Could not resist to test the printer even before completing the build. There are a few things still missing like distance tubes for sensorless homing and a bracket for the X axis.

In the printing phase no part of the eIectronics overheats but I tested again to short the secondary by moving the nozzle on the buildplate and in this condition things look different. The 50mm² cable and the toolhead stay cool but the resistors heating up until I aborted the test at 140°C. In normal operation there shold be no need to drive the nozzle in the buildplate or the workpiece but for safety reasons I will add a heat activated switch to the resistors which turns the printer off when it reachs a certain temperature.

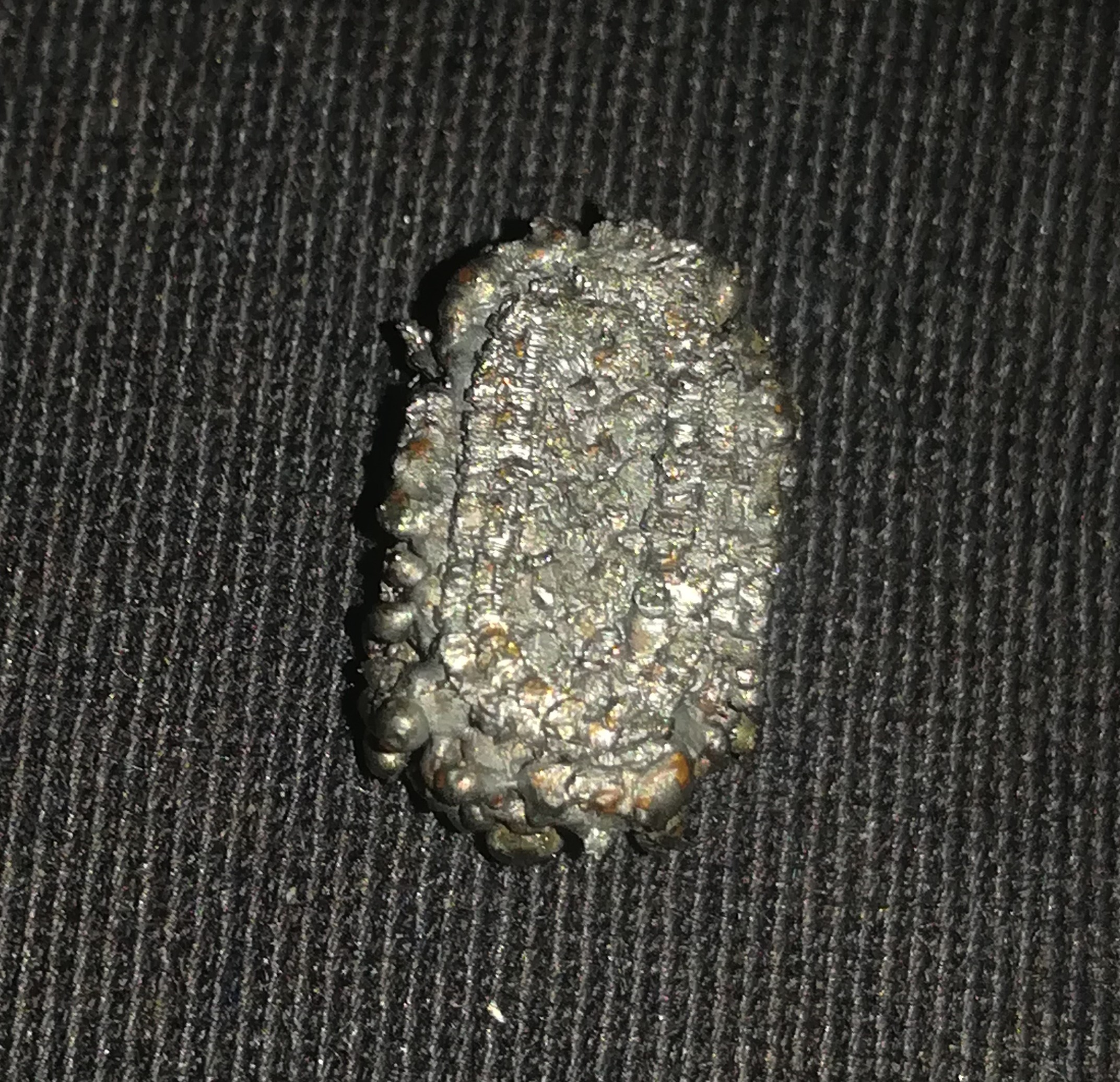

Today I tested the printer for the first time with random settings. I guess the extrusion rate and the distance between buildplate and nozzle was too high. Maybe with better settings the print quality can be improved to get usable results and so maybe the operation will switch form some sort of firework to a smooth glowing wire laying process.

Top and bottom of the printed object

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

I would suggest much faster feeding of wire. I think those sparks are because your wire is alternating between resistive heating and arc welding, it's melting too fast and distance between deposition site and wire end is increasing.

Are you sure? yes | no

Ok I will test faster feeding and smaller gap.

Are you sure? yes | no

To get optimum speed, I would suggest feeding wire by hand when printhead is moving in spiral path and checking how long will it take to feed given length of wire. That way you will have optimum volumetric speed, which probably only depends on your current and wire type. Then you have base for tweaking all other parameters.

Are you sure? yes | no

I just did some testing and even though I have no usable settings yet I noticed some interesting behavior very similar to fdm printing. The best results at this time I could get with high layer hight and width. The greatest issue at the moment is that the layer gets higher than it should until the nozzle bumps into the part.

Will continue testing. It's too bad that no one else has this kind of printer otherwise it would be possible to share experience.

Are you sure? yes | no