-

A bit of progress

01/21/2020 at 22:25 • 0 commentsSo, it's been a while since the last update. However it's mostly been waiting for parts to arrive from china. But in the mean time i've made some progress.

firstly, the sides of the gantry plates were awful, the mounting holes are machined, but the outline was done on a plasma cutter to save time. so i spent an entire evening filing and anding the sides clean and flush to make it all seem way nicer to the eye.

![The sides of the gantry plates as received The sides of the gantry plates as received]()

so i'm pretty happy with the result after some hard manual work

![]()

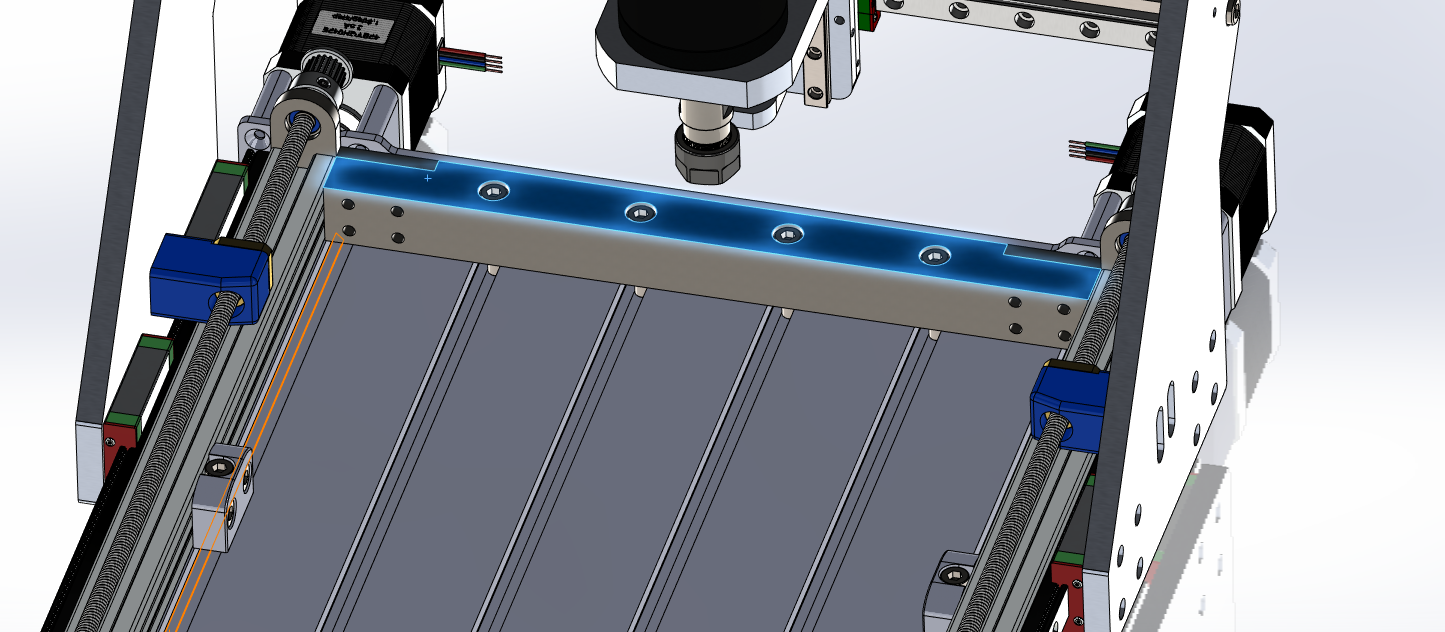

secondly, all the MGN rails and almost all of the carriages are in. Also some M3 Bolts, M5 bolts, T-slot nuts, spacer plates and 2020 extrusions have been received. So i've been able to start assembling the y-gantry.

![]()

pretty happy with the overall fit and finish. The blue printed motor mount plate is just a temporary place holder to check the design.

![]()

I designed the gantry plate to be mounted with M5 bolts to the 2020 extrusions. Now did i find out that the extrusions i ordered had a larger inner hole, so i've drilled out the gantry plates and mounted the gantry plates with M6 bolts, however i just had one bolt laying around, so it is temporarily improvised with a threaded rod and a bolt as you can see. But i ordered the right bolts and should be a drop-in replacement once i have those.

after i got my new ER11 collet set in the mail, i designed and printed a nice small box for it to prevent me from losing them.

![]()

and lastly i remembered i had a random block of scrap metal laying at my parent's house wich would be perfect for the front and back frame rigidity improvement brackets (i'm not actually sure what to call them, see the last log. those).

