-

Motors and electronics

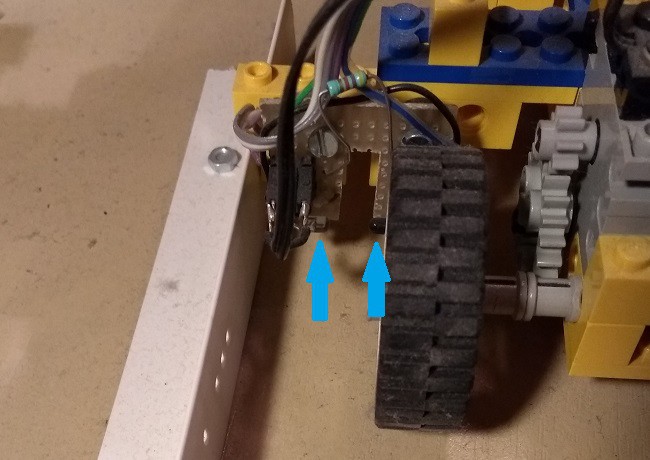

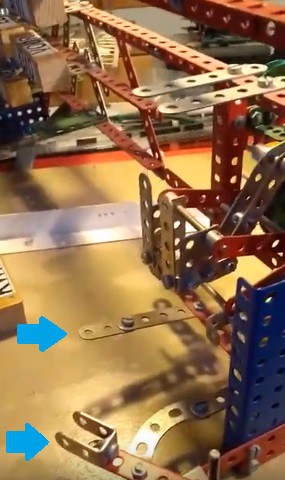

12/27/2019 at 18:55 • 0 commentsFor moving sideways, the LEGO construction is guided by a plastic rail. The rail has holes to mark the positions in the storage rack. At the end, there a few extra holes to signal to the software that the end is reached. Otherwise the truck may fall of its base if it goes too far, especially at start-up when it does not yet know its position.

![]()

Blue arrows show the position of the infrared LED and receiver, for detecting the holes for the horizontal position. You can also see the motor and some gears for the horizontal position. (For this image, the device is positioned off-track).

![]()

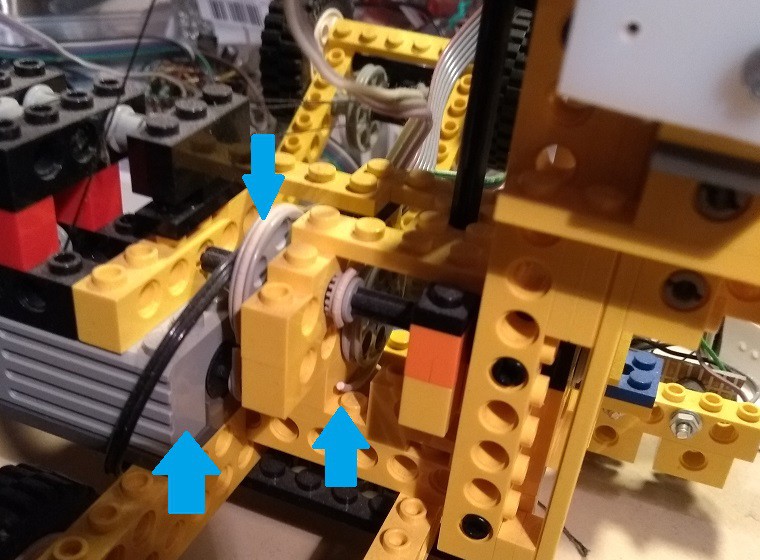

This picture shows the lift motor, one of the broken rubber belts, and the other belt (that is broken outside this view).

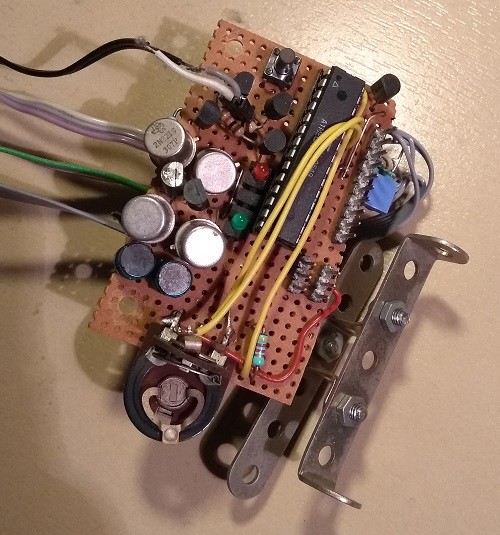

How are the motors controlled ? This is from the era before the cheap Chinese boards. And it shows that the perfboard that you have on hand, is always too small for your project...

