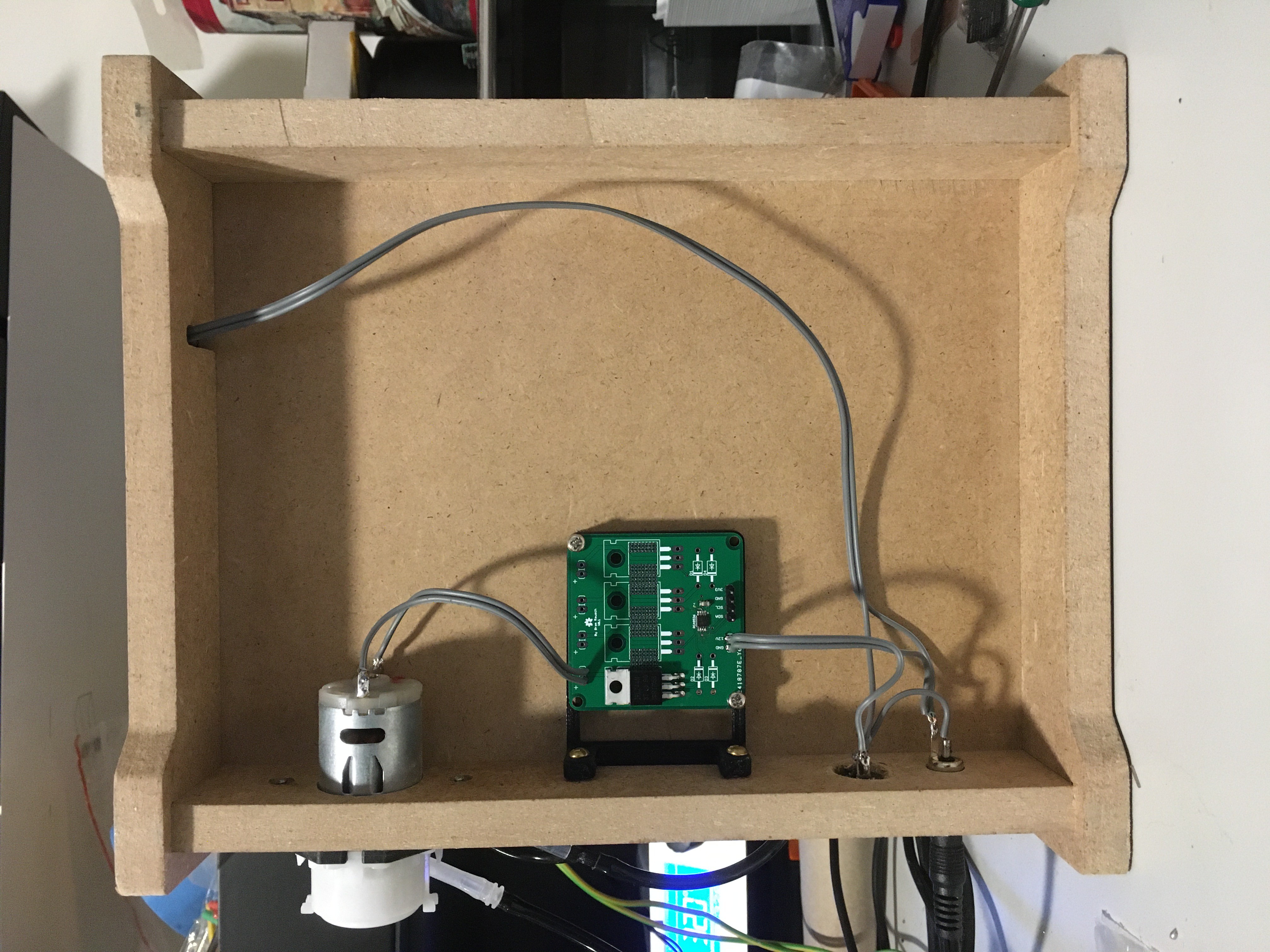

Log #3: pump controller

11/22/2019 at 23:01 • 0 comments![]()

I finally received the PCA9536 and assembled one of the pump controller boards. The board is mounted in the bottom area with the help of some 3D printed brackets. The board is connected to the 12V supply and the i2c interface that is routed in a slot to the controller. The frame used in this build didn't have this feature yet so I've hand milled it into the frame, the new design has this slot milled with the CNC making it less noticeable.