![]()

i've contacted someone from my uni to check when i can access the workshop to machine this block to finish. But as the other 2020 extrusions are not yet in, there's no real reason to hurry.

For the next few weeks i'll be focussing on my examns so i'll probably post an update as soon as the complete frame is ready for assembly.

It's great to see the interest in my little project!

-

Base design finalization

12/17/2019 at 16:31 • 0 commentsSo after considering Paulvdh's comments, i came to the conclusion that the base did lack rigidity and I wasn't quite happy with the assembly. The design relied too much on proper assembly and tramming and not enough on proper machining. As i'd rather spend an hour or two extra in the workshop so i can just throw the parts together and have them aligned and square and everything.

I've decided to add about 20 euro's of steel and an extra day of workshop time to improve the base.

The width of the base is now determined by a big chunk of precisely machined steel in the front and back instead of waterjet cut sheet steel. This will also greatly improve the rigidity of the base plate, and add some mass to the whole thing.

I've decided that this will be the final design for now, and will start making the drawings and buying the rest of the parts. The MGN rails i ordered this black friday are also in, so progress is coming.

I've uploaded a 3D pdf of the latest version. Interested people can take a look at this. Tips are still welcome and will be considered.

I'll probably be busy and away this christmas, so the next update will probably come somewhere around the half of januari. Happy new year everybody! ;)

-

Side plates done!

12/14/2019 at 15:50 • 0 commentsSo, the side plates are done! My friend did a perfect job, and i will only need to sand the surfaces for aesthetics.

![Side plates machined - front Side plates machined - front]()

![Y Gantry side plates - back Y Gantry side plates - back]()

