-

A unexpected glimpse of hackaday.com's global audience

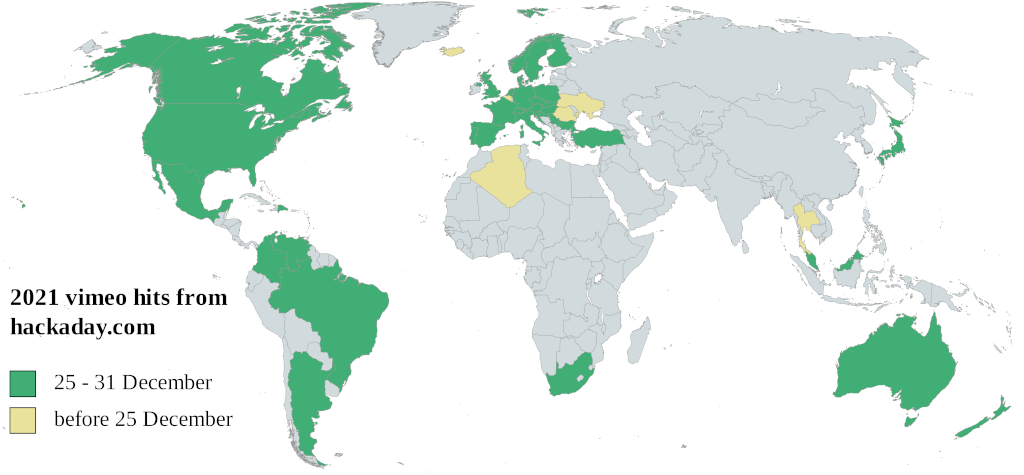

03/02/2022 at 05:23 • 0 commentsThis log is about the unexpected breadth of a narrow glimpse into where in the world people read hackaday.COM (vs. hackaday.io).

tl:dr; a brief traffic bump from . . . all over the map

![]()

I use vimeo to share videos. Vimeo shows me basic stats like which domains and which countries people click in from. Since learning a little of how to use vimeo's limited stats interface for free accounts, I've become something of a junkie for watching all the different countries where someone thought something here was worth a minute to watch. Most views come from hackaday.io. Very few views come from hackaday.COM. Few viewers visit this project (because superseded).Last Christmas day (2021 Dec 25) I noticed a "big" bump in traffic. "Big" here meaning more than the usual sparse dribble — over 200 views by the 28th.

Nearly all video views were coming from hackaday.COM.

All of the hits from hackaday.COM were viewing the lead video for this project.

That was all sorts of unusual. So I checked at hackaday.com and found a blog post about [Nemo404]'s make of "MINI LINEAR ACTUATORS FROM DVD DRIVE PARTS" by Jenny List, which she concluded with: "And introduce yourself to the world of CD drives for CNC machines by taking a look at this mill." ☚ link to this project. (A citation for Christmas☺- thanks Jenny!)

Vimeo was seeing people who:

- read Jenny's article at hackaday.COM all the way through to the last sentence, and then

- clicked the link to this project, and then

- clicked in this project page to watch the video.

So figure that was a pretty small slice of people who saw the article at hackaday.com.

Even that small slice of people reading the article at hackaday.com about something else, 314 views between Christmas and New Years Eve, came from 38 different countries! (...already 37 by the 28th, extended the window to the 31st picks up a viewer from Japan)

Top 10:

- US

- Germany, Italy

- (tie)

- UK

- Canada, Spain

- (tie)

- France

- Netherlands, Sweden

- (tie)

- Denmark

The rest, alphabetically:

- Argentina

- Australia

- Austria

- Bulgaria

- Brazil

- Colombia

- Croatia

- Czechia

- Dominican Republic

- Ethiopia

- Faroe Islands

- Finland

- Hungary

- Japan

- Malaysia

- Mexico

- New Zealand

- Norway

- Poland

- Portugal

- Serbia

- Singapore

- Slovakia

- Slovenia

- South Africa

- Switzerland

- Turkey

- Venezuela

Aside: in the rest of 2021 vimeo recorded 94 views from hackaday.com, all for the same video, in 358 days (0.26/day) before this run of 314 views in 7 days (45/day≈170x); the map shows a few more countries from the rest of 2021 in yellow.

map made with mapchart.net

-

About milling: there is no slow; only chips or no chips

11/18/2019 at 07:15 • 3 commentsAn elementary but not obvious fact of milling: a machine that's weaker cannot just simply go slower. Every time a cutting edge of a spinning mill bit comes around, it has to be far enough advanced into new material to actually cut and carve off a chunk of material. Otherwise it's just rubbing, and maybe ablating some material, but mostly making heat rather than progress. Trying to remove material that way quickly turns into too much hotness for either the cutter or the material. Like, stirring a little puddle of melted acrylic. Or if the spindle motor can't even make enough power to heat stuff, then nothing happens.

So there is no "slow" in milling. The machine either can push the cutter through the material fast enough to push each edge into new material, or it can't.

Cognoscenti call this "making chips".

My ignorance of this was a critical enabling capability for starting this project. Because clearly there's no way a CDROM sled can shove a mill bit through anything harder than floral foam.

-

About scavenging

11/18/2019 at 06:57 • 4 commentsPart of the voluntary difficulty of this project is the game of scavenging. Buying stuff is a kind of defeat. Of course you can buy a whatever for whatever. But justification for liberty in buying parts very quickly converts to warrant for simply buying a CNC mill that will be better for less than the ultimate cost of completing an inferior project paid for in small increments of direct cost + time not actually using the better machine.

On the other hand, working through building a whatever from temptingly cheap/found parts is a great way to learn what is the value of a more costly well-finished product.

Making stuff on the cheap is a hobby, not a profitable enterprise. If not fun, then likely not actually economically justifiable. Assuming first world circumstances where everyone specializes in some way to generate income more efficiently than than they can avoid expense by not paying others to do what they do more efficiently.

Paul McClay

Paul McClay