When I connected the controller I found out that the default pin state of the PCA9536 switches the MOSFET. I am currently using a workaround in the software, but this will be fixed in the next iteration of the hardware because it's currently possible that the pump would start pumping if the system crashes.

I am currently working on debugging the code and once that's finished I will start testing the automated growing feature and new light with some real microgreens, I will keep you updated.

-

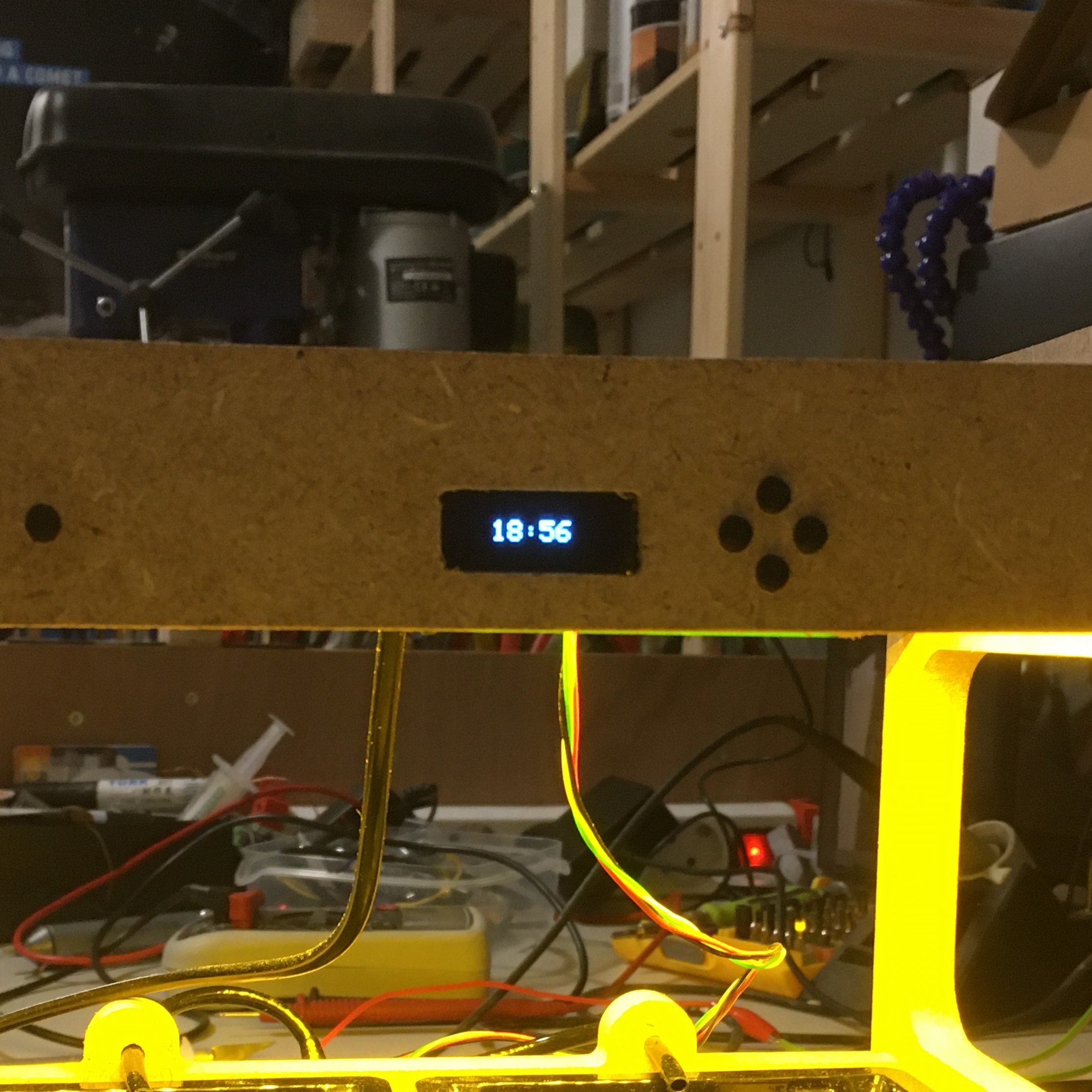

Log #2: Sofware and pump update

11/16/2019 at 19:12 • 0 commentsSoftware changes

![]()

Centered time The software now includes a setup to start a growth, this settings goes through the lighting and pump settings. I couldn't quite decide which settings would be best for the pump so I've implemented an interval timer that turns the pump on for a set amount of time.

This new code version (available on Github) has been cleaned up and the interface is easier to use due to a less nested interface. I've also centered all the text on the display.

Next up will be adding the pump output over I2C and adding labels in the grow setup.

Pump and barb

![]()

3D printed tee barb I have ordered some tee barbs to split the pump output to all the trays, but since these aren't in yet I will be using a 3D printed barb it's a bit leaky but that's something some epoxy will fix :) I am also waiting the the PCA9536 but I expect these sooner then the barbs so I will just be waiting on them. In the meantime I've been testing the pump to see what happens when you split the pump output. The first results show a 25% difference between the two output, this is pretty significant so I will try using a barb design more like the ones I've ordered to see if that makes any difference.