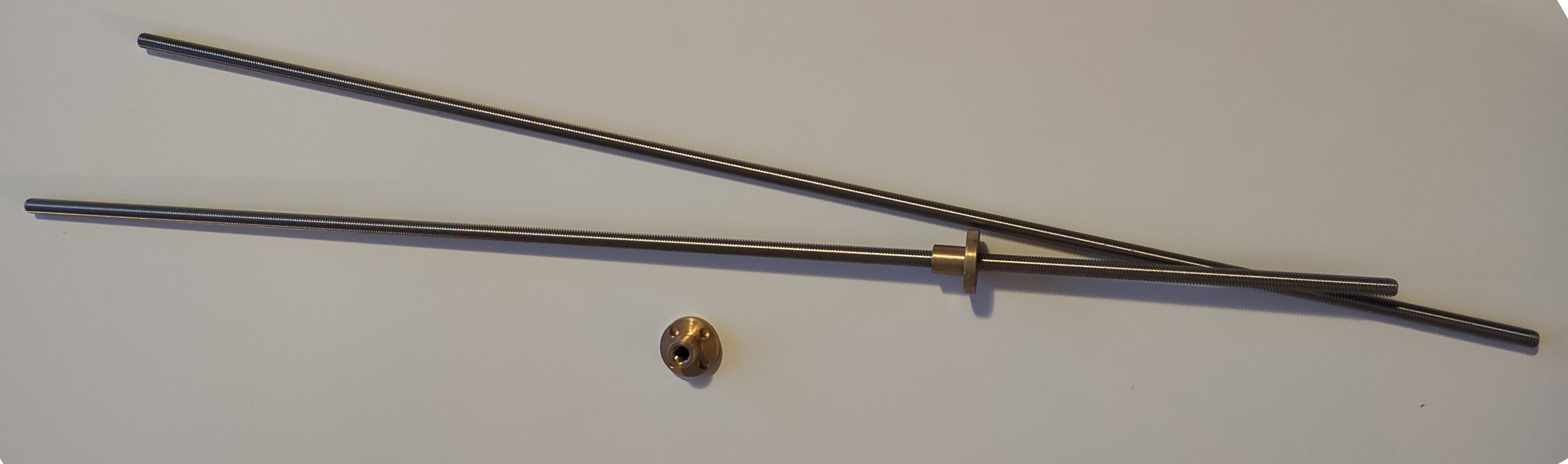

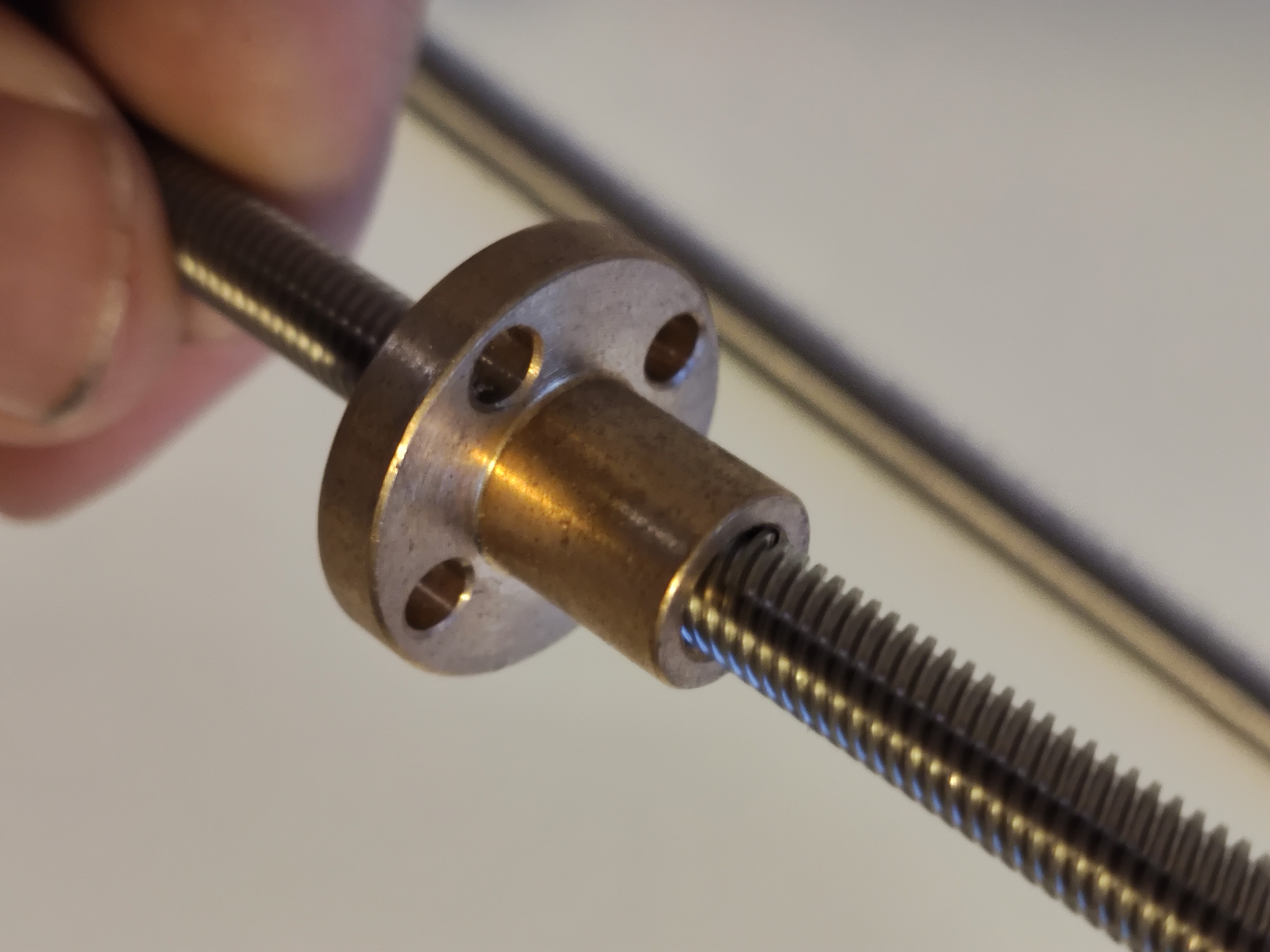

Secondly, the Leadscrews for the Y-gantry are in! they are okay-ish quality, but the nuts have a completely unacceptable amount of play in them. so i will have to find new ones. Although i had a known good quality nut laying around and that worked perfectly without any noticeable play, so the rods themselves are good (enough, for now at least).

i will probably throw them in a lathe for finishing sometime next week.

![500mm TR6*6 leadscrews - Y gantry 500mm TR6*6 leadscrews - Y gantry]()

![The crappy nut that came with the leadscrew The crappy nut that came with the leadscrew]()

