Maybe I found the cause of all the problems:

I just realised that the wire is randomly slipping in the wire feeder, so that the amount of "extruded material" was wrong the whole time and this could have caused all the problems I had with printing.

That could mean there were no problems with heat, settings, material, (oxidation), just random amount of "extruded material". What a shame that I didn't noticed that earlier.

Will change the design of the wire feeder for reliable operation.

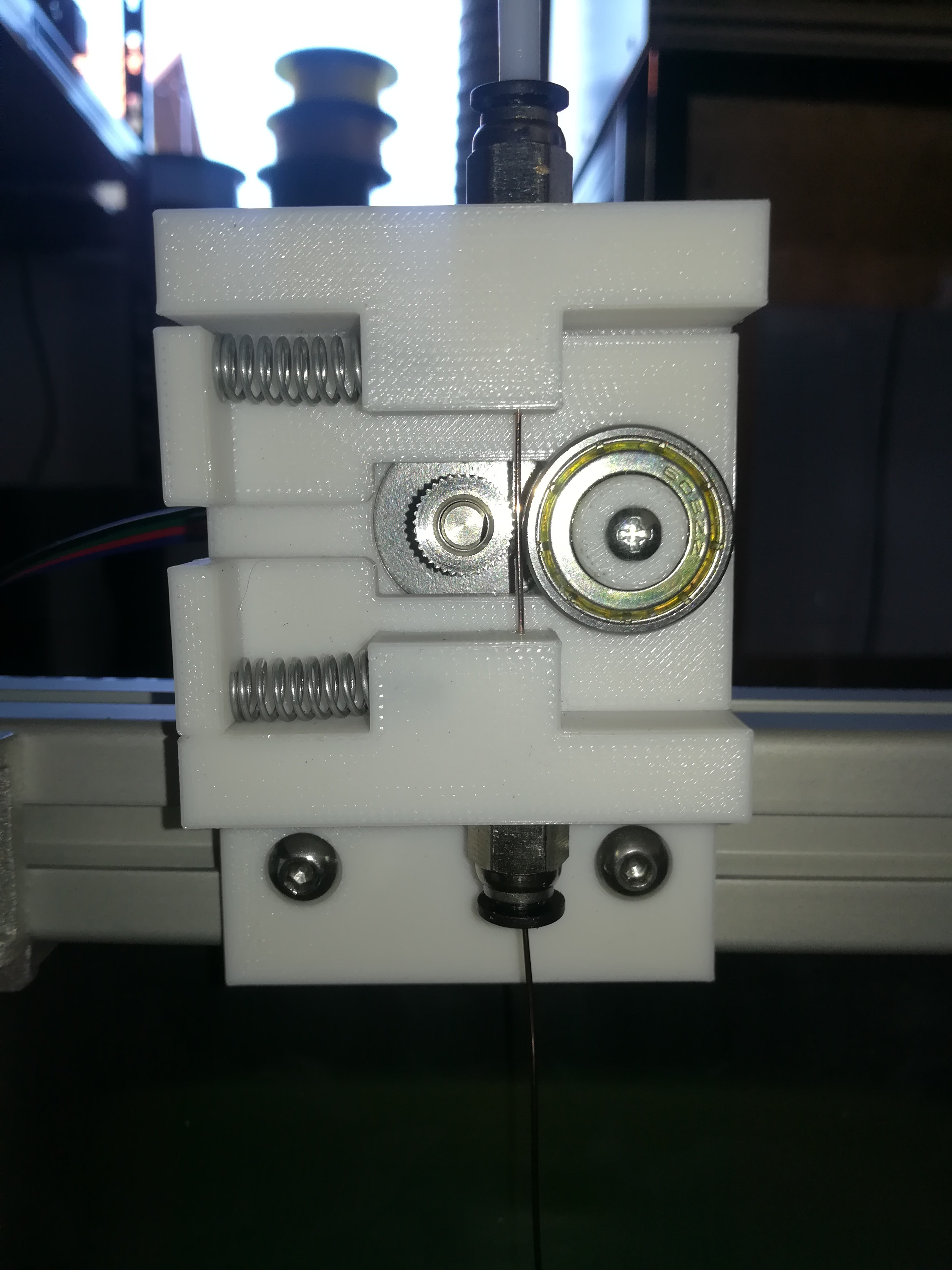

I designed a new wire feeder, but unfortunately it worked as bad as the last one.