-

Light tests #1

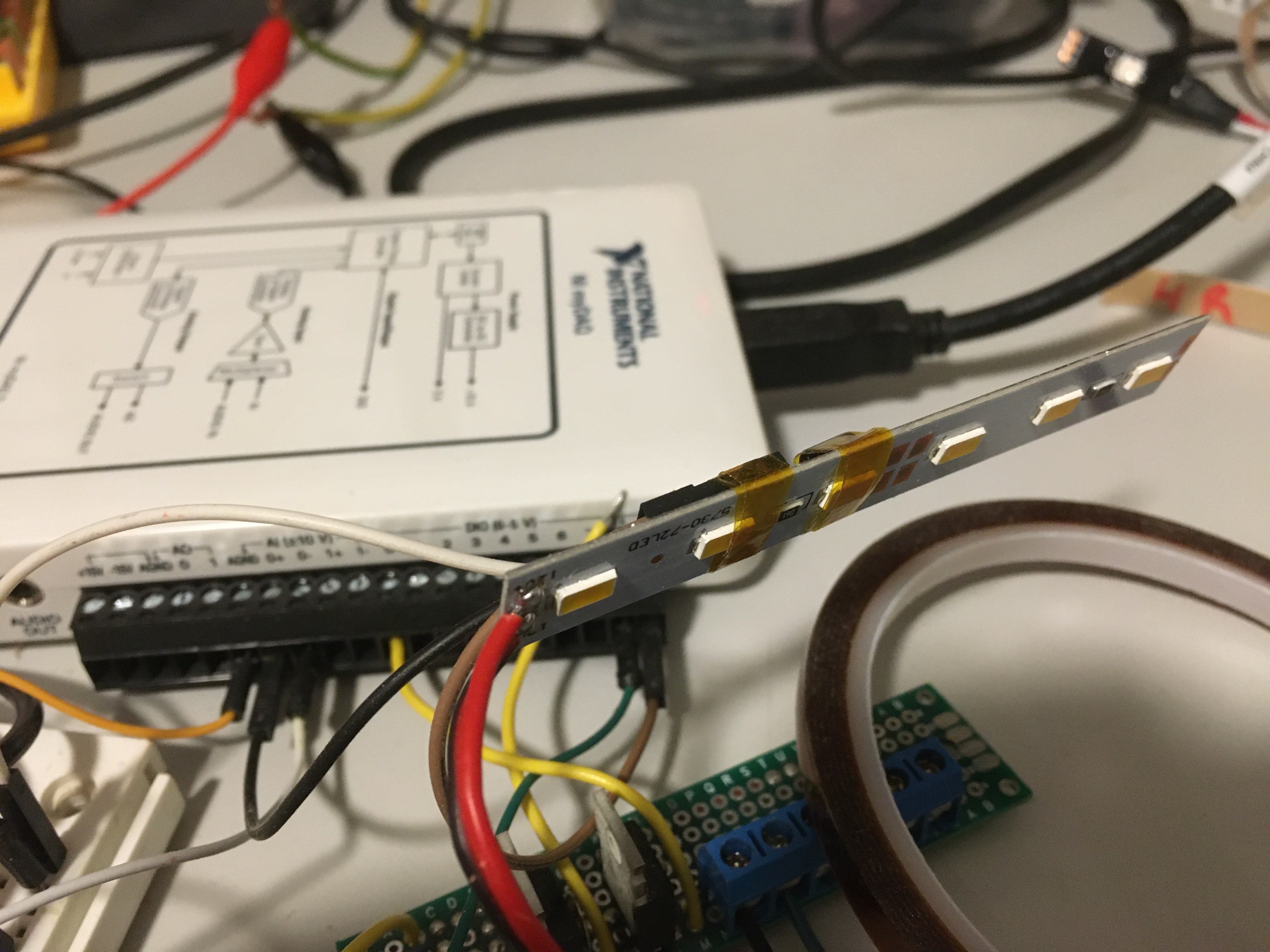

11/11/2019 at 20:10 • 0 commentsThe first lights I will test are these two Chinese led strips:

These lights don't have much information on the seller page but they are advertised as grow lights. I will be growing some microgreens under them to see how they perform. microgreens don't need a lot light and too much might even result in too spicy microgreens so they also need to be tasted.

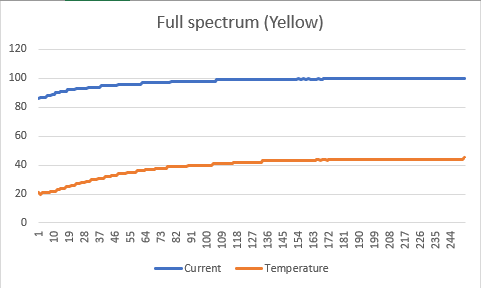

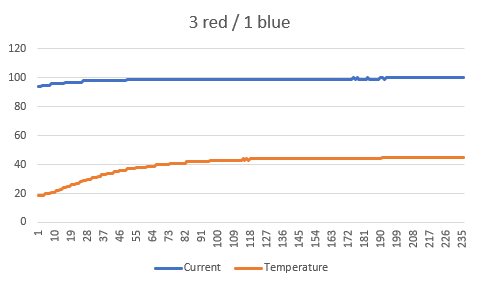

I started by testing the current draw when I noticed that the current started rising when left on for a while. So I made a small setup to measure the temperature and current at the same time. The results(below) show that both LEDs get a steady temperature/current draw at 44c, and that it might be worth it to add some passive cooling especially for the full spectrum LEDs.

-

Log #1: Design rev 1

11/07/2019 at 17:50 • 0 commentsDesign requirements

The design of the Microwth has to meet a couple of design requirements:

- The whole system has to be easy to manufacture

- The design has to be good looking

- The device has to be easy to use

- The devices should be stackable to create bigger farms

With these thing in mind I designed and manufactured the first version, that will be used to test different electronic configurations.