![]()

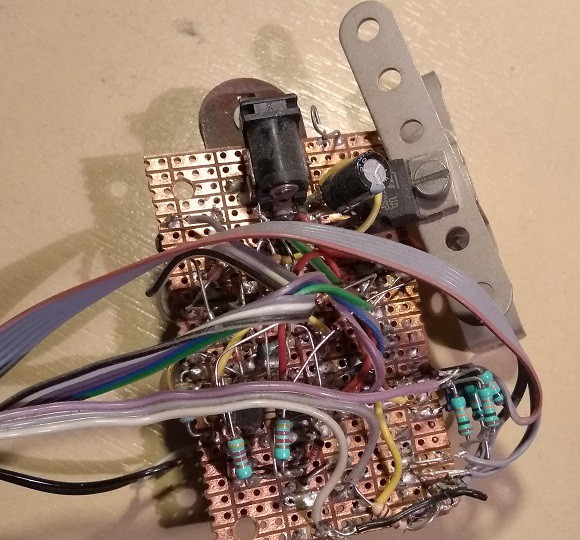

But we are lucky that the board has two sides:

![]()

Do you like meccano as heatsink for the 7805 ?

-

More about the blocks

12/27/2019 at 17:48 • 0 commentsThere are six different blocks:

- Hours, numbers 1 to 4 ( Dutch: een twee drie vier)

- Hours, numbers 5 to 8 ( Dutch: vijf zes zeven acht)

- Hours, numbers 9 to 12 ( Dutch: negen tien elf twaalf)

- Hour or Half-hour (Dutch: uur half)

- Before or After (Dutch: voor over)

- 5-minutes, 10-minutes, quarter (Dutch: vijf, tien, kwart)

![]()

The red arrows shows some places where there are holes in the bricks. The forklift has two infrared LEDs and two detectors to check presence of the holes (at both sides of the brick). Only the lower hole can be detected, the upper hole is used for the other side of the brick.

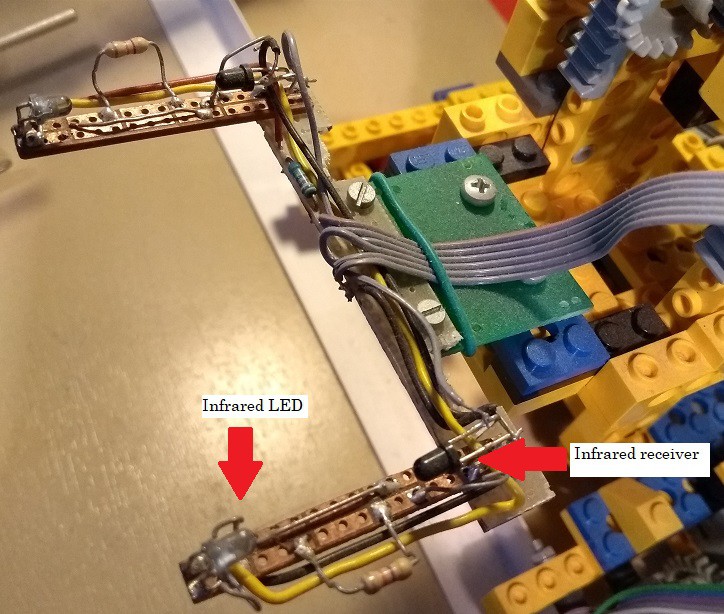

In the close-up you see the forklift with its infrared detection system:

![]()

(The resistors have only a mechanical function, they guide and hold the block to the correct position on the fork.)

When a block is in the lift, it provides a two-bit code with its holes. Only 3 combinations are used for most blocks. The code were both holes are open is used to detect that no block is present on the fork.

The two-bit code can be different for the four sides of the block.

The holes encode the identity of each block (after all sides are examined), and also encode the reference position for each block. With the correct software, the clock will always know which block it handles and which side is shown at the front. Here is the used code:

char word_code[]= { 0, 2, 0, 0, 0, // brick 1 2 3 4 1, 0, 2, 0, // brick 5 6 7 8 0, 1, 0, 0, // brick 9 10 11 12 1, 0, 0, 2, // kwart tien vijf blank4 1, 2, 0, 0, // over2 voor over voor2 3, 0, 0, 0, // half blank6 uur blank6a 3, 3, 3, 3 };// empty positionThe final picture shows the strip that has holes to encode the vertical position of the lift.