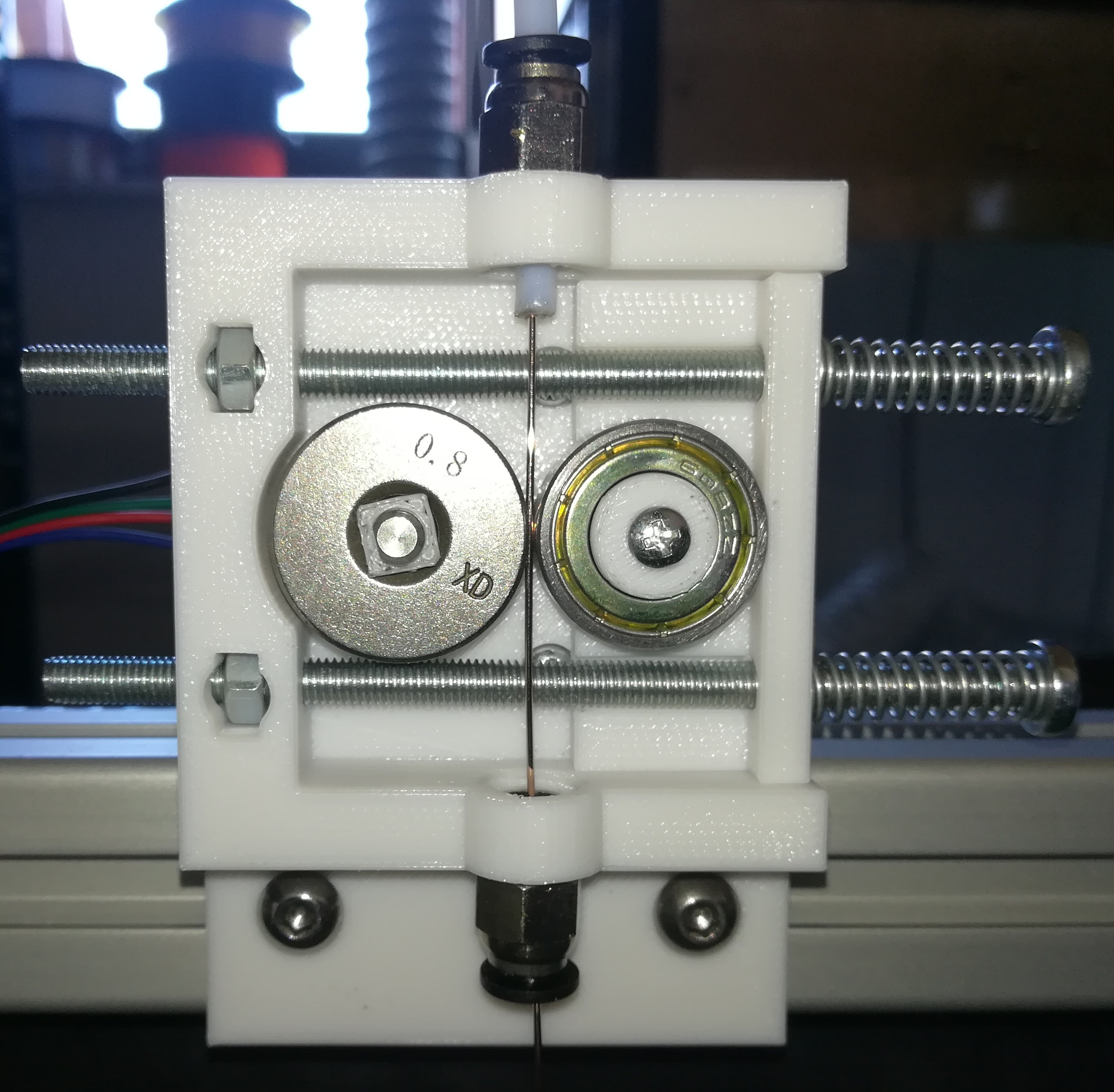

I also ordered a wire feeder roller for building a wire feeder that hopefully works. It will be delivered later this week.

Here is the new feeder with the wire feeder roller and it works very well. The feedrate should now be as set in the slicer software.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Yes, I hope it is the crucial mistake. But I think it will definitely be an improvement to print with a working wire feeder than with one that doesn't work properly.

Are you sure? yes | no

It's like with that scientist which found problems when measuring neutrinos, results suggested that neutrinos were several percent faster than light. After several other teams tested this and didn't find anything, he found that some optical cables were loose. I'm really glad you found that it's only error, not some big design or engineering problem.

Are you sure? yes | no

Awesome! It's great to find big gaping flaws. Things just improve as if by magic.

Are you sure? yes | no