LINKS SHORTCUTS!

⚠️ PolySense got the wildcard award of the Hack A Day prize!

| 💥 MORE NEWS! 💥 1) 🎓 RESEARCH 2) 💀 HACK A DAY ARTICLE 3) 🤖 MAKER FAIRE 4) ⚡ ARS ELECTRONICA | 📜 PROJECT LOGS📜 1) 🔬 REVERSE ENGINEERING 2) 🥽 HCI EXPLORATION 3) ✨ ART INSTALLATIONS 4) 🔥 HEATING + SENSING |

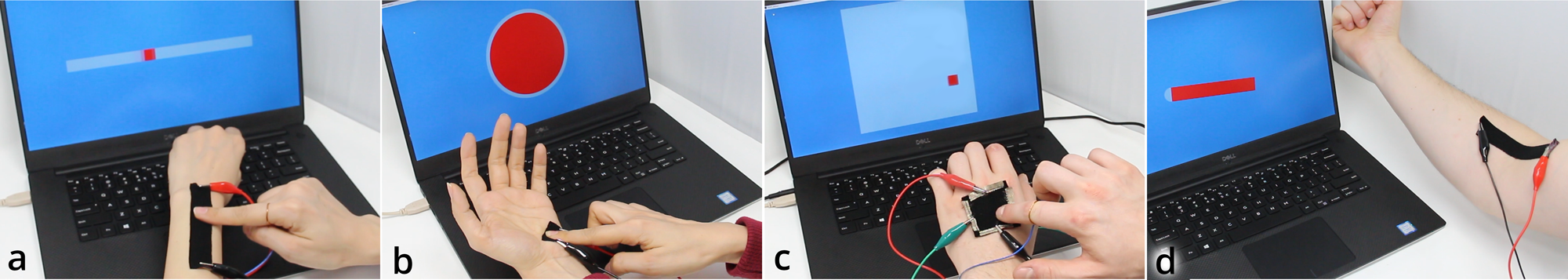

Application examples

What!?

We use a chemical process called in-situ polymerization (explained later).

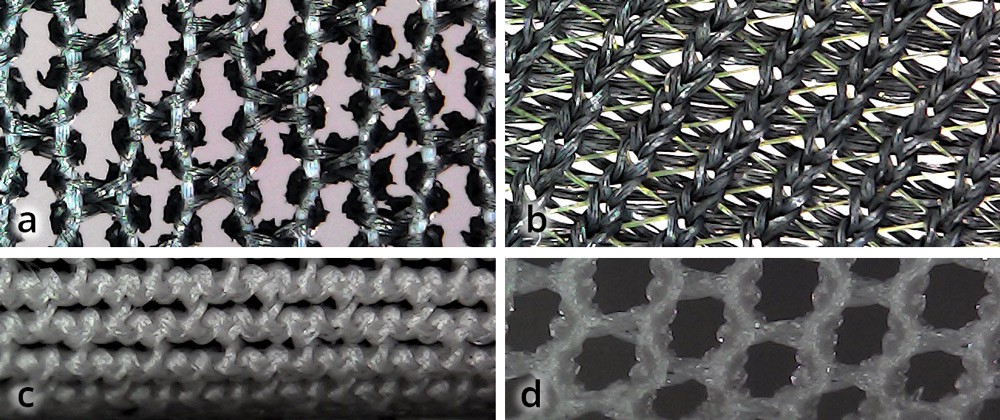

It allows functionalizing almost anything fibrous and porous materials (natural ones like cotton or cork work better than synthetics in general).

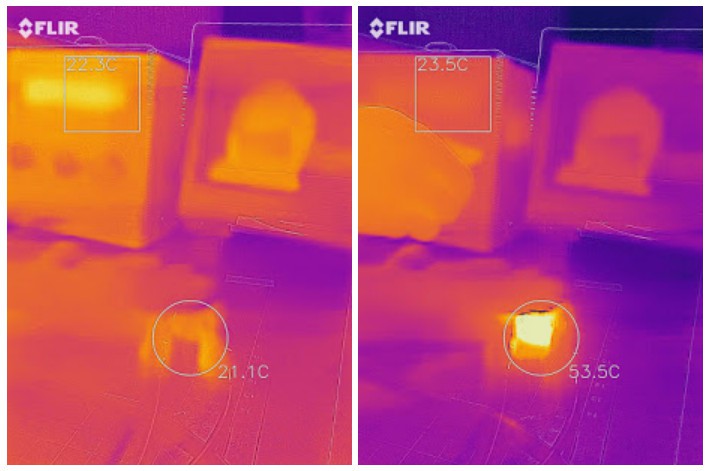

Once polymerized, your originally non-functional material ends up with sensing capabilities:

- pressure

- stretch

- capacitive

- humidity

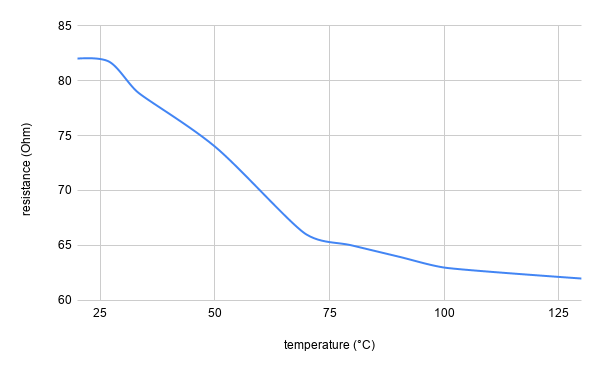

- temperature (bonus: heating is also possible)

Why!?