![]()

For each row on the rack, there are two holes:

- One for moving just above the storage positions, when a brick must be placed,

- One for moving just below the storage positions, when the brick has been placed and the fork must move back.

- You can also see the infrared detector. The infrared LED is at the other side of the strip.

-

Turning the blocks

12/27/2019 at 15:58 • 0 commentsThe meccano storage rack has a special position that can turn a brick, to show another side of it. This is a fully mechanical system, it is controlled by movements of the forklift truck.

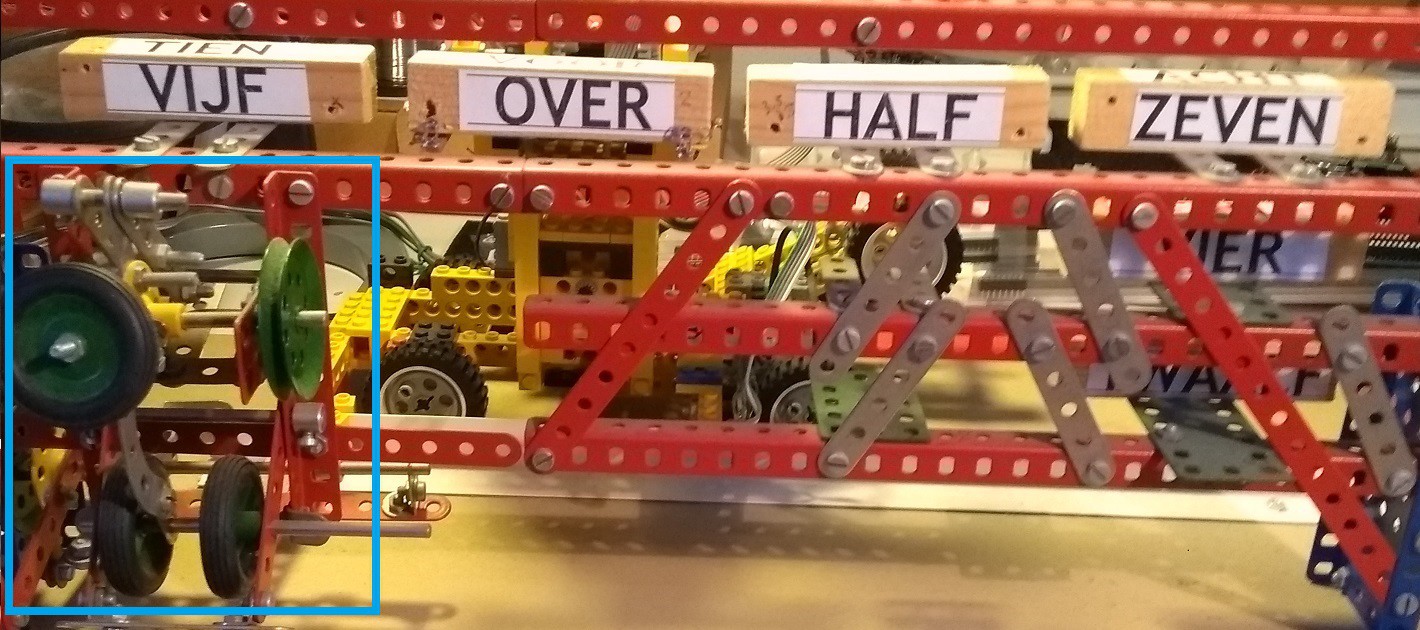

The turning mechanism is here (in the blue rectangle):

![]()

At the backside are the two control levers indicated by blue arrows (next picture).

- The upper arrow shows the lever that is pressed down by the lift, directly after the block is placed. This will turn the block. The lift will now move upward again to get the turned brick and move it to its destination.

- When the forklift turns sideways, it operates the second lever, that will reset the turning mechanism to its original position.

![]()

And now I will show the operation of the mechanism. I place and remove the brick by hand here.

In the next video, the lift is operated by hand, and it shows how the brick is turned and then moved again to the highest row.

Forklift clock

Four wooden blocks with words tell the time. Every 5 minutes, a forklift changes the blocks to the new time.