-

Small design change

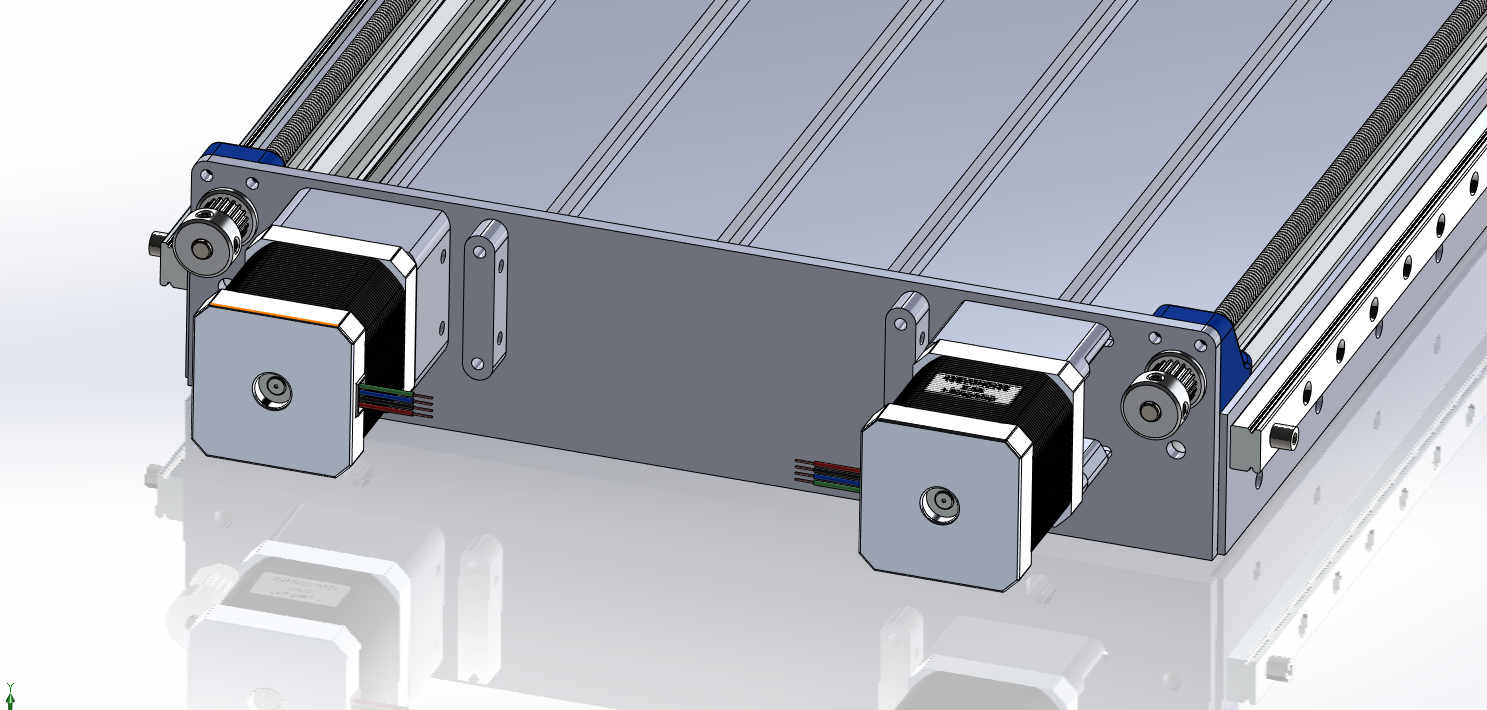

12/12/2019 at 17:38 • 0 commentsSo i decided to change the Y-axis motor configuration. The design used to use one single NEMA17 Motor with a 600mm closed GT2 belt to drive the two leadscrews synchronously. However to simplify the tramming and tweaking of the physical unit, I decided to change it to two motors each driving it's own leadscrew.

Also, both Y-Gantry side plates are done, i'll post the result later on.

-

Y-Gantry side plates and animation

12/11/2019 at 15:57 • 0 commentsSo the project has progressed a bit again. The side plates are in the making and almost finished today, just some cleaning, sanding and finishing up to do.

![Y-gantry Side plate - in progress Y-gantry Side plate - in progress]()

Secondly i finished the render of the CAD model that shows the folding mechanism. Note: Due to the fact that my trusty dual Xeon e5645 isn't really cutting it anymore these days, i had to remove pretty much all the screws from the model. However the Z-gantry is fixed with four large bolts and aligned with a tolerance fit. the animation doesn't really show this. But the bar linkages that allow the Z-axis to fold down are just for easy folding and reassembly and bear no structural loads at any point during actual use.

I'm currently looking into the Electronics side of things. At first i was planning on using a simple modified 3D printer electronics setup, pretty much like my Kossel 3D printer does. And then throw something like GRBL on it. However i'm not really sure that's the best option for this build (possibly linuxCNC or Mach4?). if anyone has any suggestions, be sure to comment, chat, mail or use carrier pidgeon whatever floats your boat.

-

The project beginning, first cuts and placed orders

12/09/2019 at 16:06 • 0 commentsSo to start i have received the base plate and cut the side plates on a plasma cutter that i could use for free.