In our hackerspaces and research labs, we explored musical textile interfaces and we used a commercial piezo-resistive material (pressure sensitive).

The only good one was expensive and became hard to get because of a new exclusive contract with another company.

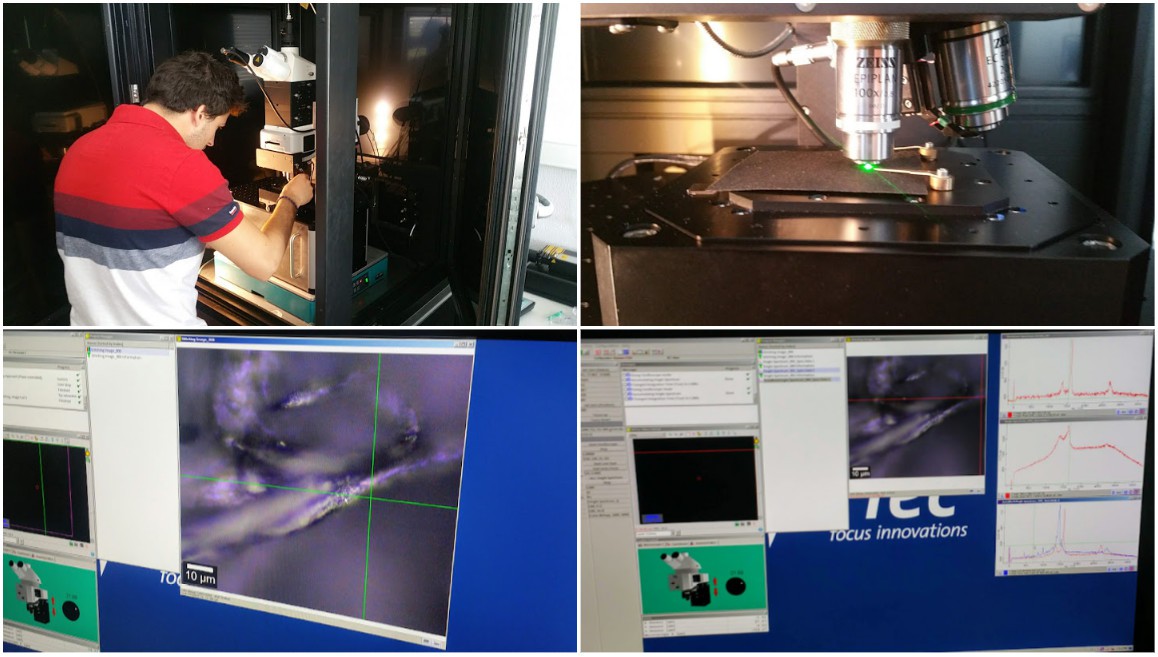

So with material scientists, we reverse-engineered it, and made a DIY process simple enough for the kitchen of our hackerspaces.