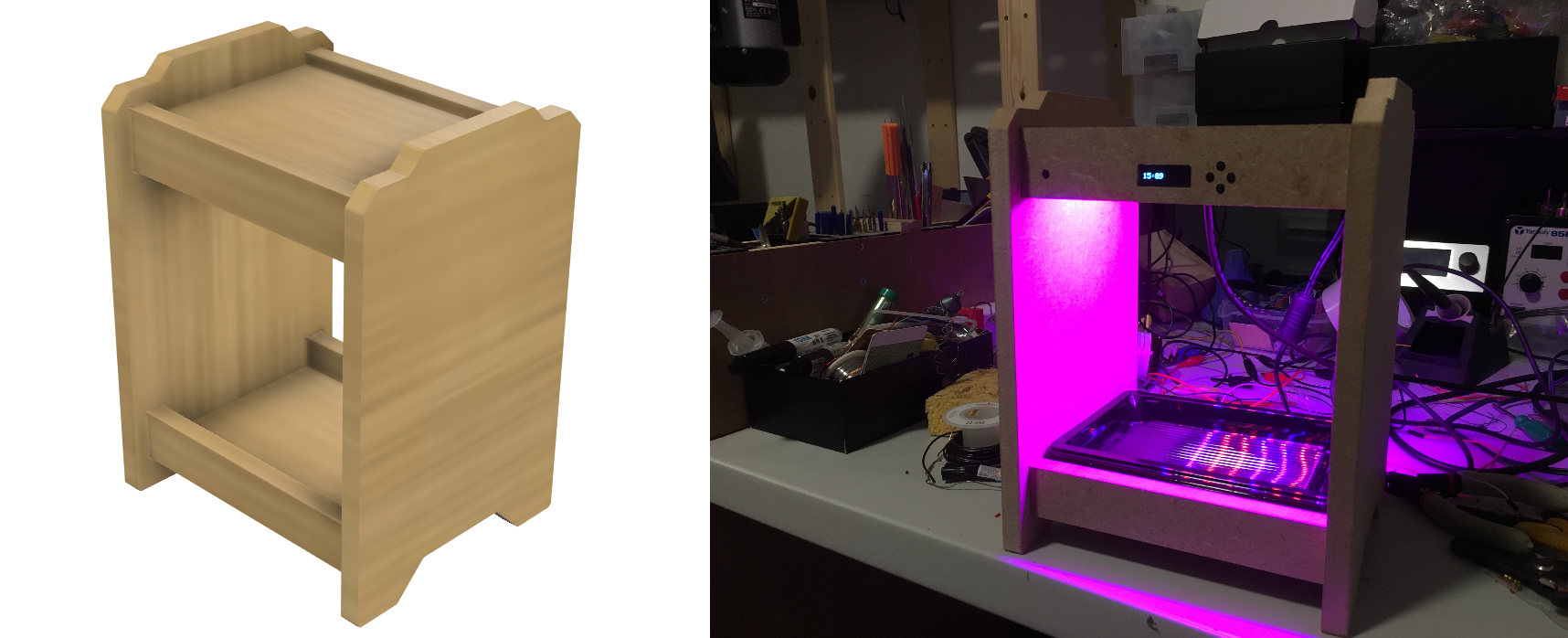

Design version 1

![]()

The first design on the right allowed for stacking, but after manufacturing and testing proved to have some design flaws.

- The growing trays in this design are hard to remove because there's no easy way to lift the trays up.

- The current lights gave a comparable result to the natural lights but the height could be reduced to increase the light intensity for better grow results or reduce power

- The closed side panels create a closed look and illusion that it takes in a lot of room, it might also look better if the plants are more visible.

Improvements in the next iteration

In the next version, I will include cut-outs to easily remove the grow trays, the height will also be reduced to lower the lights, and there will be an extra cutout in the wooden side panels to create a more open design. This version will also include a pump to automate watering for this the bottom height had to be increased to fit the pump.

![]()

Microwth - automated microgreen farm

Microwth enables you to grow your own soilless microgreens indoors to add to your meals

bram

bram