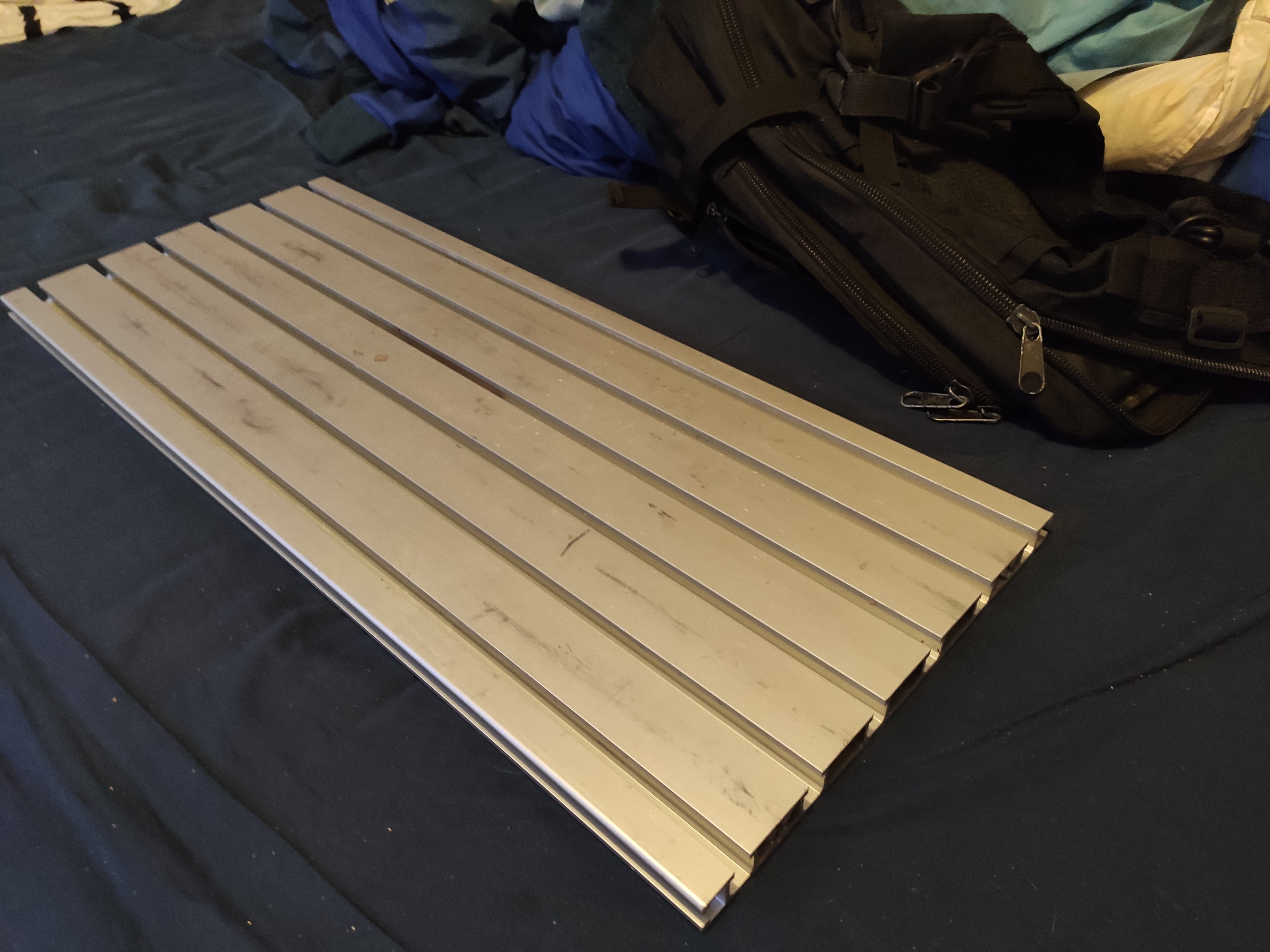

and here is the base plate for the design. It's a 19x270mm T-slot aluminium extrusion. Usually pretty expensive stuff this, but a friend did me a favor and got it for free for me.

![The baseplate as received The baseplate as received]()

![A better look at the profile A better look at the profile]()

further, on black friday i ordered as much parts as i could affort at that time to save as much money on this project as i could. The parts were going to be ordered anyway, so why not with 50% off.

these include:

- two MGN12 500mm rails

- two MGN9 300mm rails

- two TR6x6 500mm leadscrews

- various t-slot nuts and bolts

The design is currently being finalized with pretty much only some tweaks left. I will upload more pictures and renders in the coming few days.

High performance dorm room CNC

A (sort of) low cost CNC with broad capabilities and low storage volume

Oscar S.

Oscar S.