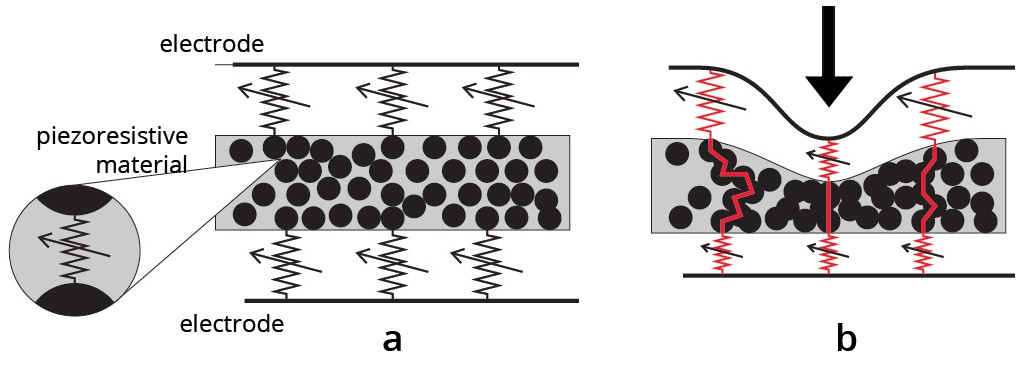

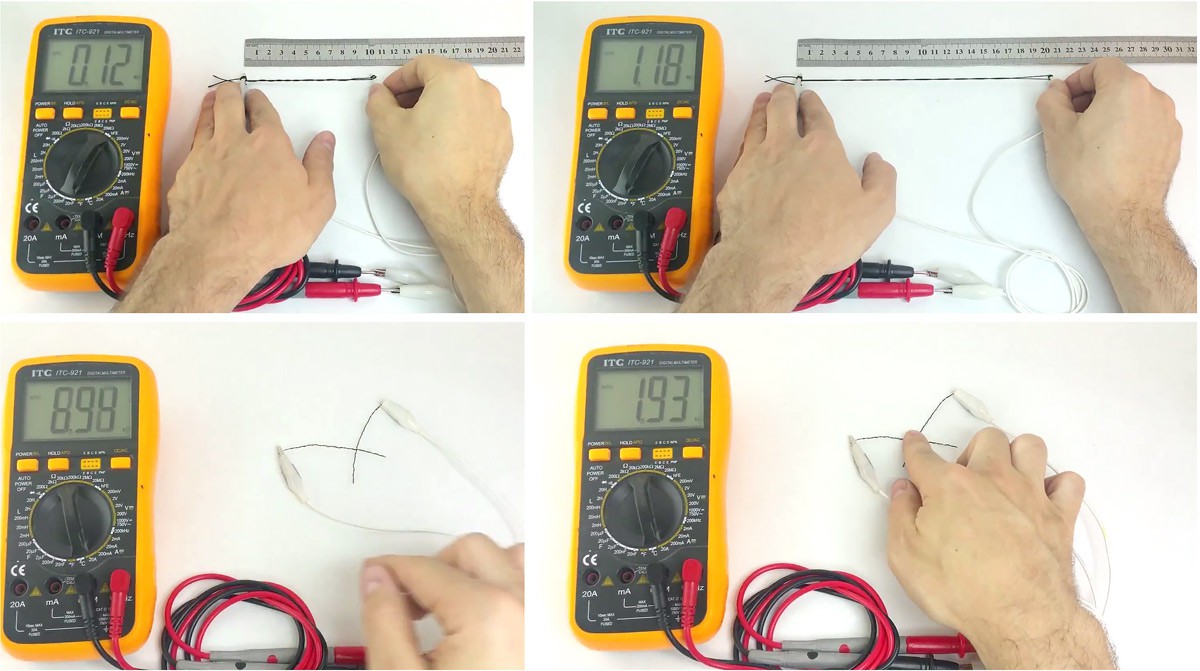

Illustration of the piezo-resistive effect:

How?

The following video summarizes the process, but you'll need chemical products:

- Europe source: Pyrrole + Iron Chloride

- US source: Pyrrole + Iron Chloride

...and get a machine to mix your materials for about 1h, example:

- chemistry magnetic stirrer

- ice cream maker

- a batter mixer

- a camping washing machine

- or you can build it with a drill and a bucket for example.

Protocol summary

(adapt X to your quantity):

1) Water: ( X ) ml - fill the container so that there's about 75% of textile (but don't put it yet!)

2) Pyrrole: ( X / 250 ) ml - add it and stir it

3) Material: add it and keep stirring for 10 minutes

4) Iron chloride: ( X / 100 ) g - keep stirring for 30-60 minutes depending on the material

5) for capacitive sensors: you can repeat this procedure, or multiply these proportions and polymerization time by 2 to 5 (depending on the material too).

💡💡💡💡💡💡💡💡💡💡💡💡💡💡

The process, called in-situ polymerization, is particularly unique because:

- First we soak the textile with the monomer (steps 1 to 3)

- Then we trigger the polymerization (in-situ, or in place)

This reaction creates "a kind of molecular dyeing with carbon" which has much stronger properties than a coating approach.

💡💡💡💡💡💡💡💡💡💡💡💡💡💡

Sourcing the products

The chemical products were ordered from 2 possible sources:

- Europe:

https://www.glentham.com/en/products/product/GK9750

https://www.glentham.com/en/products/product/GK2873

- US:

http://fishersci.com/shop/products/pyrrole-tci-america-3/P057425ML

http://fishersci.com/shop/products/iron-iii-chloride-hexahydrate-99-analysis-acros-organics-3/AC217091000

Note: every material reacts differently so you'll have to do a couple of tests to get the right chemistry ratios, and the right timings...

Cedric Honnet

Cedric Honnet

Note: an academic paper about it was published at the

Note: an academic paper about it was published at the

Chuck Glasser

Chuck Glasser

Boris van Galvin

Boris van Galvin

xdylanm

xdylanm

Michael Barton-Sweeney

Michael Barton-Sweeney

Thanks for your great documentation!

that is really an interessting e-textil-concept and i like to try it!

in your yt video you are using a *camping washing mashine* ?